Power vehicle window controller

A technology for electric windows and controllers, applied in electrical program control, starter components, program control in sequence/logic controllers, etc., can solve the problem of inability to adapt to the high voltage of the 24V power supply system, and save product costs. , The effect is obvious, the effect of avoiding contact bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

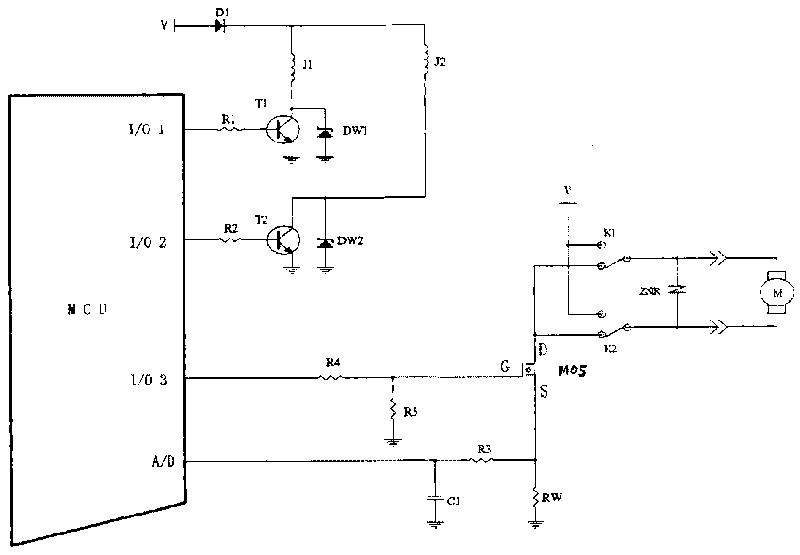

[0011] Such as figure 2 As shown, when the button is operated to raise the window, the microprocessor MCU control terminal: I / O1 outputs an electrical signal, and the transistor T1 is turned on through the resistor R1, and the contact K1 of the driving relay is pulled in, and the regulator DW1 is protected. The triode T1 works. At this time, because the MOS tube is not turned on, the motor does not start without forming a loop. After a delay of 20MS (after the relay J1 is turned on), MCL and the control terminal I / O3 output an electrical signal, and the MOS tube is turned on through the resistor R4. At this time, the positive pole of the power supply V pulls the contact K1 through the relay J1, the motor M, the normally closed contact K2 of the relay J2, the MOS tube, the sampling resistor RW, and the negative pole of the power supply V form a loop, so that the motor rotates forward and the window rises. If the car window is required to stop rising or the motor is blocked (t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com