High-rise building climbing pouring system and operation method thereof

A technology for high-rise buildings and climbing frames, which is applied to buildings, building components, building structures, etc., can solve problems such as the inability of formwork structures to climb, and achieve the effects of less manual installation, reduced deformation, and guaranteed construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The technical solution of the present invention will be described in detail below in conjunction with the drawings.

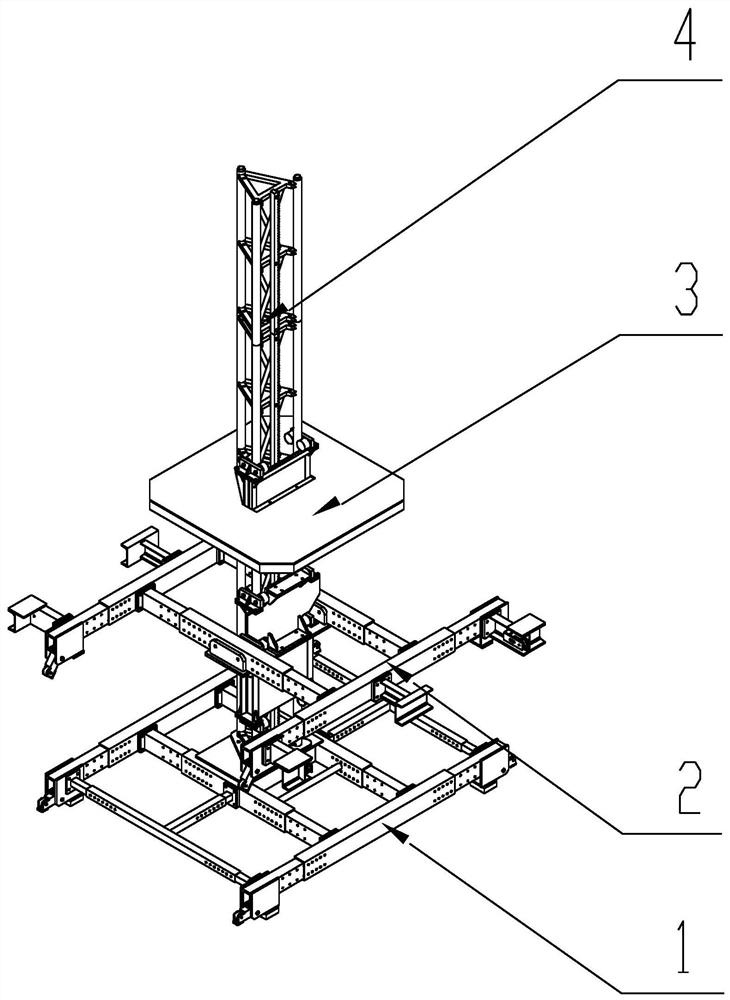

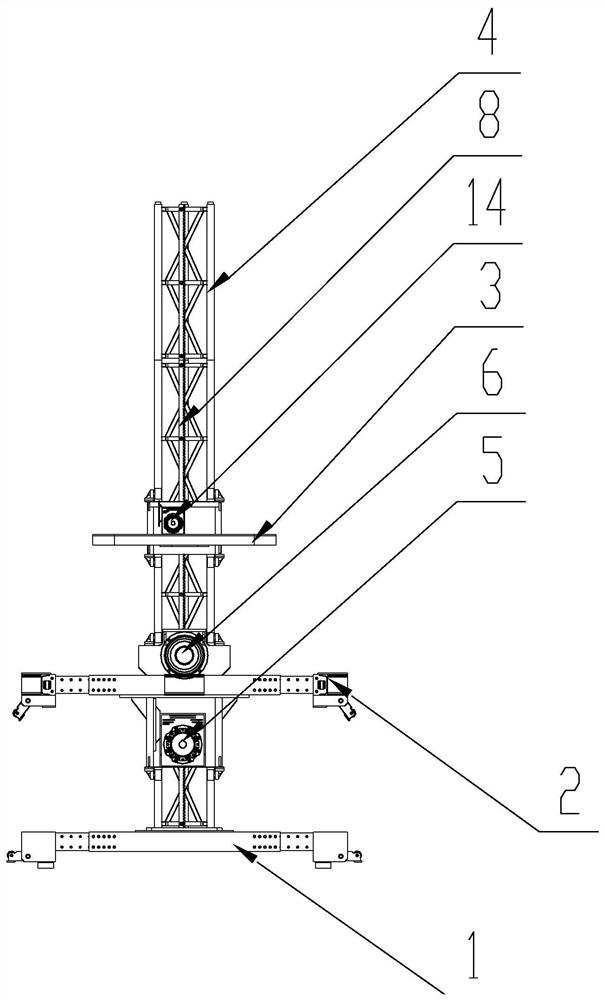

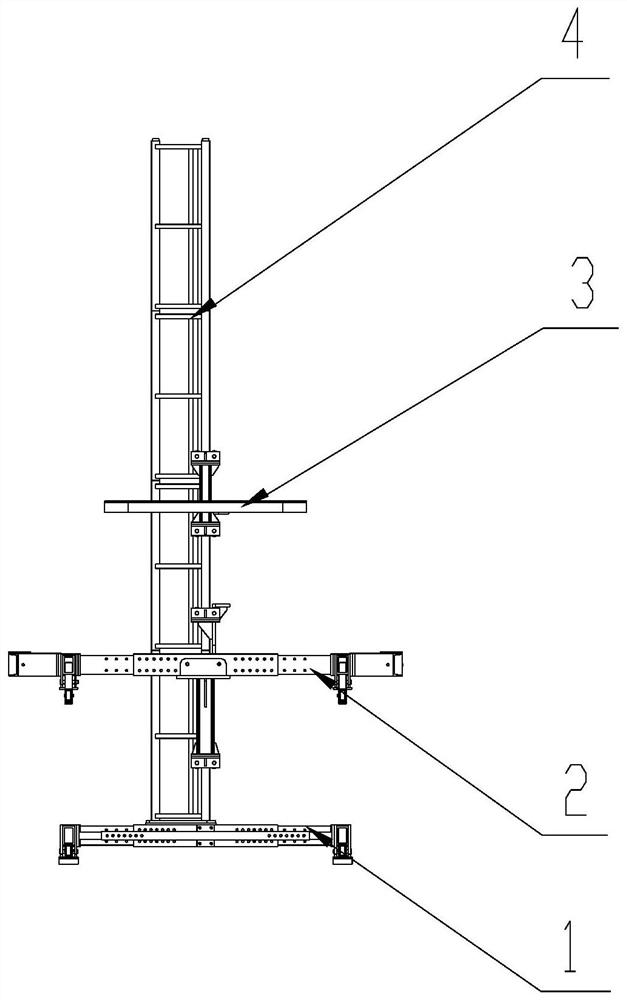

[0077] See Figure 1-Figure 3 As shown, the climbing pouring system for high-rise buildings in this embodiment includes a formwork assembly, a climbing machine assembly, a motor assembly, and a positioning box 13. Frame 2, operating platform 3 and guide frame 4, the template assembly is supported on the top of the upper climbing frame 2;

[0078] When the climbing machine assembly climbs, the upper climbing frame 2 rises a climbing height along the guide frame 4 under the action of the power of the motor assembly, and forms a climbing installation with the positioning box 13 that has been cast in the foundation pit formwork, and the lower climbing frame 1 is placed on the ground again. Under the power of the motor assembly, it is lifted along the guide frame 4 to the positioning box 13 installed in the last climb of the upper climbing frame 2 and forms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com