High-pressure-resisting pipe fitting and its preparation technique

A technology for high-pressure resistant pipe fittings, which is applied in the field of high-pressure resistant pipe fittings and its preparation process, which can solve the problems of insufficient high-pressure resistance and large differences in connection strength, and achieve the effects of smooth surface, uniform appearance, and low fluid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1: A high-pressure resistant pipe, the components included and the corresponding parts by weight are shown in Table 1, and are prepared by the following steps:

[0058] S1, mixing PVC resin, heat stabilizer, filler, impact aid, lubricant, light stabilizer, and coloring agent uniformly to obtain a first mixture;

[0059] S2, granulating the first mixture obtained in step S1 to obtain materials for high-pressure pipe fittings;

[0060] S3, extruding the high-pressure resistant pipe material obtained in step S2 to obtain the high-pressure resistant pipe.

[0061] Among them, the heat stabilizer is a calcium-zinc heat stabilizer;

[0062] The filler is nano calcium carbonate;

[0063] The impact resistance agent is KANEACE B-561 impact modifier and KANEACE PA101 processing aid with a weight ratio of 4:1;

[0064] Lubricants are ethylene bis-stearamide, oxidized polyethylene wax, and paraffin with a weight ratio of 1:1:1;

[0065] The light stabilizer is the ultraviolet absorber ...

Embodiment 2-5

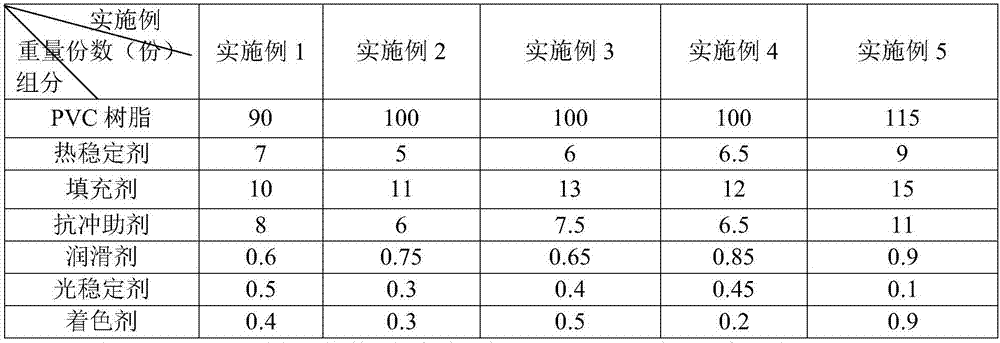

[0067] Embodiment 2-5: A high-pressure resistant pipe fitting, which is different from Embodiment 1 in that the included components and their corresponding weight parts are shown in Table 1.

[0068] Table 1 The components included in Examples 1-5 and their corresponding parts by weight

[0069]

Embodiment 6

[0070] Example 6: A high-pressure resistant pipe fitting. The difference from implementation 1 is that all the impact additives are KANE ACE B-561 impact modifiers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com