Steam box with vacuum rapid-cooling function

A steamer and quick-cooling technology, applied in the application, food preparation, food science and other directions, can solve the constraints that the pasta processing industry cannot increase production, reduce costs, and be environmentally friendly and hygienic. problems, to achieve the effect of shortening the steaming and cooling time, accurate design, and improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

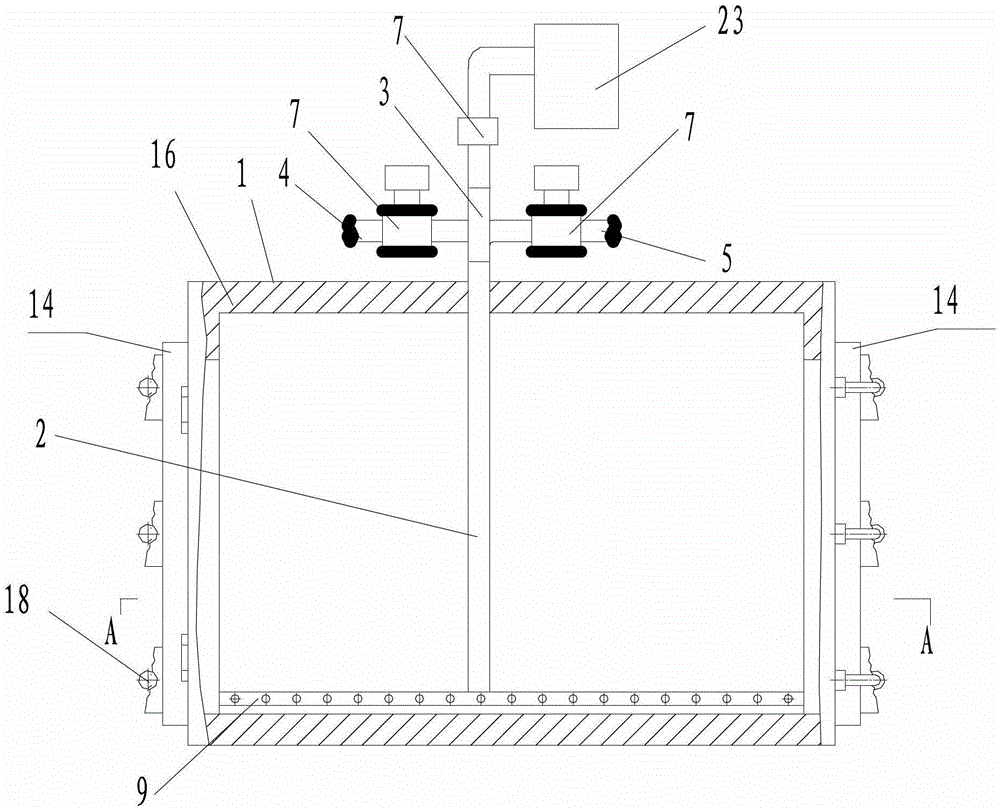

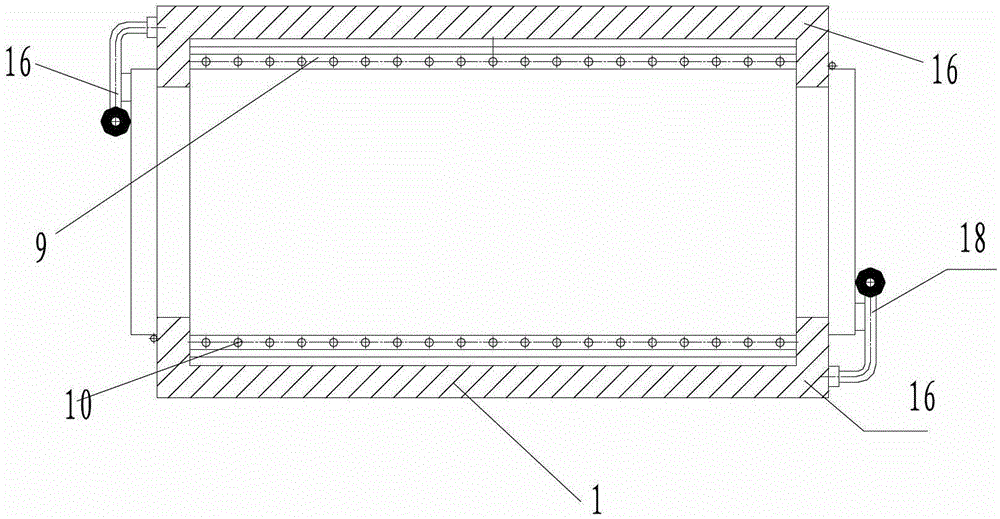

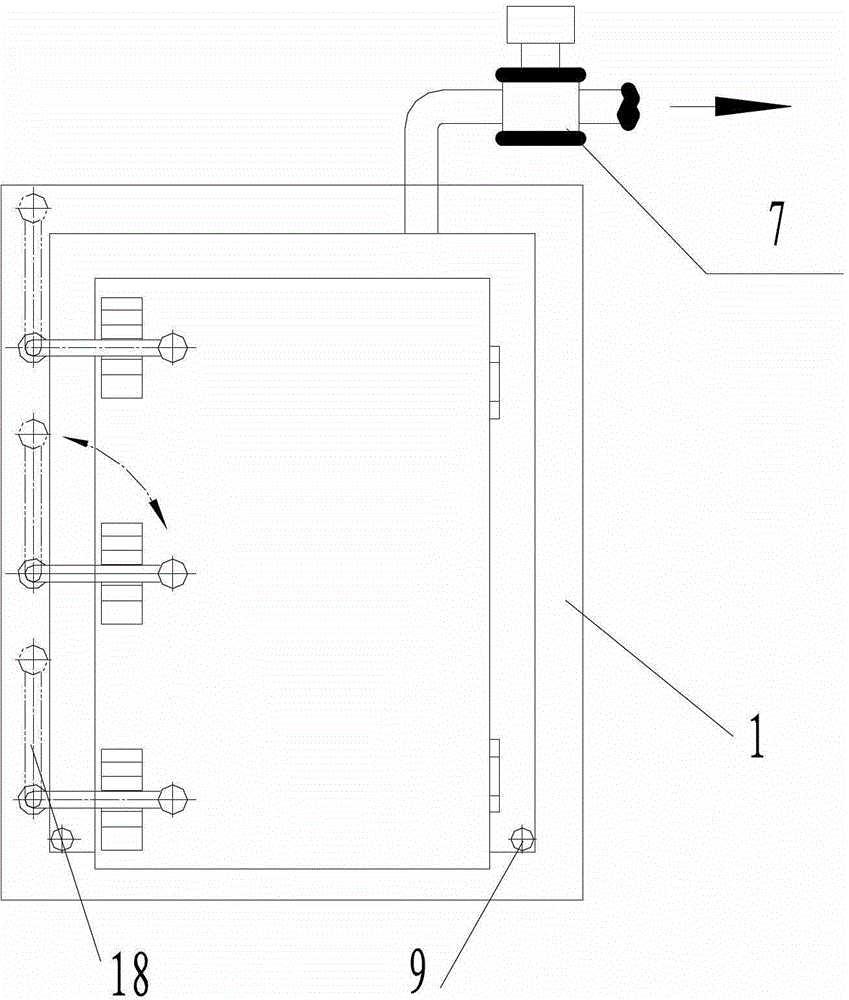

[0027] A steamer with a vacuum quick cooling function, comprising a steamer body 1 with a sealed door and a steam pipe 2 communicating with it, the steamer body is a room-type cabin capable of withstanding positive and negative pressures, the The main body of the steam box is provided with a pipeline from the top to the interior of the steam box. The part of the pipeline outside the steam box is connected with a tee 3, and the tee is connected with the steam delivery pipeline 4, the vacuum pipeline 5 and the air release pipeline 6 respectively. , the steam delivery pipeline, the vacuum pipeline and the deflation pipeline are respectively connected with a valve 7, and the vacuum pipeline is connected with a vacuum pump 8. The body of the steamer is 2.4 meters long, 1.2 meters wide, and 2.3 meters high, with a volume of 5 cubic meters and an inner space of 4.5 cubic meters. Set front and rear double doors, which can open the tunnel-type rectangular parallelepiped pressure-resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com