Cobalt-free high-nickel ternary concentration gradient core-shell structure lithium ion battery positive electrode material and preparation method thereof

A lithium-ion battery, concentration gradient technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the shortage of cobalt ore resources, hinder the wide application of high-nickel cathode materials, and high cost of raw materials. Increased cycle stability and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

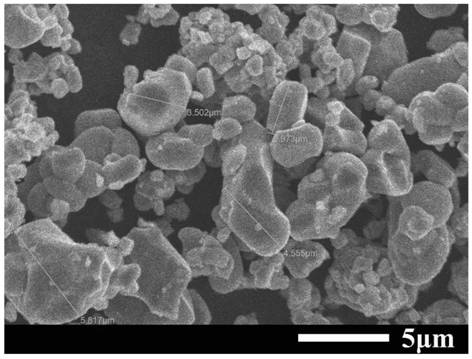

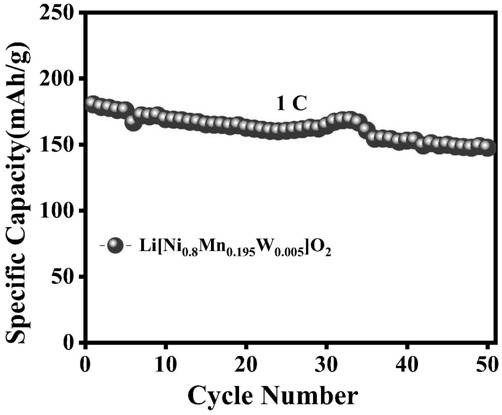

[0025] (1) Prepare the first salt solution and the second salt solution containing nickel sulfate, manganese sulfate and tungsten chloride, the molar ratio of nickel ion, manganese ion and tungsten ion in the first salt solution is 95:4.5:0.5, the first The sum of the concentrations of nickel ions, manganese ions and tungsten ions in the salt solution is 2.00mol / L. The molar ratio of nickel ions, manganese ions, and tungsten ions in the second salt solution is 65:34.5:0.5, and the sum of the concentrations of nickel ions, manganese ions, and tungsten ions in the second salt solution is 2.00 mol / L.

[0026] (2) Add 150L of the first salt solution at a rate of 5L / h to the reactor in a nitrogen atmosphere, and at the same time add sodium hydroxide solution and ammonia solution to the reactor for the first co-precipitation reaction to obtain the core part of the precursor , the molecular formula of the core part of the precursor is [Ni 0.95 mn 0.045 W 0.005 ](OH) 2 The concent...

Embodiment 2

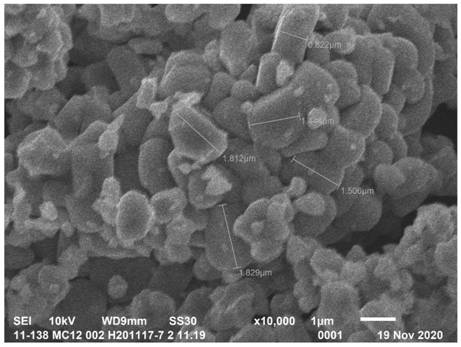

[0032] (1) Prepare the first salt solution and the second salt solution containing nickel sulfate, manganese sulfate and tungsten chloride. The molar ratio of nickel ions, manganese ions, and tungsten ions in the first salt solution is 95:4:1. The sum of the concentrations of nickel ions, manganese ions and tungsten ions in the salt solution is 2.00mol / L. The molar ratio of nickel ions, manganese ions, and tungsten ions in the second salt solution is 65:34:1, and the sum of the concentrations of nickel ions, manganese ions, and tungsten ions in the second salt solution is 2.00 mol / L.

[0033] (2) Add 150L of the first salt solution at a rate of 5L / h to the reactor in a nitrogen atmosphere, and at the same time add sodium hydroxide solution and ammonia solution to the reactor for the first co-precipitation reaction to obtain the core part of the precursor , the molecular formula of the core part of the precursor is [Ni 0.95 co 0.04 W 0.01 ](OH) 2 The concentration of sodium...

Embodiment 3

[0039] (1) Prepare the first salt solution and the second salt solution containing nickel sulfate, manganese sulfate and tungsten chloride. The molar ratio of nickel ions, manganese ions, and tungsten ions in the first salt solution is 95:3:2. The sum of the concentrations of nickel ions, manganese ions and tungsten ions in the salt solution is 2.00mol / L. The molar ratio of nickel ions, manganese ions, and tungsten ions in the second salt solution is 65:33:2, and the sum of the concentrations of nickel ions, manganese ions, and tungsten ions in the second salt solution is 2.00 mol / L.

[0040] (2) Add 150L of the first salt solution at a rate of 5L / h to the reactor in a nitrogen atmosphere, and at the same time add sodium hydroxide solution and ammonia solution to the reactor for the first co-precipitation reaction to obtain the core part of the precursor , the molecular formula of the core part of the precursor is [Ni 0.95 mn 0.03 W 0.02 ](OH) 2 The concentration of sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com