Annular open caisson structure

A caisson and ring-shaped technology, which is applied in basic structure engineering, caissons, buildings, etc., can solve problems such as poor structural impact resistance, large water flow force and wave force, and difficult to correct plane torsion, so as to reduce the foundation scale and water flow force. And the effect of small wave force and small local scour depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

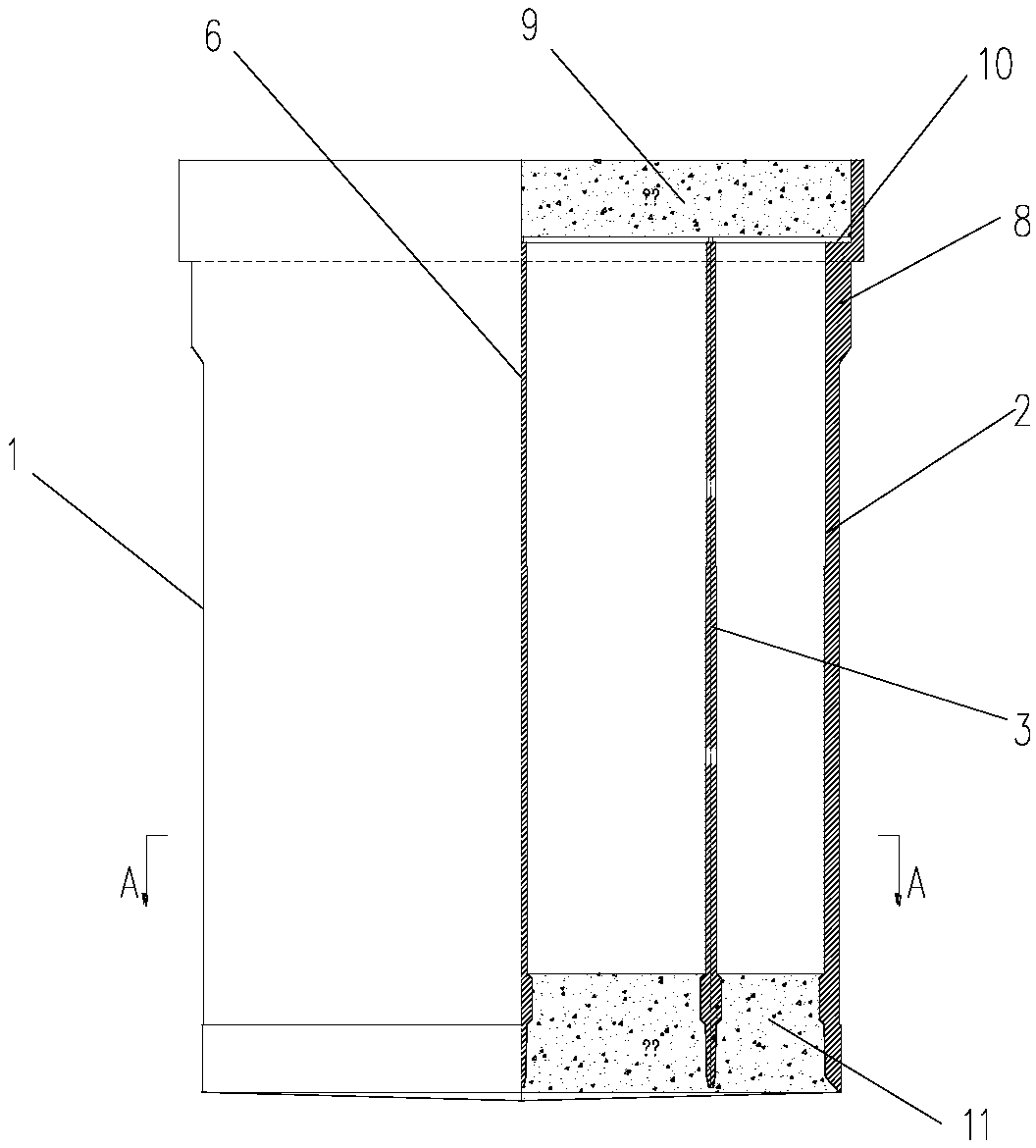

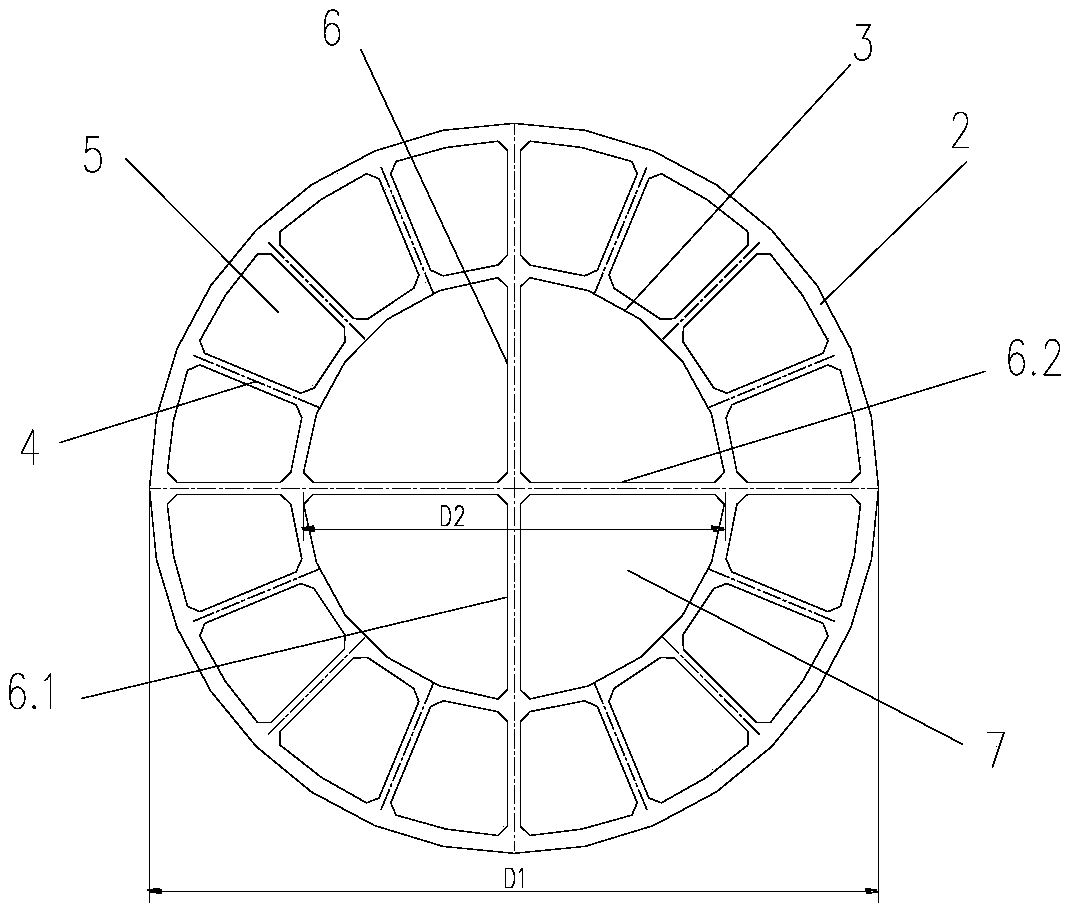

[0024] Such as figure 1 The annular caisson structure shown includes the caisson body 1, the caisson foundation can be steel caisson, concrete caisson or steel-concrete combination caisson, the caisson body 1 includes the outer ring shaft wall 2 and the inner ring shaft wall 3, The caisson adopts circular cross-section, which has good water flow adaptability, small local scour depth, and small water flow force and wave force borne by the structure. Diameter D of outer ring shaft wall 2 1 and the diameter D of the inner ring shaft wall 3 2 The ratio is 1:0.4~0.8. The top of the outer ring of the outer ring shaft wall 2 is provided with a stepped boss cap 8 that is compatible with the outer bearing structure. The top of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com