Micro-nano tube clamping device and micro-nano gas-liquid flow experiment device and method

A micro-nano tube and clamping device technology, which is applied in the field of petroleum exploration, can solve the problems of poor pressure resistance, poor flexibility, easy to break and break, etc. High pressure resistance, breaking and shattering resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

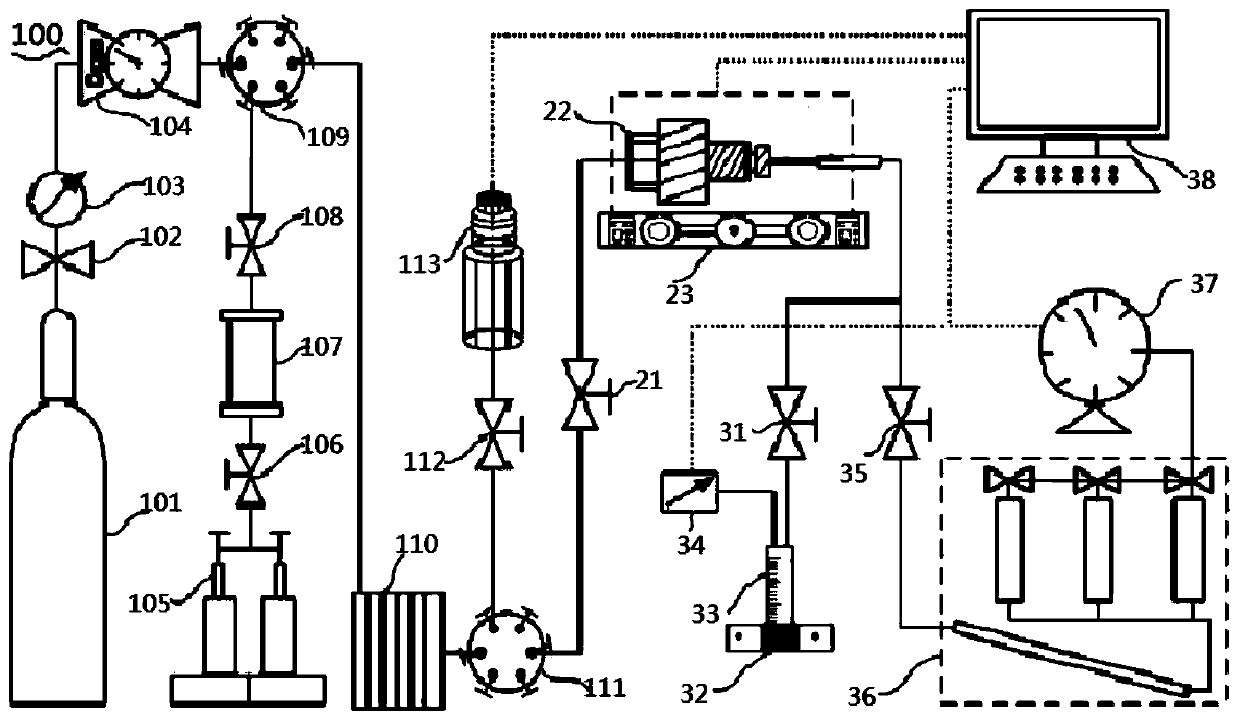

[0079] Embodiment 1 Gas micro-nanotube experiment

[0080] S1. Close all valves and switches, select a micro-nanotube 2210 with a predetermined inner diameter and length, clamp it on the micro-nanotube clamping device 22, and adjust the temperature of the constant temperature system 23 to a predetermined temperature;

[0081] S2. After the temperature of the constant temperature system 23 is constant, open the first switch 102, the fourth switch 112, the fifth switch 21, and the seventh switch 35;

[0082] S3, open the decompression valve 104 to set the predetermined gas pressure, record the reading of the wet gas flowmeter 37 and the experiment time;

[0083] S4, adjust the pressure reducing valve 104 to change the experimental pressure, repeat step S3, until the required number of experimental groups;

[0084] S5. After the experiment is over, close the first switch 102, and close the decompression valve 104 after releasing the pressure to 0, and remove the micro-nanotube c...

Embodiment 2

[0085] Embodiment 2 liquid micro-nanotube experiment

[0086] S1. Close all valves and switches, select a micro-nanotube 2210 with a predetermined inner diameter and length, clamp it on the micro-nanotube clamping device 22, and adjust the temperature of the constant temperature system 23 to a predetermined temperature;

[0087] S2. After the temperature of the constant temperature system is constant, first turn on the second switch 106, the third switch 108, the fifth switch 21, and the sixth switch 31, and finally turn on the ISCO pump 105;

[0088] S3, adjust the ISCO pump 105 to set a predetermined pressure, record the volume of the liquid in the measuring cylinder 33 and the experiment time;

[0089] S4, adjust the ISCO pump 105 to change the pressure, repeat step S3, until the required number of experimental groups;

[0090] S5. Turn off the ISCO pump 105 after the experiment, release the pressure to 0, and remove the micro-nanotube clamping device 22 .

[0091] Wherei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com