M-type bag forming clamping device

A bag holder and bag forming technology, applied in the field of packaging equipment, can solve the problems of low coordination, complex and bulky structure of the M-bag bag holder, and low packaging efficiency, so as to achieve compact equipment structure, reduce dust overflow and improve packaging. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

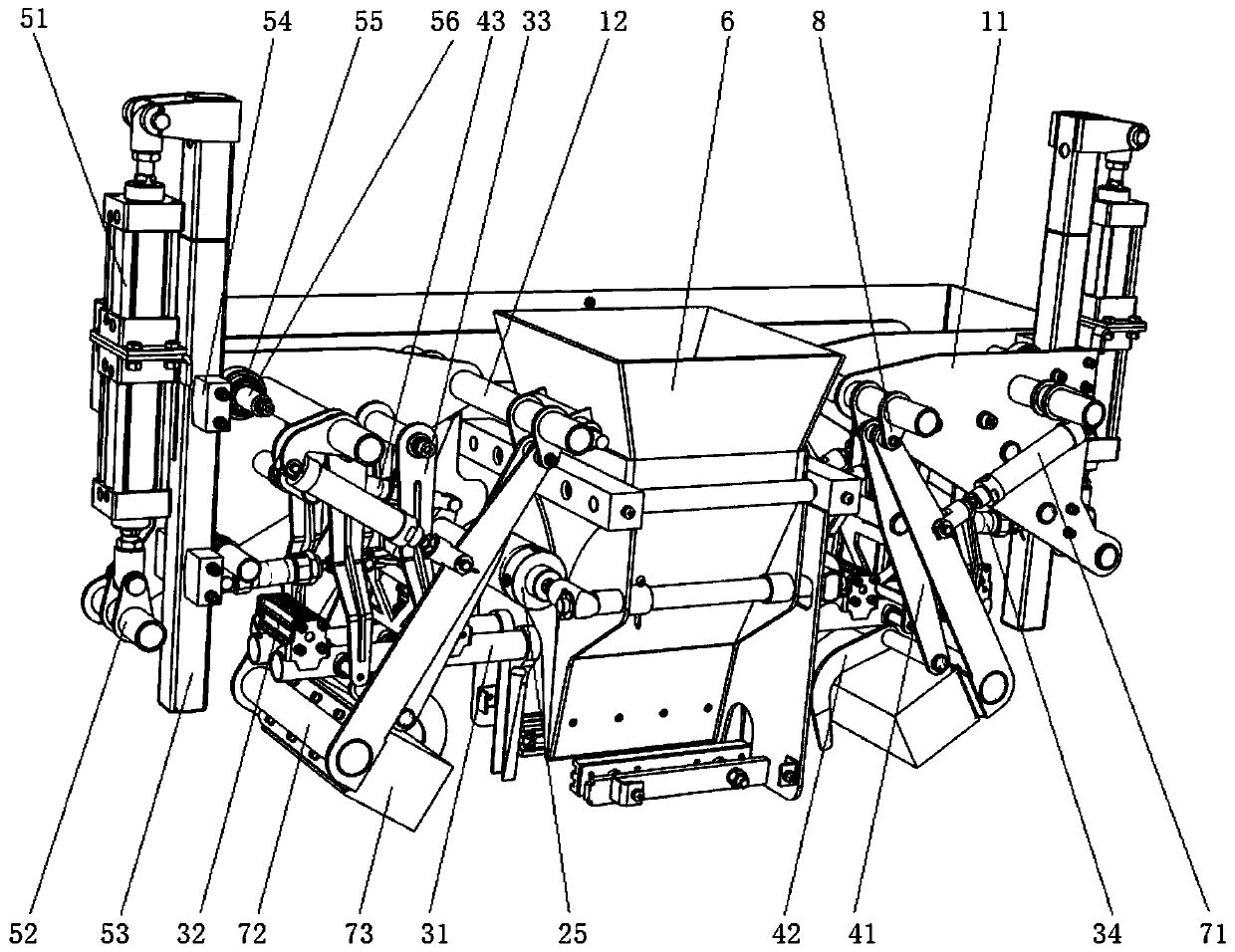

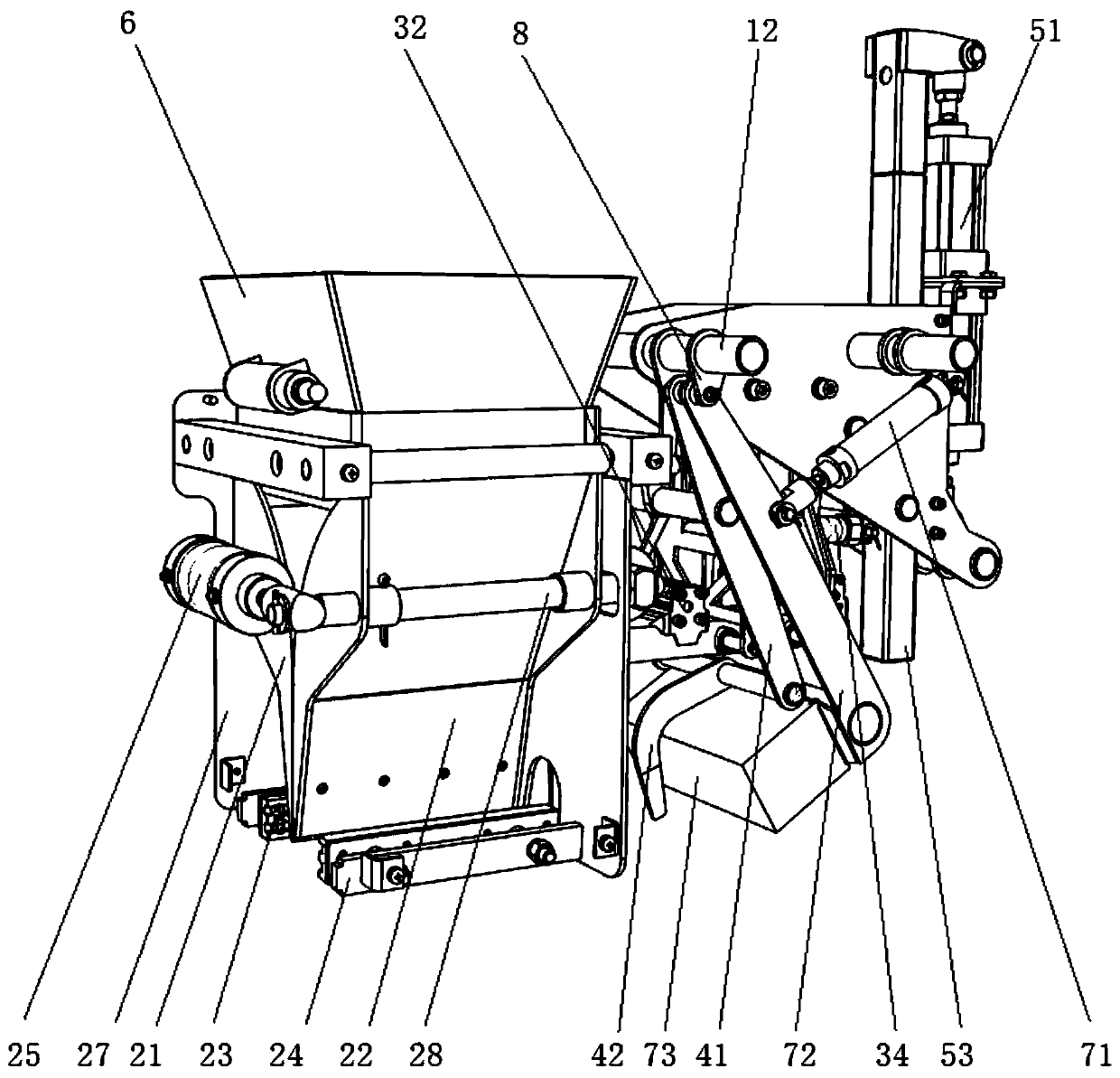

[0039] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

[0040] For the sake of convenience only, in the following description, specific direction terms are used, which are referred to the corresponding drawings, and cannot be considered as limitations on the present invention. When the defined directions of the drawings change, these The directions indicated by the words should be interpreted as corresponding different directions.

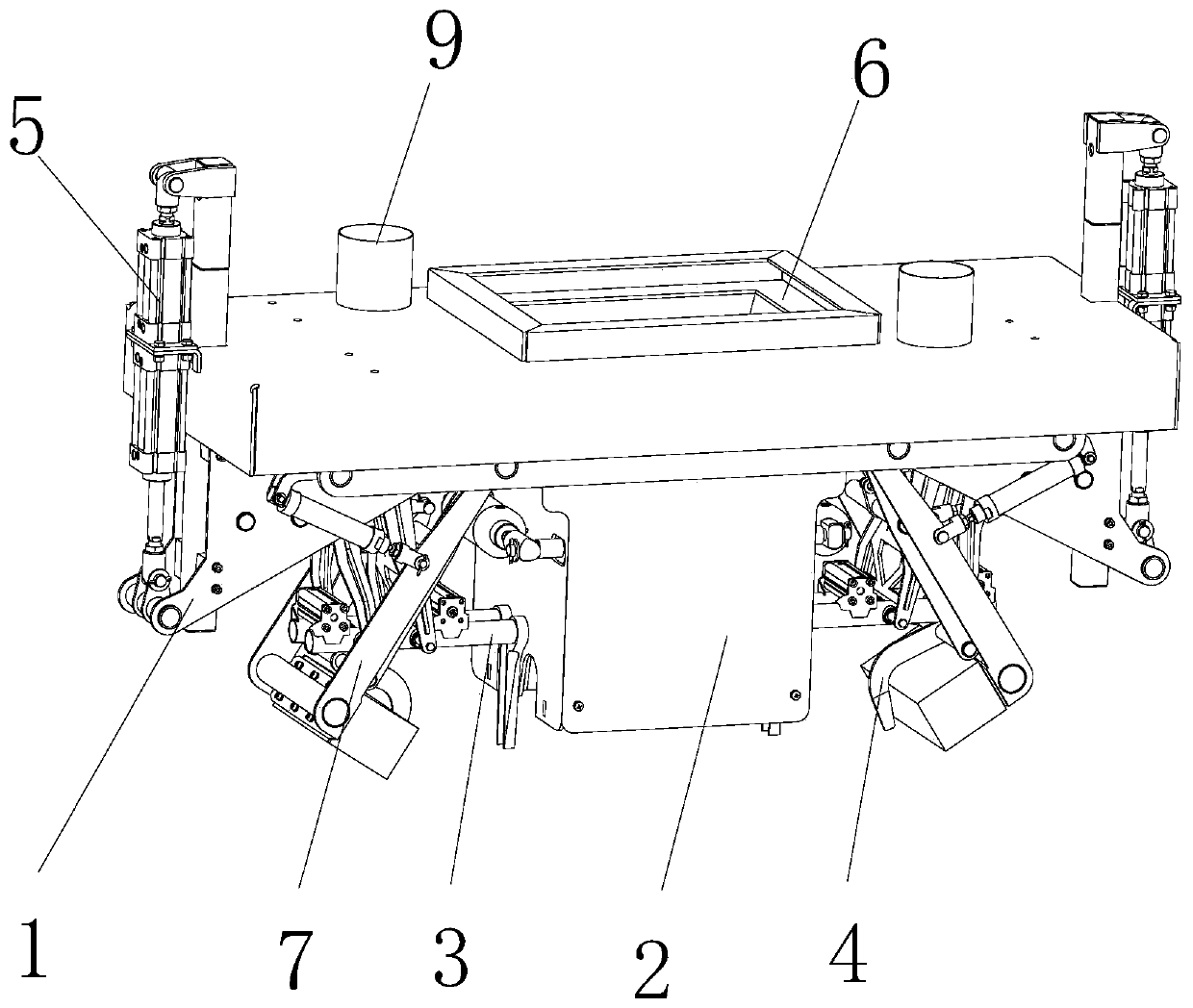

[0041] Such as Figure 1-Figure 9 As shown, the M-bag forming bag clamp includes a mounting frame 1, a bag clamping assembly 2, two sets of bag support bar assemblies 3, two sets of M forming assemblies 4, two sets of cover bag assemblies 7 and two sets of lifting assemblies 5.

[0042] Wherein, the mounting frame 1 includes two sets of mounting plates 11 and two beams 13; each set of mounting plates includes two mounting plates 11, and the two mounting plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com