Internally-engaged gear pump applicable to high pressure and large flow

An internal gear pump, large flow technology, applied in the direction of rotary piston type/swing piston type pump components, pumps, pump components, etc., can solve the problem of difficult to meet the requirements of high-precision hydraulic system, Pressure/flow lift suppression and other issues, to achieve the effects of small deformation, suppression of pulsation, and improvement of output flow and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

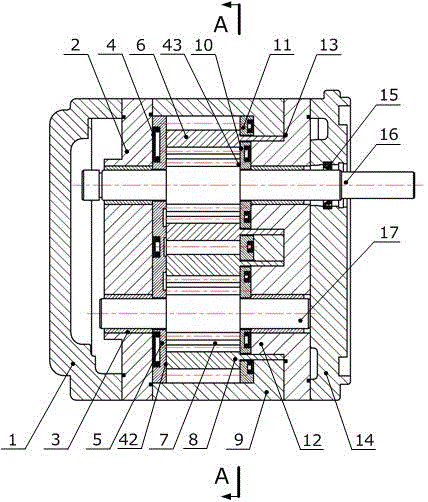

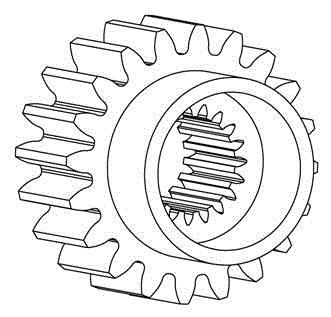

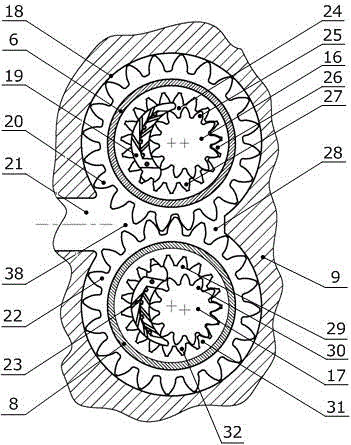

[0039] figure 1 It is a schematic cross-sectional view of the overall structure of the present invention. In the figure, the pump casing of the gear pump is composed of rear pump cover 1, rear connection cover 2, pump body 9, front connection cover 12, front pump cover 14 and other components, and a sealing ring 13 is added between the two components to prevent Leakage of oil in the pump. The first double ring gear 6, the second double ring gear 8, the radial compensation device 7, the first gear shaft 16, the second gear shaft 17, the rear side plate 5, the first front side plate 11, the second Two front side plates 10, sliding bearings 3, compensation plates 4, and sealing rings 13, wherein the first double ring gear 6 and the second double ring gear 8 are embedded in the pump body 9, and the ring gear and the pump body are transi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com