Patents

Literature

100results about How to "Strong high pressure resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

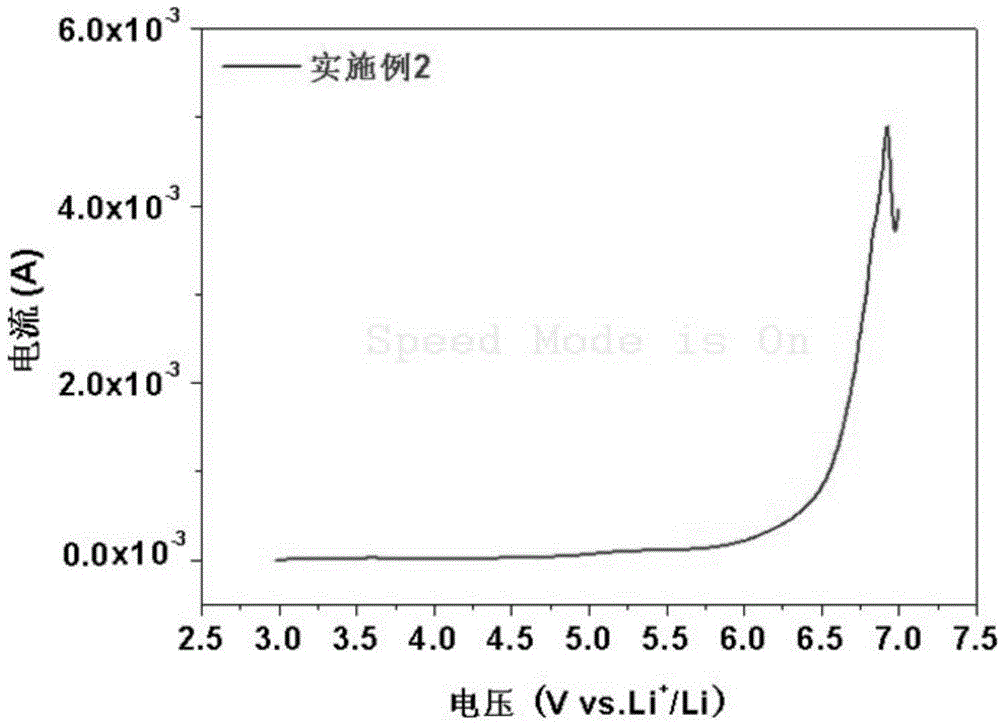

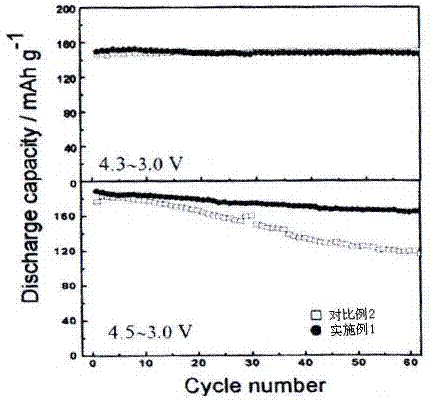

High-voltage lithium-ion battery electrolyte

InactiveCN103456993AImprove cycle lifeIncrease oxidation potentialSecondary cellsElectrolytic agentInternal resistance

The invention belongs to the technical field of lithium-ion battery electrolytes, and particularly relates to a high-voltage lithium-ion battery electrolyte. The high-voltage lithium-ion battery electrolyte comprises non-aqueous solvents, lithium salt and additives, wherein the additives comprise the mixture of fluoro phosphonitrile, fluoro-ether and unsaturated olefinic sultone. A lithium-ion battery using the high-voltage lithium-ion battery electrolyte is long in cycle life under the high voltage and small in internal resistance change. The high-voltage lithium-ion battery electrolyte is simple in preparing technique, easy to realize, and broad in market prospect.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

Press fit method for high-voltage-resistant PCB with thick copper plate

InactiveCN105472912AMeet reliabilityImprove liquidityMultilayer circuit manufactureCircuit laminationHigh resistanceVitrification

The invention discloses a press fit method for a high-voltage-resistant PCB with a thick copper plate. The method includes the following steps: S1, cutting, i.e., cutting an outer-layer copper foil, a polyimide medium, pure-glue prepreg and a polyimide copper-clad plate according to required dimensions; S2, inner-layer pattern making; and S3, conducting press fit after plate lamination, the press fit including the first heating stage at the temperature of 100-140 DEG C, the second heating stage at the temperature of 140-180 DEG C, the third heating stage at the temperature of 180-220 DEG C, a warm-keeping stage, the first cooling stage at the temperature of 220-150 DEG C and the second cooling stage at the temperature of 150-100 DEG C. Conventional FR-4 prepreg is replaced by a polyimide material that has higher glass transition temperature and exhibits higher resistance to voltage, so a PCB with a thick copper plate is made to have the excellent resistance to voltage, and polyimide having high glass transition temperature can effectively ensure that resin is fully filled among lines during press fit. Moreover, press fit parameters can be adjusted and the operating time of a high-temperature and high-voltage stage can be prolonged, thus helping polyimide materials to fully fill line gaps in a high-temperature and high-voltage condition.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Organic synthetic plugging granules for well drilling, and preparation method and application thereof

ActiveCN104531109AGood dispersionStrong high pressure resistanceDrilling compositionSealing/packingDispersityFiber

The invention discloses organic synthetic plugging granules for well drilling, and a preparation method and application thereof, belonging to the field of organic synthetic granular plugging agents in the technical field of well drilling. The plugging granules are prepared by blending one or more of calcium carbonate whisker, magnesium borate whisker and calcium sulfate whisker with polyetheretherketone and polyetherimide. The preparation method comprises the following steps: adding one or more of calcium carbonate whisker, magnesium borate whisker and calcium sulfate, polyetheretherketone and polyetherimide into a high-speed mixer, mixing at 380 DEG C at the shear velocity of 2.5 / s for 10-30 minutes, extruding at 300 DEG C, cooling, and granulating. The organic synthetic plugging granules can be used as plugging granules and matched with plugging fibers and plugging flexible fragments for bridging plugging. The method solves the problems of poor dispersity, improper density, high water absorptivity, high degradation tendency, high brittleness, high breaking tendency, high sedimentation tendency and the like, and enhances the compression resistance and temperature resistance of the plugging bridging granules.

Owner:CHENGDU DEDAO IND

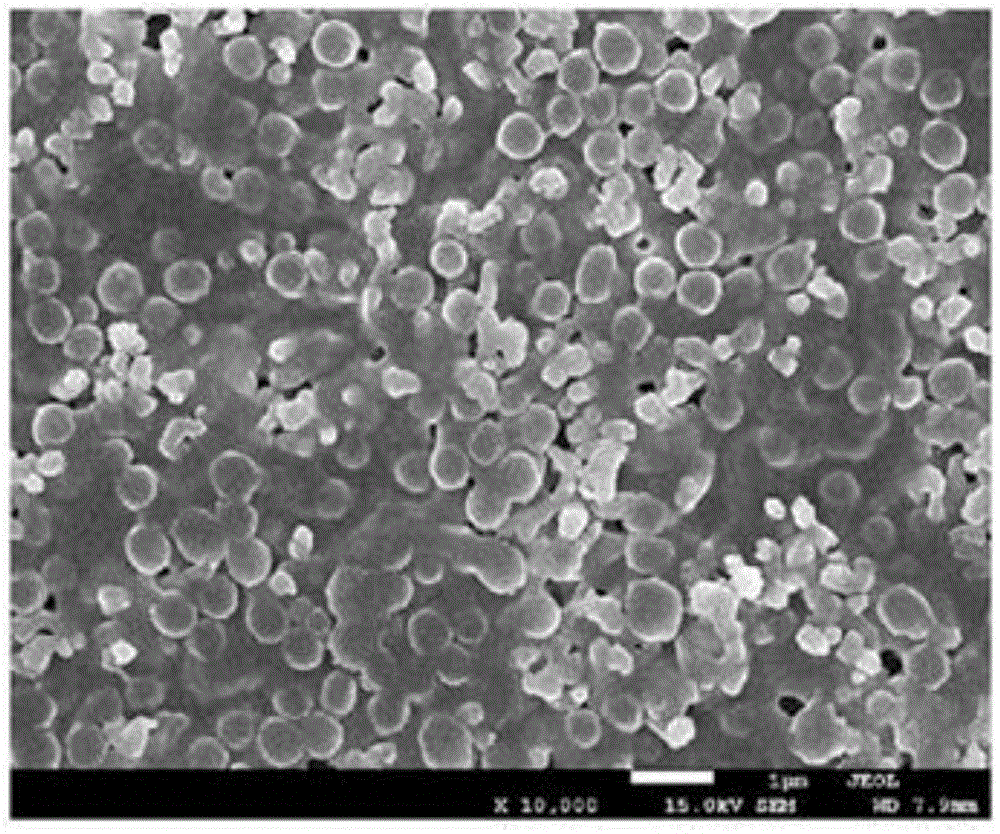

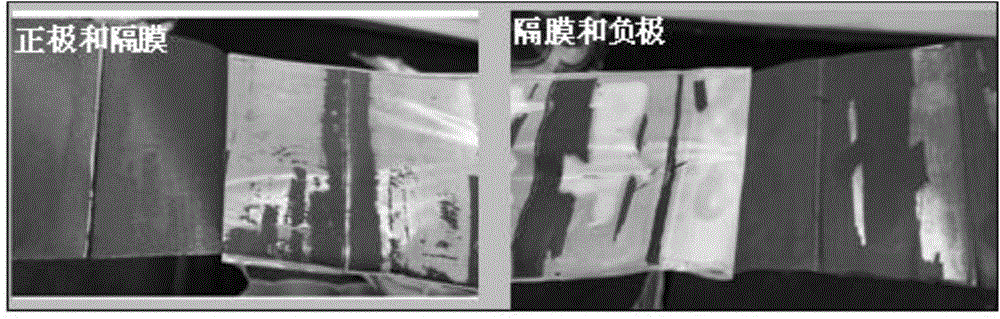

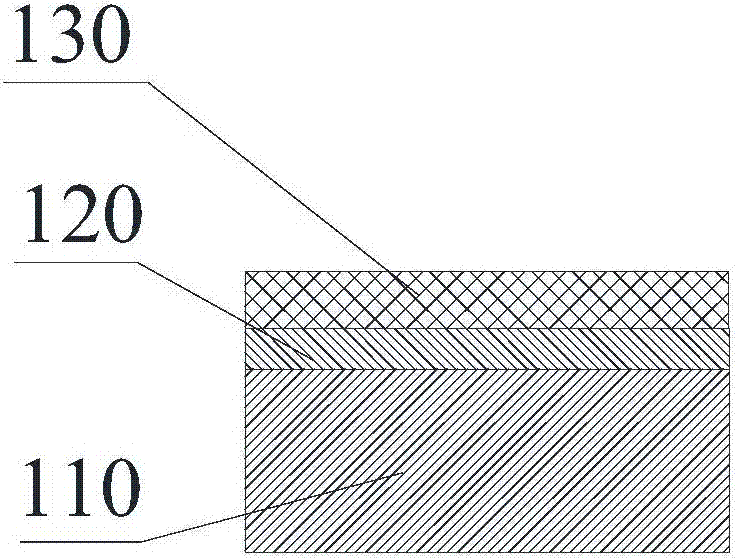

Polymer film and preparation method thereof, gel electrolyte and polymer battery

InactiveCN105529495AImprove breathabilityEffective bondingSecondary cellsPolymer electrolytesVitrification

The invention provides a polymer film to overcome the problem that a gel polymer electrolyte is relatively low in ionic conductivity in the prior art. The polymer film comprises a first polymer matrix, second polymer particles and inorganic particles, wherein the second polymer particles and the inorganic particles are distributed in the first polymer matrix; the glass-transition temperature of the first polymer matrix is lower than 40 DEG C; the glass-transition temperature of the second polymer particles is higher than 40 DEG C; the glass-transition temperature of the polymer film is 30-60 DEG C; and the air permeability is 150-600sec / 100mL. Meanwhile, the invention further discloses a preparation method of the polymer film and a gel electrolyte and a polymer battery comprising the polymer film. The gel electrolyte prepared by the polymer film provided by the invention has excellent ionic conducting properties.

Owner:BYD CO LTD

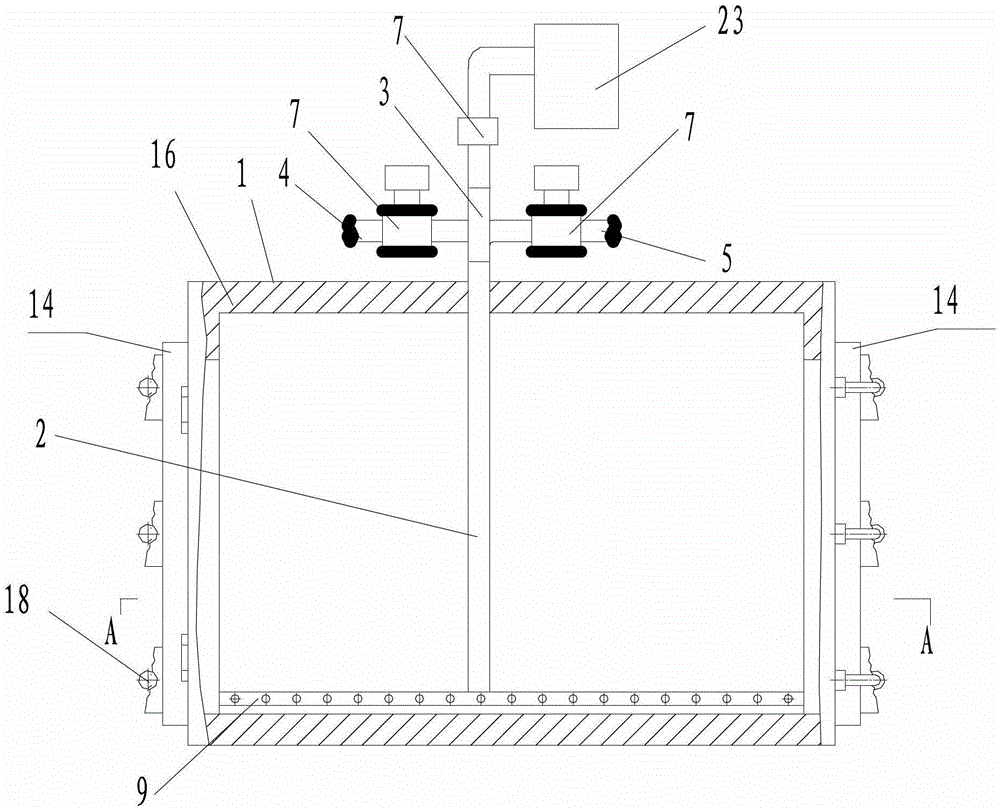

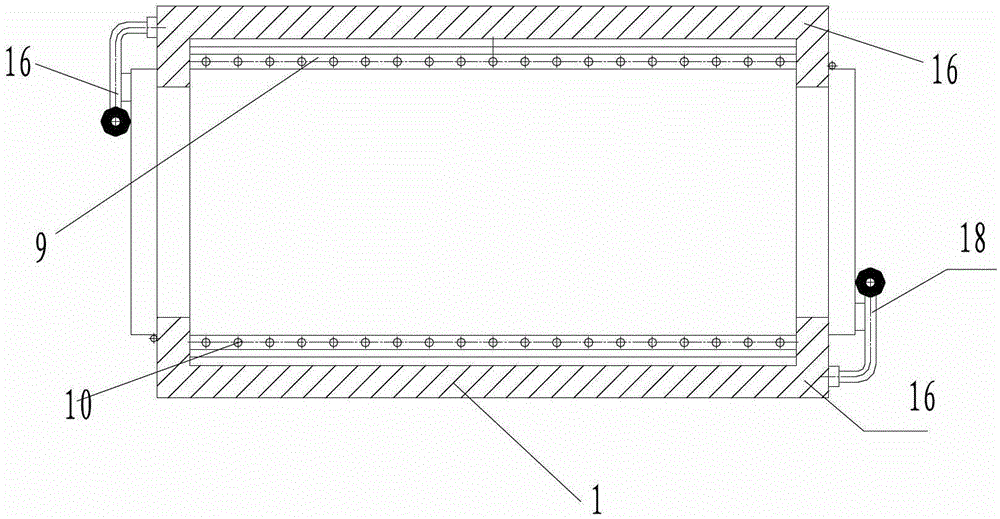

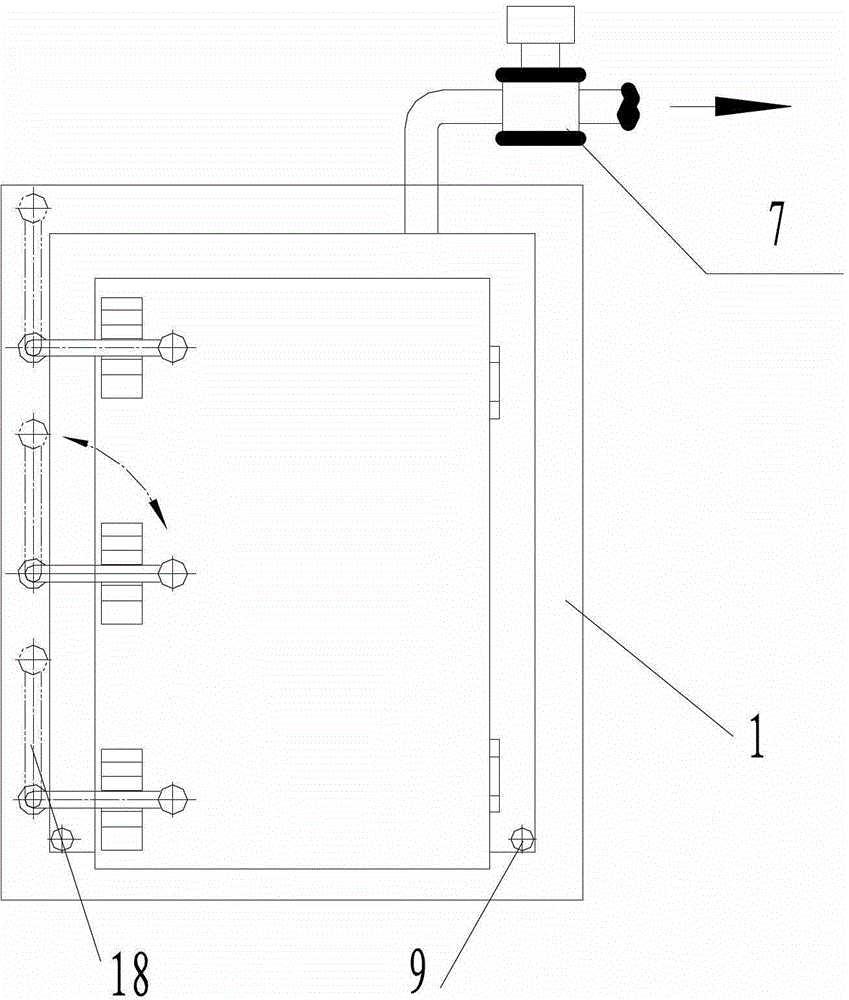

Steam box with vacuum rapid-cooling function

The invention relates to a steam box with a vacuum rapid-cooling function. The steam box comprises a steam box body and a steam pipeline, wherein the steam box body is provided with a sealing door, and the steam pipeline is communicated with the steam box body. The steam box is characterized in that the steam box body is a house type cabin box capable of bearing a positive pressure and a negative pressure and is provided with a pipeline penetrating into the steam box from the top; the part, outside of the steam box, of the pipeline is connected with a tee joint; the tee joint is respectively communicated with a steam conveying pipeline, a vacuumizing pipeline and a deflating pipeline; the steam conveying pipeline, the vacuumizing pipeline and the deflating pipeline are respectively connected with valves; and the vacuumizing pipeline is connected with a vacuum pump. The steam box with the vacuum rapid-cooling function has the beneficial effects that the steam box has very strong high pressure resistance and negative pressure resistance, the occupied area is only two square meters, and steamed foods can be rapidly cooled to the normal temperature within 3-5 minutes, so that the labor productivity is effectively improved, and the production and processing costs are lowered.

Owner:张庆利

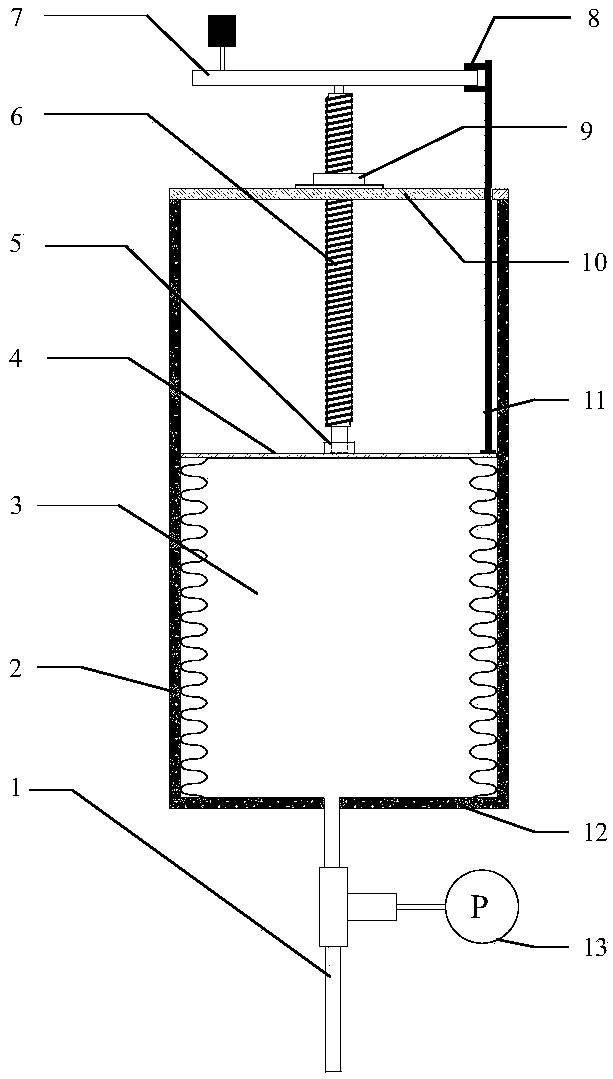

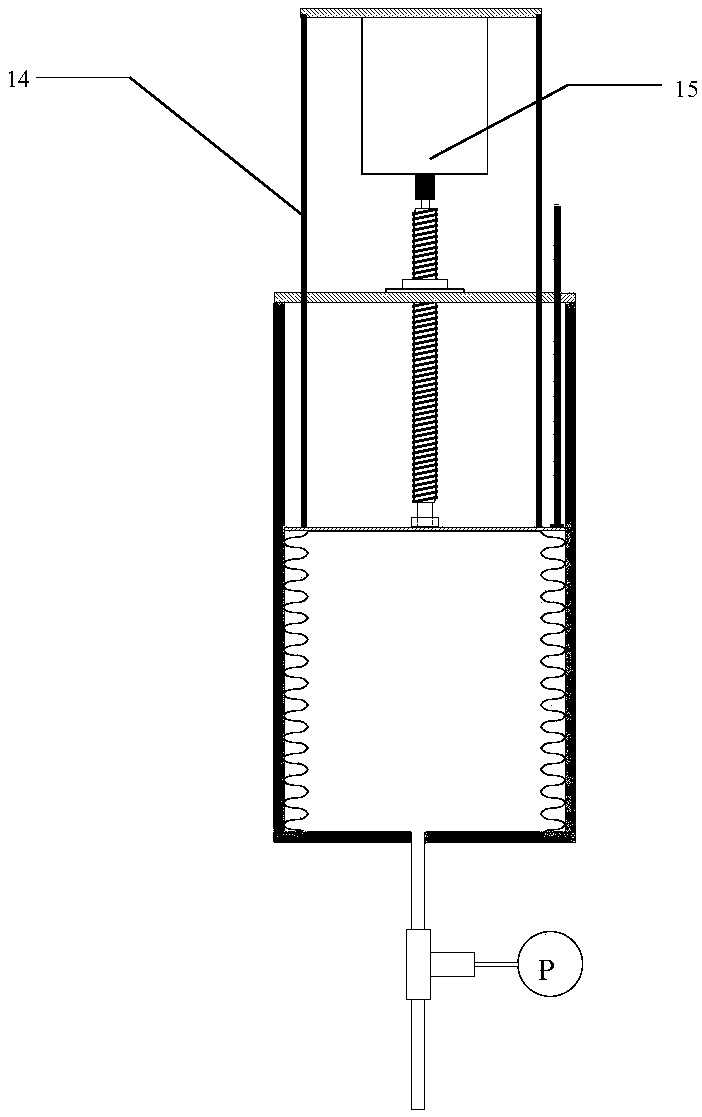

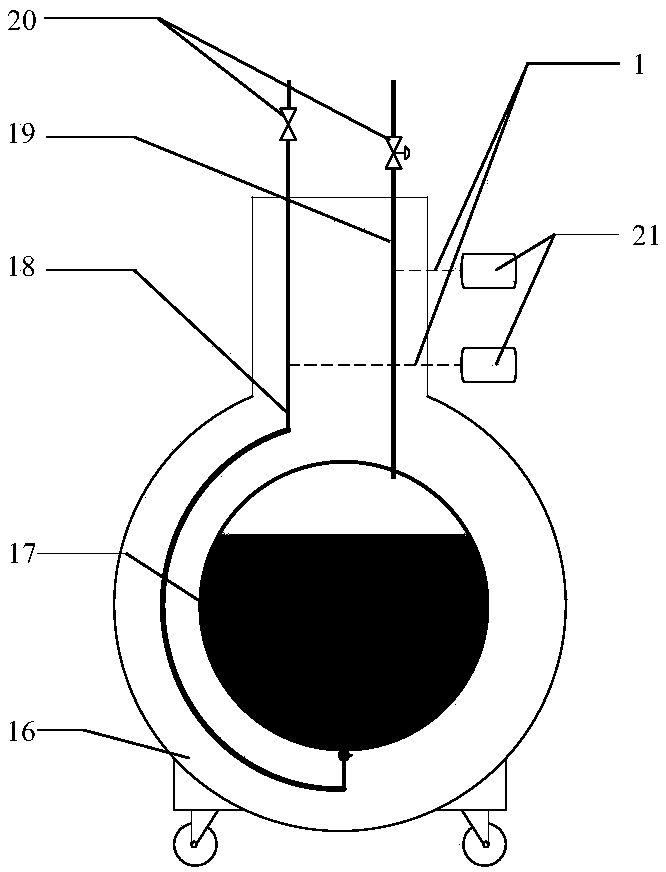

Thermoacoustic oscillation suppression device based on variable-volume damping gas storage for liquid helium container

ActiveCN107917337ACircumferential distortion does not occurImprove sealingContainer filling methodsPressure vesselsFixed bearingThermoacoustics

The invention discloses a thermoacoustic oscillation suppression device based on a variable-volume damping gas storage for a liquid helium container. The thermoacoustic oscillation suppression devicecomprises a capillary tube, a gas storage sleeve, the damping gas storage, a moving plate, a screw rod fixing bearing, a ball screw, a nut pair, a screw nut fixing plate, a scaleplate, a gas storage fixing plate and a pressure sensor, wherein a corrugated pipe is adopted for the damping gas storage, so that the gas storage has the characteristics of being resistant to high pressure and high in sealing performance, and change for the volume of the damping gas storage can also be realized by virtue of the axial scalability of the corrugated pipe. Manual or automatic adjustment can be carried outon the volume of the gas storage according to the different use working conditions of the liquid helium container, so that the optimal suppression effect of the device for the thermoacoustic oscillation of the liquid helium container is guaranteed.

Owner:SHANGHAI JIAO TONG UNIV +1

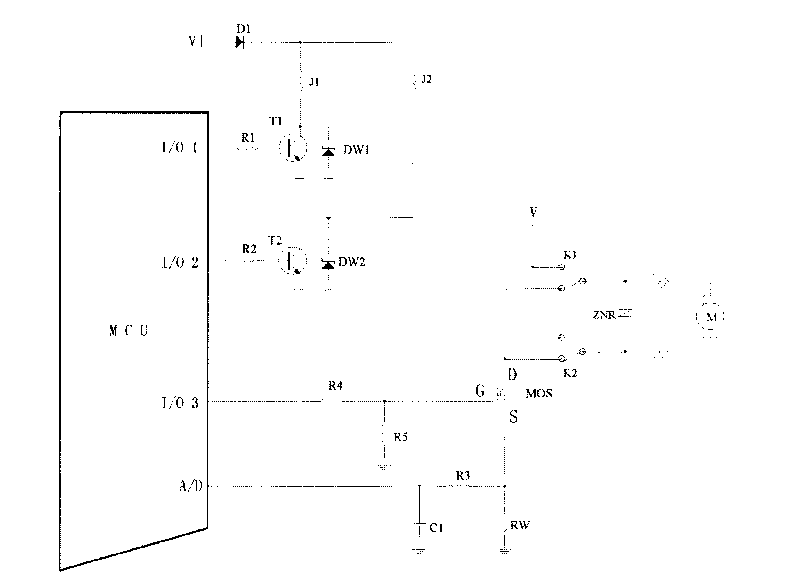

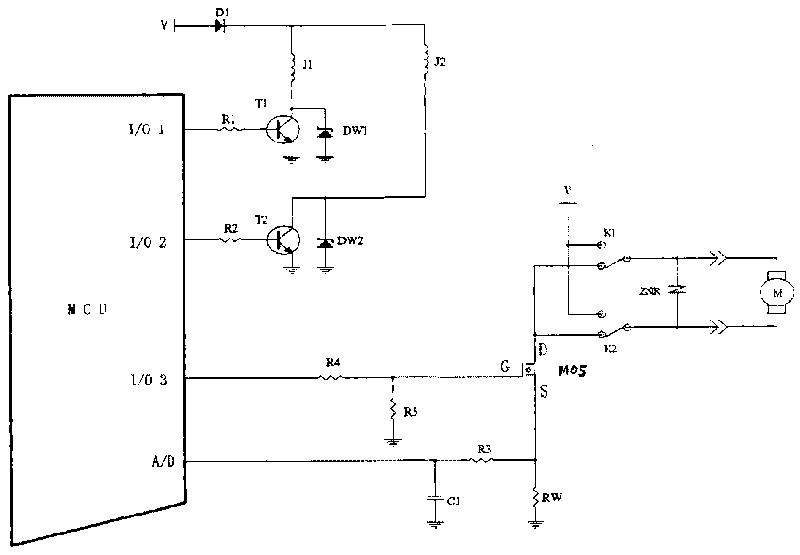

Power vehicle window controller

InactiveCN101692169ASolve the problem of not being able to withstand high voltageSolve the impactStarter detailsProgramme control in sequence/logic controllersElectrical resistance and conductanceElectricity

The invention provides a power vehicle window controller applying an MOS tube. The MOS tube is connected in serial with an output circuit of a controller circuit; a grid G thereof is connected with a control terminal of a microprocessor; a drain D thereof is connected with normally closed contacts of two normally open relays; and a source S thereof is connected with a sampling resistor and the control terminal of the microprocessor. When the power vehicle window controller circuit is turned on or turned off, a vehicle window motor can generate a startup heavy current peak value or a back-EMF which impacts relay contacts during the actuation, causes the phenomena of burning or bonding the contacts, and leads to the failure of the operation. The power vehicle window controller utilizes a microprocessor control circuit to switch on the MOS tube after the relay contacts are actuated; and the MOS tube has a rapid switching speed and can entirely bear high-power impact generated by the motor so that the power vehicle window controller can be widely applied to various large-scale vehicles with automotive electrical appliance adopting a 24V power supply.

Owner:SHANGHAI HUGONG AUTO ELECTRIC

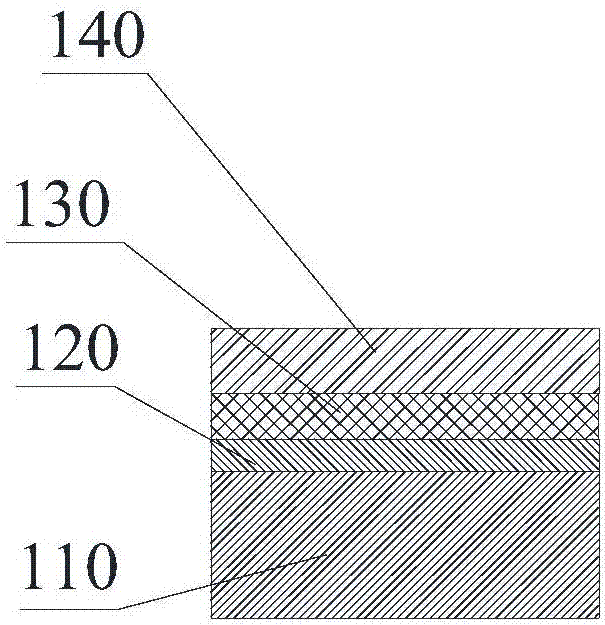

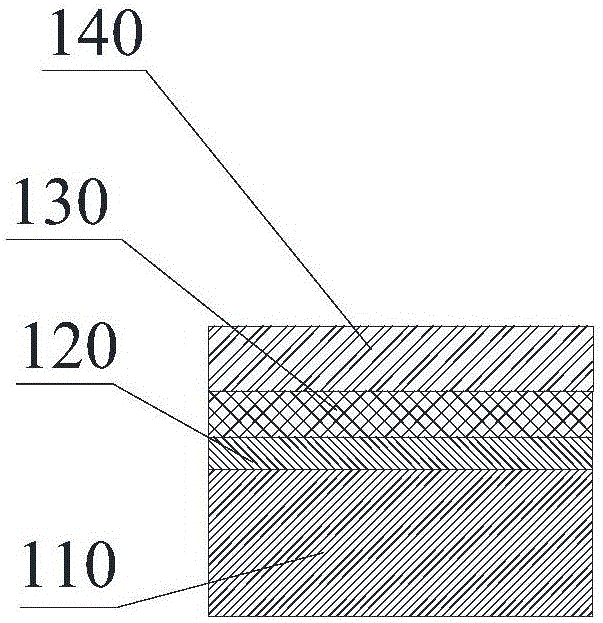

Manufacturing method of metal-ceramic composite substrate and composite substrate manufactured through manufacturing method

ActiveCN107546132ASmall electrical impedancePromote wettingSemiconductor/solid-state device detailsSolid-state devicesComposite substrateCopper foil

The invention discloses a manufacturing method of a metal-ceramic composite substrate and the composite substrate manufactured through the manufacturing method and belongs to the technical field of ceramic metallization. The manufacturing method comprises the following steps of forming a first brazing material layer on the surface of a ceramic substrate, wherein the first brazing material layer isa copper, silver and active metal brazing material layer; forming a second brazing material layer on the surface of the first brazing material layer, wherein the second brazing material layer is a copper and silver brazing material layer; forming a copper layer on the surface of the second brazing material layer; and sintering a metal-ceramic composite substrate precursor in vacuum. According tothe manufacturing method, an active metal in the first brazing material layer reacts with ceramic during vacuum sintering, so that the binding force is high and the thermal shock resistance is high. Copper and silver in the second brazing material layer are subjected to eutectic reaction with copper foil, so that the copper and the silver are tightly combined with the copper foil; and meanwhile, by adopting two brazing material layers, on one hand, the content of the silver is reduced and the cost is lower, and on the other hand, the content of the active metal is reduced, electrical impedanceis reduced and the metal-ceramic composite substrate is higher in high voltage resistance and high current resistance.

Owner:ZHEJIANG TC CERAMIC ELECTRONICS

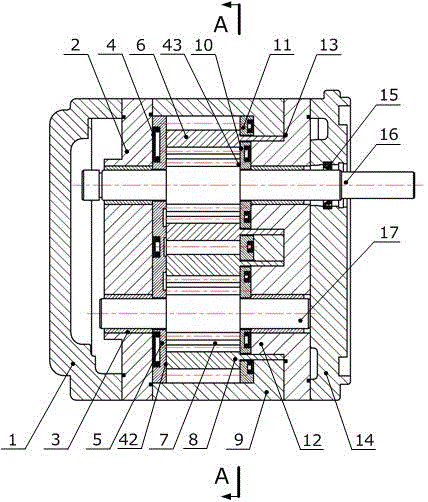

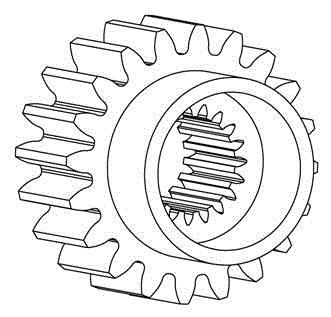

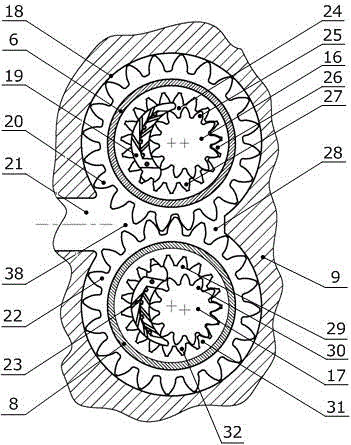

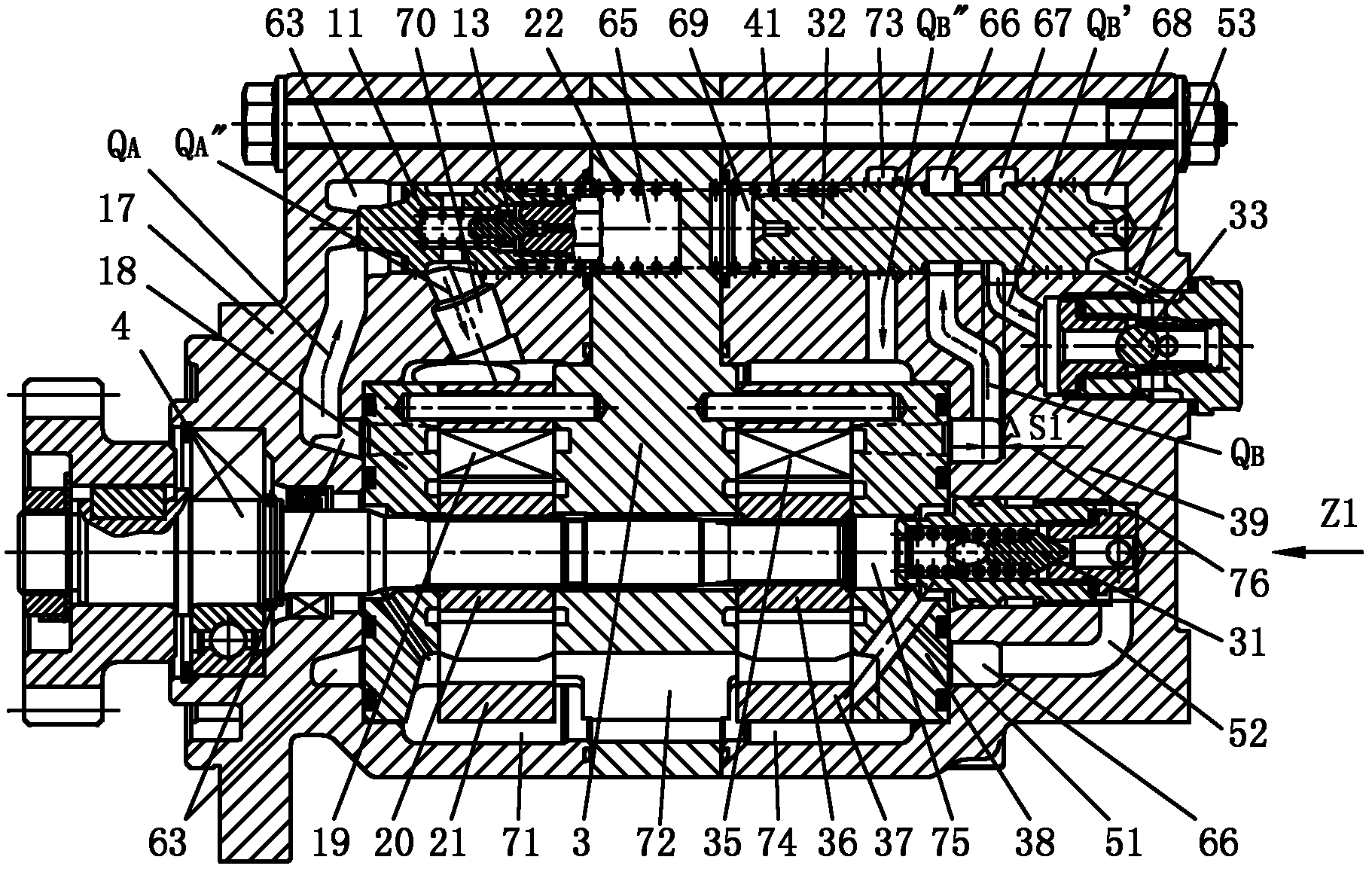

Internally-engaged gear pump applicable to high pressure and large flow

ActiveCN104454511AReasonable forceReduce distortionRotary piston pumpsRotary piston liquid enginesDouble teethEngineering

The invention discloses an internally-engaged gear pump applicable to high pressure and large flow. The internally-engaged gear pump is composed of a pump shell, a first double-tooth ring, a second double-tooth ring, a first gear shaft, a second gear shaft, a radial compensation device, a sliding bearing, a side plate and the like, wherein the first double-tooth ring and the second double-tooth ring are symmetrically arranged in the pump body, and outer teeth of the first double-tooth ring and the second double-tooth ring are engaged to form a first gear pair; the first gear shaft and the first double-tooth ring are engaged to form a second gear pair; and the second gear shaft and the second double-tooth ring are engaged to form a third gear pair. A single input shaft is used for driving the gear pairs to rotate by grades and the distribution of moment on the shaft is reasonable; and the radial unbalance force on each grade of gear pair is small and the anti-pressure ability of the pump under a high pressure working condition is improved. Oil in the pump is pressurized by the plurality of grades of gear pairs so that the output pressure and the flow of the oil are effectively improved; and meanwhile, the two paths of oil on the outlet of the pump are overlapped so that the flow and the pressure pulse of the pump are remarkably reduced and the requirements of a high-precision hydraulic system can be met.

Owner:FUZHOU UNIV

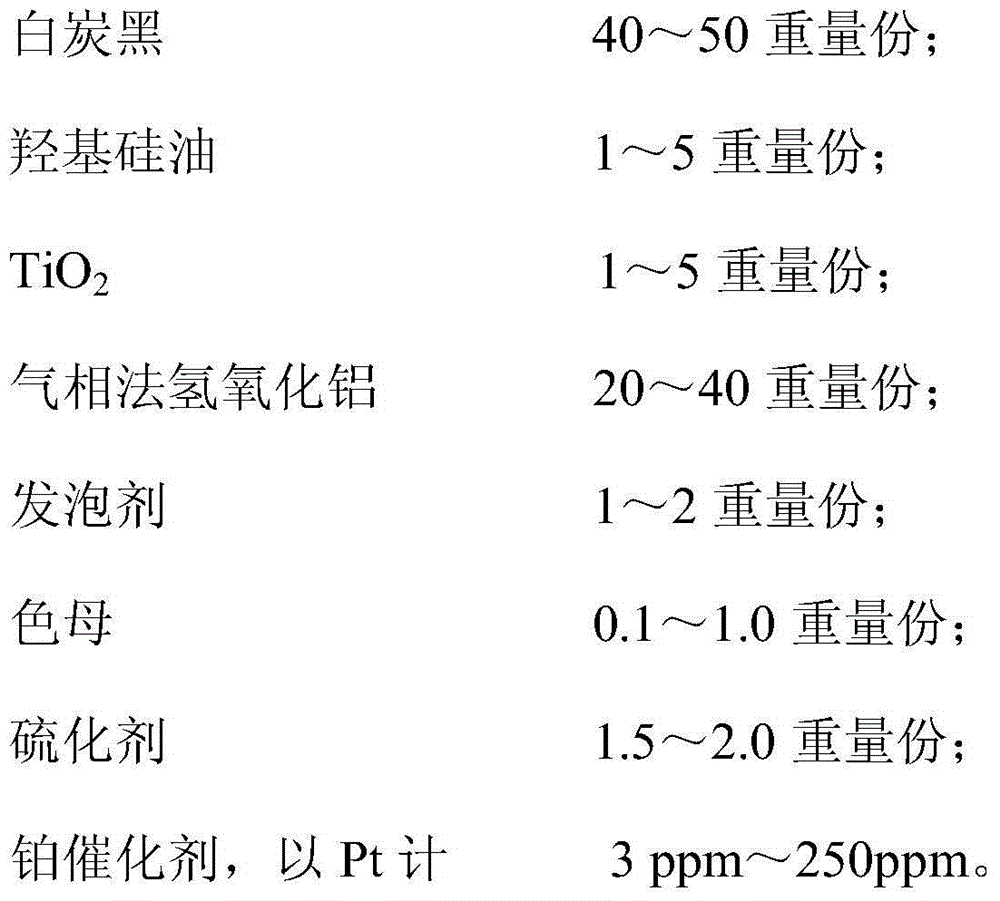

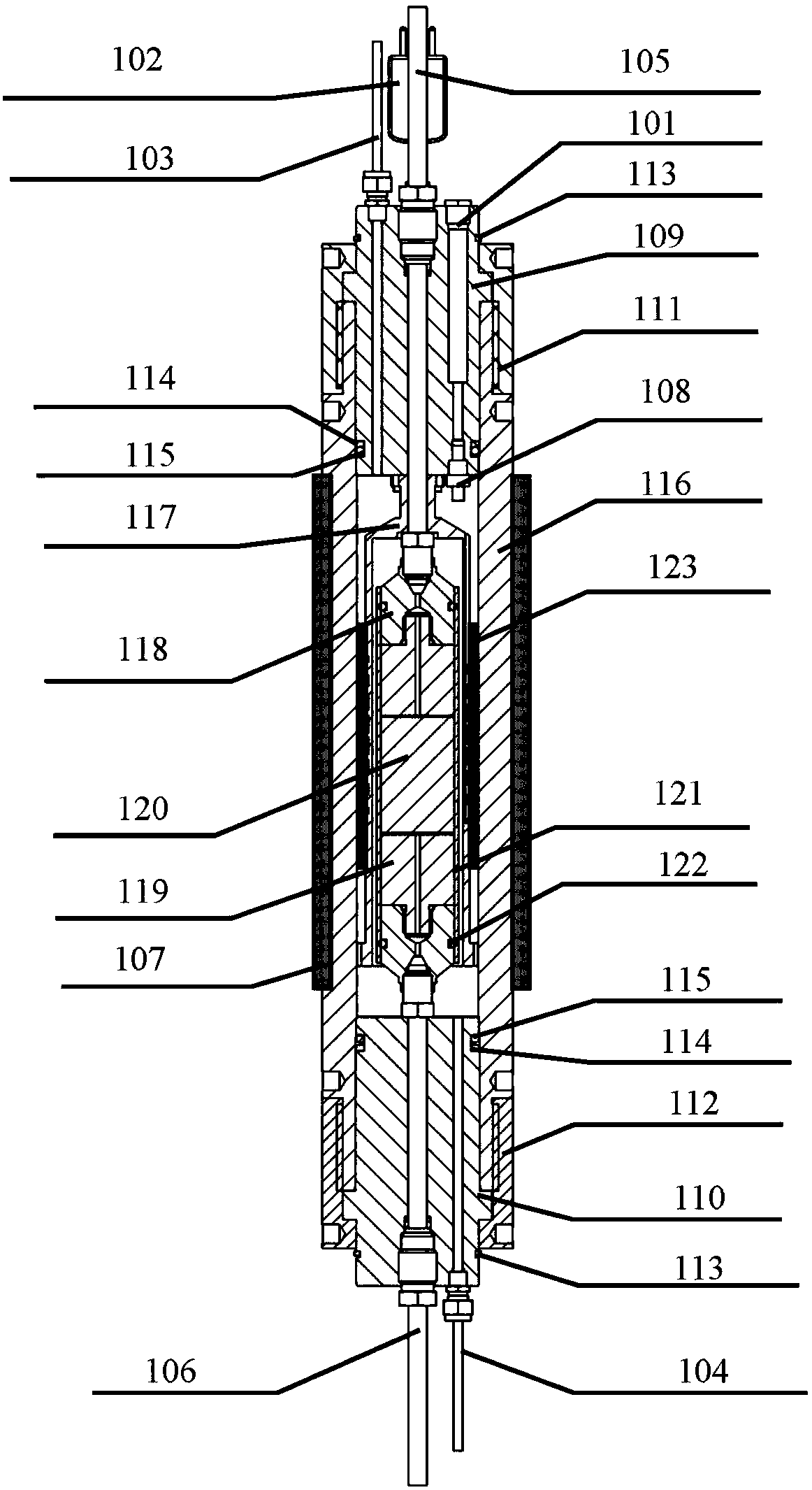

Silicone rubber insulating sizing material, high-temperature and high-pressure resistant silicone rubber wire and preparation process

InactiveCN104479358AMeet environmental protection requirementsImprove high temperature resistanceRubber insulatorsPolymer scienceHigh pressure

The invention discloses a silicone rubber insulating sizing material, a high-temperature and high-pressure resistant silicone rubber wire and a preparation process of the wire; the high-temperature and high-pressure resistant silicone rubber wire is made of the silicone rubber insulating sizing material; the silicone rubber insulating sizing material comprises raw silicone rubber, white carbon black, hydroxyl silicone oil, TiO2, aluminum hydroxide prepared through a vapour phase method, a foaming agent, a platinum catalyst, colour master, a vulcanizing agent and the like; and an antistatic agent can also be added properly. The silicone rubber insulating sizing material disclosed by the invention can satisfy the environment-friendly requirements and has excellent high-temperature and high-pressure resistant performances; the addition proportion of TiO2 is proper; the heat-resistant effect is increased while the purity and the ageing resistance of rubber cannot be influenced; the cost is relatively lower; the aluminum hydroxide prepared through the vapour phase method is small in grain size and few in impurity; the flame retardant efficiency is increased while withstand voltage influence of aluminum hydroxide prepared through a precipitation method is little; the platinum catalyst is capable of isolating air under the catalytic action of platinum, so that flame is extinguished; the foaming agent has the effect of isolating air; and thus, the flame retardant property is increased.

Owner:DONGGUAN SUNTRACK WIRE

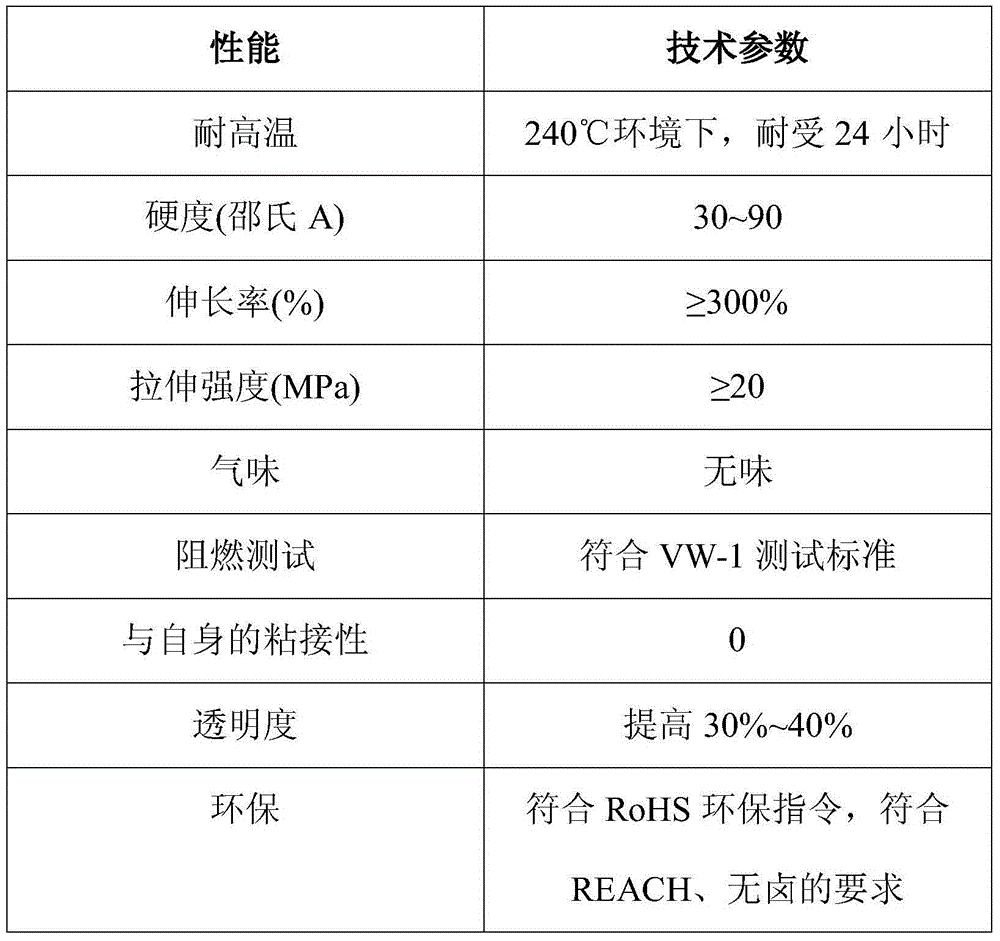

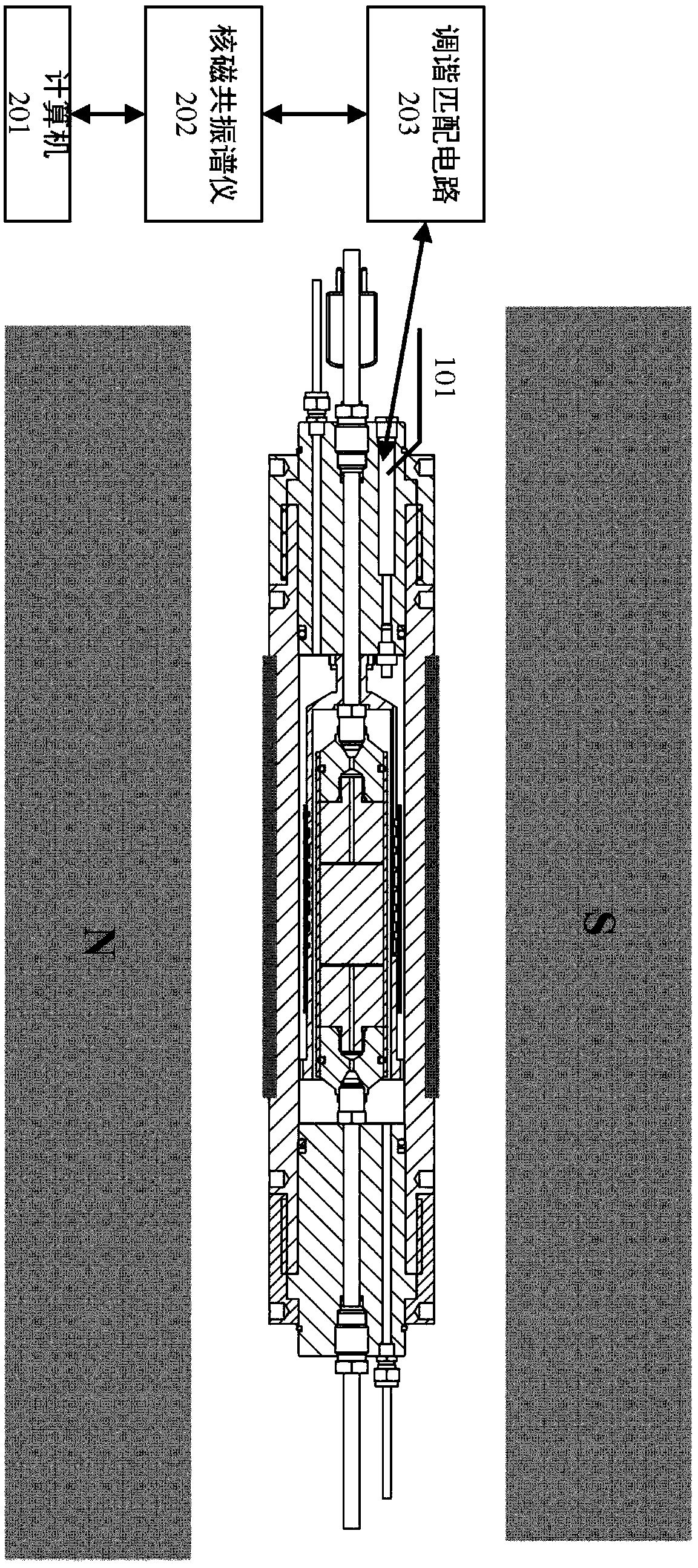

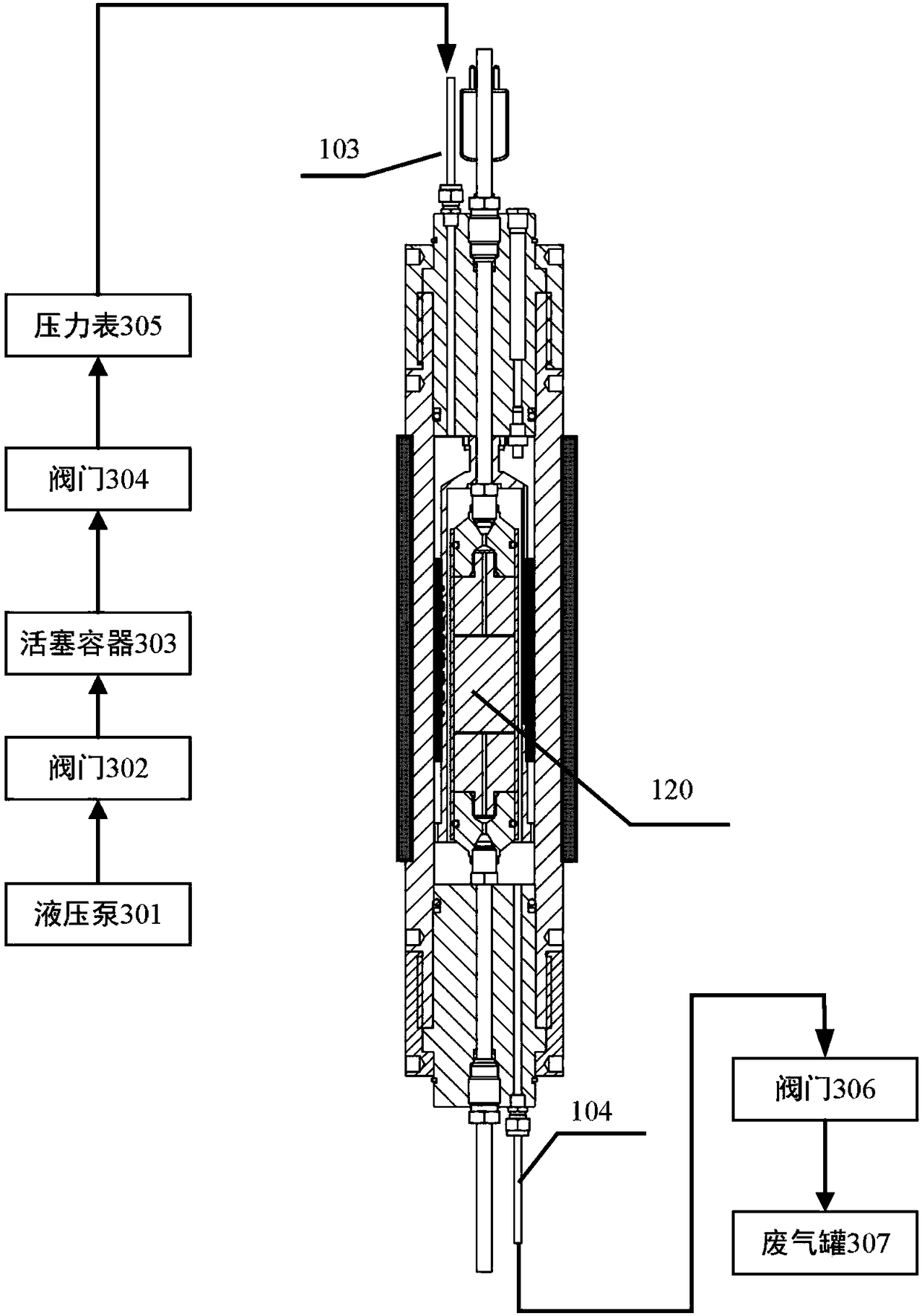

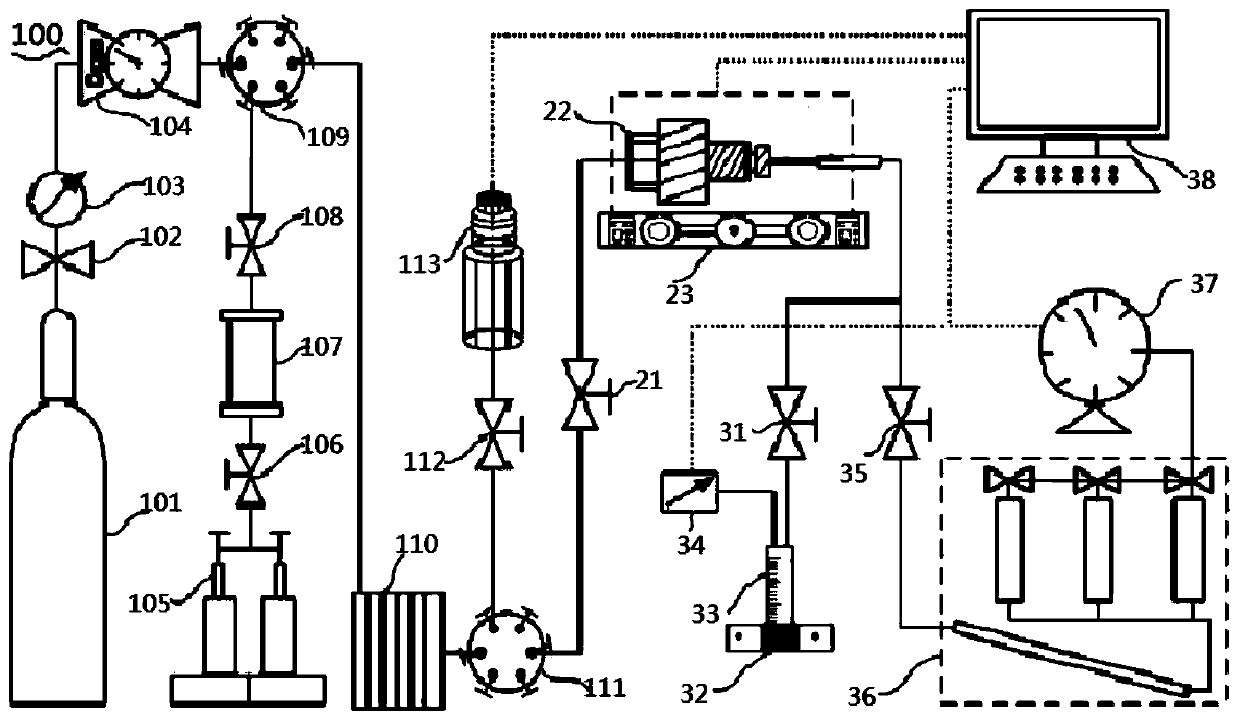

Variable temperature and variable pressure probe for nuclear magnetic resonance detection, and nuclear magnetic resonance detection method

InactiveCN108267393AStrong high pressure resistanceMeet the needs of variable temperature detectionAnalysis using nuclear magnetic resonancePermeability/surface area analysisNMR - Nuclear magnetic resonanceTest sample

The invention discloses a variable temperature and variable pressure probe for nuclear magnetic resonance detection, and a nuclear magnetic resonance detection method. The probe comprises a nuclear magnetic resonance detection system, a confining pressure applying system, a displacement pressure applying system and a variable temperature system; and the probe can simultaneously or separately realize the nuclear magnetic resonance detection of a test sample under applied confining pressure, applied displacement and variable temperature conditions. The nuclear magnetic resonance detection methodincludes the following steps: installation of the test sample, connection of a nuclear magnetic detection circuit, connection of the confining pressure applying system, connection of the displacementpressure applying system, connection of the variable temperature system, and testing. The probe has the advantages of high pressure resistance, low manufacturing cost and flexibility in testing.

Owner:SOUTHEAST UNIV +1

High pressure resistant sacculus molding technology

InactiveCN101811157AEnhance memoryStrong high pressure resistanceHigh pressureBiomedical engineering

The invention relates to a high pressure resistant sacculus molding technology. Sacculus tubing is put into a sacculus mould, one end of the sacculus tubing is connected with high-pressure air or liquid, and the other end is sealed; the sacculus mould is heated, and the internal sacculus tubing is heated and softened; one end of the sacculus tubing is acted with high pressure to ensure that the sacculus tubing expands and deforms; the outer wall of the sacculus tubing is tightly stuck to the inner wall of the sacculus mould; in the heating and pressurizing process, the sacculus tubing is lengthways stretched; after being molded, the sacculus is cooled to prepare the sacculus of the invention. The sacculus prepared with the technology has thin and even wall and favorable excellent pressure resistant performance and memory performance.

Owner:SINO MEDICAL SCI TECH INC

Manufacturing method of metal-ceramic composite substrate and composite substrate manufactured by manufacturing method

InactiveCN106328543AImprove conductivityStrong high pressure resistanceSemiconductor/solid-state device detailsSolid-state devicesHigh resistanceComposite substrate

The invention discloses a manufacturing method of a metal-ceramic composite substrate and a composite substrate manufactured by the manufacturing method, and belongs to the technical field of ceramic metallization. The manufacturing method comprises the following steps: forming a first brazing filler metal layer on the surface of a ceramic substrate, wherein the first brazing filler metal layer is a copper and active metal brazing filler metal layer; forming a second brazing filler metal layer on the surface of the first brazing filler metal layer, wherein the second brazing filler metal layer is a copper and silver brazing filler metal layer; forming a copper layer on the surface of the second brazing filler metal layer in order to form a metal-ceramic composite substrate precursor; and sintering the metal-ceramic composite substrate precursor in vacuum. In the manufacturing method, an active metal of the first brazing filler metal layer reacts with ceramic during vacuum sintering, so that high bonding force and high thermal shock resistance are achieved. Copper and silver of the second brazing filler metal layer undergo a eutectic reaction with a copper foil, so that the copper and the silver are combined tightly with the copper foil, and the metal-ceramic composite substrate has higher resistance to high voltages and heavy current at the same time.

Owner:ZHEJIANG TC CERAMIC ELECTRONICS

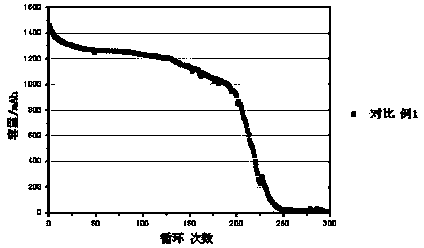

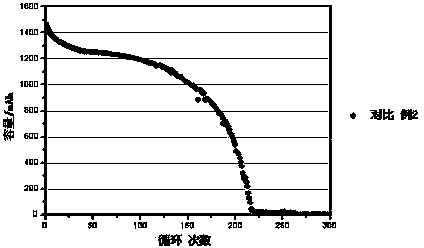

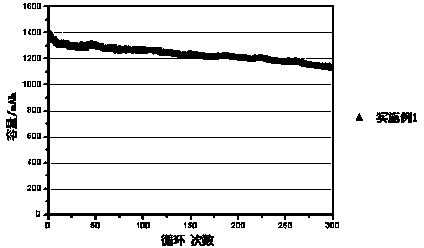

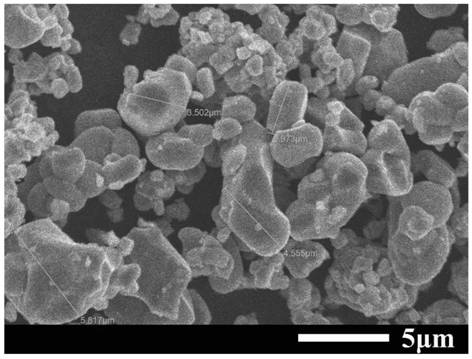

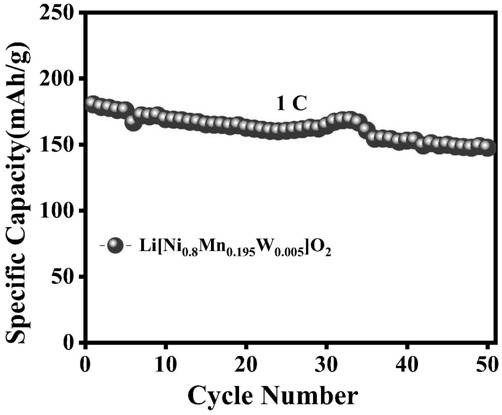

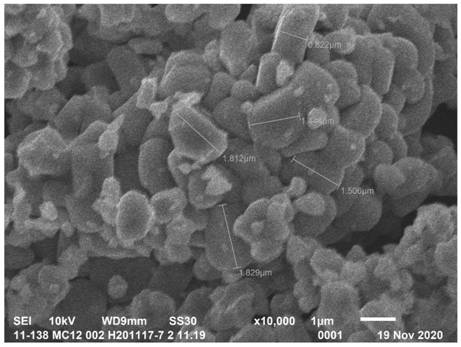

Cobalt-free high-nickel ternary concentration gradient core-shell structure lithium ion battery positive electrode material and preparation method thereof

PendingCN113889615ALow costImprove mechanical stabilitySecondary cellsPositive electrodesElectrical batteryLithium hydroxide

The invention discloses a cobalt-free high-nickel ternary concentration gradient core-shell structure lithium ion battery positive electrode material and a preparation method thereof. The chemical formula of the positive electrode material is Li [NixMn1-x-yWy] O2, wherein x and y are mole numbers, x is larger than or equal to 0.8 and smaller than 1, and y is larger than 0 and smaller than or equal to 0.1. The preparation method comprises the following steps: adding a first salt solution containing nickel, manganese and tungsten, a sodium hydroxide solution and an ammonia water solution into a reaction kettle, reacting to form a precursor inner core, adding a second salt solution containing nickel, manganese and tungsten in different proportions into the reaction kettle, fully reacting, carrying out centrifugal washing, drying, screening to remove iron, mixing with lithium hydroxide, and roasting to obtain the lithium ion battery positive electrode material with the ternary concentration gradient core-shell structure. The concentration gradient positive electrode material disclosed by the invention has a relatively good crystal structure and relatively high tap density, and a battery prepared by taking the concentration gradient positive electrode material as the positive electrode material has excellent electrochemical performance; and the preparation method is simple, controllable, low in cost and suitable for industrial production.

Owner:CENT SOUTH UNIV

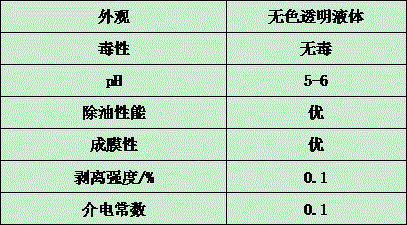

Antifouling treating agent for cleaning electrical insulator and preparation method of antifouling treating agent

InactiveCN106047510AGood film formingImprove insulation performanceInorganic/elemental detergent compounding agentsCationic surface-active compoundsPolyvinyl alcoholActive agent

The invention relates to an antifouling treating agent for cleaning an electrical insulator. The antifouling treating agent comprises the following raw materials: modified silicone oil, a surfactant, an acid, an oxidant, modified polyvinyl alcohol, modified polyacrylic acid, water and ethanol, wherein the modified silicone oil is prepared from silicone oil, ethanol and polyacrylic acid through a reaction; modified polyvinyl alcohol is prepared from polyvinyl alcohol, silicone oil, a silane coupling agent, the surfactant and a dispersing agent through a reaction; modified polyacrylic acid is prepared from polyacrylic acid, the silicone oil, the silane coupling agent, the surfactant and the dispersing agent through a reaction. The antifouling treating agent for cleaning the electrical insulator has excellent oil stain removal, saline water removal, inorganic matter impurity removal and self-cleaning performance and the advantages of being non-toxic, environment-friendly, simple and convenient to operate and the like.

Owner:孟根森

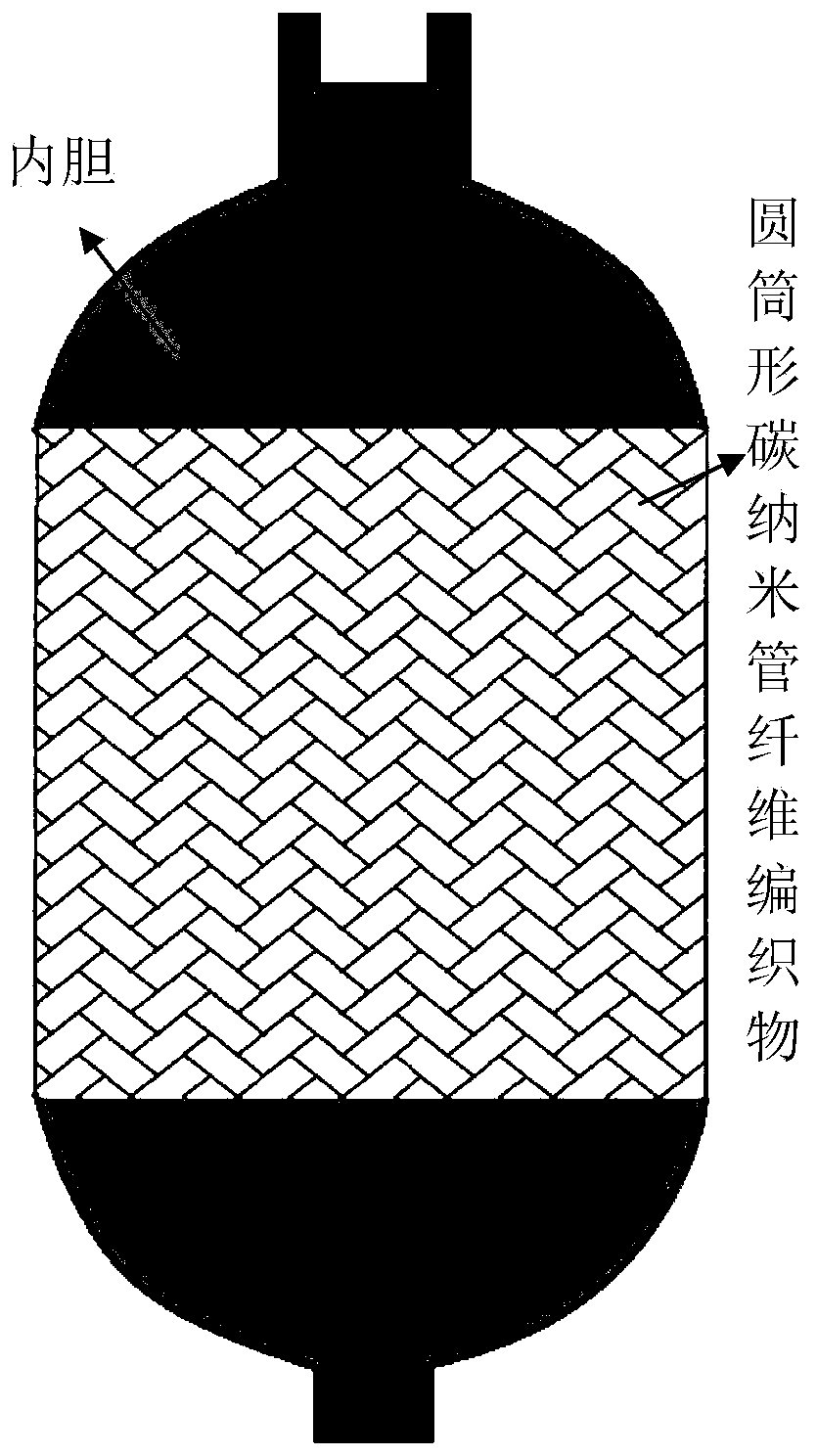

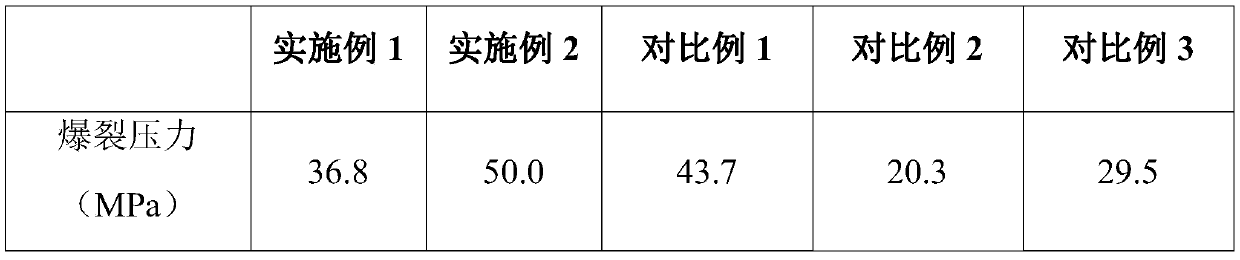

High-pressure hydrogen storage bottle and manufacturing method thereof

PendingCN111251631AIncrease elasticityImprove mechanical propertiesHollow articlesFiberCarbon nanotube

The invention belongs to the technical field of hydrogen storage, and particularly relates to a manufacturing method of a high-pressure hydrogen storage bottle. The manufacturing method of the high-pressure hydrogen storage bottle comprises the following steps that a cylindrical carbon nanotube fiber braided fabric is obtained, the cylindrical carbon nanotube fiber braided fabric is of an integralstructure, and the cylindrical carbon nanotube fiber braided fabric is not provided with a joint in the longitudinal direction; and an inner container is obtained, after the cylindrical carbon nanotube fiber braided fabric sleeves the outer surface of the inner container, curing treatment is carried out to obtain the high-pressure hydrogen storage bottle with carbon nanotube fibers wrapped on theouter surface. According to the manufacturing method of the high-pressure hydrogen storage bottle, after the cylindrical carbon nanotube fiber braided fabric not provided with the joint in the longitudinal direction and of the integral structure sleeves the outer surface of the inner container, curing treatment is carried out to obtain the high-pressure hydrogen storage bottle with the carbon nanotube fibers wrapped on the outer surface, the cylindrical carbon nanotube fiber braided fabric and the inner container are closely combined, the circumferential compression strength of a container can be effectively improved, the high-pressure hydrogen storage bottle is suitable for storing hydrogen, good in storage stability and high in compression strength, and simple preparation process and easy operation are achieved.

Owner:SHENZHEN XIWAN TECH CO LTD

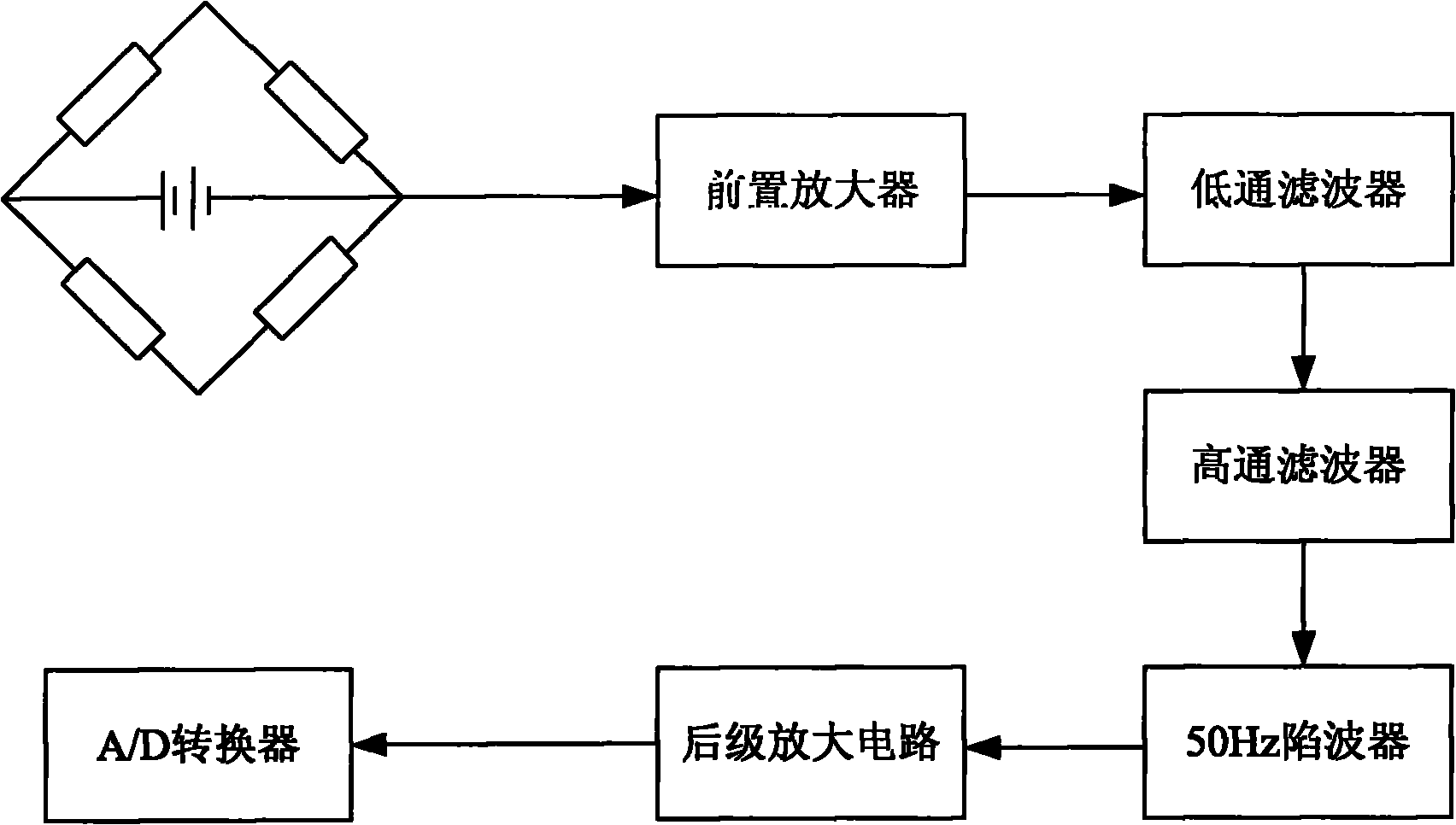

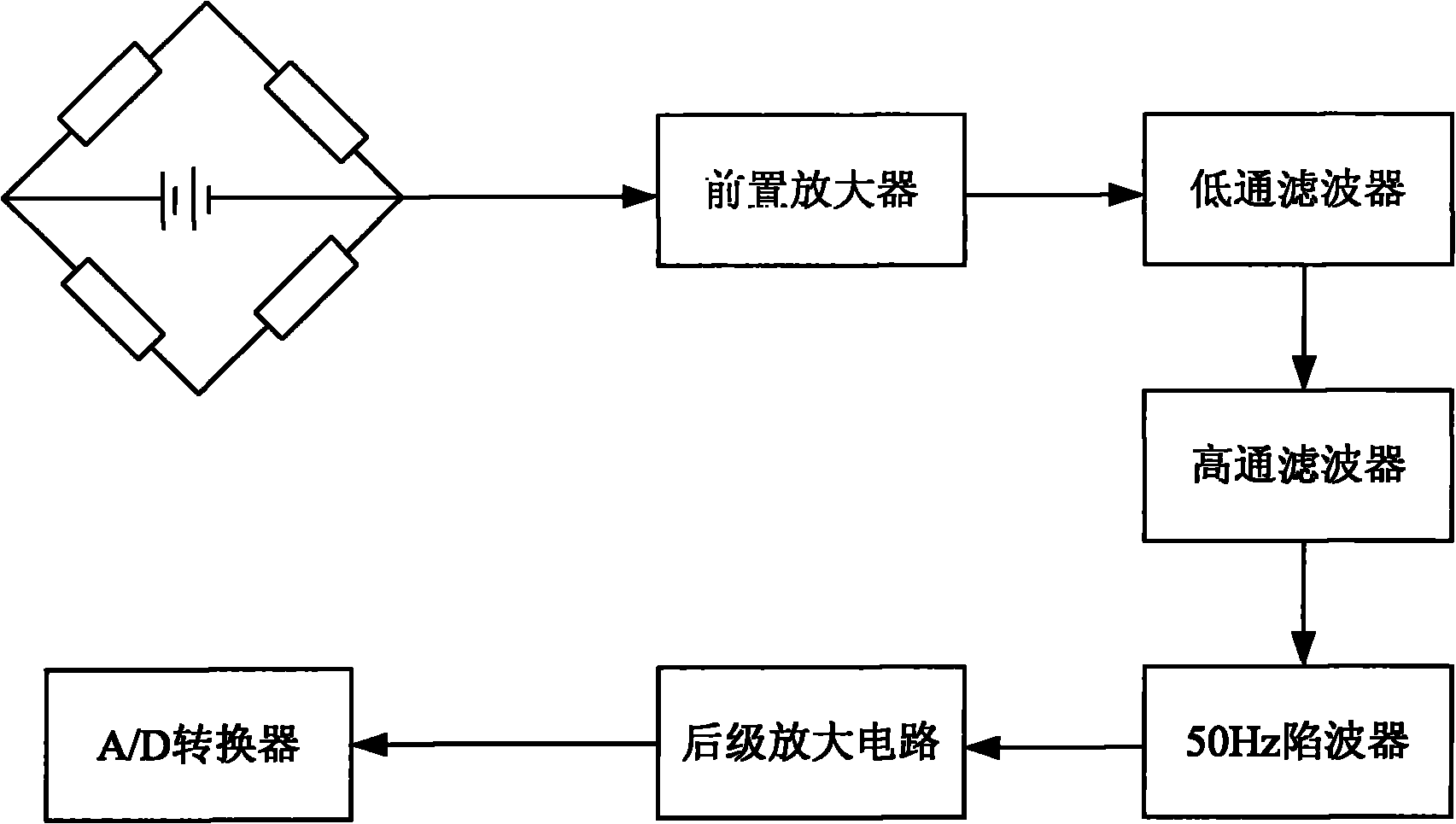

Small signal amplifier for underground engineering parameter test

InactiveCN102094618AImprove anti-interference abilityImprove stabilitySurveyAudio power amplifierFixed gain

The invention discloses a small signal amplifier for an underground engineering parameter test and belongs to signal amplification technologies. The small signal amplifier mainly solves the problem that signals are difficult to accurately test due to over strong signal interference during the underground engineering parameter test in the prior art. The small signal amplifier for the underground engineering parameter test comprises a voltage source, a preamplifier, a low-pass filter, a high-pass filter, a trapper, a post-stage amplifying circuit and an analog to digital (A / D) converter which are connected sequentially, wherein the voltage source is connected with the preamplifier through a bridge type circuit; the preamplifier is a fixed gain amplifier or a program-controlled gain amplifier; and the post-stage amplifying circuit is a gain-adjustable amplifier. The small signal amplifier has a reasonable design and stable component performance, can effectively eliminate noise interference around the signals in underground engineering and improves the accuracy of the signal parameter test.

Owner:武侯区巅峰机电科技研发中心

High-voltage-resistant and flame-retardant type lithium ion battery electrolyte and preparation method therefor

InactiveCN107359367ALow conductivityLittle impact on magnification performanceSecondary cells servicing/maintenanceOrganic solventElectrical battery

Disclosed is a high-voltage-resistant and flame-retardant type lithium ion battery electrolyte. The electrolyte consists of a lithium salt, an organic solvent, a film-forming additive and a flame retardant; the lithium salt is 1.5-3mol / L in concentration; the flame retardant is a fluoro phosphonitrile compound; the fluoro phosphonitrile compound has the chemical formula of N<3>P<3>F<5>OH<2>CH<3> which accounts for 5-10% of the total organic solvent based on mass percentage; and the mass of the film-forming additive is 2-4% of the that of lithium salt. The invention discloses the high-voltage-resistant and flame-retardant type lithium ion battery electrolyte and a preparation method therefor.

Owner:无锡九宇宝新能源科技有限公司

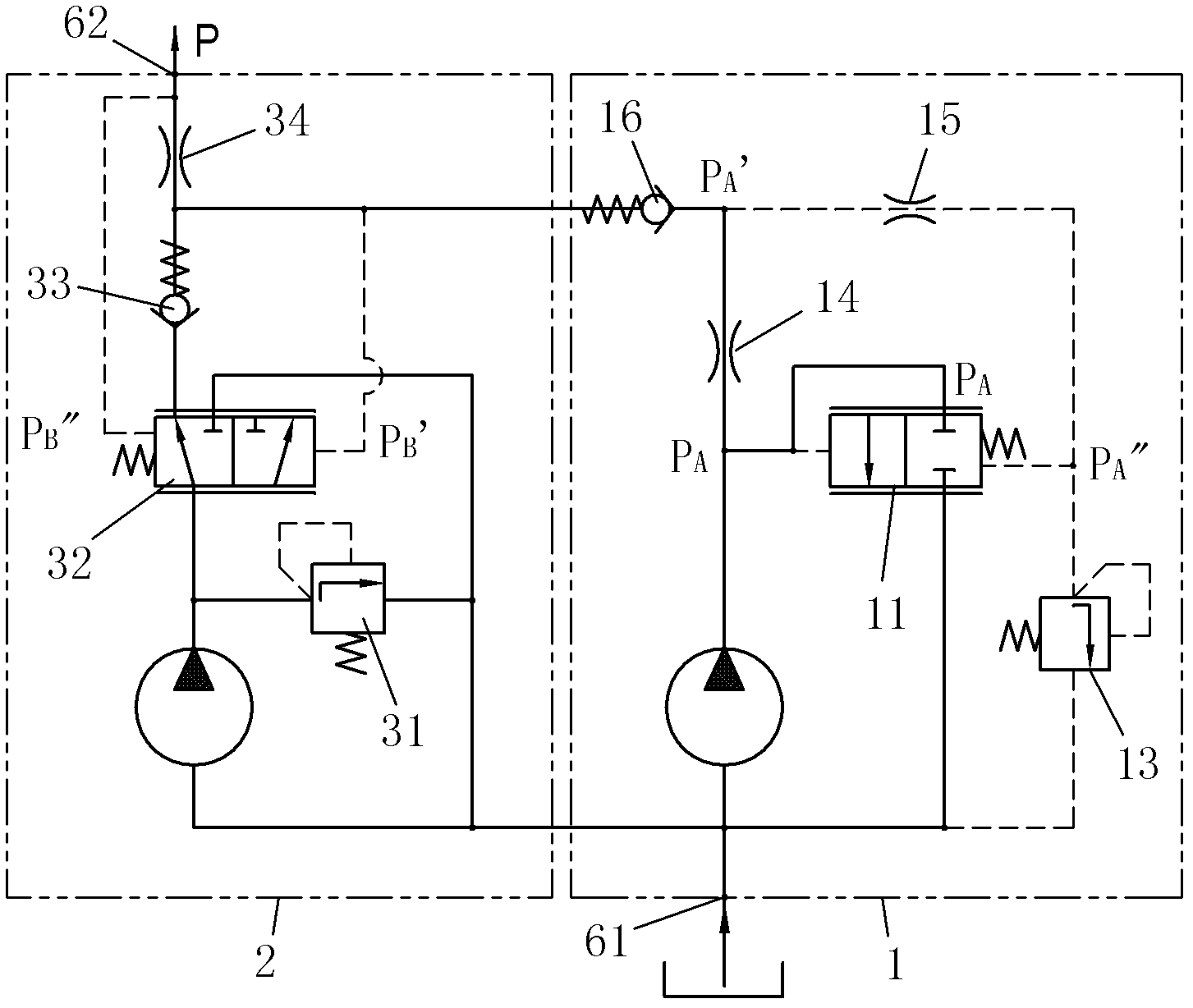

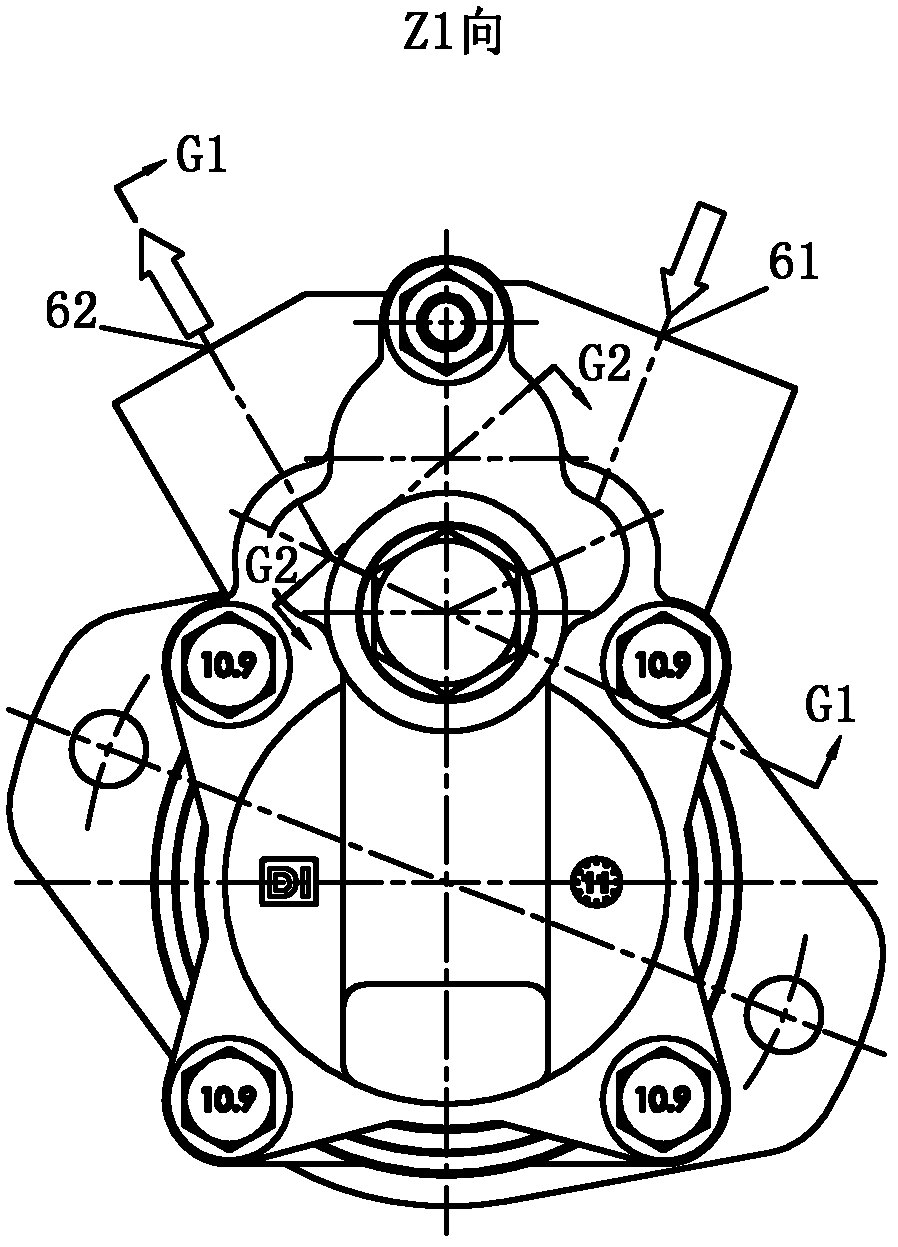

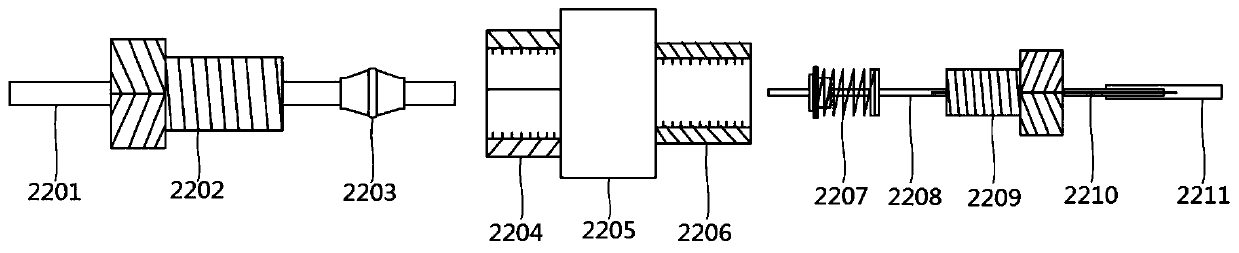

Sequentially controlled twin steering pump

ActiveCN102322420AWith overpressure safety protection functionLow failure rateRotary/oscillating piston combinationsMachines/enginesEngineeringCheck valve

The invention discloses a sequentially controlled twin steering pump, which comprises a main pump, an auxiliary pump, an intermediate and a pump shaft. The main pump includes a flow control valve I, a safety valve I, a flow control damping hole I, a pressure control damping hole, a check valve I, a pump body, a pressure side plate I, a blade I, a rotor I, a stator I, and a flow control valve spring. The auxiliary pump consists of a safety valve II, a reversing valve, a check valve II, a flow control damping hole II, a blade II, a rotor II, a stator II, a pressure side plate II, a pump cover I, and a reversing valve spring. An annular oil suction chamber of the main pump is communicated with an oil inlet and is also communicated with an annular oil suction chamber of the auxiliary pump through an intermediate oil suction window, so that the oil inlet can deliver an oil medium simultaneously to the main pump and the auxiliary pump. The pump of the invention improves steering security, prolongs service life, reduces energy consumption, enhances reliability and lowers steering oil medium consumption. In the pump of the invention, even if the main pump breaks down, the auxiliary pump can substitute automatically, and realizes the function of emergency oil supply.

Owner:DALIAN INNOVATION PARTS MANUFACTURING CO LTD

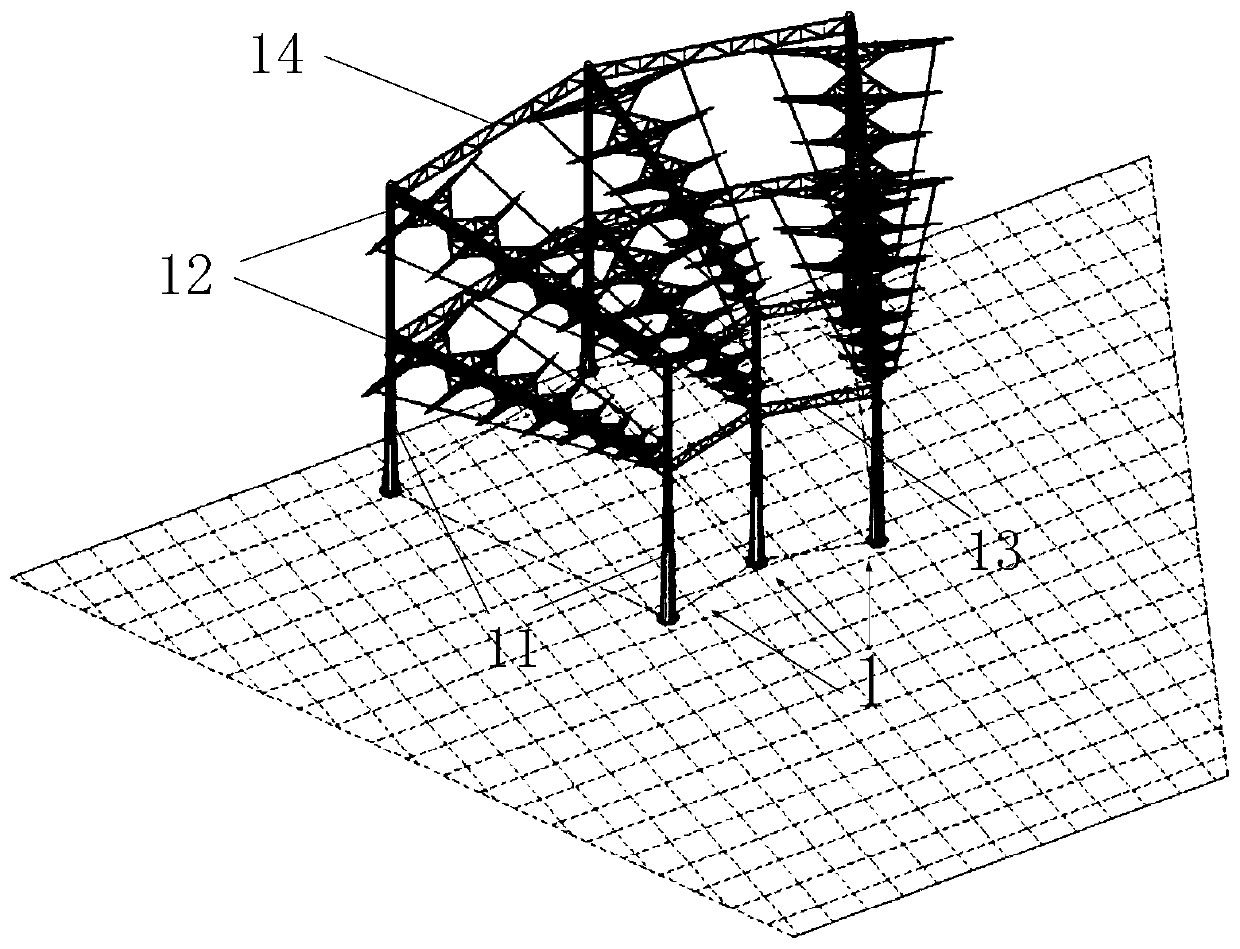

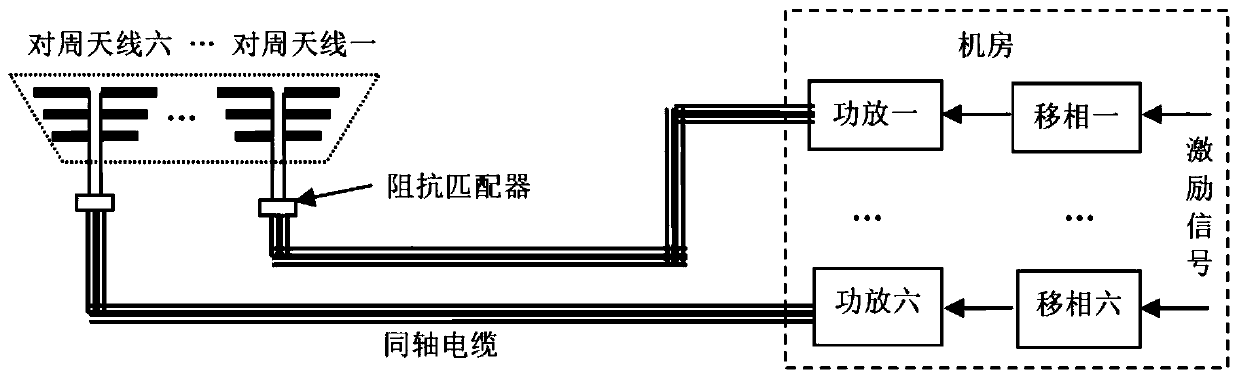

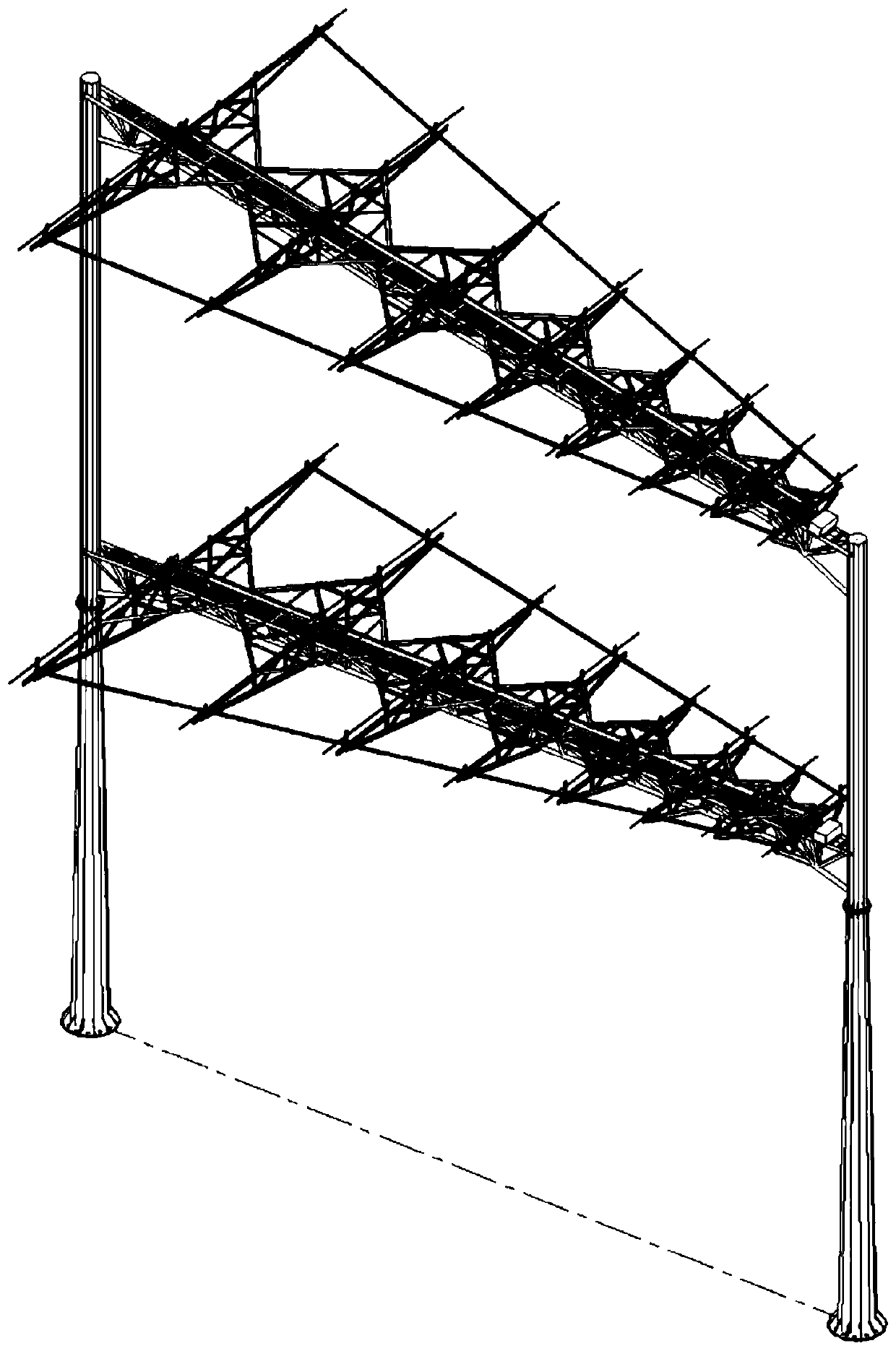

Short-wave double-layer log-periodic antenna fan-shaped array with rigid structure

ActiveCN111430873AHigh gainAvoid cleavageLogperiodic antennasAntenna arraysSoftware engineeringEngineering

The invention discloses a short-wave double-layer logarithm periodic antenna fan-shaped array with a rigid structure. The short-wave double-layer logarithm periodic antenna fan-shaped array is characterized by comprising a plurality of double-layer horizontal logarithm periodic antennas supported by the double-layer door-shaped supports, wherein the projections of the double-layer horizontal logarithm periodic antennas on a horizontal plane form the fan-shaped arrays with equal included angles, each double-layer door-shaped support comprises two supporting towers, an upper cross beam and a lower cross beam which are arranged between the two supporting towers, a pair of short-wave horizontal log-periodic antennas is fixed to each cross beam along the length direction of the cross beam, anda fan-shaped inward double-layer log-periodic antenna phased array is formed. The short-wave double-layer logarithm periodic antenna fan-shaped array has the advantages of being full in rigidity, widein frequency band, high in gain, high in power and good in maintainability.

Owner:泰兴英武舟科技有限公司

Production technology of plastic film

The invention relates to a production technology of a plastic film, and belongs to the technical field of plastic films. The production technology of the plastic film comprises the following steps of1, screening raw materials; 2, melting the raw materials; 3, adding the melted raw materials into a film blowing machine and blowing out a film; 4, cooling the film; 5, conducting corona treatment; 6,removing electricity and dust; 7, conducting spraying; 8, conducting drying; 9, cutting waste edges and coiling the film. According to the production technology of the plastic film, a free radical reaction is generated on the surface of the plastic film through corona treatment, so that a polymer is crosslinked, the surface becomes rough, the wettability of the polymer to a polar solvent is improved, and plasmas enter the surface of a printed object through electric shock and penetration to destroy the molecular structure of the printed object, so that molecules of the treated surface are oxidized and polarized; ion electric shock erodes the surface, so that the adhesion capability of the surface of printing stock is improved, and the quality of subsequent spraying is improved.

Owner:SUZHOU NIUDONG PRECISION MFG TECH CO LTD

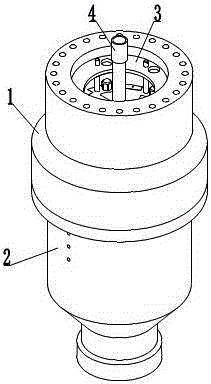

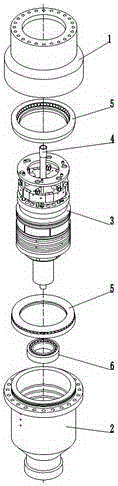

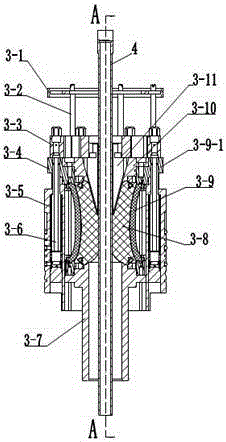

Annular preventer for drilling and workover in oil field

The invention provides an annular preventer for drilling and workover in an oil field, belonging to the technical field of drilling equipment. The annular preventer for drilling and workover in the oil field comprises an upper end cover, a shell and a preventer core, wherein the upper end cover is assembled with the shell through a bolt component; the preventer core is arranged in a cavity enclosed by the upper end cover and the shell; a slip assembly, a vertically-arranged packing element and a rigid torsion transfer drum are arranged in the preventer core; a packing element upper torsion conduction shaft and a packing element lower torsion conduction shaft are respectively arranged at the upper and lower ends of the packing element; the packing element upper torsion conduction shaft is of a hollow structure, and the inner wall of the packing element upper torsion conduction shaft is a circular conical surface matched with the slip assembly; and the torsion transfer drum sleeves outside the packing element. The annular preventer for drilling and workover in the oil field has the characteristics of strong high pressure resistance, good universality and long working life and is suitable for conventional down-hole operation, operation under pressure and under-balanced drilling operation.

Owner:韩咏利

High-voltage-resistant aqueous electrolyte solution for active carbon supercapacitor and preparation method for high-pressure-resistant aqueous electrolyte solution

ActiveCN105405683AIncrease working voltageShort processHybrid capacitor electrolytesHybrid/EDL manufactureAqueous electrolyteDissolution

The invention provides a high-voltage-resistant aqueous electrolyte solution for an active carbon supercapacitor and a preparation method for the high-voltage-resistant aqueous electrolyte solution, so that working voltage and energy density of the supercapacitor can be increased. The technical scheme is as follows: the preparation method comprises: (1) selecting a solvent and solutes, wherein the solvent adopts de-ionized water or distilled water, the solutes adopt analytically pure KHSO4 and LiCl, a mass ratio of the water to KHSO4 is 1,000 : (28-210), and a mass ratio of the water to LiCl is 1,000 : (0-20); and (2) preparing the electrolyte solution: pouring accurately weighed KHSO4 into the de-ionized water or the distilled water with the temperature of 20-50 DEG C, stirring to ensure that KHSO4 is completely dissolved, and adding weighed LiCl to perform dissolution so as to obtain the high-voltage-resistant aqueous electrolyte solution for the active carbon supercapacitor. The electrolyte solution prepared with the method has good use performance, good solution stability, high voltage resistance, low current collector corrosion performance and good low-temperature conductivity, thereby having wide application prospects.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

Micro-nano tube clamping device and micro-nano gas-liquid flow experiment device and method

PendingCN110487698AAchieve seamless connectionStrong high pressure resistanceHydrodynamic testingPermeability/surface area analysisMicro nanoLine tubing

The invention provides a micro-nano tube clamping device, and a micro-nano gas-liquid flow experiment device and method. The micro-nano tube clamping device comprises a routine experiment pipeline, anupstream hollow sealing bolt, a sealing ring, an upstream sealing cavity, a fluid buffer cavity, a downstream sealing cavity, a mechanical compaction sealing lantern ring, a high-pressure-resistant micro-nano tube butt joint sleeve, a downstream hollow sealing bolt, a micro-nano tube and a sealing sleeve. The micro-nano tube clamping device is outstanding in high-pressure resistance and sealing performance, and seamless butt joint between a conventional seepage experiment and a micro-nano experiment can be achieved; and the micro-nano tube clamping device is arranged in the micro-nano gas-liquid flow experiment device, the high-pressure condition of a real stratum can be simulated, and the micro-nano scale gas-liquid phase flow experiment can reflect the nonlinear seepage mechanism of thereal stratum more accurately.

Owner:SOUTHWEST PETROLEUM UNIV

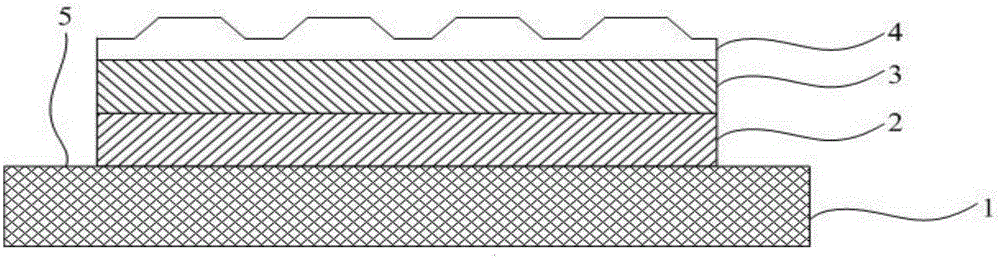

Ultra-thin high-temperature-resistant polypropylene capacitor metallized film and preparation method thereof

ActiveCN106024378AImprove cooling effectImprove safety and reliabilityFixed capacitor electrodesThin/thick film capacitorShrinkage rateTemperature resistance

The invention discloses an ultra-thin high-temperature-resistant polypropylene capacitor metallized film. The ultra-thin high-temperature-resistant polypropylene capacitor metallized film comprises a base film, an aluminum coating and a zinc coating, wherein the aluminum coating and the zinc coating are sequentially plated on the base film. The zinc coating is provided with a high-temperature-resistant layer. The high-temperature-resistant layer is made of the polyurethane material. The high-temperature-resistant layer is provided with a plurality of convex thickened regions. Accordingly, the invention discloses a preparation method of the ultra-thin high-temperature-resistant polypropylene capacitor metallized film. According to the method, an electrician-level isotactic structured polypropylene resin is adopted as a raw material. The raw material is successively subjected to fusing, plasticizing, extruding through a die head, casting into a strip, bilaterally stretching, cooling, shaping, tentering, trimming, thickness inspection and corona treatment to obtain the base film. The base film is wound and parted off. After that, the aluminum coating, the zinc coating and the high-temperature-resistant layer are successively plated onto the base film in the vacuum condition to obtain the ultra-thin high-temperature-resistant polypropylene capacitor metallized film. The method is simple in operation and the prepared capacitor metallized film is 2-3 mum in thickness. Moreover, the capacitor metallized film is low in hot-shrinkage rate and good in temperature resistance.

Owner:南通百正电子新材料股份有限公司

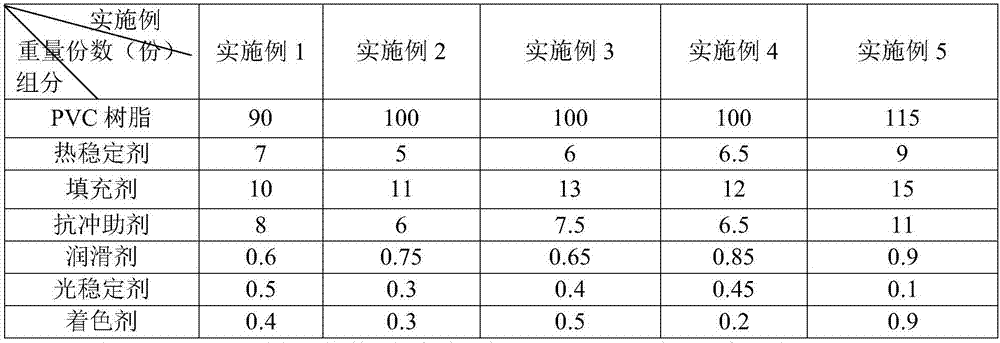

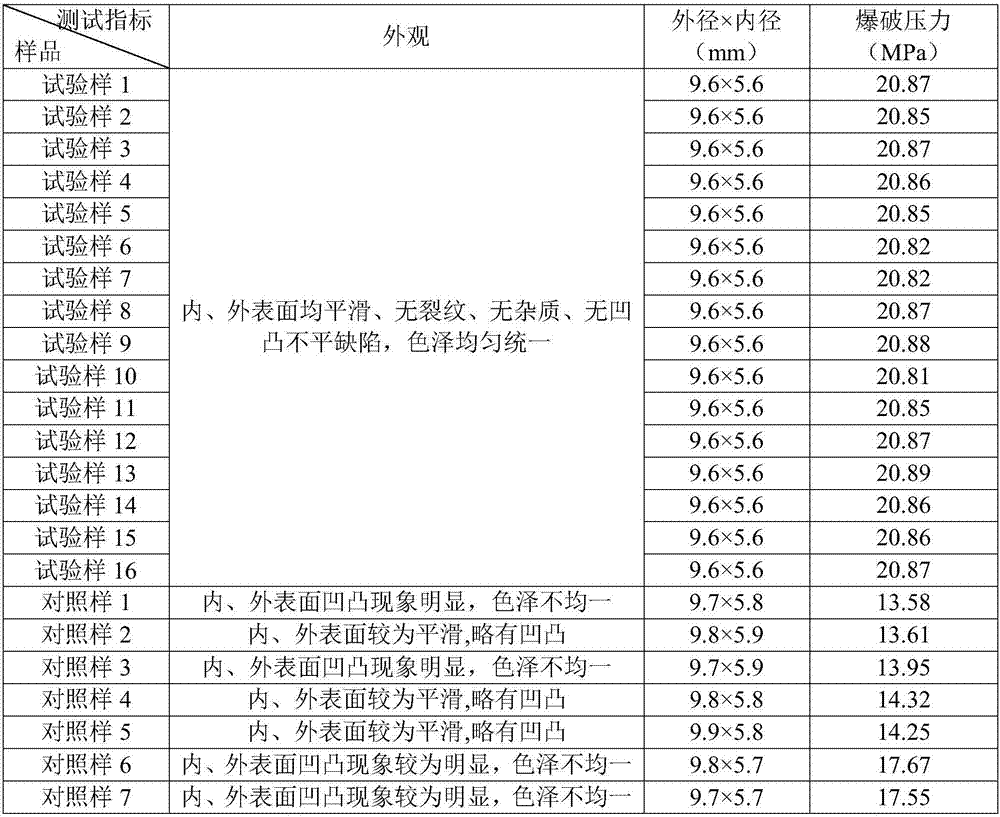

High-pressure-resisting pipe fitting and its preparation technique

The invention discloses a high-pressure-resisting pipe fitting and its preparation technique. The high-pressure-resisting pipe fitting is prepared from, by weight, 100 parts of PVC resin, 5-9 parts ofheat stabilizer, 10-15 parts of filling agent, 6-11 parts of antishock assistant, 0.25-0.9 part of lubricant, 0.1-0.5 part of light stabilizing assistant, and 0.2-0.9 part of coloring agent; the antishock assistant includes at least one of KANE ACE B-561 anti-impact modifier, KANE ACE PA 101 processing assistant; the lubricant includes at least one of ethylene bis-stearamide, oxidized polyethlenewax and paraffin. The high-pressure-resisting pipe fitting has a smooth surface and is not easy to scale; besides, the high-pressure-resisting pipe fitting can reduce fluid resistance and has good high-pressure resisting effect.

Owner:ZHEJIANG DEYU TECH

Sealing material for high-pressure medium delivery valves

InactiveCN105647033APrevent leakageStrong high pressure resistanceOther chemical processesAlkylphenolHigh pressure

The invention discloses a sealing material for high-pressure medium delivery valves, and relates to the technical field of sealing materials. The sealing material comprises, by weight, 60-70 parts of butyl rubber, 15-20 parts of stearic acid, 12-17 parts of phenolic resin, 10-15 parts of attapulgite, 10-15 parts of ceramic powder, 8-12 parts of asbestos powder, 8-12 parts of hydrogenated castor oil, 6-10 parts of alkylphenol ethoxylates, 5-8 parts of adhesive assistants, 5-8 parts of epoxidized soybean oil, 3-6 parts of nanometer titanium dioxide, 2-4 parts of polyoxyethylene polyoxy-propanol amidogen ether, 2-4 parts of barium stearate and 1-2 parts of alumina powder. The sealing material has the advantages that the sealing material is excellent in high-pressure resistance, impact resistance, corrosion resistance and high-temperature and low-temperature resistance; good sealing effects can be realized, high-pressure media can be effectively prevented from leaking, and accordingly safety accidents can be prevented; the adhesion performance of raw materials further can be improved by the aid of the adhesive assistants, and rubber mixing and vulcanizing can be facilitated.

Owner:ANHUI ZHENHAI HEAVY IND MASCH CO LTD

High-pressure metal hose and preparation method thereof

ActiveCN106523812AStrong high pressure resistanceImprove corrosion resistanceFlexible pipesTitaniumTin bronze

The invention discloses a high-pressure metal hose and a preparation method thereof. The metal hose comprises a net-body part and connectors arranged at two ends of the net-body part, wherein the net-body parts comprises a metal corrugated pipe, a connecting pipe, a ring and a steel wire net sleeve; and the metal corrugated pipe is prepared from the following components in parts by weight: 21-39 parts of iron, 12-25 parts of nickel, 11-22 parts of chromium, 4-11 parts of tin bronze, 5-11 parts of titanium, 3-8 parts of silicon nitride, 1-5 parts of aluminum oxide and 1-4 parts of tin oxide. The metal hose disclosed by the invention has the following advantages: (1) the high-pressure-resistance performance is excellent, and the water attack and the pressure of a conveying medium can be effectively resisted; and (2) through addition of a reasonable amount of carbon, the own anti-corrosion performance of the metal hose is improved, and the possibility of fatigue failure of the metal hose is lowered.

Owner:江苏亚星波纹管有限公司

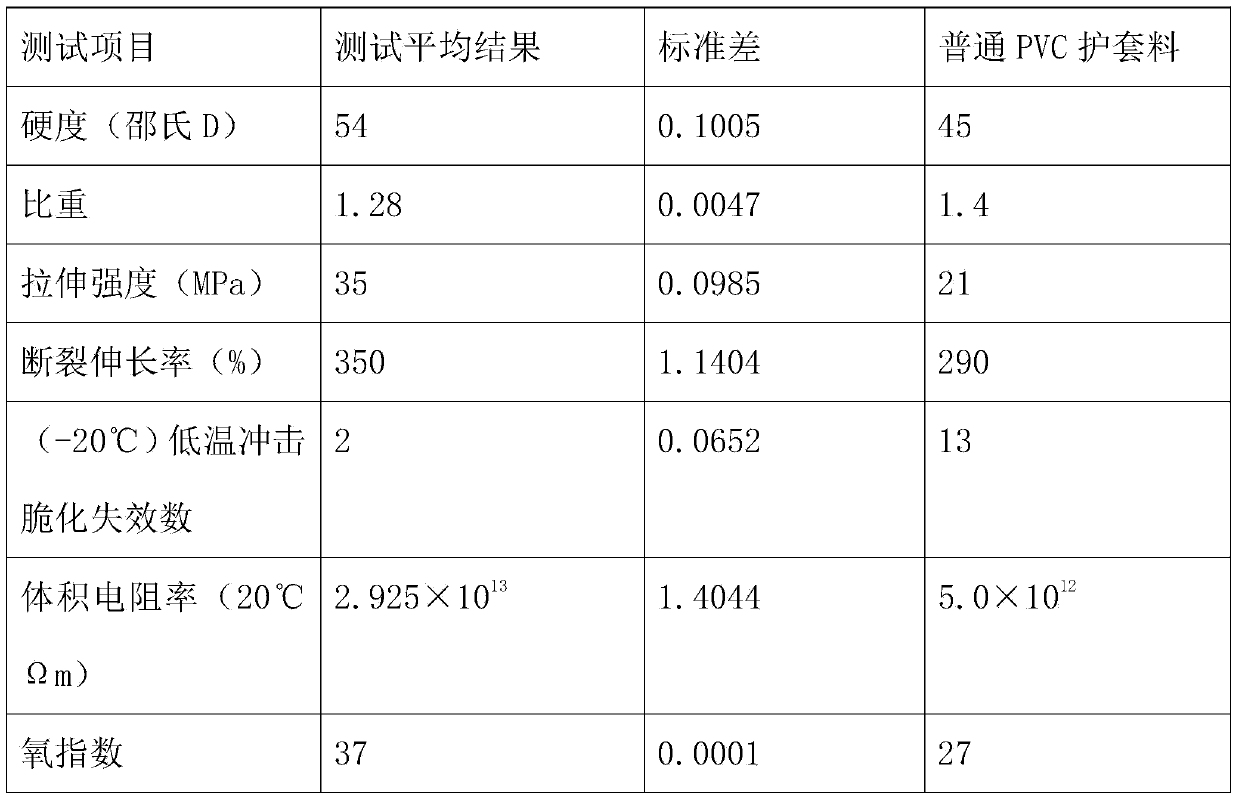

Weather-resistant high-voltage-resistant cable sheath material

InactiveCN103992543AImprove filler compatibilityGood lubricityInsulated cablesInsulatorsEnvironmental resistancePOLYETHYLENE WAX

The invention discloses a weather-resistant high-voltage-resistant cable sheath material, and the preparation method comprises the following steps: putting metallocene polyethylene, ethylene-vinyl acetate resin, 5-8 parts of polymethyl methacrylate, a composite environmental-friendly heat stabilizer, micro encapsulated red phosphorus, expandable graphite, polyethylene wax and a super lubricant into a low speed kneader for mixing evenly; putting phthalate, conductive metal powder, carbon fiber, calcined clay, talcum powder and an antioxidant in the low speed kneader for mixing evenly with the obtained material, then putting the prepared material into a high speed kneader for heating for mixing evenly at a high speed, and cooling; sending the obtained material into a twin-screw granulator for extrusion granulating, and drying to obtain the high-voltage-resistant cable sheath material. The weather-resistant high-voltage-resistant cable sheath material is excellent in high-voltage-resistant performance, free of falling off, higher in hardness and good in thermal stability.

Owner:ANHUI ELECTRIC GRP SHARES

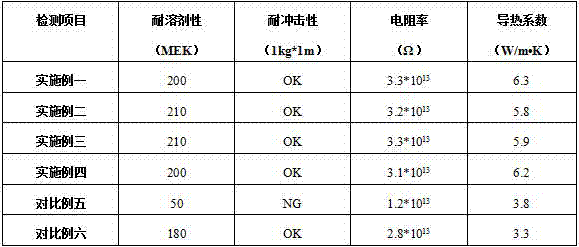

Heat-conducting paint and preparation thereof and aluminum-based composite material using heat-conducting paint for coating

ActiveCN106947375AEasy to storeEasy to useLiquid surface applicatorsPolyurea/polyurethane coatingsEpoxyOrganic solvent

The invention discloses a heat-conducting paint and preparation thereof and an aluminum-based composite material using the heat-conducting paint for coating. The heat-conducting paint comprises the following ingredients (by weight): 30-40 parts of polyurethane resin, 5-10 parts of epoxy resin, 5-10 parts of a curing agent, 0.2-0.5 part of a catalyst, 10-15 parts of a heat-conducting filler and 30-40 parts of an organic solvent. The preparation method comprises the following steps: adding polyurethane resin and epoxy resin into the organic solvent at 60-70 DEG C and stirring until the solution is clear and transparent, cooling to room temperature; and successively adding the curing agent, the catalyst and the heat-conducting filler, and continuously stirring until the materials are uniformly mixed. The aluminum-based composite material is produced by the following steps: uniformly coating an aluminum coil material with the heat-conducting paint; baking-curing at 250-270 DEG C for 2-3 min; and finally naturally cooling to 20-30 DEG C. The aluminum-based composite material produced by the above paint has good flexibility, high resistivity and high heat conductivity coefficient.

Owner:江门市德佑金属材料实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com