Slightly-dragged accumulating conveying mechanism

A transmission mechanism and accumulation-type technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as unreasonable accumulation methods, shortened service life of the system, and unstable driving force of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

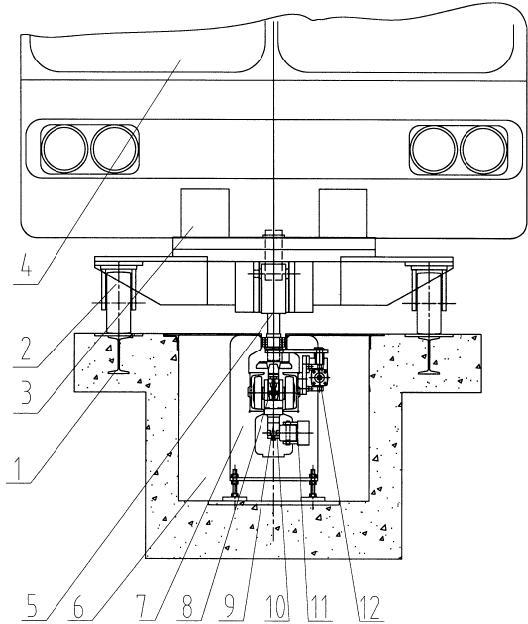

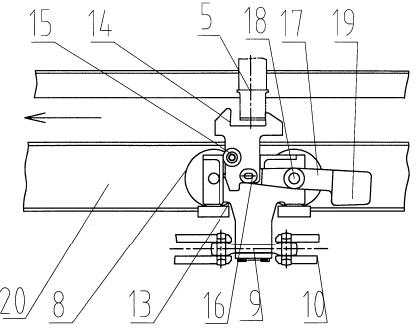

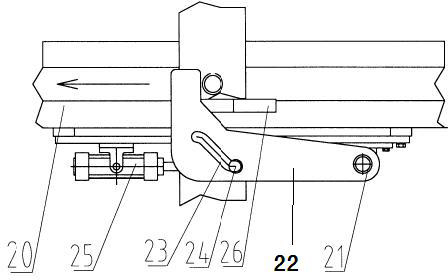

[0012] A shallow drag-and-place transmission mechanism, comprising a trolley track 1 set on the ground, a trolley 2 is set on the trolley track 1, a workpiece 4 is set on a trolley support block 3 on the trolley 2, and The center of the bottom of the trolley 2 is fixedly provided with a trolley drawbar 5, and a pit 6 is arranged between the two trolley tracks 1, and in the pit 6 is provided with a door-shaped channel steel track fixing frame 7. A pair of channel steel tracks 20 are correspondingly arranged on the inboard two facades of the channel steel track fixing frame 7, and the accumulating and releasing trolley 8 is movably arranged on the channel steel rails 20, and the vehicle body 13 of the accumulating and releasing trolley is T-shaped. Traction chain 10 is provided with in the track fixed frame 7, and the vehicle body 13 of accumulating dolly is connected together with traction chain 10 by chain traction bar 9, because traction chain 10 is in the non-stop rotation, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com