High-pressure hydrogen storage bottle and manufacturing method thereof

A manufacturing method and technology for a hydrogen storage bottle, which are applied in the field of high-pressure containers, can solve the problems of poor uniformity of wound fiber tow, easy to produce slip tow, poor resin wettability, etc., and achieve the effects of uniform distribution, good elasticity and improved toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

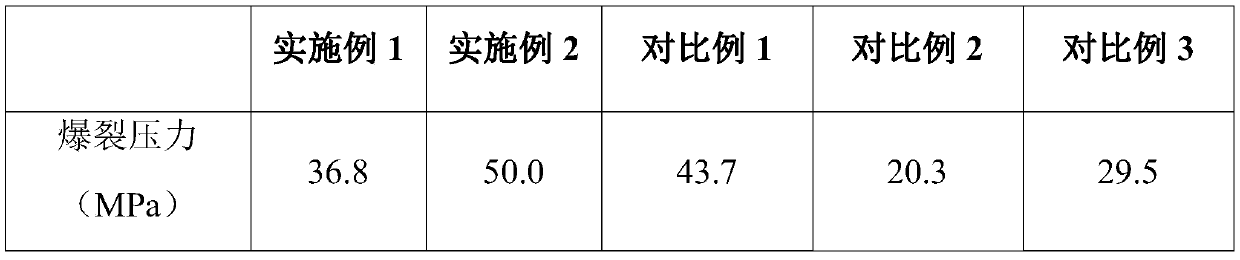

Embodiment 1

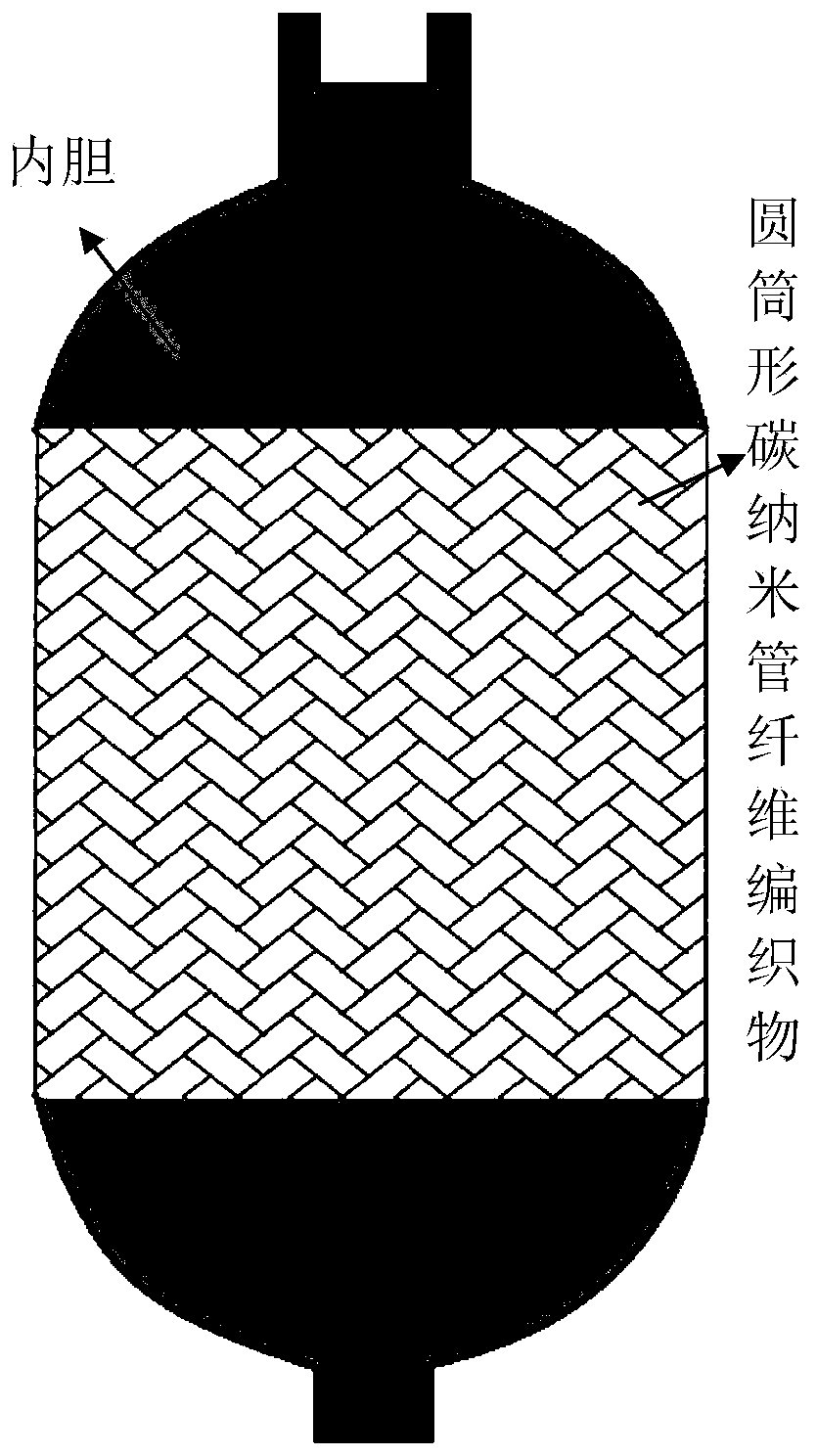

[0064] A container, comprising the following preparation steps:

[0065] S1, the inner tank is sprayed with polyurethane layer;

[0066] S2. Pull a 0.5cm carbon nanotube film in the carbon nanotube array, and twist it into carbon nanofibers at 100tpm; 50 carbon nanotube fibers are paralleled to form carbon nanotube fiber bundles, and go through hot-melt epoxy resin impregnated to obtain carbon nanotube fiber prepreg yarn; the carbon nanotube fiber prepreg yarn is cross-woven into a cylindrical weaving fabric through a braiding machine to obtain a carbon nanotube fiber tubular braided cylinder with a diameter of 118 mm and a thickness of 20 mm . The carbon nanotube fiber tubular braiding tube is nested in the polytetrafluoroethylene hollow sleeve, the inner diameter of the polytetrafluoroethylene sleeve is consistent with the outer diameter of the inner tank, and the thickness is 0.4mm.

[0067] S3. Nesting the polytetrafluoroethylene sleeve tube nested with the cylindrical c...

Embodiment 2

[0070] S1, the inner tank is sprayed with polyurethane layer;

[0071] S2. Pull a 0.5cm carbon nanotube film in the carbon nanotube array, and twist it into carbon nanofibers at 100tpm; 50 carbon nanotube fibers are paralleled to form carbon nanotube fiber bundles, and go through hot-melt epoxy resin impregnated to obtain carbon nanotube fiber prepreg yarn; the carbon nanotube fiber prepreg yarn is cross-woven into a cylindrical weaving cloth through a braiding machine to obtain a carbon nanotube fiber cylindrical braided cylinder with a diameter of 118 mm. The carbon nanotube fiber tubular braiding tube is nested in the polytetrafluoroethylene hollow sleeve, the inner diameter of the polytetrafluoroethylene sleeve is consistent with the outer diameter of the inner tank, and the thickness is 0.4mm.

[0072] S3. Nesting the polytetrafluoroethylene sleeve tube nested with the cylindrical carbon nanotube fiber braid on the inner liner, and taking out the polytetrafluoroethylene s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com