Manufacturing method of metal-ceramic composite substrate and composite substrate manufactured by manufacturing method

A technology of ceramic composite and manufacturing method, applied in the field of ceramic metallization, can solve the problems of affecting conductivity and thermal shock resistance, high content of silver in brazing material, decrease in conductivity, etc. The effect of high rate and strong thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

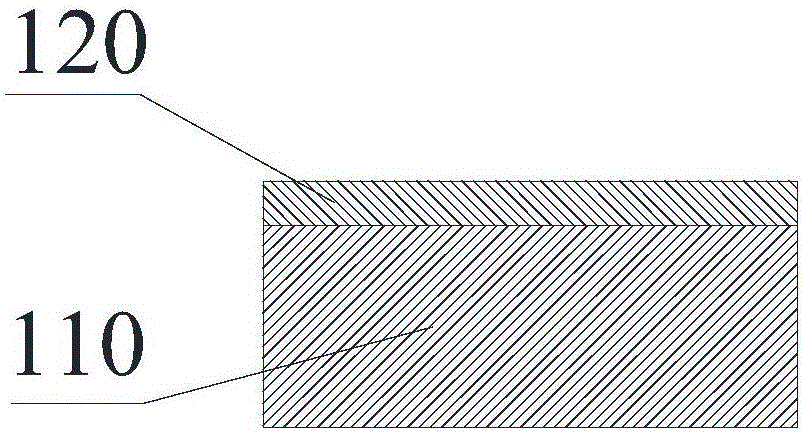

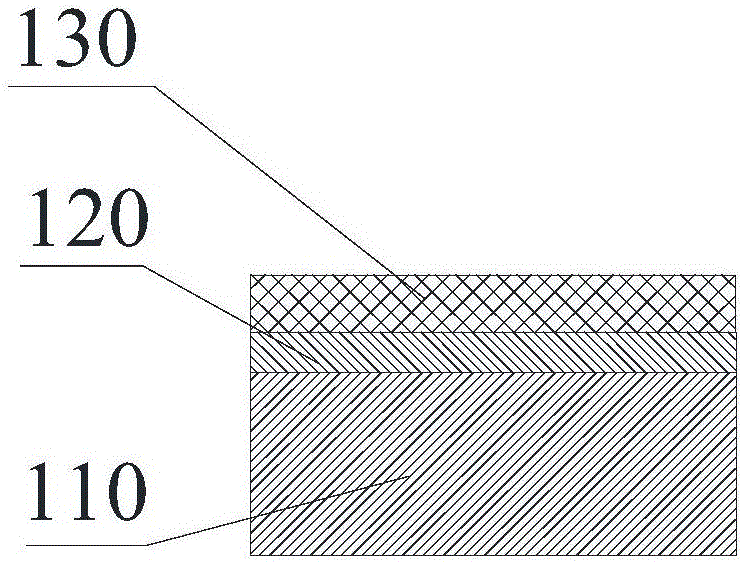

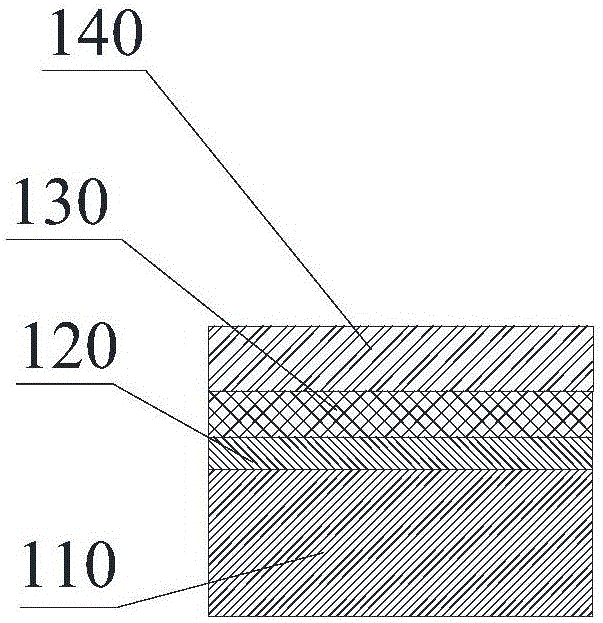

[0042] See figure 1 , Coating the first copper paste with a viscosity of 100 mPa·s on the surface of the ceramic substrate 110 and drying at 90° C. for 15 minutes to obtain the first brazing material layer 120.

[0043] See figure 2 Coating the second copper paste with a viscosity of 100 mPa·s on the surface of the first brazing material layer 120 away from the ceramic substrate 110 and drying at 110° C. for 5 minutes to obtain the second brazing material layer 130.

[0044] See image 3 , The copper foil is soaked in a sodium hydroxide solution with a content of 5wt% at 60°C for 10 minutes, and washed twice with distilled water; then at room temperature, soaked with a sulfuric acid solution with a content of 10wt% for 2 minutes, using distilled water Wash twice. The processed copper foil is placed on the surface of the second brazing material layer 130 away from the first brazing material layer 120 to form a copper layer 140.

[0045] See Figure 4 , The metal-ceramic composite su...

Embodiment 2

[0048] The first copper paste with a viscosity of 300 mPa·s was coated on the surface of the ceramic substrate 110 and dried at 110° C. for 10 minutes to obtain the first brazing material layer 120.

[0049] A second copper paste with a viscosity of 50 mPa·s was applied to the surface of the first brazing material layer 120 away from the ceramic substrate 110 and dried at 90° C. for 15 minutes to obtain the second brazing material layer 130.

[0050] Soak the copper strip in a sodium hydroxide solution with a content of 5wt% at 60℃ for 5 minutes and wash it twice with distilled water; then at room temperature, soak it with a sulfuric acid solution with a content of 10wt% for 1 minute and wash it with distilled water twice. The processed copper tape is placed on the surface of the second brazing material layer 130 away from the first brazing material layer 120 to form a copper layer 140.

[0051] The metal-ceramic composite substrate precursor is placed at a temperature of 400°C for ...

Embodiment 3

[0053] The first copper paste with a viscosity of 150 mPa·s was coated on the surface of the ceramic substrate 110 and dried at 100° C. for 11 minutes to obtain the first brazing material layer 120.

[0054] A second copper paste with a viscosity of 80 mPa·s was applied to the surface of the first brazing material layer 120 far away from the ceramic substrate 110 and dried at 100° C. for 12 minutes to obtain the second brazing material layer 130.

[0055] The copper foil is soaked in a sodium hydroxide solution with a content of 5wt% at 60℃ for 10 minutes and washed twice with distilled water; then at room temperature, it is soaked with a sulfuric acid solution with a content of 10wt% for 2 minutes and washed with distilled water twice. The processed copper foil is placed on the surface of the second brazing material layer 130 away from the first brazing material layer 120 to form a copper layer 140.

[0056] Put the metal-ceramic composite substrate precursor under the condition of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com