High-pressure metal hose and preparation method thereof

A metal hose and high-pressure-resistant technology, which is applied in the direction of hoses, pipes, mechanical equipment, etc., can solve the problems of high-pressure resistance of metal hoses that cannot be solved, and achieve the goal of improving corrosion resistance, excellent high-pressure resistance, and reducing fatigue failure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

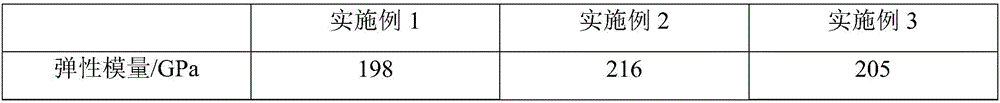

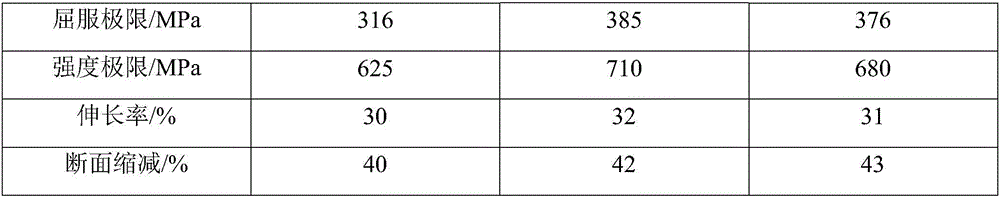

Embodiment 1

[0023] A high-pressure resistant metal hose, the metal hose includes a mesh body part and connecting joints at both ends, the mesh body includes a metal bellows, a connecting pipe, a ring, and a steel wire mesh sleeve; wherein the metal bellows is composed of the following components: The parts by weight are formulated as follows: 21 parts of iron, 12 parts of nickel, 11 parts of chromium, 4 parts of tin bronze, 5 parts of titanium, 3 parts of silicon nitride, 1 part of aluminum oxide, and 1 part of tin oxide.

[0024] A method for preparing a high-pressure resistant metal hose. The metal hose is welded by a mesh body part and connecting joints at both ends, and the mesh body is welded by a metal bellows, a connecting pipe, a ring, and a steel wire mesh sleeve; the metal bellows The preparation process is as follows:

[0025] (1) Substrate preparation: Put iron and chromium into a metal melting furnace, melt at a temperature of 1920°C, then put nickel and tin bronze into it, u...

Embodiment 2

[0032] A high-pressure resistant metal hose, the metal hose includes a mesh body part and connecting joints at both ends, the mesh body includes a metal bellows, a connecting pipe, a ring, and a steel wire mesh sleeve; wherein the metal bellows is composed of the following components: The parts by weight are formulated as follows: 32 parts of iron, 21 parts of nickel, 16 parts of chromium, 8 parts of tin bronze, 9 parts of titanium, 6 parts of silicon nitride, 4 parts of aluminum oxide and 3 parts of tin oxide.

[0033] A method for preparing a high-pressure resistant metal hose. The metal hose is welded by a mesh body part and connecting joints at both ends, and the mesh body is welded by a metal bellows, a connecting pipe, a ring, and a steel wire mesh sleeve; the metal bellows The preparation process is as follows:

[0034] (1) Substrate preparation: Put iron and chromium into a metal melting furnace and melt at a temperature of 2150°C, then put nickel and tin bronze into i...

Embodiment 3

[0041] A high-pressure resistant metal hose, the metal hose includes a mesh body part and connecting joints at both ends, the mesh body includes a metal bellows, a connecting pipe, a ring, and a steel wire mesh sleeve; wherein the metal bellows is composed of the following components: The parts by weight are formulated as follows: 39 parts of iron, 25 parts of nickel, 22 parts of chromium, 11 parts of tin bronze, 11 parts of titanium, 8 parts of silicon nitride, 5 parts of aluminum oxide, and 4 parts of tin oxide.

[0042] A method for preparing a high-pressure resistant metal hose. The metal hose is welded by a mesh body part and connecting joints at both ends, and the mesh body is welded by a metal bellows, a connecting pipe, a ring, and a steel wire mesh sleeve; the metal bellows The preparation process is as follows:

[0043] (1) Substrate preparation: Put iron and chromium into a metal melting furnace and melt at a temperature of 2300°C, then put nickel and tin bronze int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com