Treatment process for degradation-resistant organic wastewater containing aniline high-salt content

A technology of organic wastewater and treatment process, which is applied in water/sewage treatment, water treatment parameter control, heating water/sewage treatment, etc. It can solve the problems of increasing wastewater treatment costs, high cost, increasing the salt content of wastewater, etc., and achieves improvement. Effects of biodegradability, improved service life, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

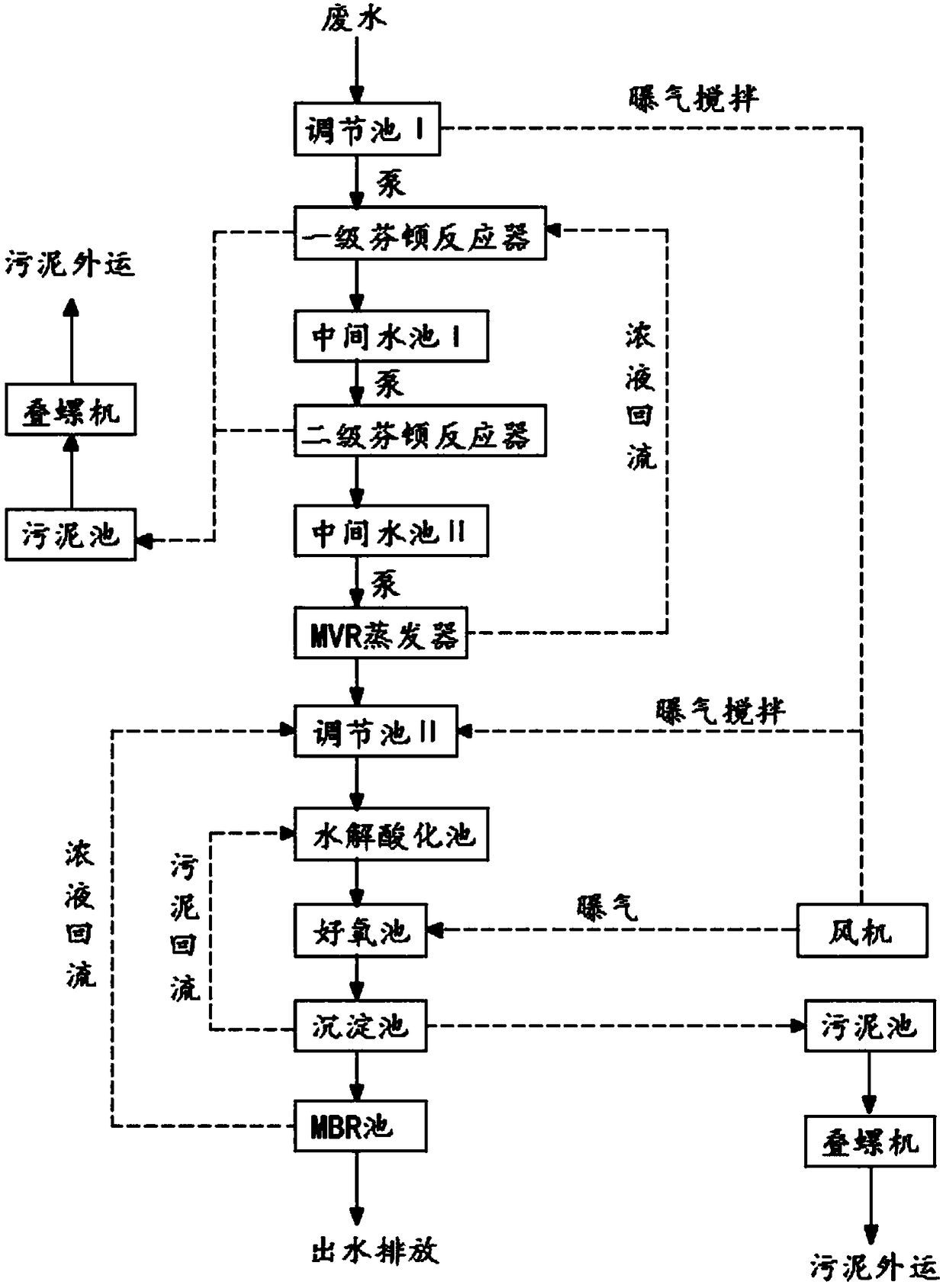

[0047] Such as figure 1 As shown, the present embodiment provides a treatment process for refractory organic wastewater containing aniline with high salt content, comprising the following steps:

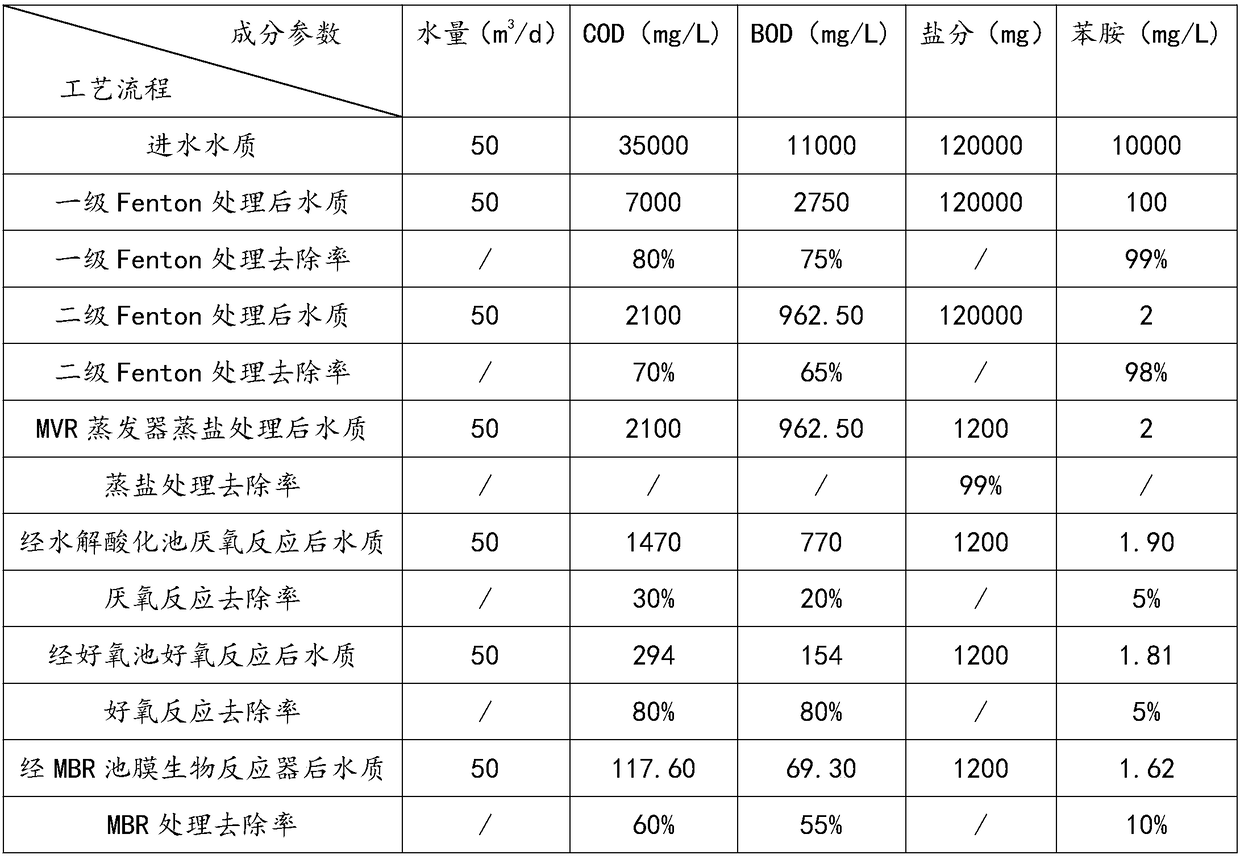

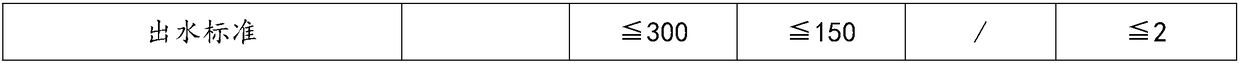

[0048] 1) will 50m 3 Refractory organic wastewater containing aniline and high salt content, (COD in the original wastewater solution is 35000mg / L, BOD is

[0049] 11000mg / L, the concentration of aniline is 10000mg / L) into the regulating tank Ⅰ to adjust the uniform water quality, aeration and stirring by the fan for 10h;

[0050] 2) Lift the waste water in the adjustment tank I in step 1) to the first-stage Fenton reactor through the pump, add 10% sulfuric acid in the waste water to adjust the pH value of the aniline waste water to 3.5, and add a mass fraction of 10% % ferrous sulfate solution and mass fraction are 27.5% hydrogen peroxide, based on the volume of aniline wastewater, the dosage of ferrous sulfate is 0.75L / m 3 , the dosage of hydrogen peroxide is 2L / m 3 and stay fo...

Embodiment 2

[0063] Such as figure 1 As shown, the present embodiment provides a treatment process for refractory organic wastewater containing aniline with high salt content, comprising the following steps:

[0064] 1) will be 80m 3 Refractory organic wastewater containing aniline and high salt content, (COD in the original wastewater solution is 36000mg / L, BOD is

[0065] 11500mg / L, the concentration of aniline is 11200mg / L) into the regulating tank Ⅰ to adjust the uniform water quality, aeration and stirring by the fan for 15h;

[0066] 2) Lift the waste water in the adjustment tank I in step 1) to the first-stage Fenton reactor through a pump, add 10% sulfuric acid in the waste water to adjust the pH value of the aniline waste water to 2.5, and add a mass fraction of 10% % ferrous sulfate solution and mass fraction are 27.5% hydrogen peroxide, based on the volume of aniline wastewater, the dosage of ferrous sulfate is 1.0L / m 3 , the dosage of hydrogen peroxide is 2.5L / m 3 and stay ...

Embodiment 3

[0079] Such as figure 1 As shown, the present embodiment provides a treatment process for refractory organic wastewater containing aniline with high salt content, comprising the following steps:

[0080] 1) will be 100m 3 Refractory organic wastewater containing aniline with high salt content (COD in the original wastewater solution is 35500mg / L, BOD is 11200mg / L, and aniline concentration is 11000mg / L) is sent to the adjustment tank I to adjust the uniform water quality, and the fan is used for aeration and stirring for 15 hours ;

[0081] 2) Lift the waste water in the adjustment tank I in step 1) to the first-stage Fenton reactor through the pump, add 10% sulfuric acid in the waste water to adjust the pH value of the aniline waste water to 3, and add a mass fraction of 10% % ferrous sulfate solution and mass fraction are 27.5% hydrogen peroxide, based on the volume of aniline wastewater, the dosage of ferrous sulfate is 0.8L / m 3 , the dosage of hydrogen peroxide is 2L / m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com