Steel bridge with inverted ribs and orthotropic composite bridge deck

An orthotropic, steel bridge technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of long-term maintenance of railway steel decks, stress concentration of highway steel decks, and fragile pavement, etc., to avoid Effects of stress concentration and fatigue cracks, good durability, and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

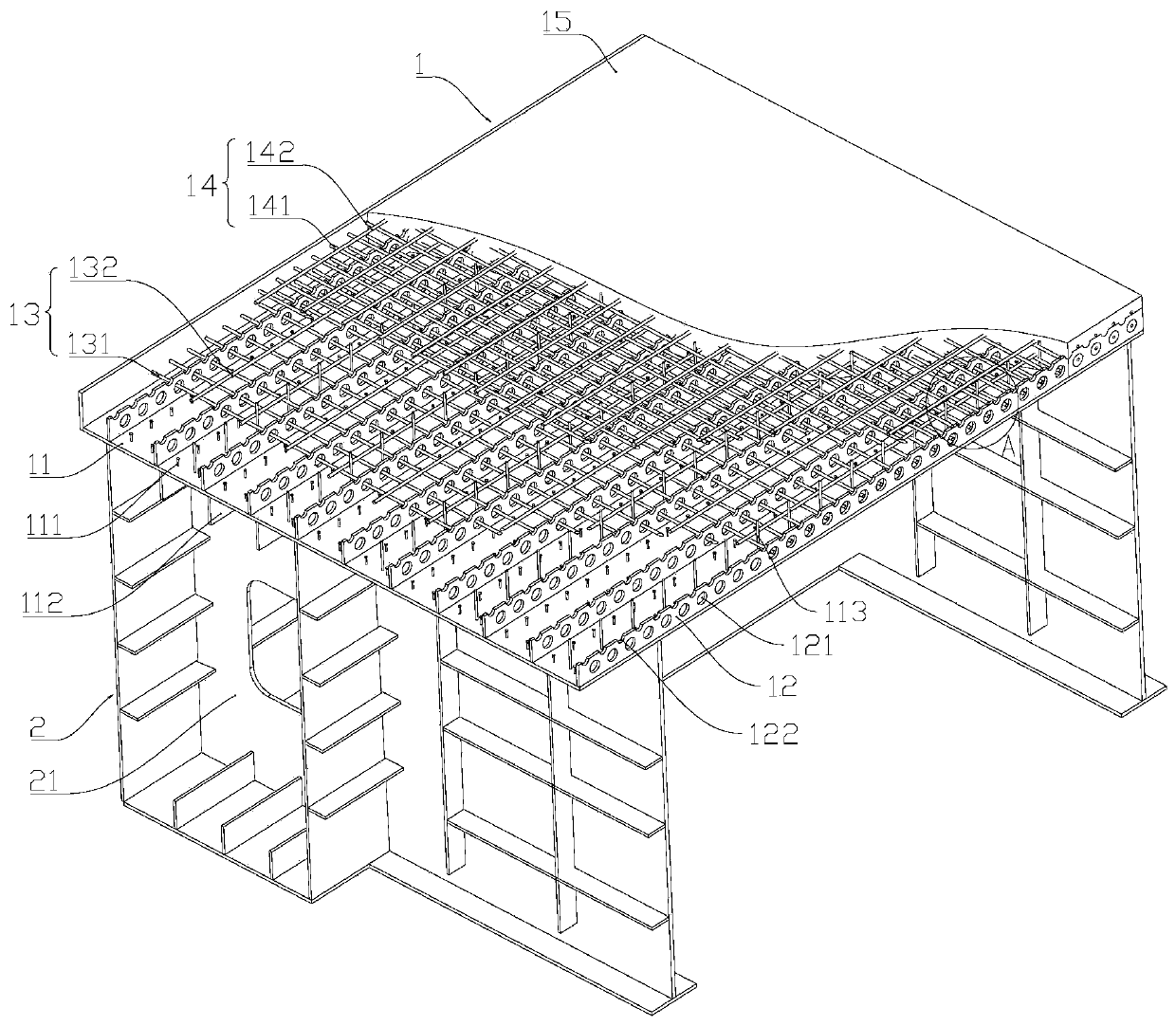

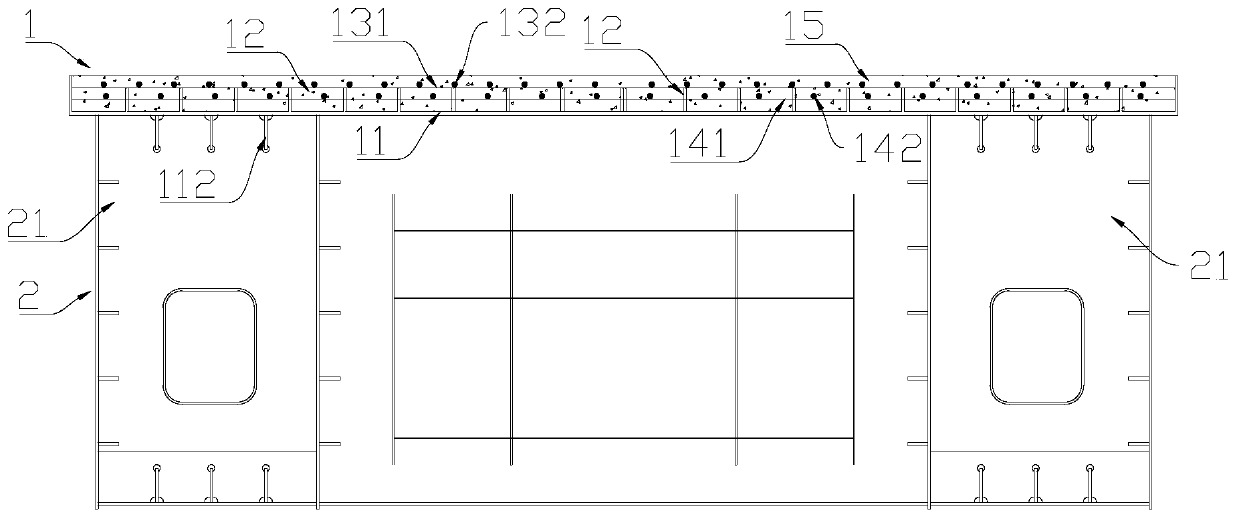

[0040] refer to figure 1 , an inverted rib orthotropic composite deck steel bridge, characterized in that it includes: a steel-concrete composite deck 1 and a support beam 2 for supporting the steel-concrete composite deck 1, the support beam 2 is a separate double box Main beam;

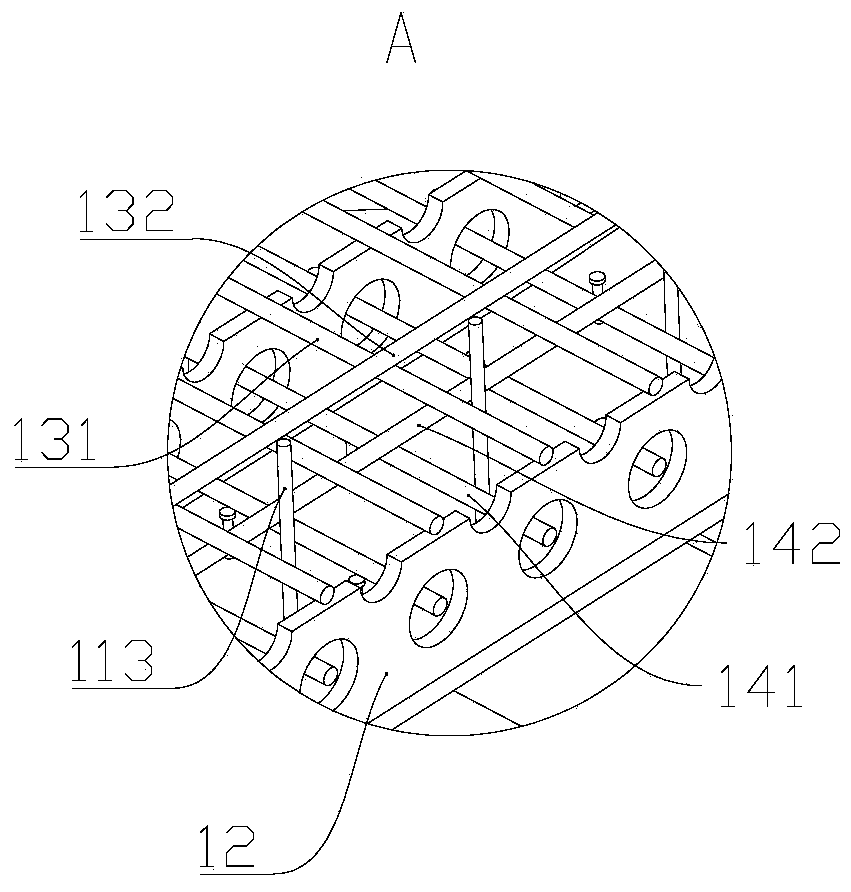

[0041] refer to figure 1 , image 3 and Figure 4 , the steel-concrete composite deck 1 comprises: a steel bridge deck 11, a plurality of perforated steel plates 12, an upper reinforcement mesh 13, a lower reinforcement mesh 14 and a concrete layer 15, and the perforated steel plates 12 are arranged on the steel bridge along the longitudinal intervals of the steel bridge decks. panel and arranged over the full width of the steel bridge deck, refer to Figure 5 , a plurality of through holes 121 are provided on the perforated steel plate 12, a plurality of rectangular notches 122 are provided on the top of the perforated steel plate 12, and multiple columns of shear-resistant nails 111 are arrang...

Embodiment 2

[0045] refer to Figure 6 , an inverted rib orthotropic composite deck steel bridge, characterized in that it comprises: a steel-concrete composite deck 1 and a supporting beam 2 for supporting the steel-concrete composite deck 1, the supporting beam 2 is a steel truss beam;

[0046] refer to Figure 6 and Figure 7 , the steel-concrete composite deck 1 comprises: a steel bridge deck 11, a plurality of perforated steel plates 12, an upper reinforcement mesh 13, a lower reinforcement mesh 14 and a concrete layer 15, and the perforated steel plates 12 are arranged on the steel bridge along the longitudinal intervals of the steel bridge decks. panel and arranged over the full width of the steel bridge deck, refer to Figure 8 , a plurality of through holes 121 are provided on the perforated steel plate 12, a plurality of semicircular notches 122 are provided on the top of the perforated steel plate 12, and multiple columns of shear force nails 111 are arranged between adjacent ...

Embodiment 3

[0050] refer to Figure 9 , an inverted rib orthotropic composite deck steel bridge, characterized in that it includes: a steel-concrete composite deck 1 and a support beam 2 for supporting the steel-concrete composite deck 1, the support beam 2 is a separate double box Main beam;

[0051] refer to Figure 9 and Figure 10 The steel bridge deck 1 includes: a steel-concrete composite bridge deck 11, a plurality of perforated steel plates 12, an upper reinforcement mesh 13, a lower reinforcement mesh 14 and a concrete layer 15, and the perforated steel plates 12 are arranged on the steel bridge deck at intervals along the longitudinal interval of the steel bridge deck. and arranged over the full width of the steel bridge deck, refer to Figure 11 , a plurality of through holes 121 are provided on the perforated steel plate 12, a plurality of V-shaped notches 122 are provided on the top of the perforated steel plate 12, and multiple rows of shear force nails 111 are arranged b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com