A combined type seamless expansion joint structure used for bridge pavement structures

A pavement structure, seamless expansion and contraction technology, applied in the direction of roads, roads, pavement details, etc., can solve problems such as the inability to meet seamless expansion joints, and achieve the effect of convenient installation, good cost performance, and improved compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

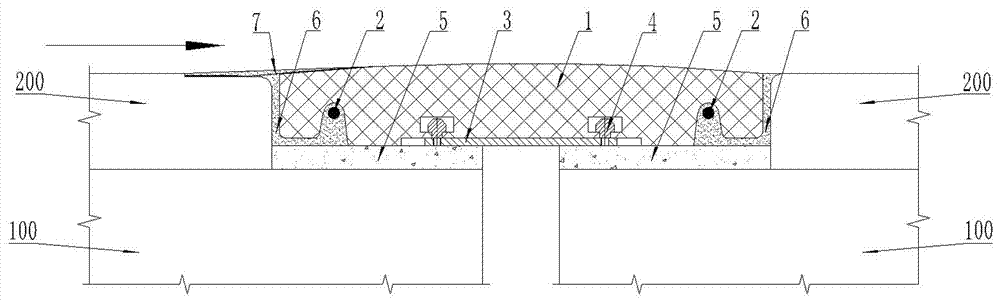

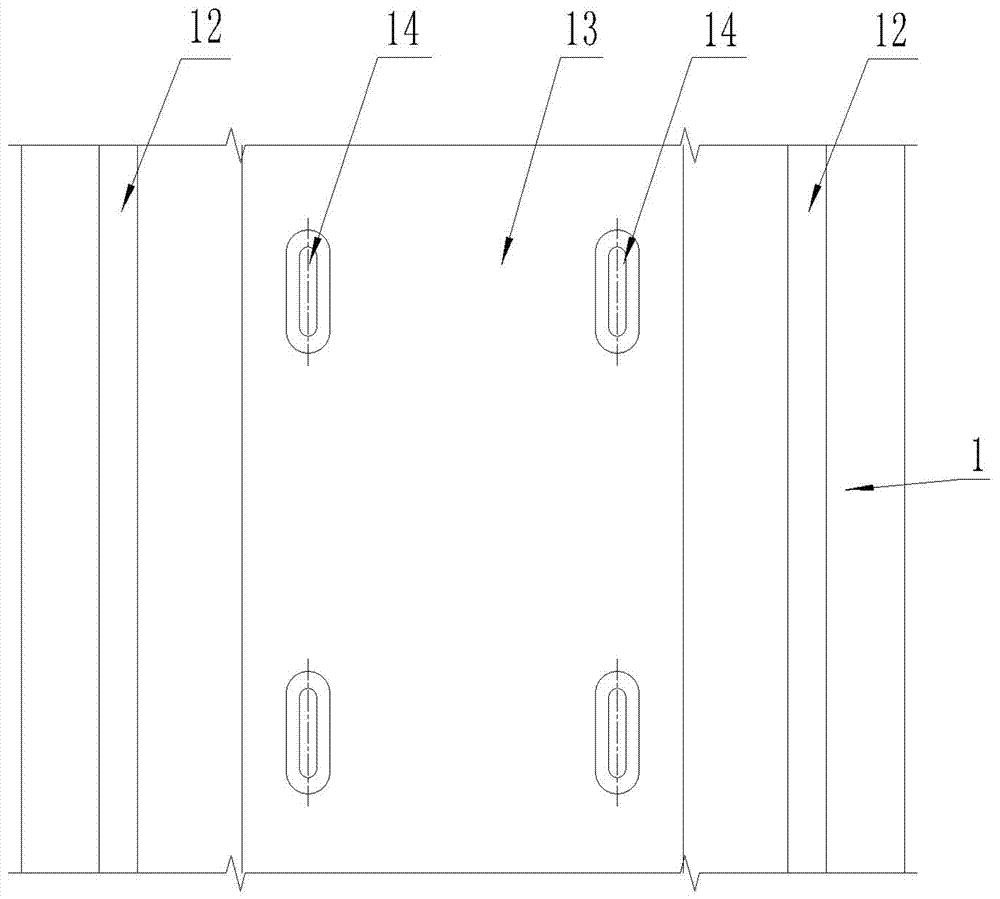

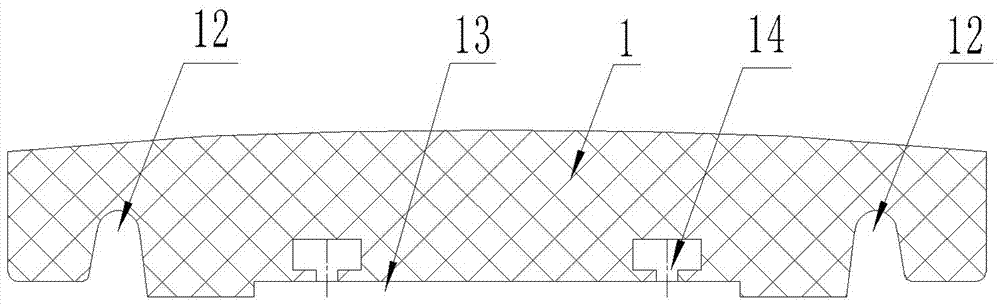

[0033] Such as figure 1 As shown, the combined seamless expansion joint structure proposed by the present invention, the bridge pavement structure includes two bridge structures 100 arranged at intervals and two pavement structures 200 respectively laid on the top of the two bridge structures 100, the two pavement structures 200 The distance between them is greater than the distance between the two bridge structures 100, the cavity between the two bridge structures 100 forms an expansion joint, the cavity between the two pavement structures 200 is an installation cavity, and the combined seamless expansion joint structure Installed in the installation cavity, take the length direction of the expansion joint as the longitudinal direction and the width direction as the transverse direction.

[0034] Such as Figures 1 to 3 As shown, the combined seamless expansion joint structure includes: a self-leveling mortar base layer 5, a seam-riding steel plate 3, an elastic expansion me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com