High-voltage lithium-ion battery electrolyte

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of battery cycle performance deterioration, battery performance decline, battery bulging, etc., achieving easy implementation, small change in internal resistance, and improved The effect of cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

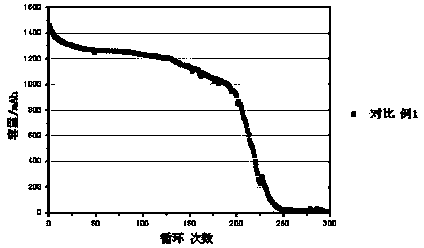

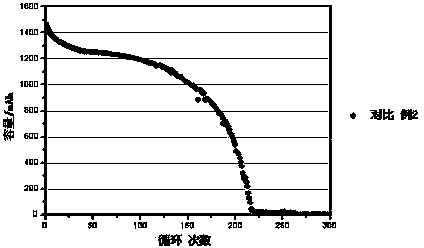

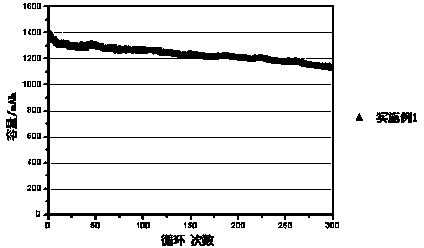

Image

Examples

Embodiment 1

[0045] In an argon-filled glove box (moisture 2 HCF 2 CH 2 OCF 2 CF 2 H, ethoxy pentafluorocyclotriphosphazene and 1,3-propene sultone account for 0.5%, 3.0%, 3.0%, and 0.5% of the total mass respectively; 13.5% lithium hexafluorophosphate, after being stirred evenly, the lithium-ion battery electrolyte of Example 1 was obtained.

Embodiment 2

[0047] In an argon-filled glove box (moisture 2 HCF 2 CH 2 OCF 2 CF 2 H, Ethoxypentafluorocyclotriphosphazene, 1,3-propene sultone, the addition amount accounted for 1.0%, 2.0%, 3.0%, 1.0% of the medium mass respectively; finally slowly added to the mixed solution accounting for the total Lithium hexafluorophosphate with a mass of 13.5% was stirred evenly to obtain the lithium ion battery electrolyte of Example 2.

Embodiment 3

[0049] In a glove box filled with argon (moisture 2 HCF 2 CH 2 OCF 2 CF 2 H, ethoxypentafluorocyclotriphosphazene, 1,3-propene sultone, the addition amount accounted for 2.5%, 3.0%, 2.0%, 2.0% of the medium mass respectively; finally slowly added to the mixed solution accounting for the total Lithium hexafluorophosphate with a mass of 13.5% was stirred evenly to obtain the lithium ion battery electrolyte of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com