Sequentially controlled twin steering pump

A sequential control and steering pump technology, which is applied in the direction of pump control, pump, rotary piston type/oscillating piston type pump combination, etc., can solve the problems of increased failure rate, short service life, difficult to realize, etc., and reduce the possibility of carbonization performance, improve work reliability, and reduce the consumption of oil medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

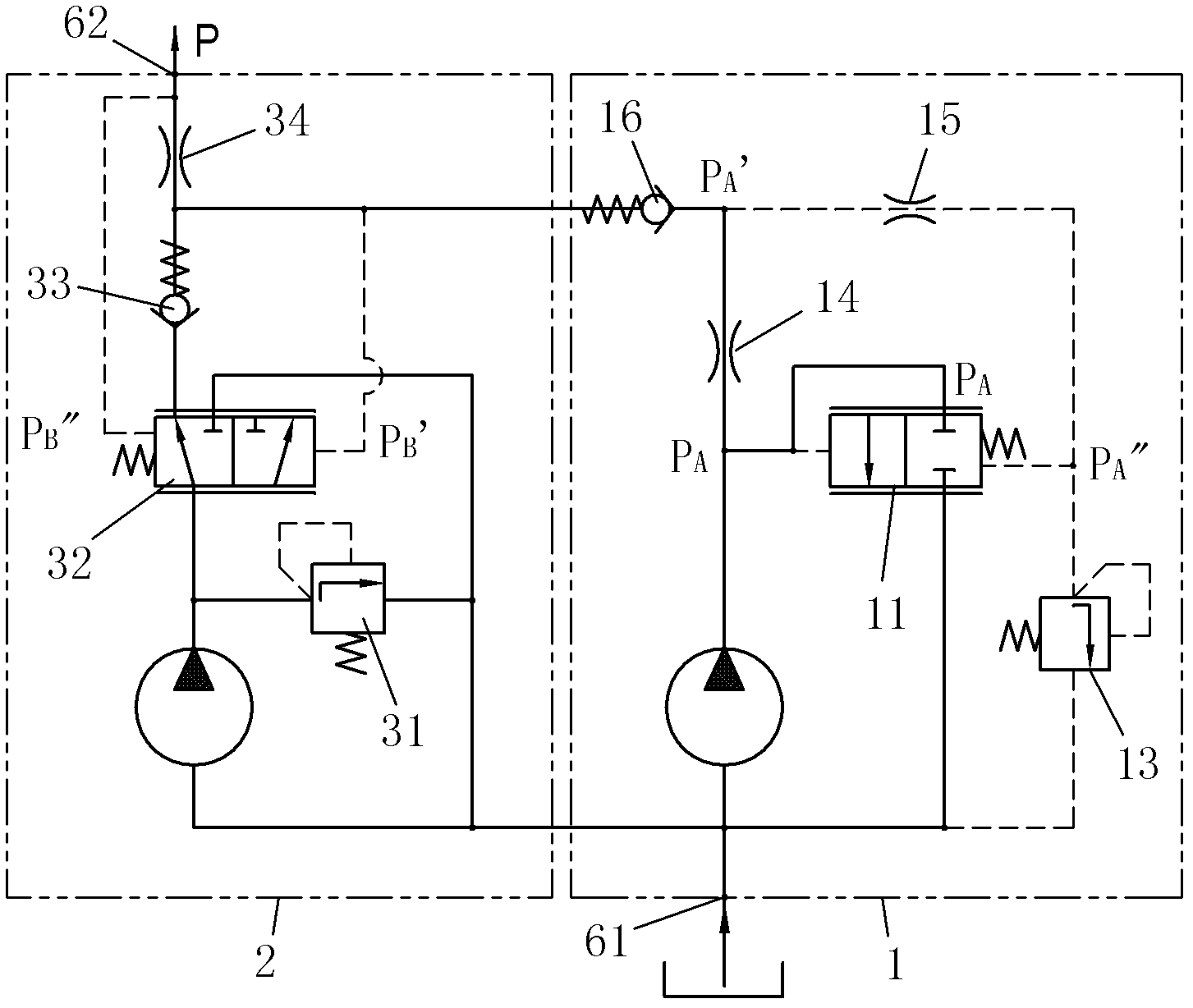

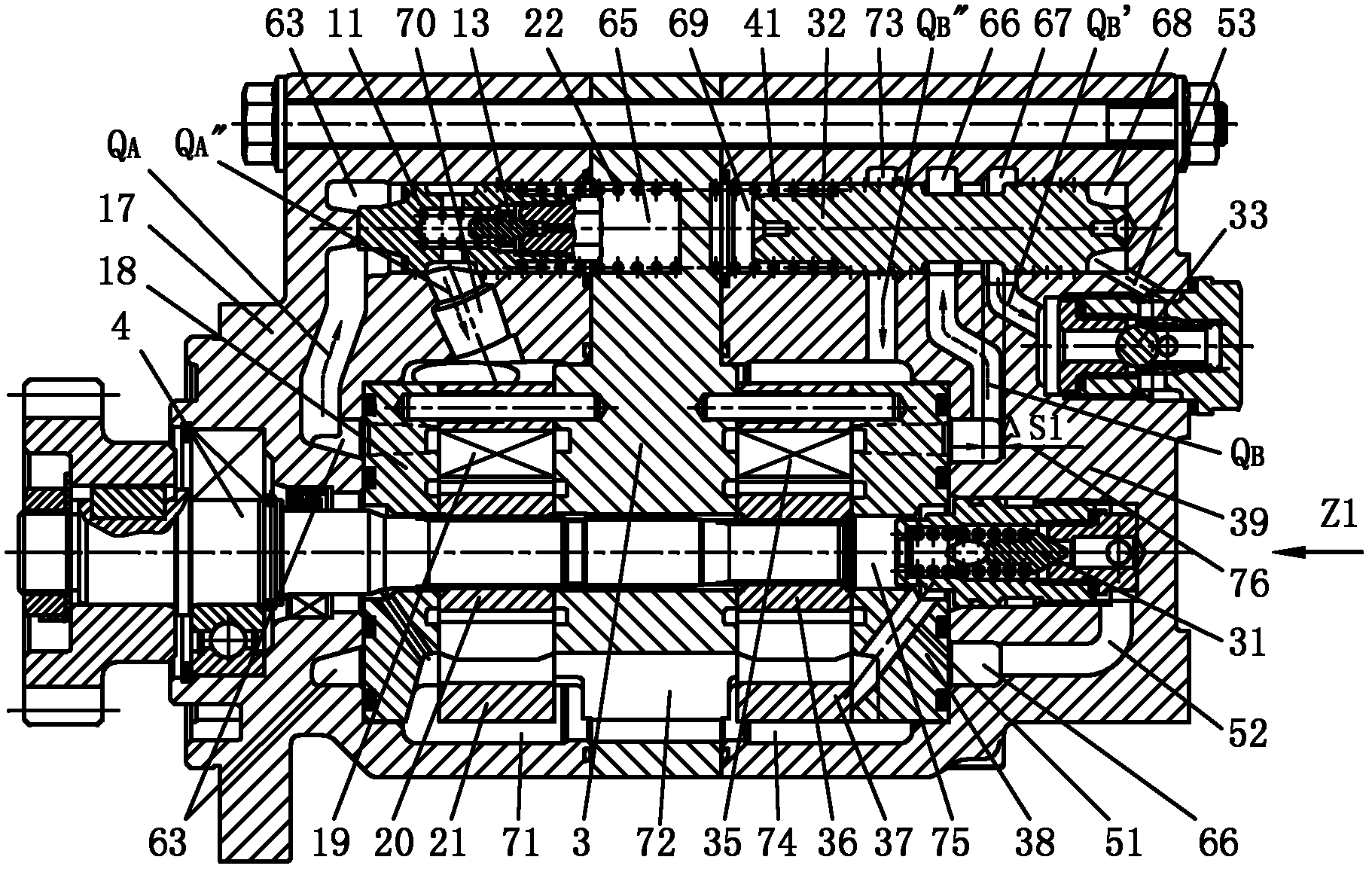

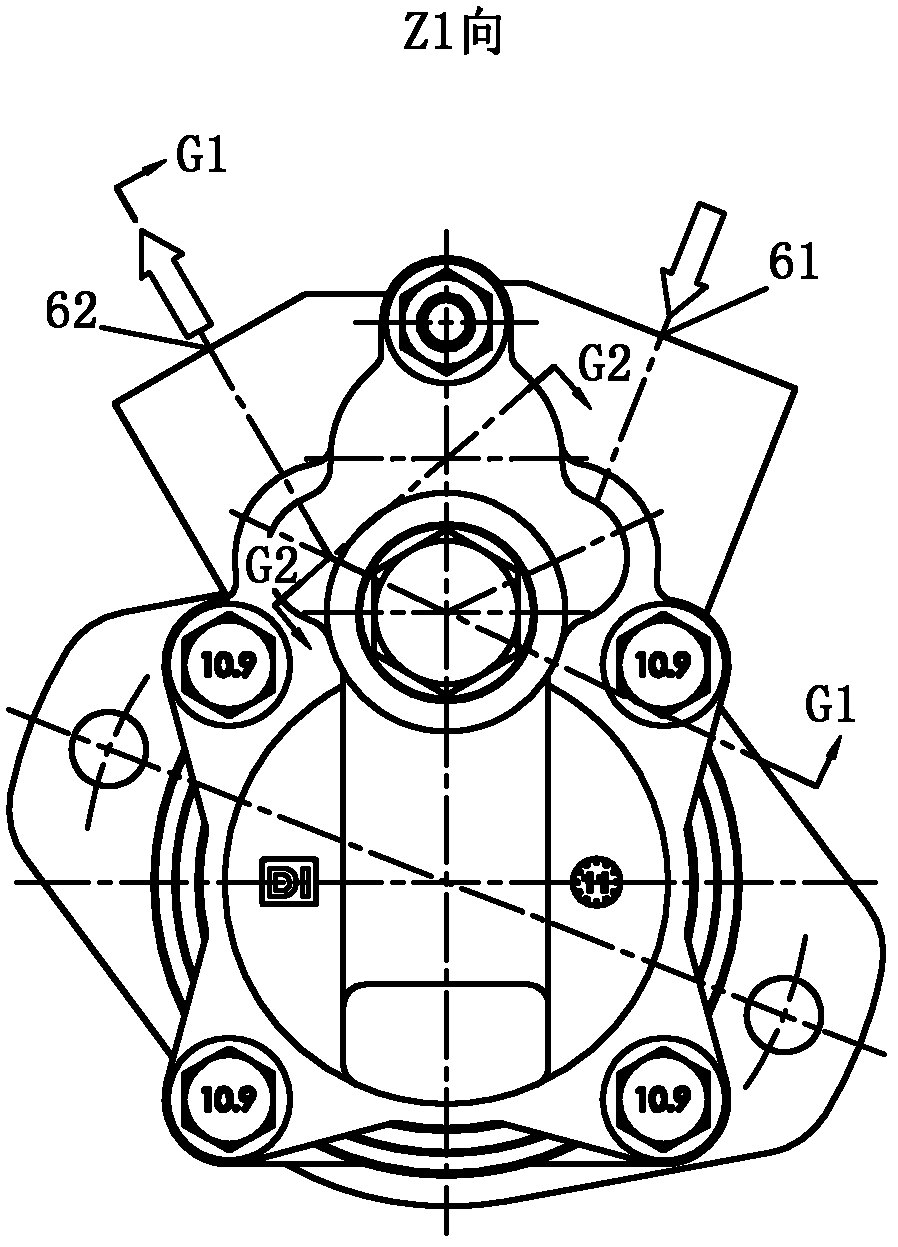

[0036] Below in conjunction with accompanying drawing, the present invention is described in further detail: as Figure 1-12 As shown, a sequence control dual steering pump includes a main pump 1, an auxiliary pump 2, an intermediate body 3 and a pump shaft 4, and the main pump 1 includes a flow control valve I 11, a safety valve I 13, a flow control damping Hole I 14, pressure control damping hole 15, one-way valve I 16, pump body 17, pressure side plate I 18, blade I 19, rotor I 20, stator I 21 and flow control valve spring 22, the auxiliary pump 2 Including safety valve II 31, reversing valve 32, check valve II 33, flow control orifice II 34, vane II 35, rotor II 36, stator II 37, pressure side plate II 38, pump cover I 39 and reversing valve spring 41;

[0037] The annular oil suction chamber 71 of the main pump communicates with the oil inlet 61, and communicates with the annular oil suction chamber 74 of the auxiliary pump through the intermediate oil suction window 72,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com