Clamping mechanism of injection molding machine

A technology of injection molding machine and mold clamping mechanism, applied in the field of injection molding machine manufacturing, can solve the problems of complex mold, low production efficiency, long waiting time, etc., and achieve the effect of ensuring sealing, preventing leakage and stable force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the embodiments of the drawings.

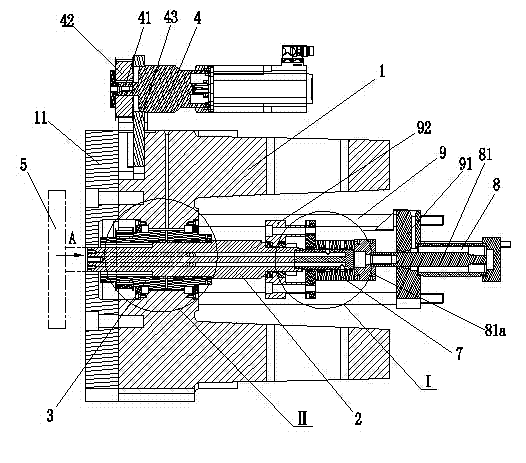

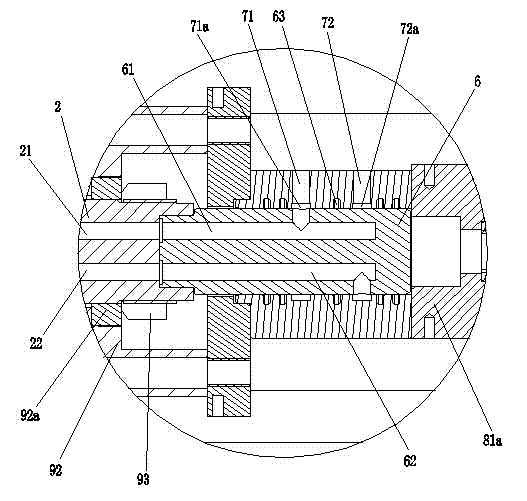

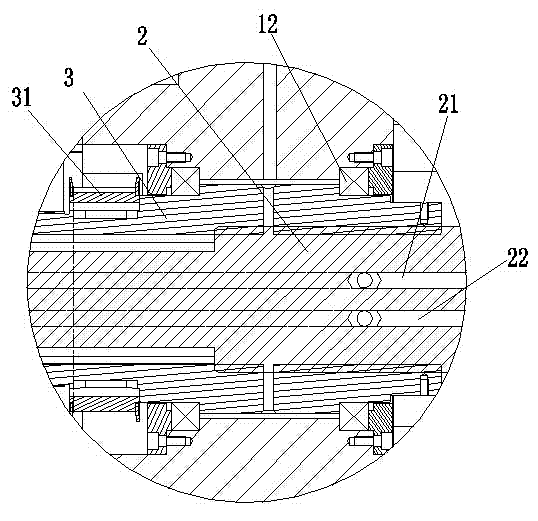

[0026] Such as Figure 1 to Figure 4 Shown is a schematic diagram of the structure of the present invention,

[0027] The reference signs are: movable wall 1, movable wall backing plate 11, bearing 12, linear motion shaft 2, screw hole 2a, water inlet passage 21, water inlet hole 21a, water outlet passage 22, water outlet hole 22a, rotary motion shaft 3. The second synchronous belt wheel 31, the servo motor 4, the output shaft 41, the first synchronous belt wheel 42, the servo motor mounting bracket 43, the mold core 5, the rotating shaft connecting rod 6, the water inlet connection hole 61, the water outlet connection hole 62 , Sealing ring 63, water jacket 7, water inlet 71, annular water inlet 71a, water outlet 72, annular water outlet 72a, drag mold cylinder group 8, drag mold piston rod 81, adapter seat 81a, fixed rod 9, drag mold Cylinder block mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com