Construction method for changing steel pipe supports of ramp foundation pit

A construction method and technology of steel pipe braces, which are applied in infrastructure engineering, excavation, construction, etc., to achieve stable force balance, ensure balanced force transmission and rigidity stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

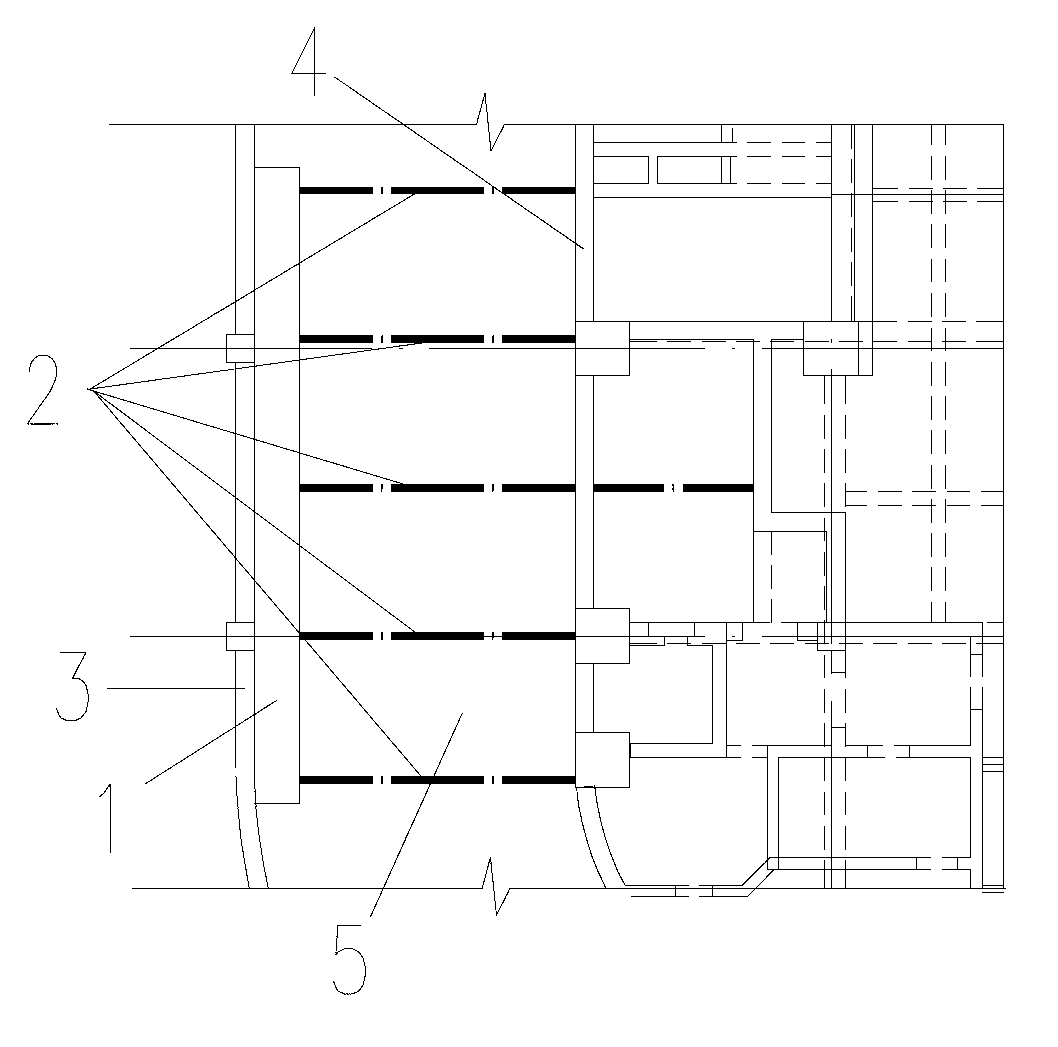

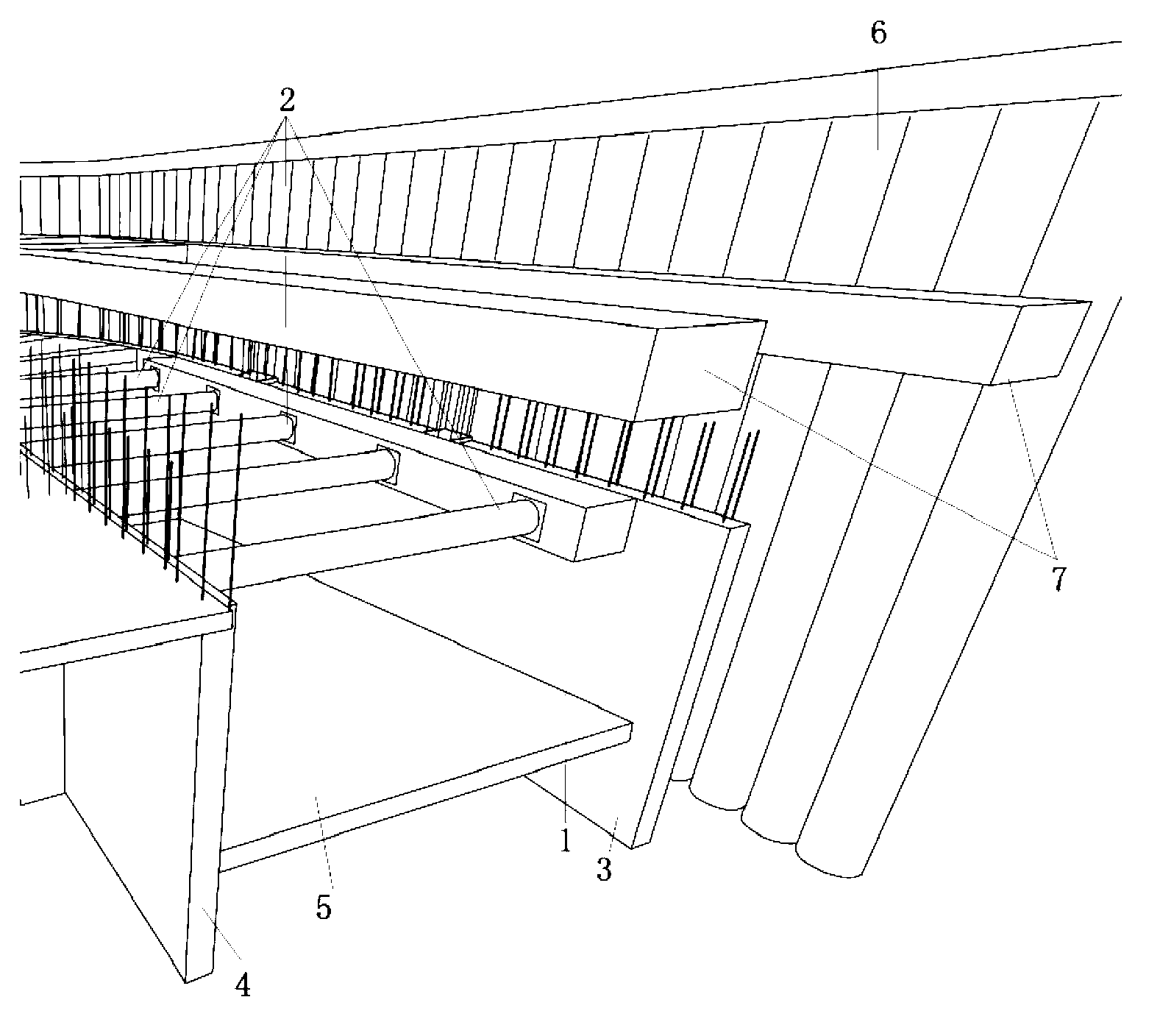

[0023] (1) Set up support piles 6 in the length direction of the outer circumference of the ramp, connect the inner support system 7 inside the support piles, and then dig the foundation pit; (2) lay the bottom plate 5 at the ramp in the foundation pit and build a The ramp inner wall 4 and the ramp outer wall 3 on both sides of the bottom plate 5 at the ramp are at an elevation position higher than the beam bottom of the side beam 1, and at the same time, ribs are reserved at the tops of the ramp inner wall 4 and the ramp outer wall 3; (3) Construct a side beam 1 along the length direction of the ramp on the inside of the ramp outer wall 3, and pre-embed a plurality of pre-embedded steel plates at intervals in sequence on the side beam 1; A plurality of pre-embedded steel plates correspond to the post-embedded steel plates set one by one; (5) steel pipe supports 2 are connected between each pre-embedded steel plate and the corresponding post-embedded steel plates; (6) between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com