Ultra-thin high-temperature-resistant polypropylene capacitor metallized film and preparation method thereof

A metallized film, polypropylene technology, applied in film/thick film capacitors, capacitors, laminated capacitors, etc., can solve problems such as capacitor stability decline, power grid safety hazards, capacitor failure, etc., to reduce thickness, improve safety and reliability. resistance, the effect of preventing breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

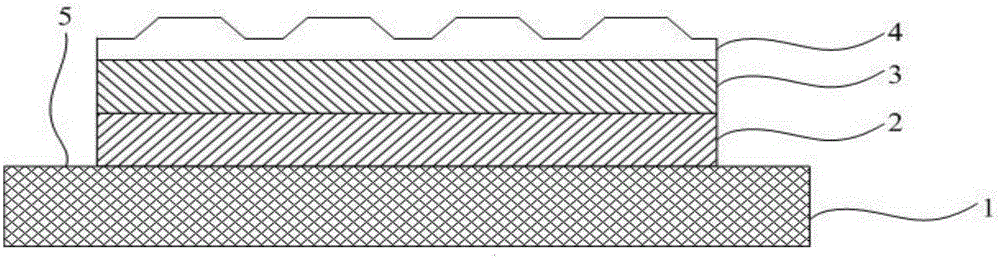

[0028] Such as figure 1 As shown, the present invention provides a metallized film for an ultra-thin high temperature resistant polypropylene capacitor, comprising a base film 1 and an aluminum coating 2 and a zinc coating 3 that are sequentially plated on the base film 1, the aluminum coating 2 and the There is a blank area 5 at the edge of the base film 1; a high temperature resistant layer 4 is provided on the zinc coating 3, the high temperature resistant layer 4 is polyurethane, and the high temperature resistant layer 4 has a plurality of convex thickened regions.

[0029] In this embodiment, the base film 1 is a polypropylene capacitor film.

[0030] In this embodiment, the base film 1 has a thickness of 1 μm and a width of 280 mm.

[0031] In this embodiment, the number of base films 1 is 50.

[0032] In this embodiment, the width of the blank area 5 is 1 mm.

[0033] In this embodiment, the number of the convex thickened region is one.

[0034] Correspondingly, th...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 is:

[0045] In this embodiment, the thickness of the base film is 1.5 μm, the width is 540 mm, and the number is 25.

[0046] In this embodiment, the width of the blank area is 1.5 mm.

[0047] In this embodiment, the film has a thickness of 2.5 μm, and is heated for 18 minutes at a temperature of 112° C., with a transverse heat shrinkage rate of 0.15% and a longitudinal heat shrinkage rate of 1.25%.

Embodiment 3

[0049] The difference between this embodiment and the previous embodiment is:

[0050] In this embodiment, the thickness of the base film is 2 μm, the width is 800 mm, and the number is one.

[0051] In this embodiment, the width of the blank area is 2 mm.

[0052] The film has a thickness of 3 μm, and is heated for 20 minutes at a temperature of 120° C., with a thermal shrinkage rate of 0.2% in the transverse direction and a thermal shrinkage rate of 1.5% in the longitudinal direction.

[0053]The ultra-thin high-temperature-resistant polypropylene capacitor metallized film of the present invention and its preparation method have the following beneficial effects:

[0054] 1. The metallized film of the ultra-thin high-temperature resistant polypropylene capacitor of the present invention can greatly enhance the heat dissipation performance of the capacitor by providing a layer of zinc coating on the aluminum coating, improve the safety and reliability of the capacitor, and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com