Polymer film and preparation method thereof, gel electrolyte and polymer battery

A polymer film and polymer technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problem of low electrical conductivity, and achieve the effects of excellent air permeability, excellent high pressure resistance, and excellent ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Simultaneously, the present invention also provides the preparation method of above-mentioned polymer membrane, comprises the following steps:

[0039] S1. Mix the first polymer emulsion and the second polymer emulsion to obtain a mixed emulsion; the glass transition temperature of the mixed emulsion is 30-60°C; the glass transition temperature of the first polymer emulsion is less than 40°C , the glass transition temperature of the second polymer emulsion is above 40°C;

[0040] S2. Mix the mixed emulsion with a dispersion containing inorganic particles to obtain a coating solution; in the coating solution, the mass ratio of the total solid content of the mixed emulsion to the inorganic particles is 1:10-10:1.

[0041] S3. Apply the coating liquid to form a liquid film, and obtain the polymer film after curing; the curing temperature is higher than the glass transition temperature of the first polymer emulsion and lower than the second polymer emulsion The glass trans...

Embodiment 1

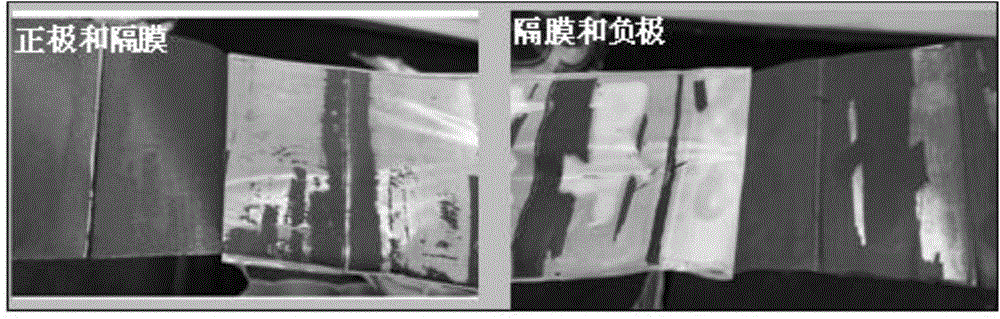

[0094] This example is used to illustrate the polymer membrane and its preparation method, gel electrolyte and polymer battery disclosed in the present invention.

[0095] 1. Dissolve PAM with a weight average molecular weight of 10000g / mol in water to form a 0.6wt% aqueous solution, and then use NH 3 ·H 2 O adjust the solution to pH = 8-9 to form a dispersant solution.

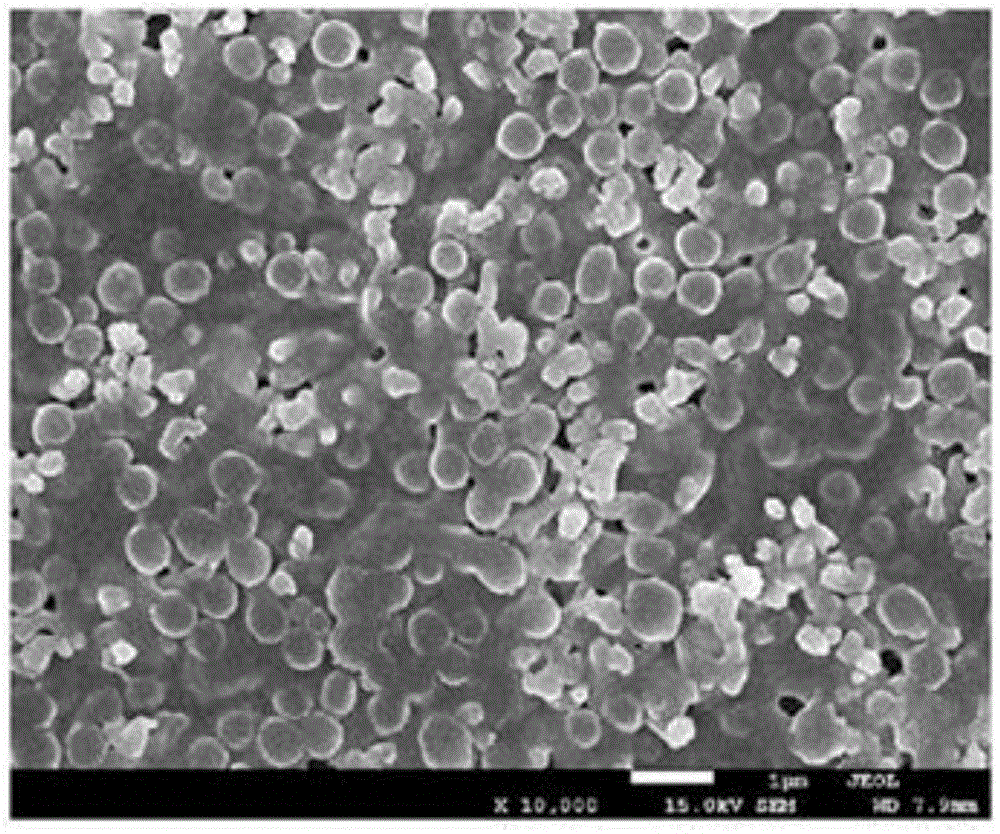

[0096] 2. Mix α-Al with mechanical stirring at 800rpm 2 o 3 (100wt%, 300nm) is added slowly in the dispersant solution that sufficient step 1 obtains, makes dispersant PAM relative to α-Al 2 o 3 The mass ratio of is 1.2wt%. Then, mechanically stir at a low speed of 800 rpm for 15 minutes, and then mechanically stir at a high speed of 4000 rpm for 15 minutes. A dispersion containing inorganic particles is formed.

[0097] 3. The second polymer emulsion P1040 (T g =60°C, solid content 50wt%), the first polymer emulsion P1005 with low glass transition temperature (T g =-18°C, solid content 50wt%), S601 ...

Embodiment 2

[0102] This example is used to illustrate the polymer membrane and its preparation method, gel electrolyte and polymer battery disclosed in the present invention.

[0103] 1. The concentration of the dispersant solution used is 0.8wt%, and all the others are the same as in Example 1. A dispersant solution is obtained.

[0104] 2. Dispersant PAM relative to α-Al 2 o 3 The mass ratio of the compound is 0.8wt%, and the rest are the same as in Example 1 to obtain a dispersion containing inorganic particles.

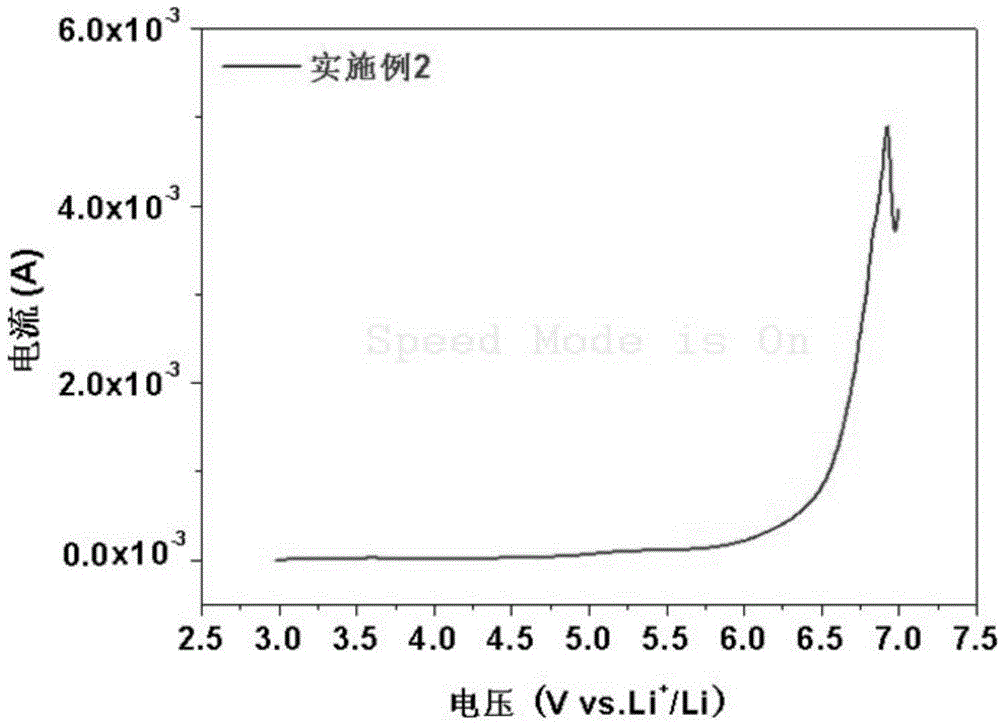

[0105] 3. The volume ratio of the second polymer emulsion P1040, the first polymer emulsion P1005, and S601 is 65:1:34, and the rest are the same as in Example 1 to obtain a mixed emulsion, and the polymer film after casting is denoted as M2 . The calculated value of its glass transition temperature is 48° C., and the volume fraction of the second polymer emulsion P1040 relative to the total emulsion is 65%.

[0106] 4. SDS relative to α-Al 2 o 3 The mass ratio is 0.5w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com