Antifouling treating agent for cleaning electrical insulator and preparation method of antifouling treating agent

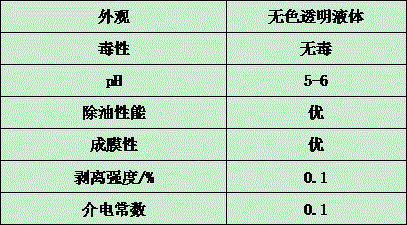

An anti-fouling treatment and insulator technology, applied in the field of electric power, can solve the problems of cleaning dead corners and low cleaning efficiency of grease electric insulator cleaning anti-fouling treatment agent, and achieve the effects of excellent oil removal, high insulation and high voltage resistance, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A cleaning and antifouling treatment agent for power insulators, the preparation method of which comprises the following steps:

[0024] (1), 100 parts of polyacrylic acid, 3.6 parts of hydroxyl hydrogen-containing silicone oil, 4 parts of aminopropyltrimethoxysilane coupling agent, 3.7 parts of glyceryl monostearate, and 3.2 parts of vinyl bisstearamide were added to the reaction In the reactor, the stirring speed was 165r / min, and the system temperature was maintained at 73°C for 2 hours to obtain modified polyacrylic acid;

[0025] (2), 100 parts of polyvinyl alcohol, 3.4 parts of methyl hydroxy silicone oil, 3.8 parts of aminopropyltrimethoxysilane coupling agent, 3.2 parts of glyceryl monostearate, 3.9 parts of vinyl bis stearamide are added to In the reaction kettle, react for 1.8 h at a temperature of 71 °C and a stirring speed of 173 r / min to obtain modified polyvinyl alcohol;

[0026] (3) Add 100 parts of ethyl hydrogen-containing silicone oil, 160 parts of et...

Embodiment 2

[0029] A cleaning and antifouling treatment agent for power insulators, the preparation method of which comprises the following steps:

[0030] (1) Add 100 parts of polyacrylic acid, 1 part of methyl ethoxy silicone oil, 3 parts of phenyltrichlorosilane coupling agent, 3 parts of sodium lauryl sulfate, and 2 parts of glyceryl tristearate into the reactor , the stirring speed is 120r / min, and the system temperature is maintained at 50°C for 1h to obtain modified polyacrylic acid;

[0031] (2) Add 100 parts of polyvinyl alcohol, 2 parts of ethyl hydrogen-containing silicone oil, 3 parts of phenyltrichlorosilane coupling agent, 2 parts of sodium glycocholate, and 3 parts of vinylbisstearamide into the reaction kettle , reacted for 1 h at a temperature of 60 °C and a stirring speed of 140 r / min to obtain modified polyvinyl alcohol;

[0032] (3) Add 100 parts of methyl ethoxy silicone oil, 150 parts of ethanol, and 10 parts of polyacrylic acid into the reaction kettle, and react f...

Embodiment 3

[0035] A cleaning and antifouling treatment agent for power insulators, the preparation method of which comprises the following steps:

[0036] (1) Add 100 parts of polyacrylic acid, 7 parts of methyl ethoxy silicone oil, 9 parts of aminopropyltrimethoxysilane coupling agent, 8 parts of sodium glycocholate, and 5 parts of polyethylene glycol into the reactor , the stirring speed was 180r / min, and the system temperature was maintained at 90°C for 3 hours to obtain modified polyacrylic acid;

[0037](2) Add 100 parts of polyvinyl alcohol, 10 parts of ethyl hydrogen-containing silicone oil, 8 parts of phenyltrichlorosilane coupling agent, 7 parts of sodium lauryl sulfate, and 6 parts of glyceryl tristearate into the reaction kettle , reacted for 4 hours at a temperature of 85 ° C and a stirring speed of 210 r / min to obtain modified polyvinyl alcohol;

[0038] (3) Add 100 parts of phenyl silicone oil, 170 parts of ethanol, and 20 parts of polyacrylic acid into the reaction kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com