Patents

Literature

53 results about "High speed deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

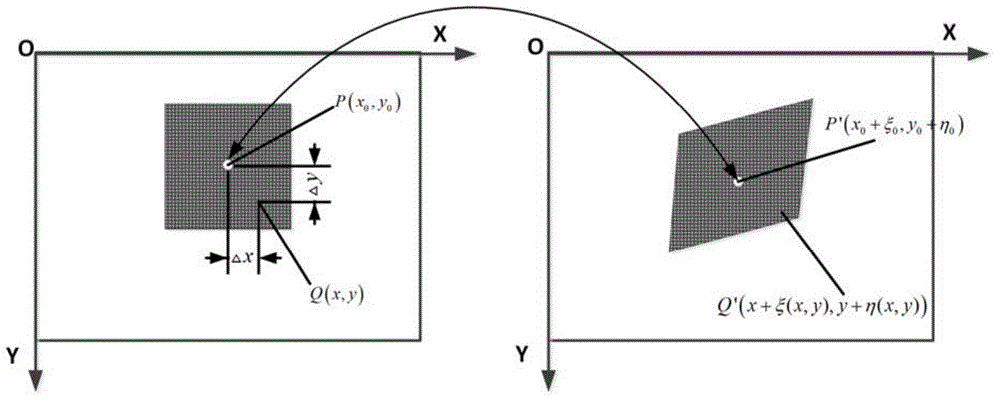

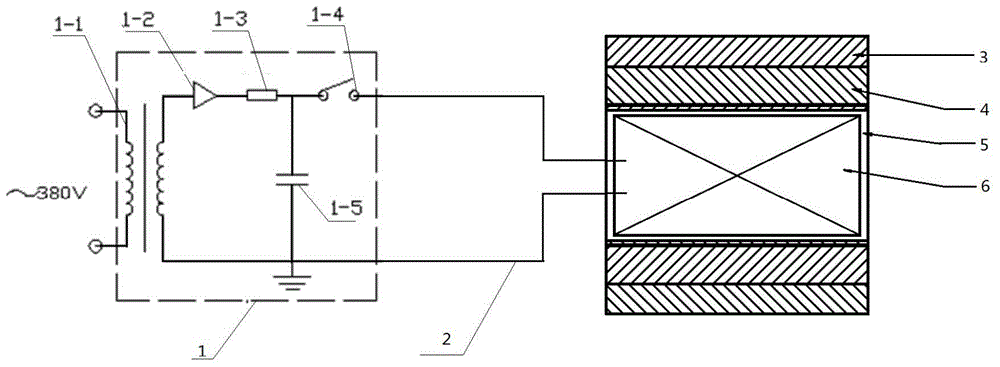

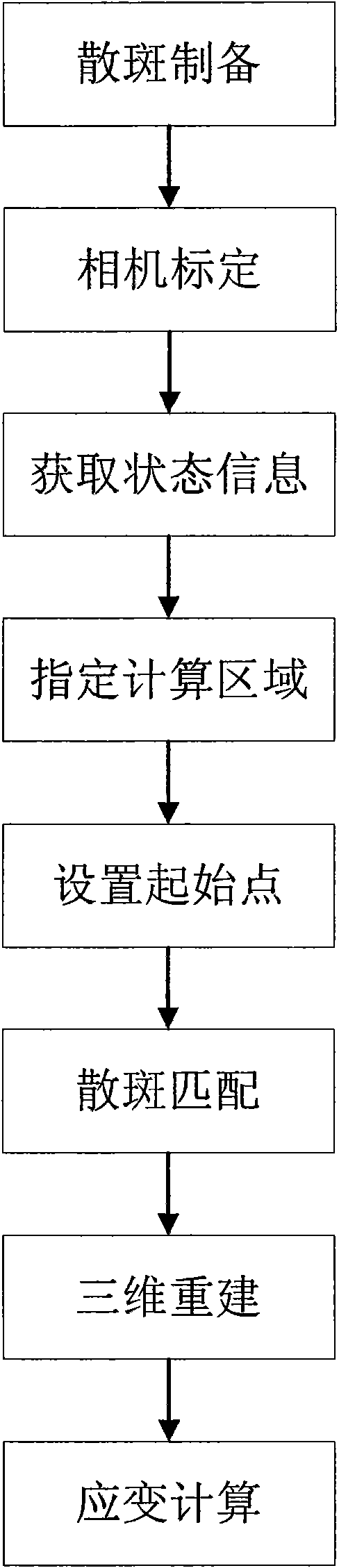

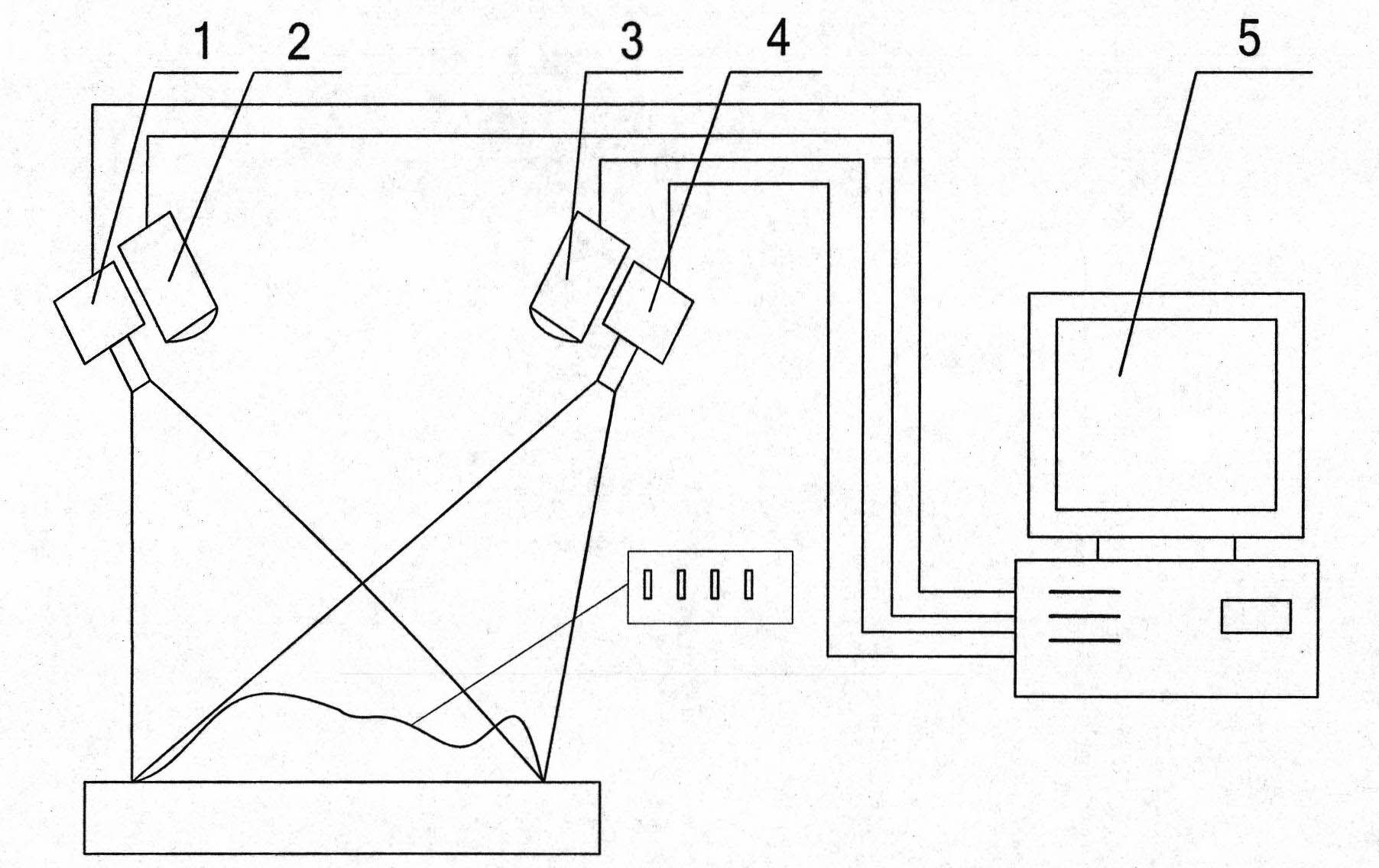

Three-dimensional speckle strain measurement device and measurement method thereof

ActiveCN101655352AHigh measurement accuracySimplify requirementsUsing optical meansVibration measurementFracture mechanics

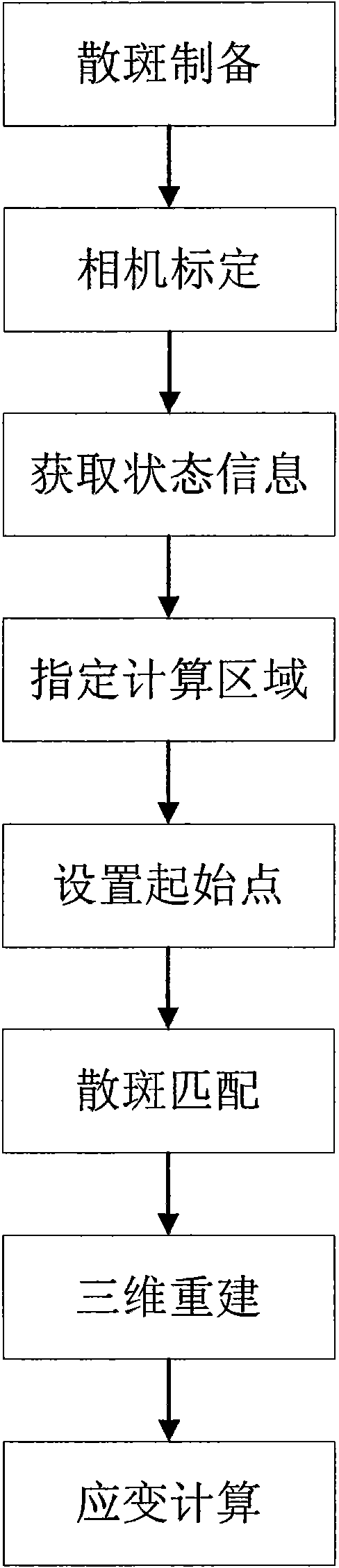

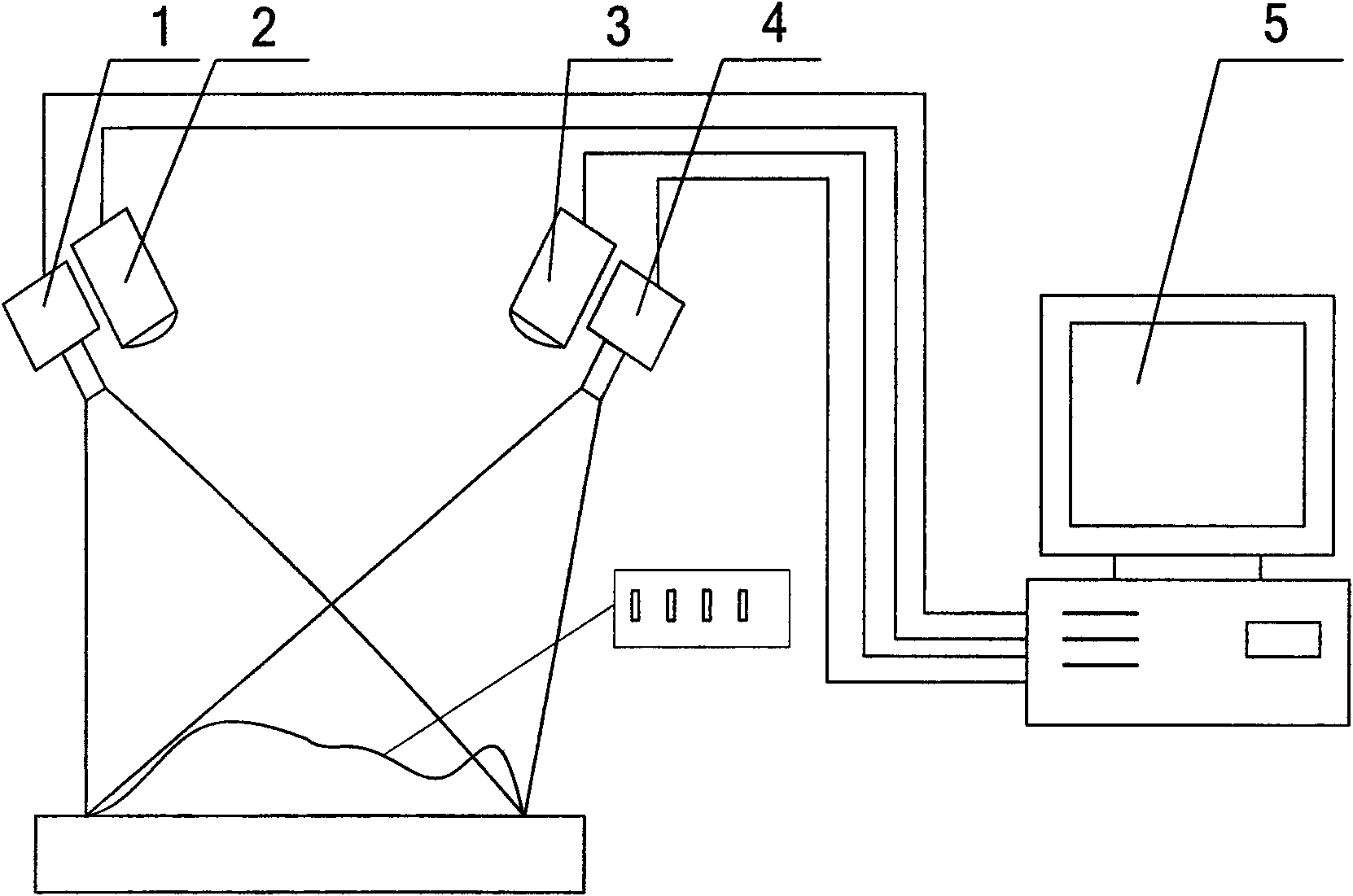

The invention discloses a three-dimensional speckle strain measurement method, comprising: (1) speckle preparation; (2) camera calibration; (3) state information acquisition; (4) computational domaindesignation; (5) initial point setting; (6) speckle matching; (7) three-dimensional reconstruction; and (8) strain computation. By the above operation steps, the invention provides a three-dimensionalspeckle strain measurement method, which can effectively obtain high preciseness measurement results in measurements of material characteristic parameters such as full-field vibration measurement, dynamic strain measurement, high speed deformation measurement, fracture mechanics, impact excitation and dynamic material experiments. The invention has the characteristics of convenient measurement operation, high automation degree, exact and reliable results, high efficiency and non-contact measurement.

Owner:XI AN JIAOTONG UNIV

High speed processing method for realizing superfine crystal grain structure on metallic material surface

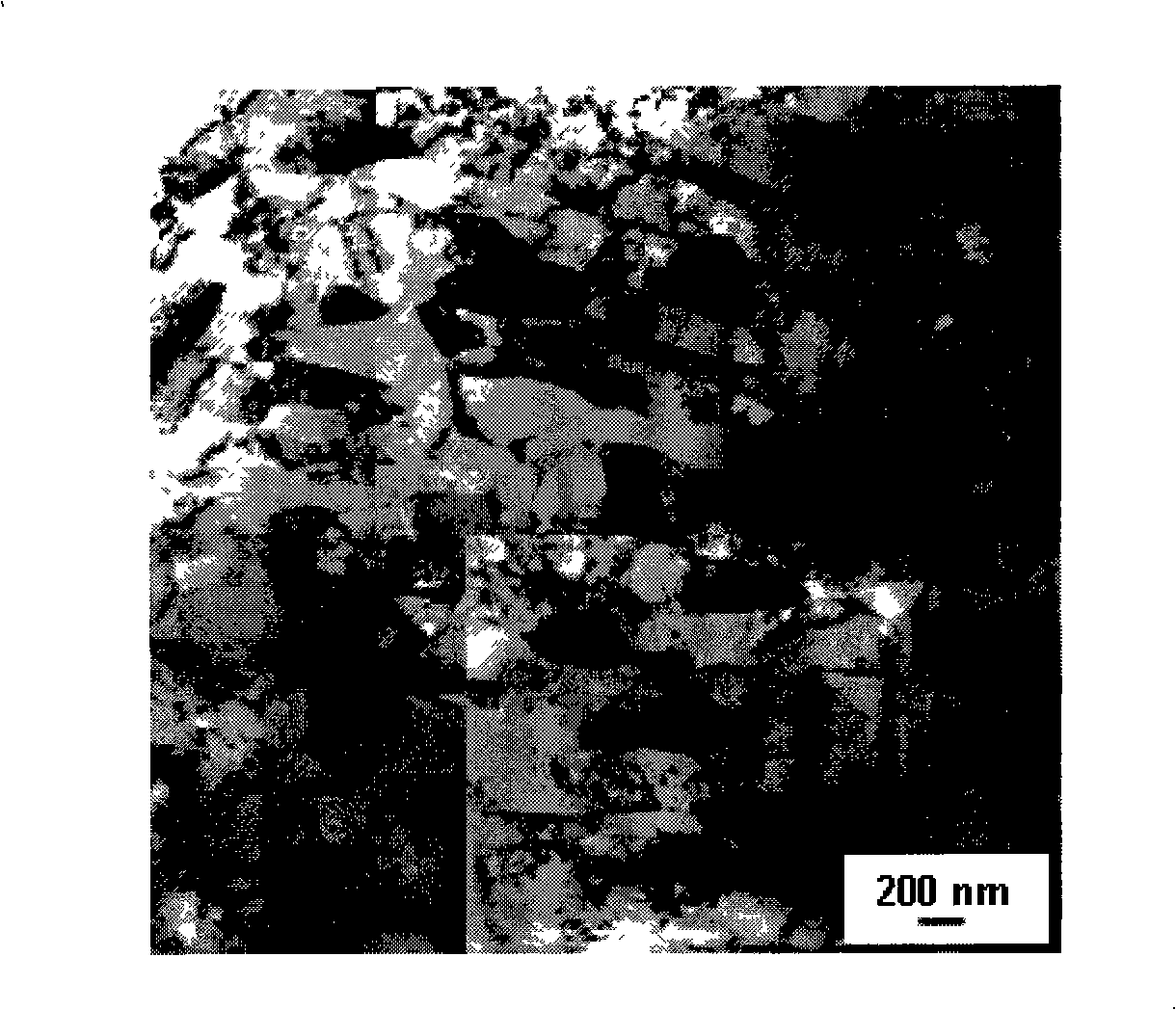

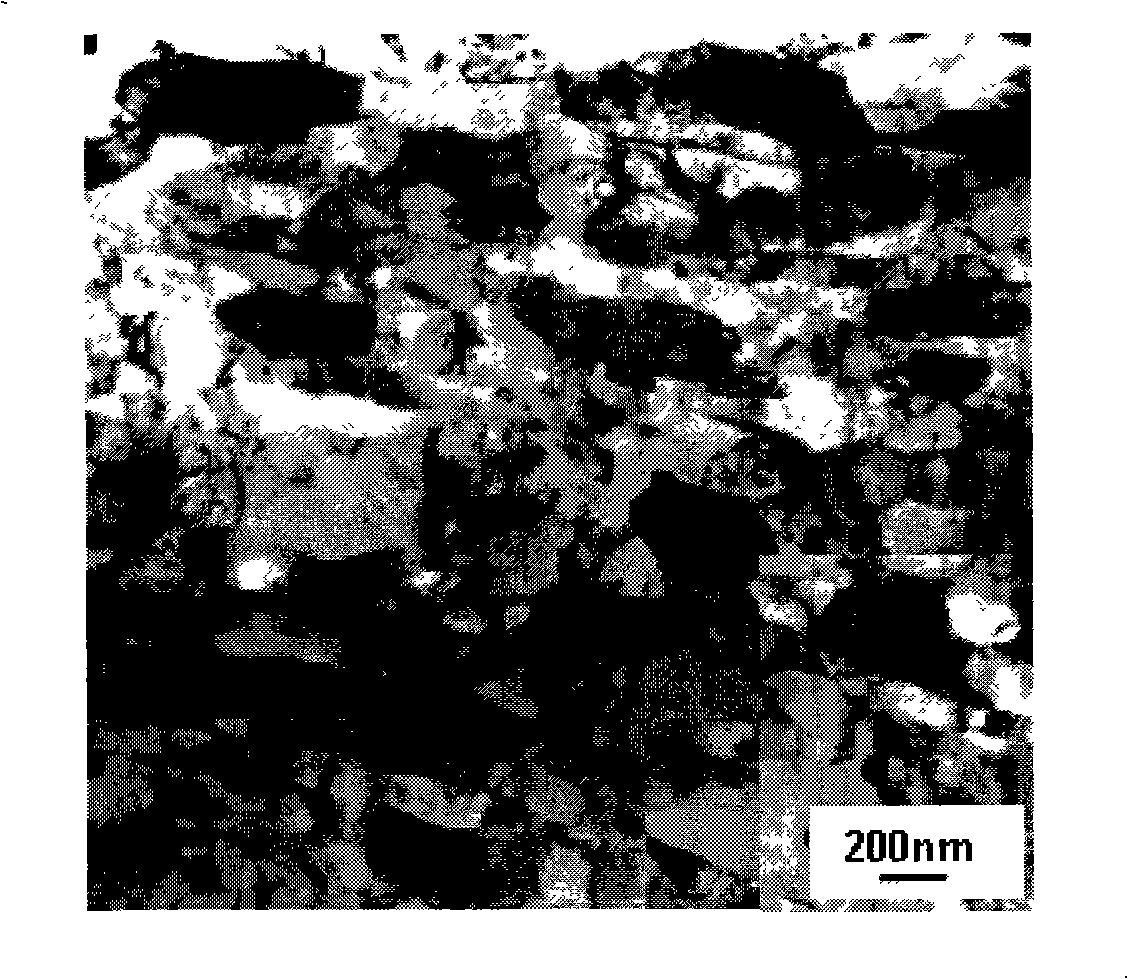

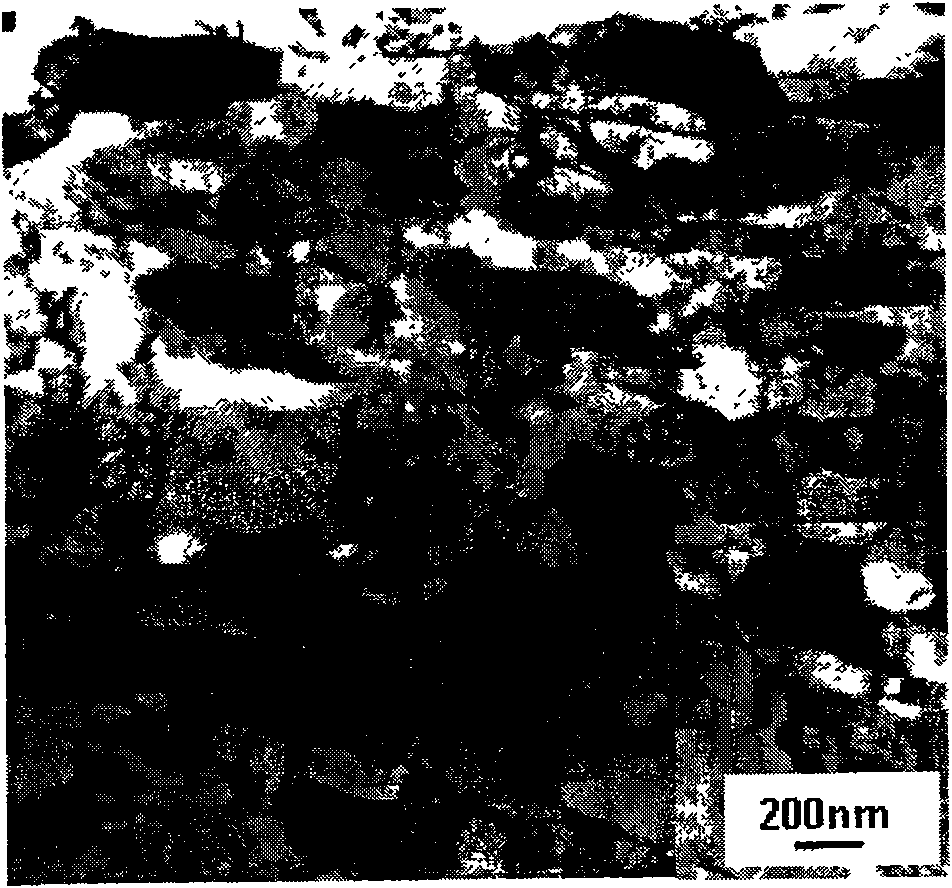

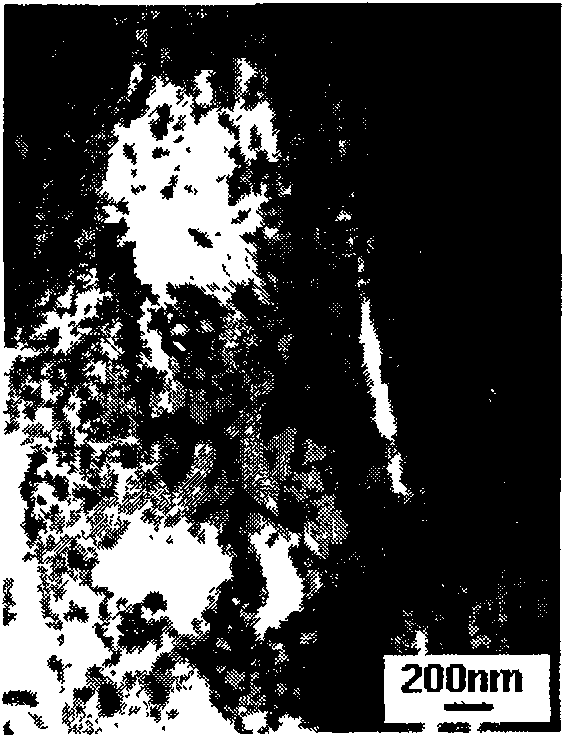

The invention relates to a method for processing the high-speed deformation on the surface of metallic material with nano structure, and particularly provides a method for realizing high-speed processing of the organization structure of ultra-fine grains. On the condition of room temperature or low temperature, by adopting a mechanical treatment method with high-speed plastic deformation, the nanoscale bulky crystalline grain structure on the surface layer of the metallic material is refined as equiaxial submicron crystalline grain or nano crystalline grain to form an ultra-fine organization structure of the crystalline grain on the surface layer of the metallic material. With the increase of the depth to the processing surface, the size of microstructure has the change of gradient, increasing from nanoscale and submicron size to micron size. Compared with the existing processing method for forming a surface ultra-fine crystalline grain structure, the high-speed processing method of the invention greatly reduces the roughness of the surface of the processed metallic material and increases the thickness of a deformation layer, and has simple processing method and high working efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

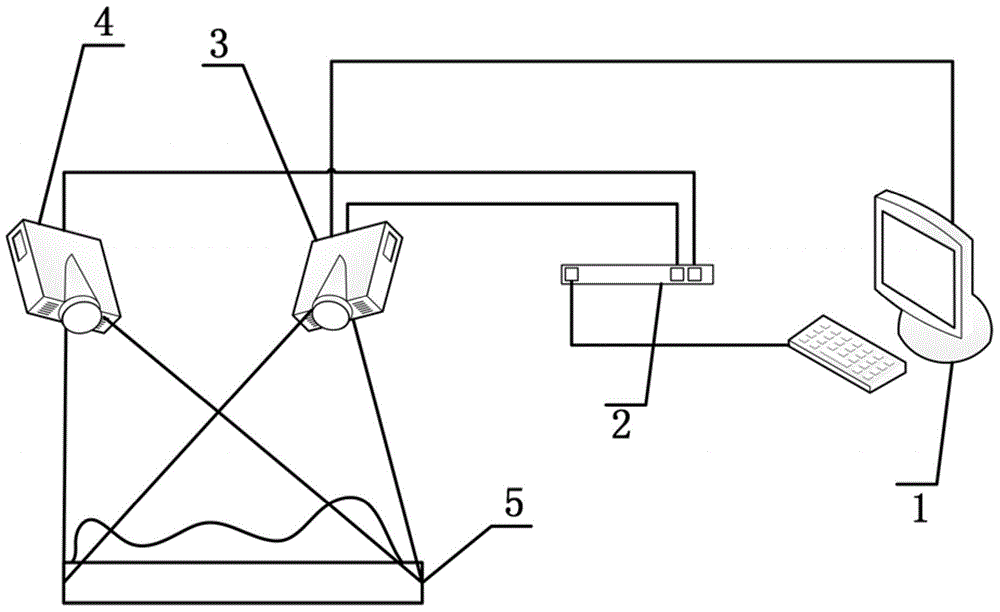

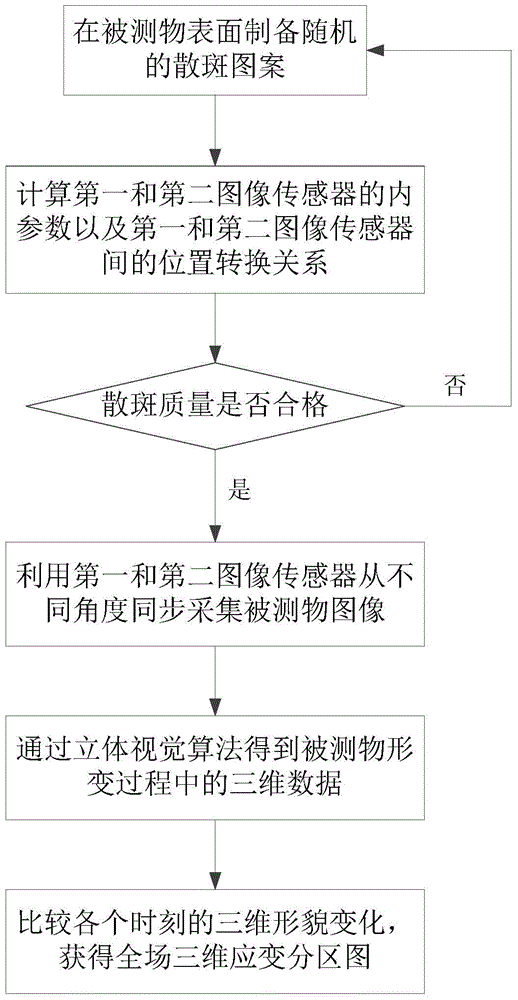

Digital speckle-based high-speed three-dimensional strain measurement method

ActiveCN104864819AImprove relevanceRealize 3D strain measurementUsing optical meansImage sequenceImage acquisition

The invention discloses a digital speckle-based high-speed three-dimensional strain measurement method. According to the method, a high-speed image acquisition system is adopted to acquire high-speed deformation objects; the quality of speckle images is evaluated through utilizing speckle particle size mean or gray scale gradient of the images; the images have high correlation and high quality in a measurement process assuredly, and the accuracy of measurement can be effectively improved; and therefore, real-time continuous three-dimensional reconstruction and strain measurement can be performed on measured objects in deformation according to the image sequence of the deformation objects which are acquired quickly, and three-dimensional strain measurement of the high-speed deformation objects can be realized finally.

Owner:HUAZHONG UNIV OF SCI & TECH

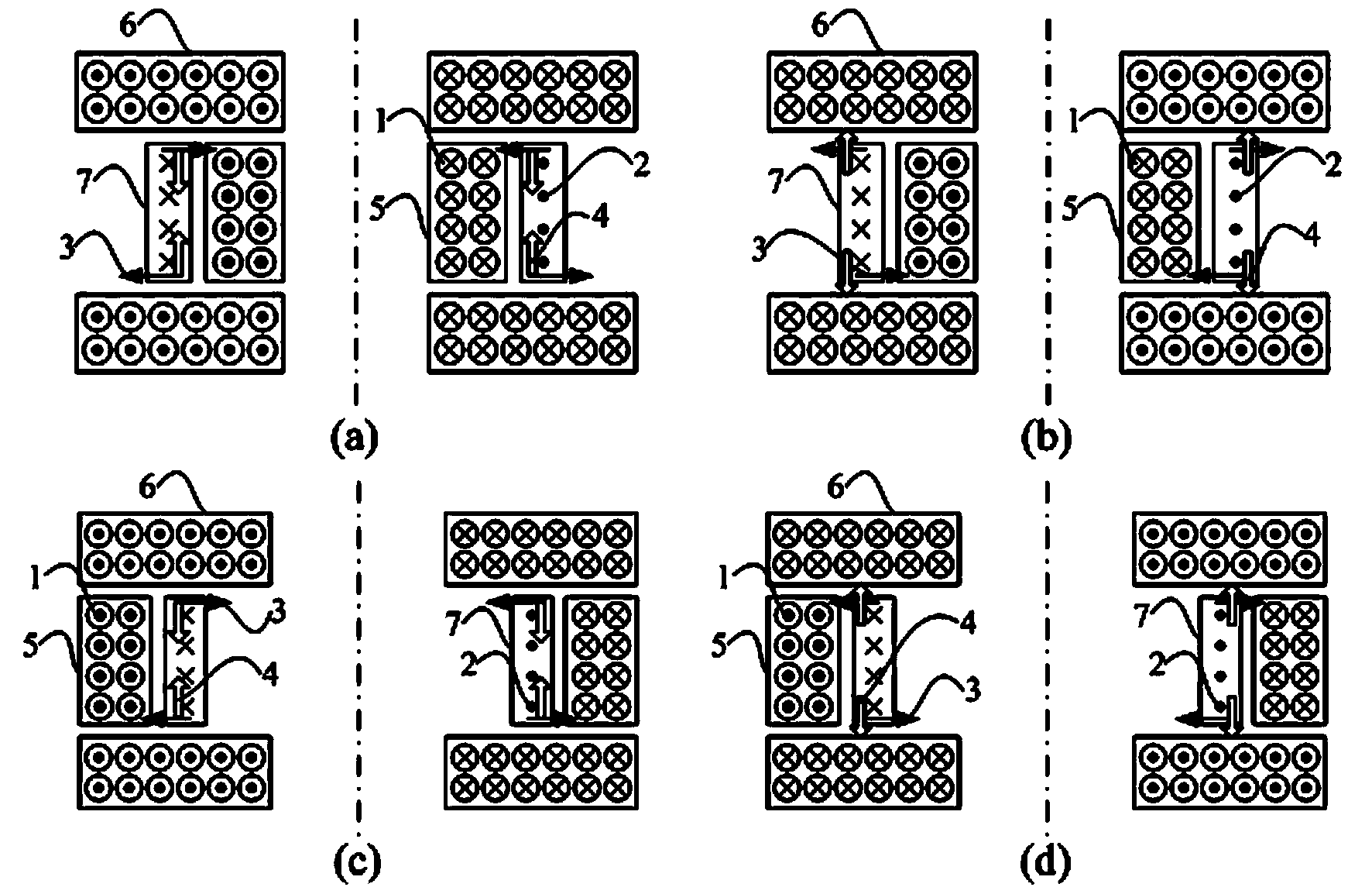

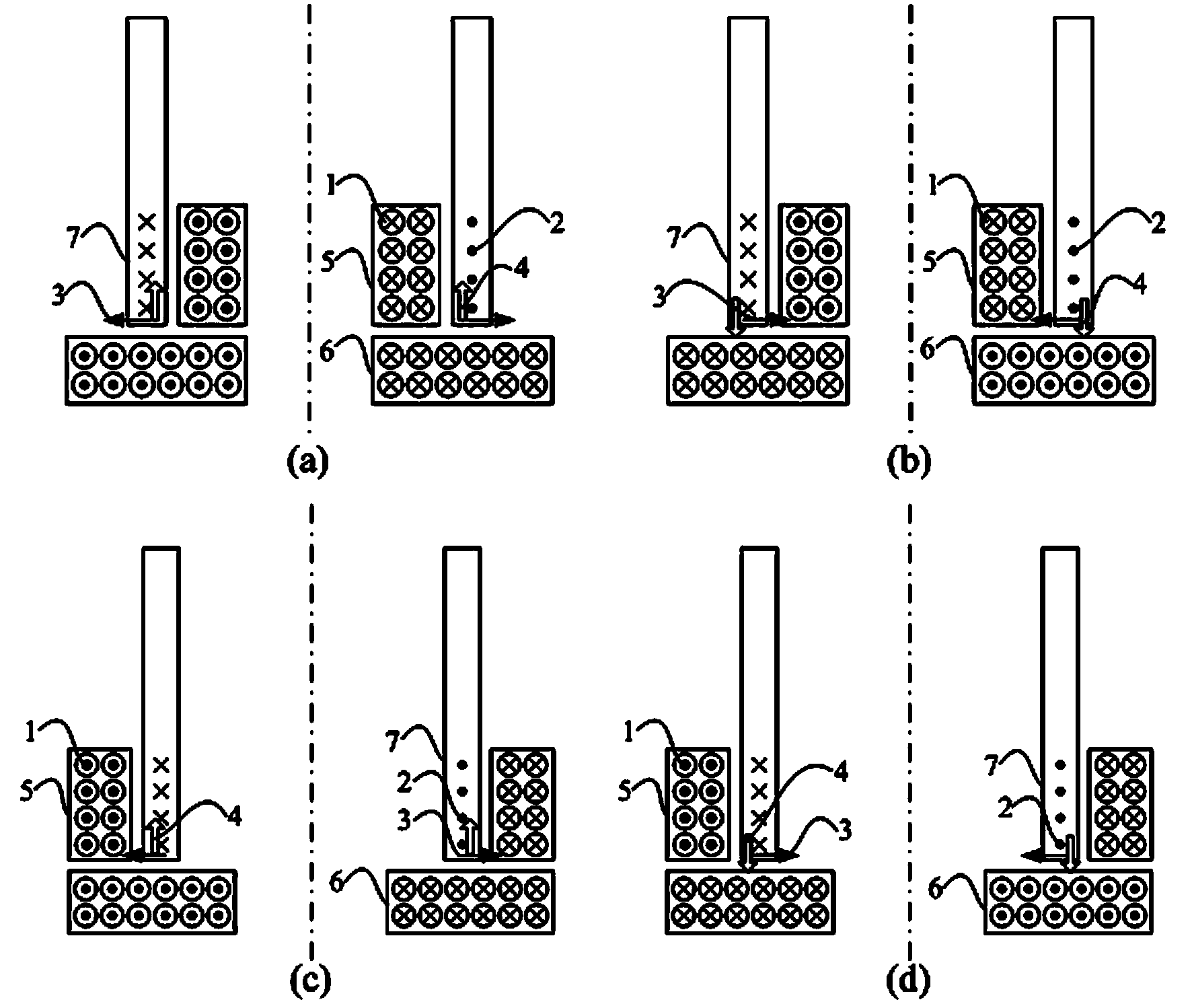

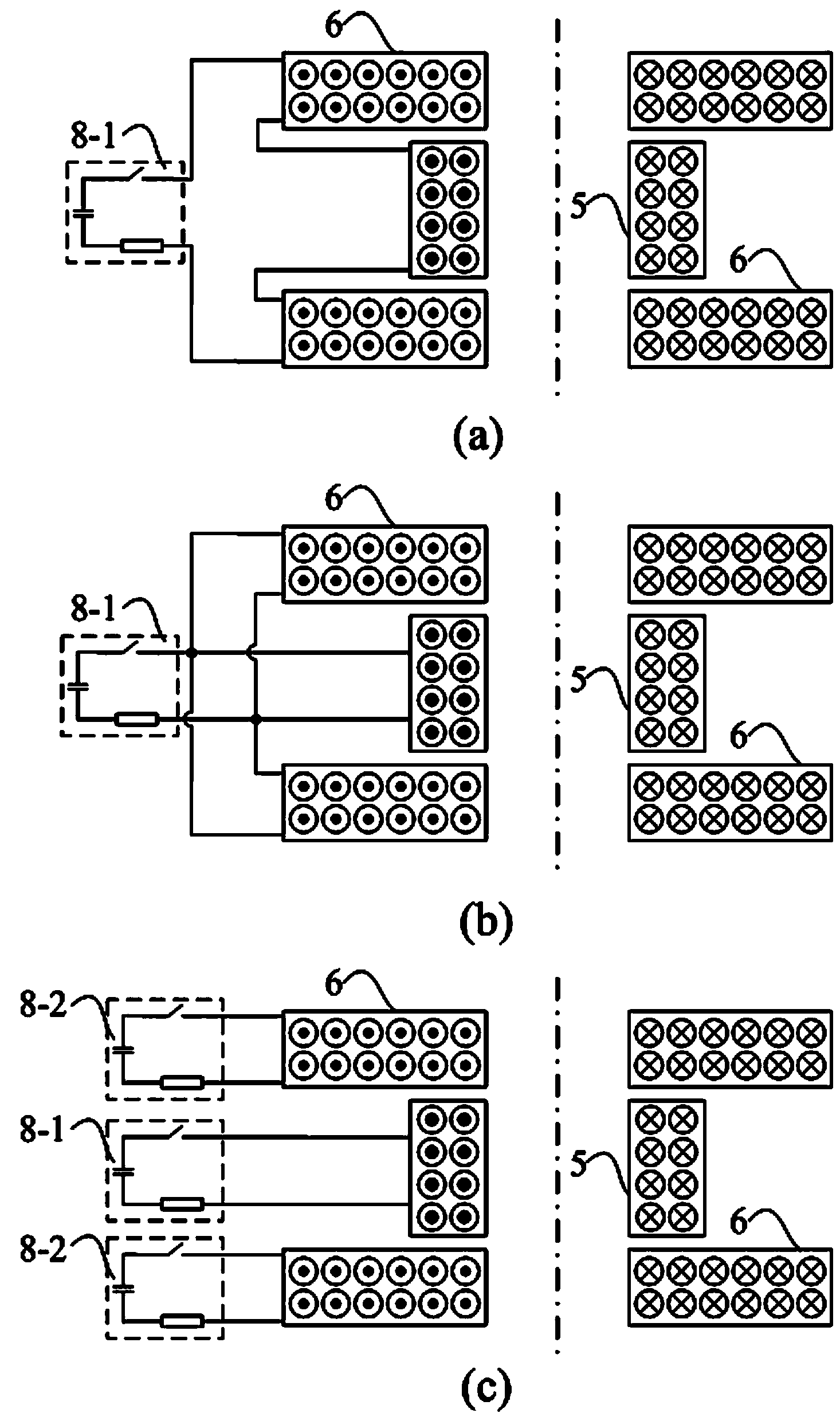

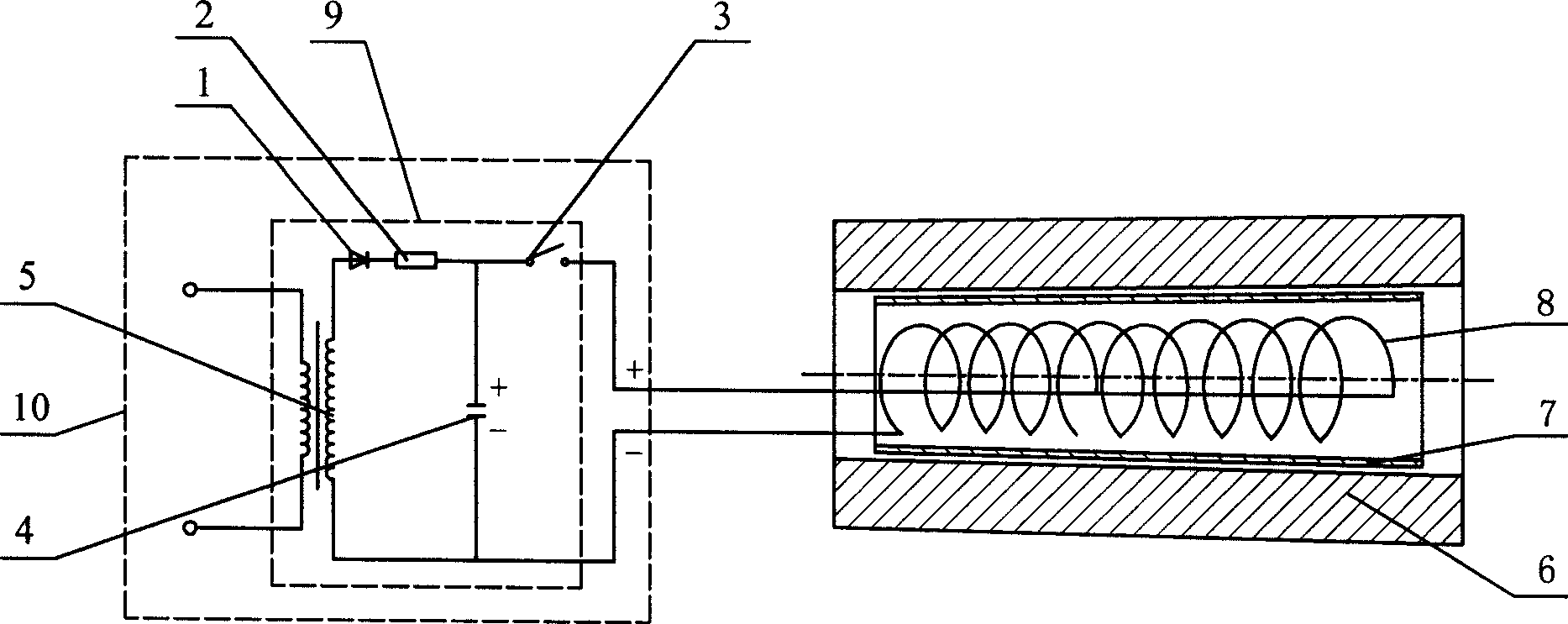

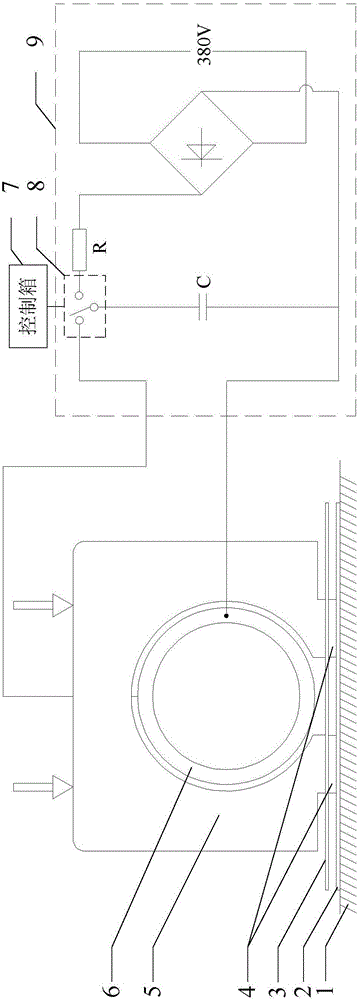

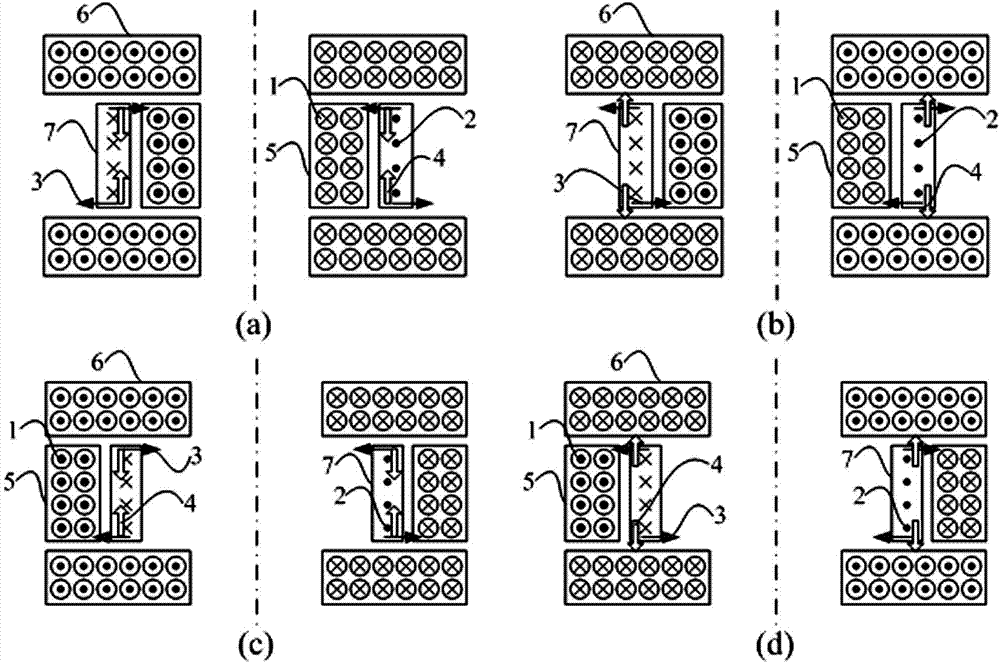

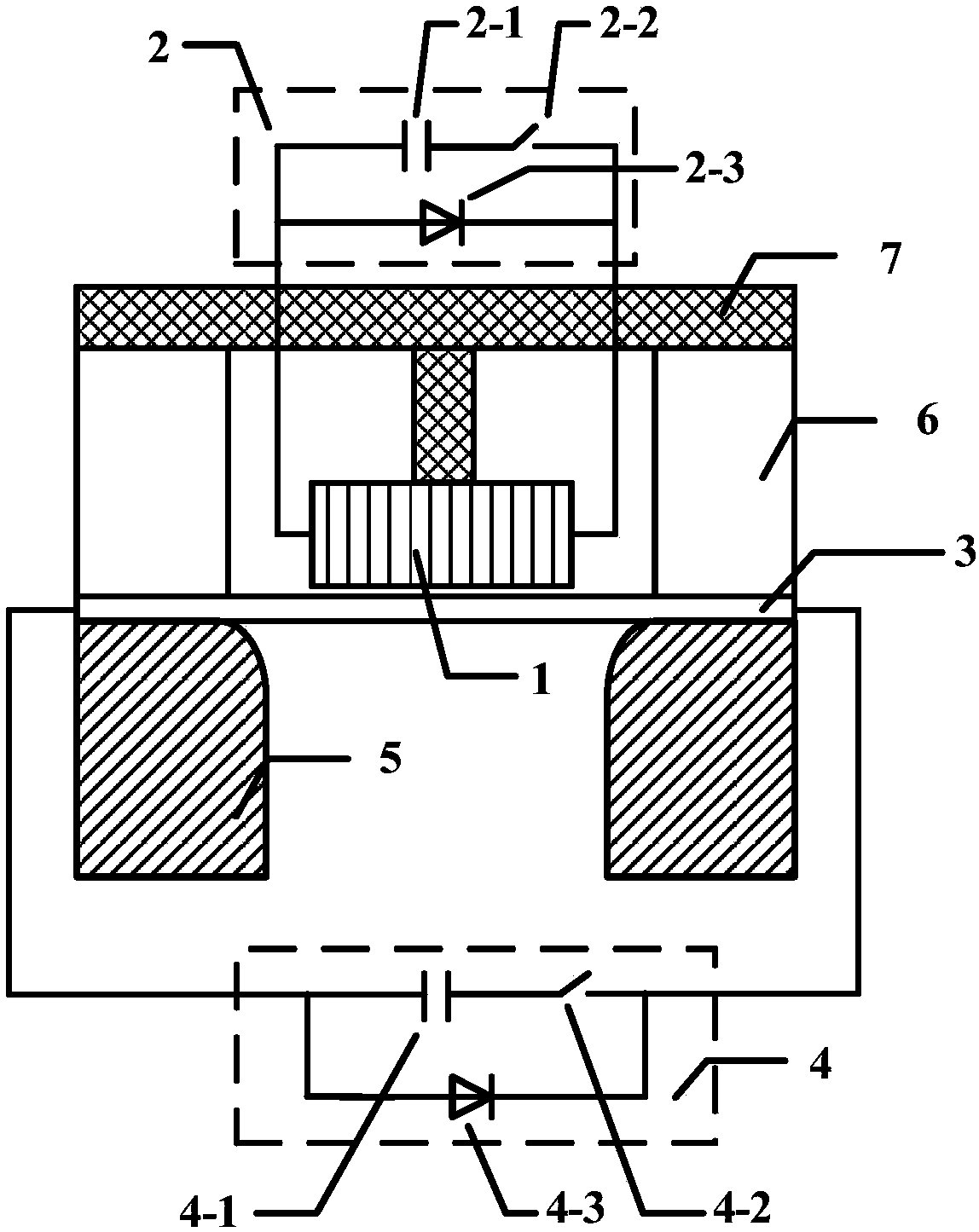

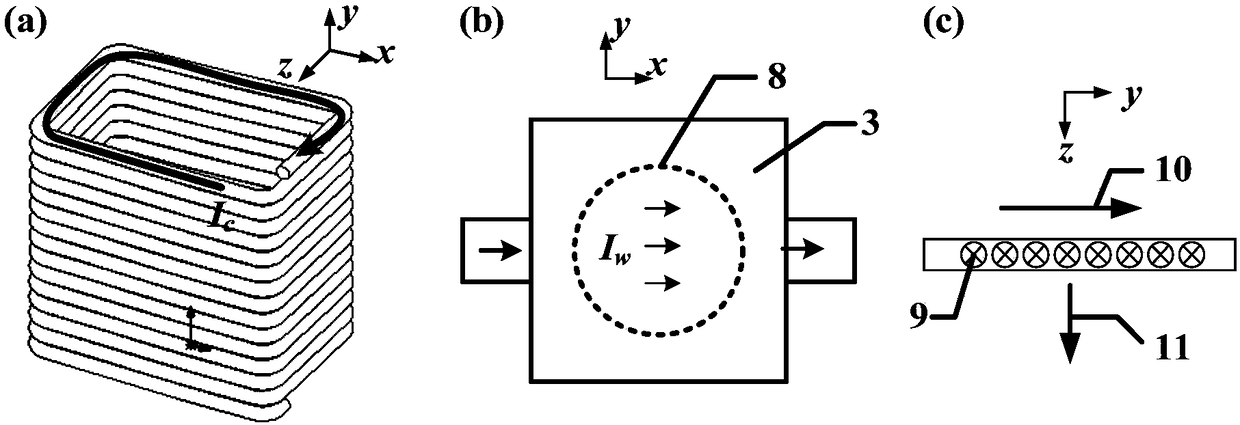

Method and device for electromagnetically forming metal pipe fitting in radial and axial loading mode

ActiveCN103406418ASolve the single load of electromagnetic forming factorSolve the problem caused byAxial compressionPipe fitting

The invention discloses a method and a device for electromagnetically forming a metal pipe fitting in a radial and axial loading mode. The device mainly comprises an eddy current coil, magnetic field coils and power systems. The eddy current coil generates induced eddy currents, the magnetic field coils generate radial magnetic fields, and the eddy current coil and the magnetic field coils are powered by the power systems. The method and the device have the advantages that electromagnetic force can be radially and axially loaded simultaneously in a procedure for electromagnetically forming the metal pipe fitting, an electromagnetic force loading mode can be adjusted, and accordingly machining requirements of different workpieces can be met; the axial compression type pipe fitting is electromagnetically expanded, so that the thickness reduction of a pipe wall in an expansion procedure can be effectively reduced, the forming limit of a formed workpiece is increased, and the forming performance of the formed workpiece is improved; high-speed deformation experiment conditions in different load forms can be provided for metal pipe fittings by the method for electromagnetically forming the metal pipe fitting in the radial and axial loading mode, and novel experiment measures are provided for research on high-speed deformation mechanisms of materials.

Owner:湖北继扬电力科技有限公司

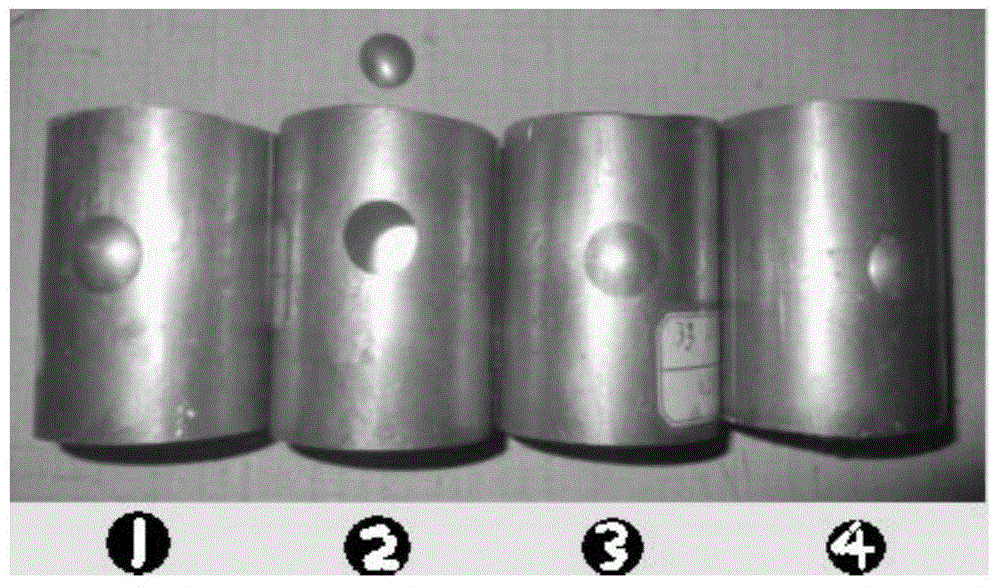

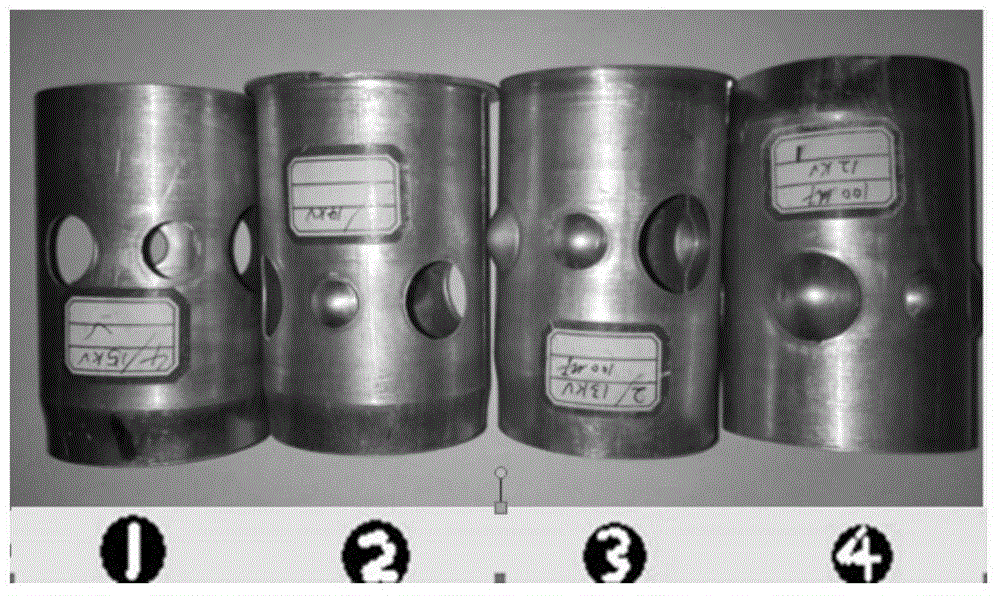

Method for increasing the circular degree of the metal thin-walled cylinder using pulse magnetic pressure

The invention discloses a method for improving roundness of a metal thin-wall cylindrical workpiece by pulsed magnetic pressure, and relates to a method for improving roundness of a metal thin-wall cylindrical workpiece. The method solves the problems that the existing cylindrical workpiece shape correction method has the disadvantages of complex mechanism and die, uneasy operation and low accuracy of shape correction, and the existing cylindrical workpieces have the disadvantages of easy wearing surface, residual stress, short service life, difficult sealing, high cost and difficult operation, both of which are not favorable for the small-batch and diversified development trend. The method comprises the following steps: step one: the metal thin-wall cylindrical workpiece is arranged in a high-accuracy shape correction die, and magnetic impulse processed coils are placed in the cylindrical workpiece; step two: a high-frequency pulse capacitor bank is used for discharging the magnetic pulse processing coils, high-frequency pulse acts on the cylindrical workpiece to cause the cylindrical workpiece to generate high-speed deformation and generate impact contact and adhere to the die. The invention has the advantages of simple mechanism and die, high machining accuracy, long service life and low cost, and is favorable for the small-batch and diversified development trend, etc.

Owner:HARBIN INST OF TECH

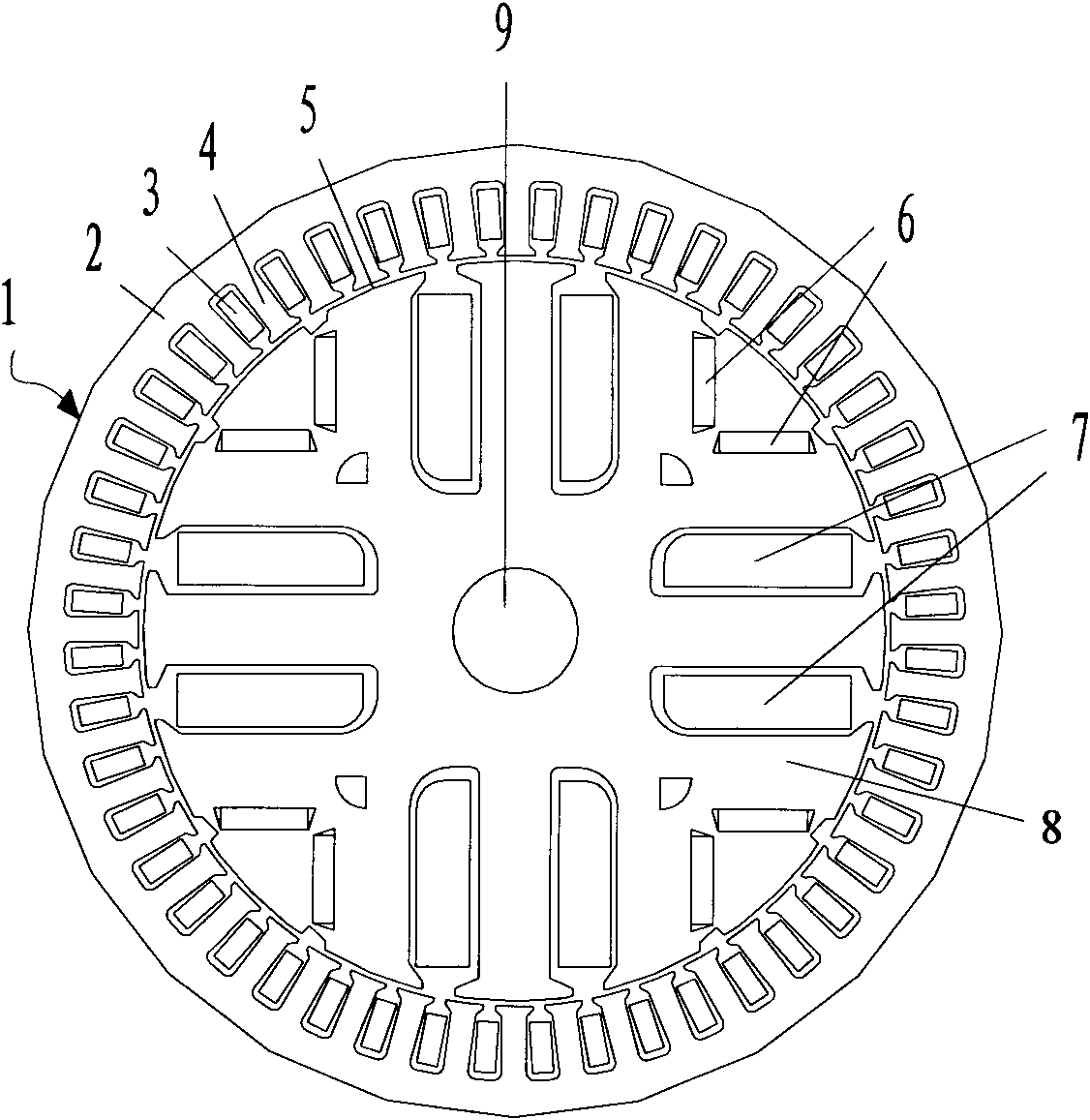

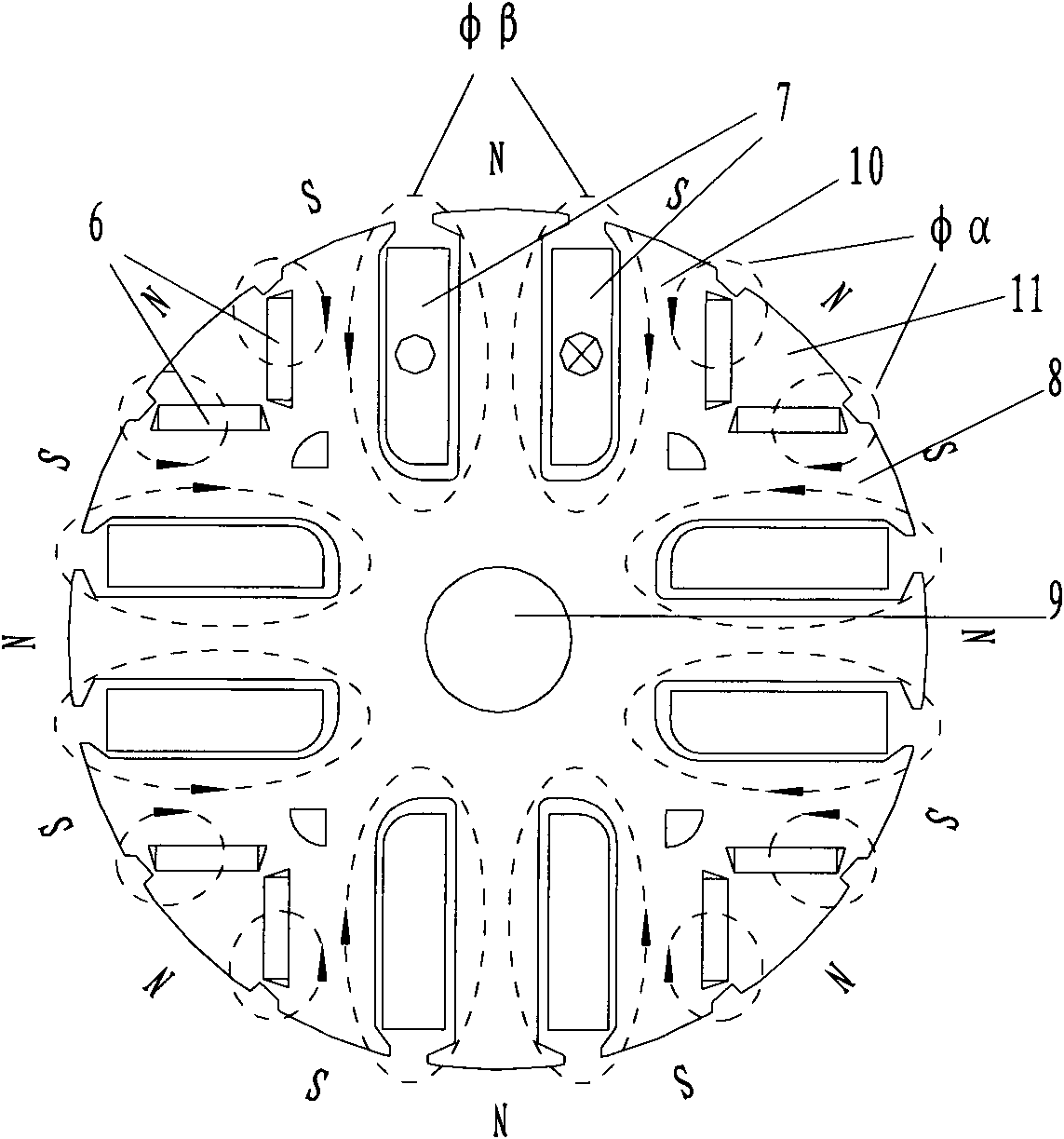

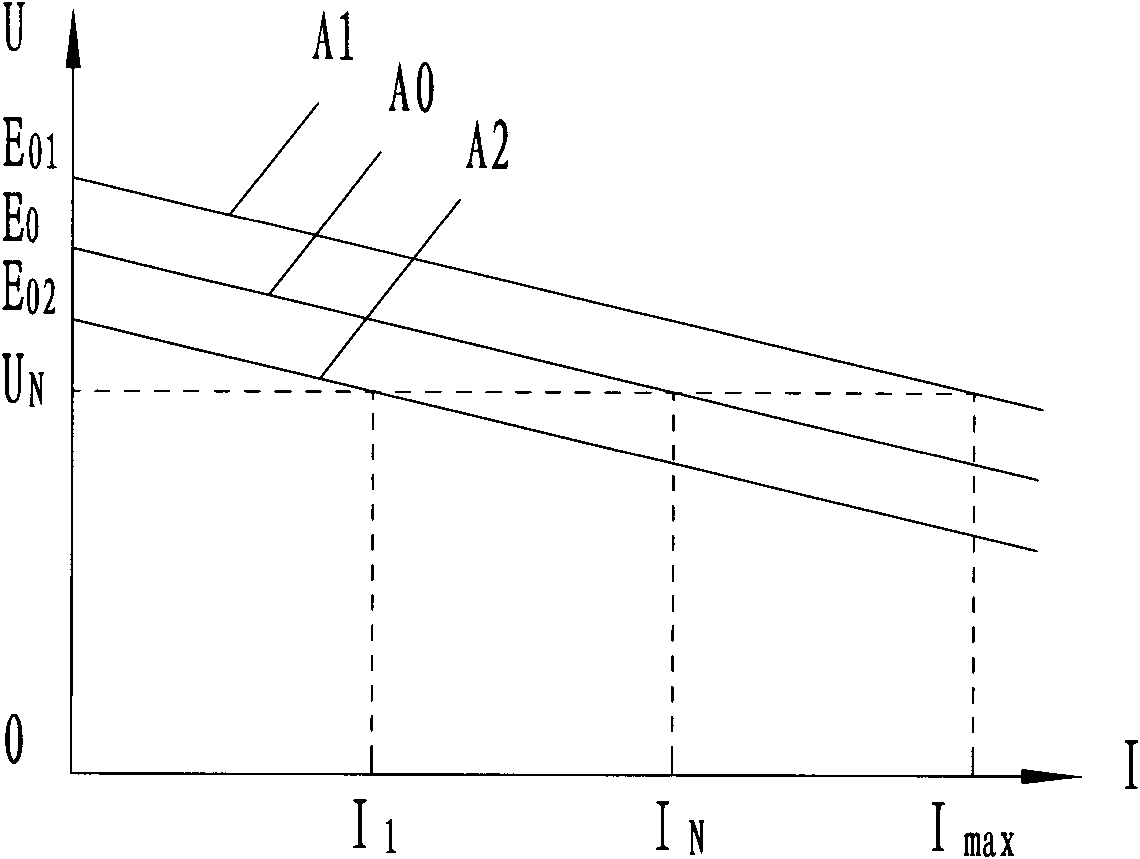

Compound excitation permanent magnet synchronous generator for electric vehicles

InactiveCN101662197AHighlight substantive featuresSignificant progressMagnetic circuit rotating partsElectric machinesPermanent magnet rotorElectrical conductor

The invention relates to a compound excitation permanent magnet synchronous generator for electric vehicles. An auxiliary electric excitation winding and built-in V-shaped magnetic steel are arrangedin a rotor iron core in the circumferential direction; the built-in V-shaped magnetic steel and a pole shoe form a permanent magnet pole, and the auxiliary electric excitation winding and an interwinding iron core form an excitation pole; the permanent magnet and the auxiliary electric excitation winding together generate armature induction potential, the air gap magnetic field can be adjusted conveniently by adjusting the magnitude and the direction of the DC excitation current in the electric excitation winding, and the purposes of high efficiency, energy saving and high-precision adjustmentof the voltage at an output end are achieved; meanwhile, the permanent magnet rotor is made of the V-shaped segmented magnetic steel, and holes are arranged in the pole shoe to lighten the weight ofthe rotor to avoid the high-speed deformation of the rotor; a groove is formed at the center of the pole shoe in the radial direction, and nonmagnetic good conductors are filled in the groove; and magnetism isolating grooves are arranged at two ends of the V-shaped magnetic steel, thereby inhibiting the static and dynamic armature reaction, improving the output voltage waveform, increasing the airgap magnetic density, reducing the magnetic leakage and increasing the output power. The compound excitation permanent magnet synchronous generator can smoothly operate at high power density, speed and precision.

Owner:苏州工业园区美能新能源有限公司 +1

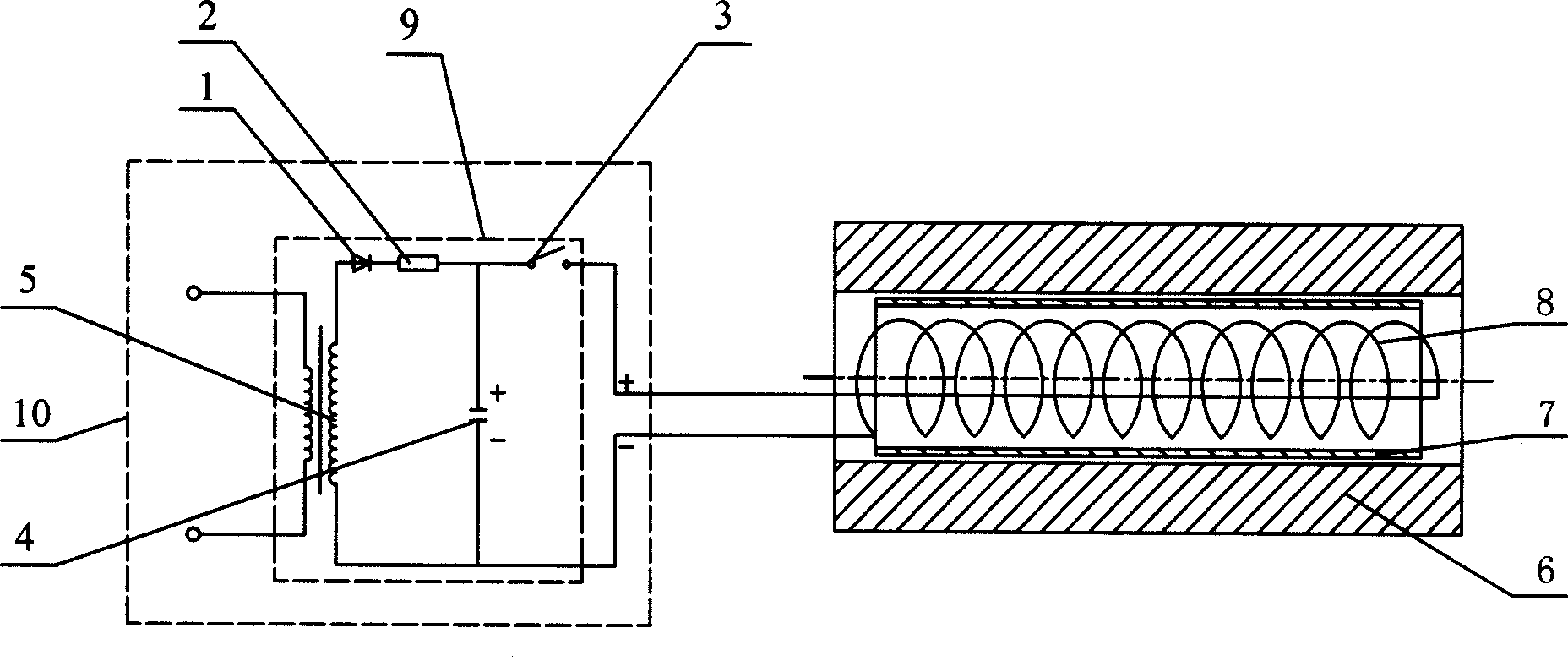

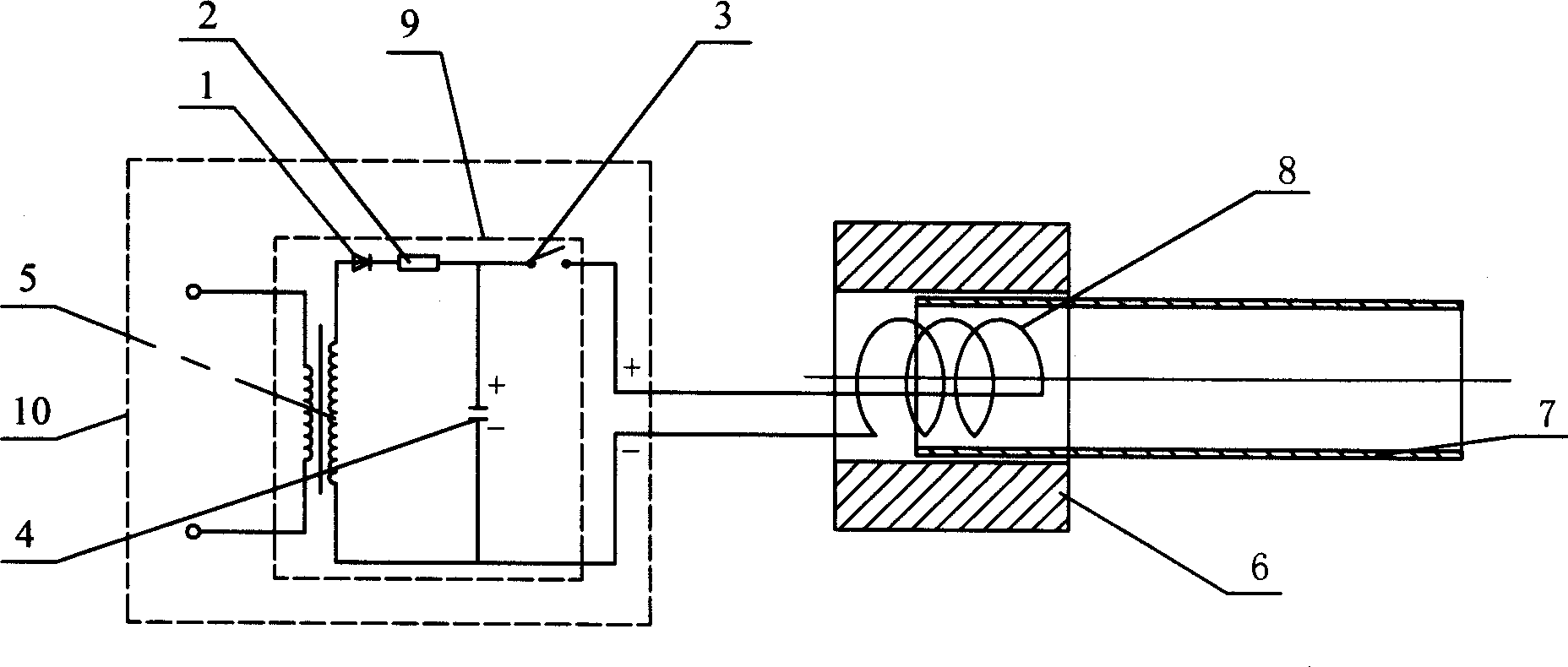

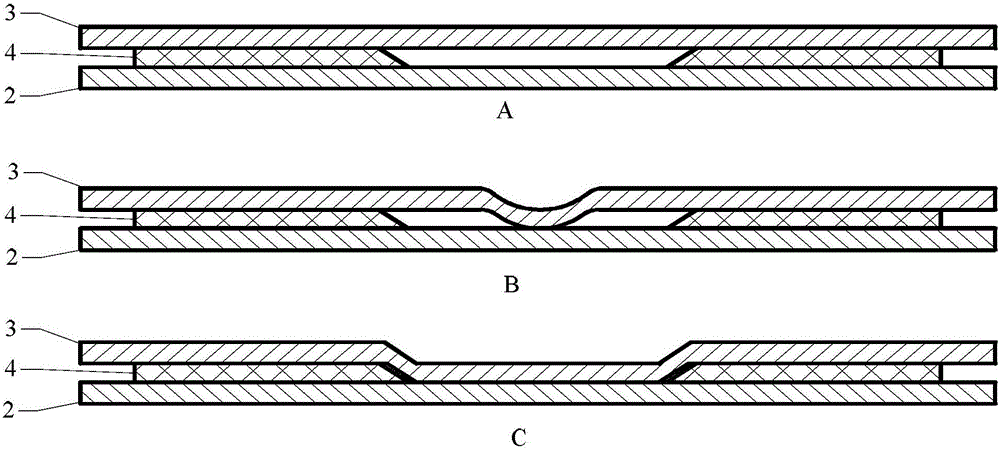

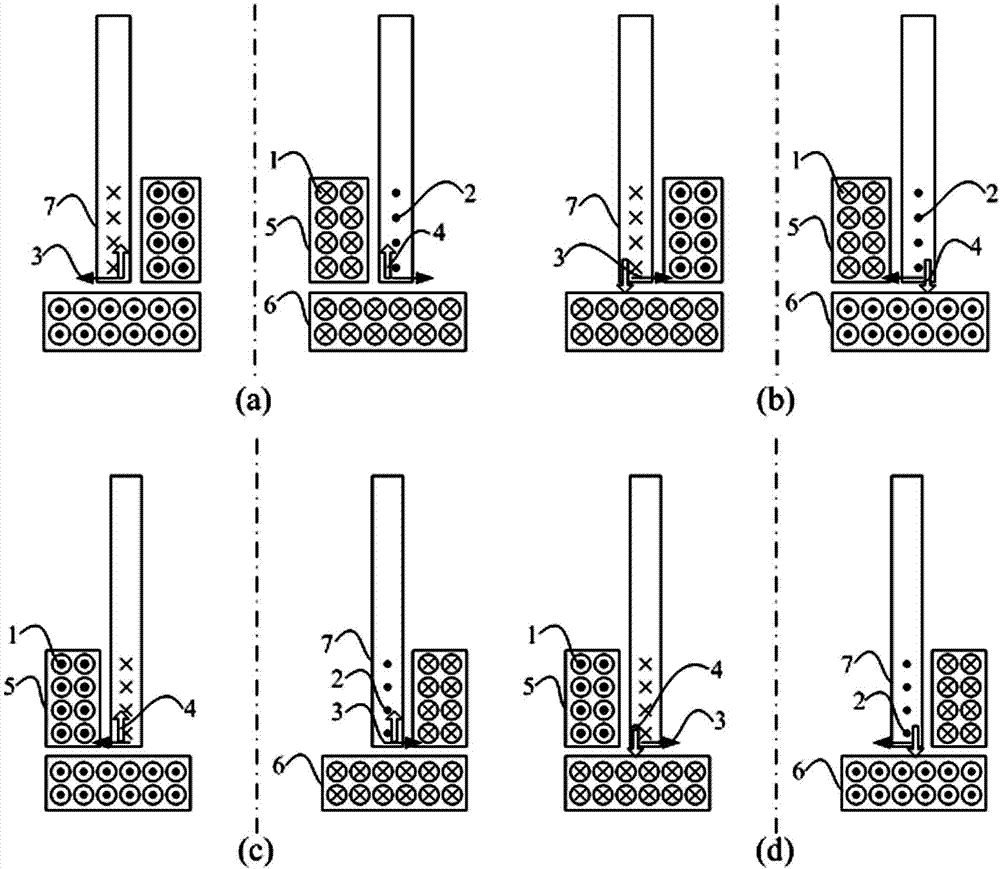

High-speed deformation connecting method and device for dissimilar metal sheets

ActiveCN105014224AFirmly connectedIncrease flexibilityNon-electric welding apparatusPower flowCurrent channel

The invention provides a high-speed deformation connecting method and device for dissimilar metal sheets and belongs to the field of plastic deformation connection. The high-speed deformation connecting method and device for the dissimilar metal sheets aim at solving the problem that the energy utilization rate existing in an existing sheet magnetic pulse connecting technology is low. According to the high-speed deformation connecting method and device for the dissimilar metal sheets, a magnetic pulse deformation connecting device is used for conducting discharging on a solenoid coil placed in an induced current channel, and the current of the coil enables an induced current to be produced in a connecting plate adjacent to the coil. The induced current flows in a loop formed by the connecting plate and the induced current channel. The coil current magnetic field and the induced current magnetic field produce superposition to be enhanced in gaps of the series loop of the solenoid coil and the connecting plate-induced current channel. The function for enhancing the magnetic field and the induced current of the connecting plate enables the connecting plate to bear normal downward high-strength pulse pressure load action, downward high-speed deformation and accelerated movement are generated, and then collisions happen between the connecting plate and a connected plate. Acute shearing plastic deformation occurs on the impact contacting interface, and the connection of the dissimilar metal sheets is achieved.

Owner:HARBIN INST OF TECH

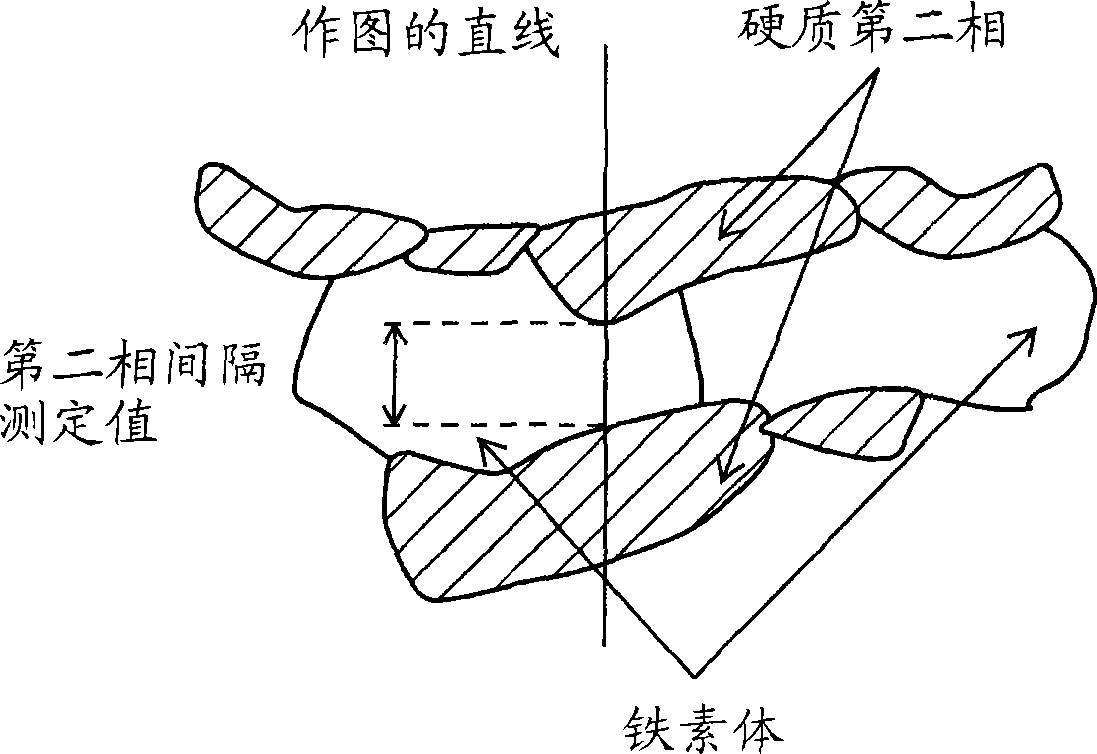

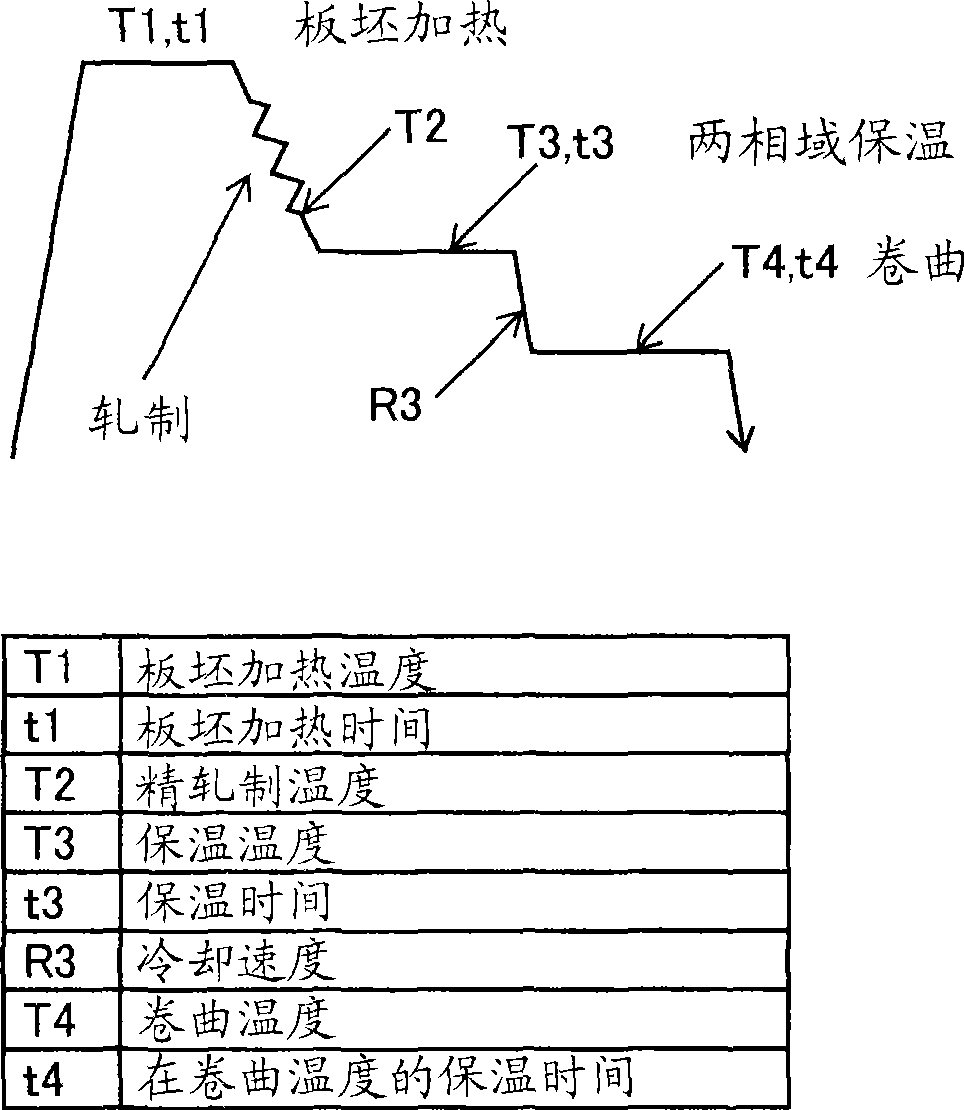

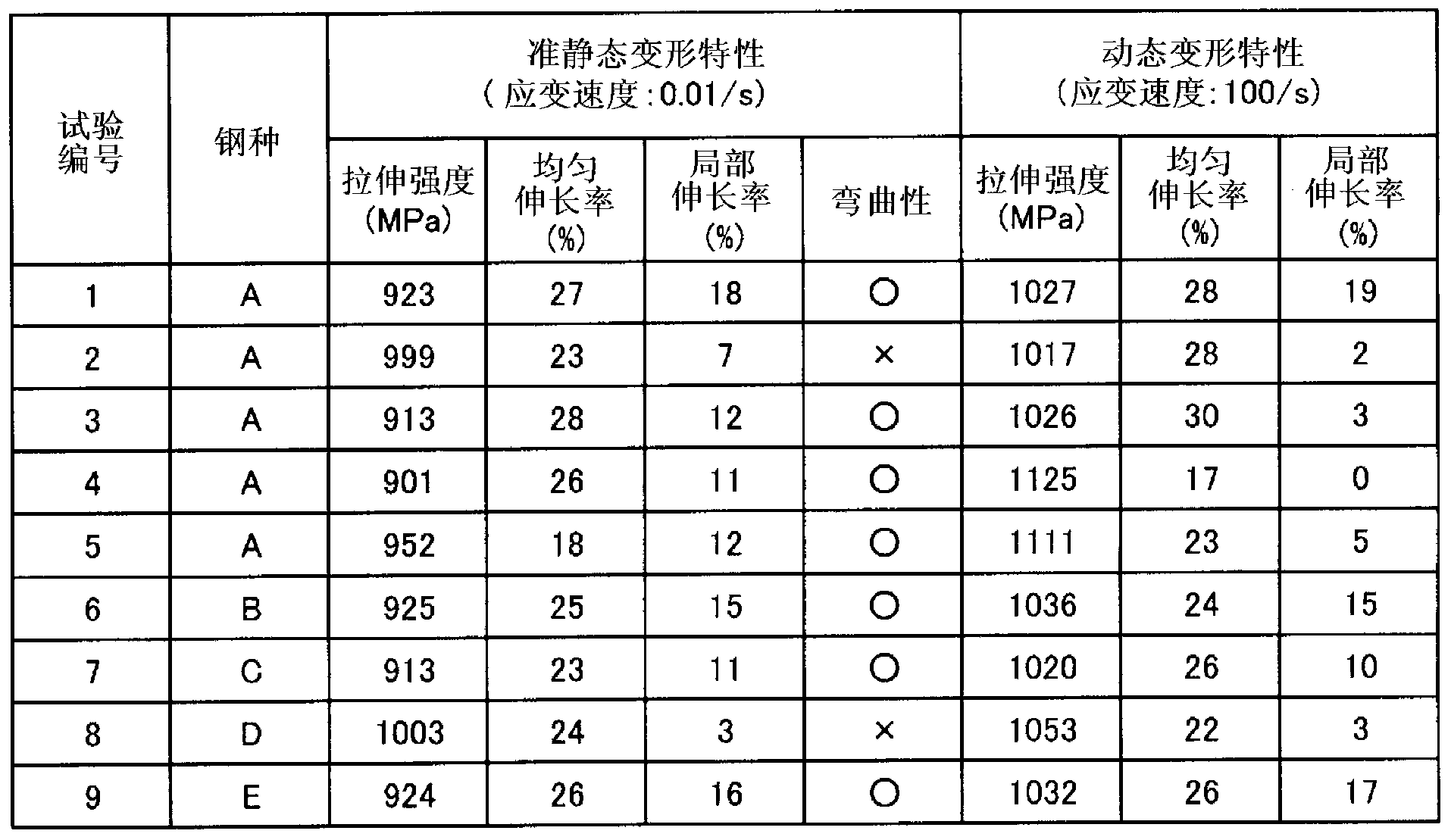

High-strength steel sheet and its production method

InactiveCN101460644AInhibition effectFurnace typesMetal rolling arrangementsSheet steelEnergy absorption

A high-strength steel sheet which has a metallic structure comprising a ferrite phase and a second hard phase dispersed in the steel sheet. In the metallic structure, the areal proportion of the second hard phase is 30-70%. In the ferrite phase, the areal proportion of ferrite having a crystal grain diameter not larger than 1.2 [mu]m is 15-90% and the average grain diameter of ferrite having a crystal grain diameter not larger than 1.2 [mu]m (ds) and the average grain diameter of ferrite having a crystal grain diameter exceeding 1.2 [mu]m (dL) satisfy the relationship dL / ds=3. The size of the ferrite crystal grains has been reduced by reducing the amount of alloying elements to be added. The steel sheet hence has an increased strength. The steel sheet has an excellent balance between strength and ductility, which is important for press molding. It is excellent in energy absorption in high-speed deformation. Also provided is a process for producing the steel sheet.

Owner:HONDA MOTOR CO LTD

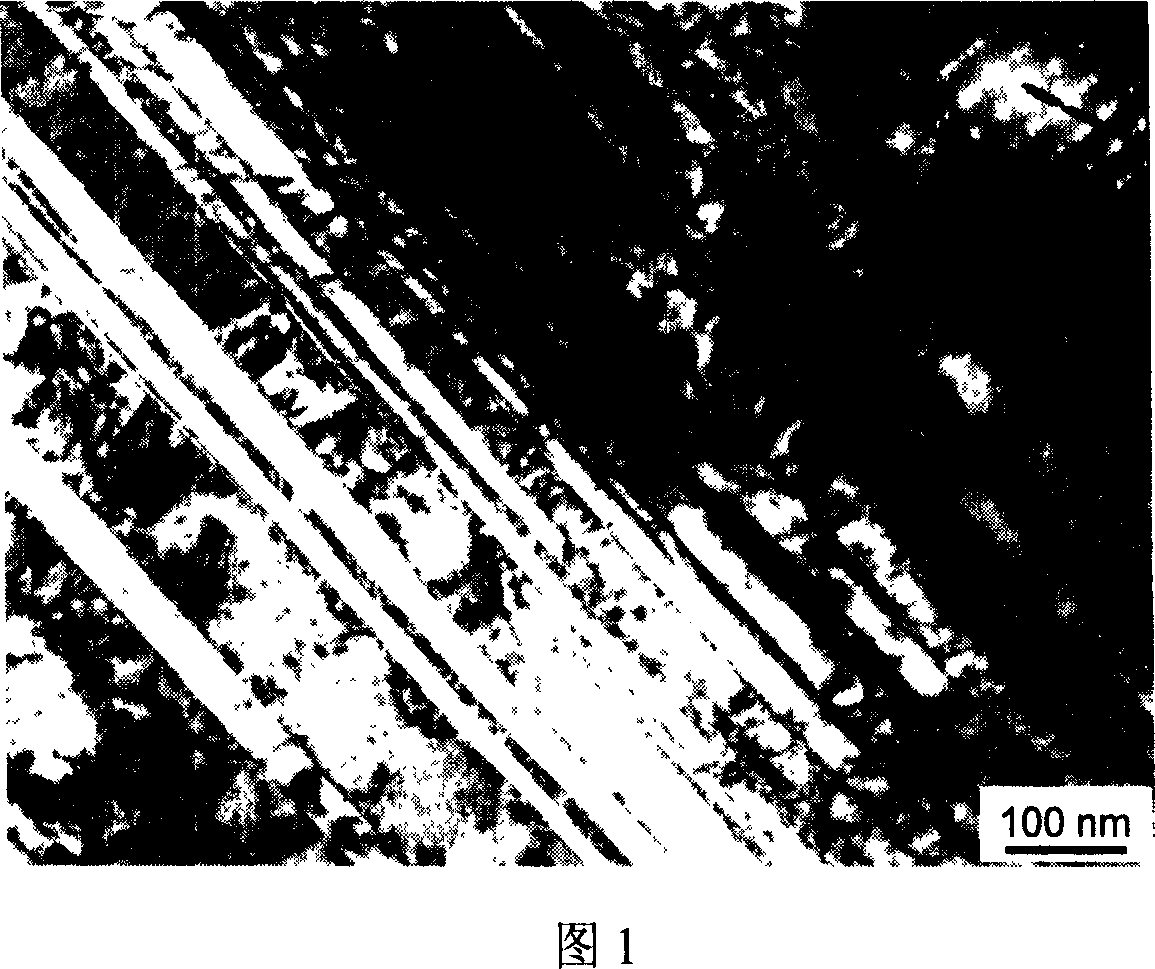

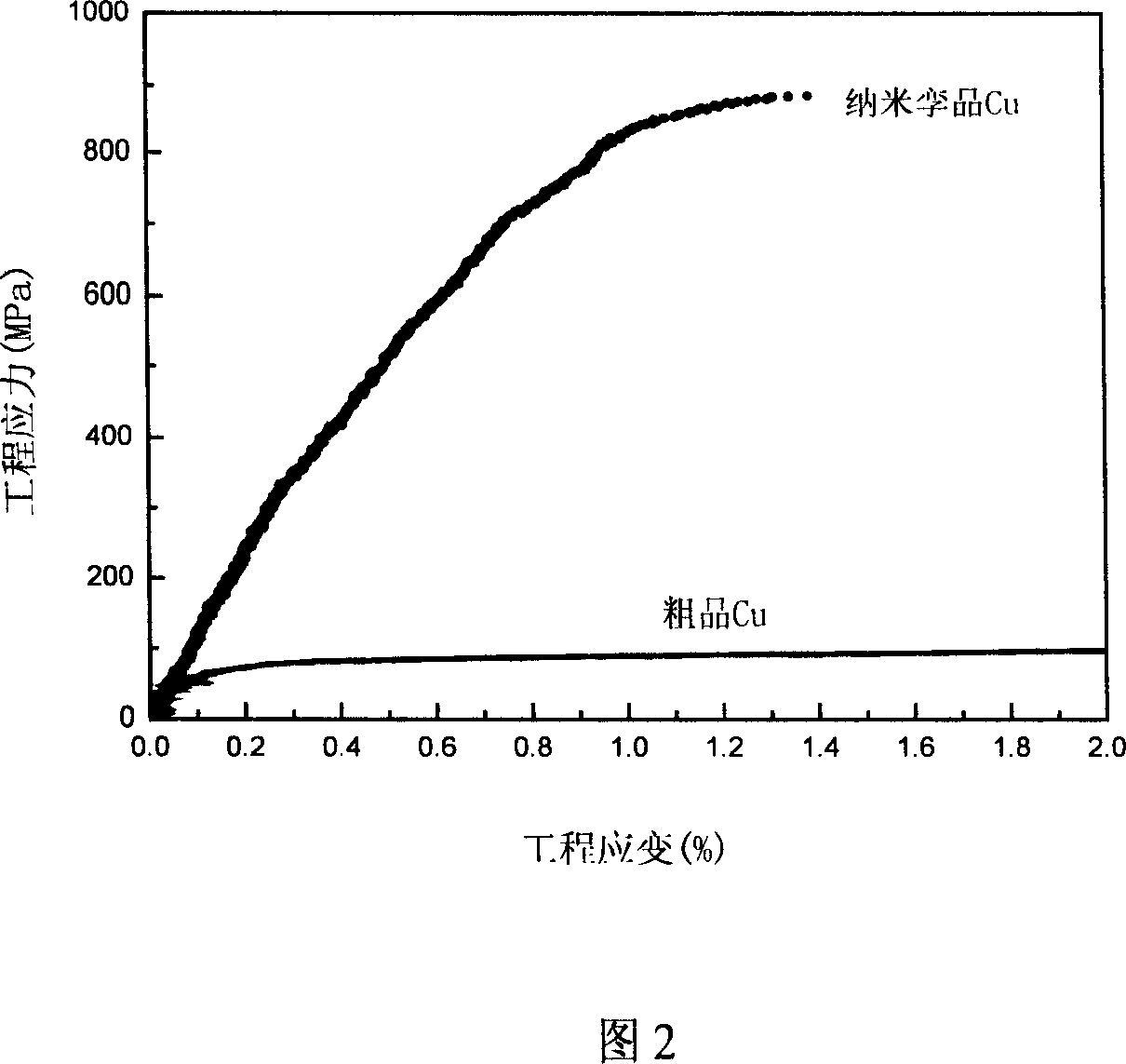

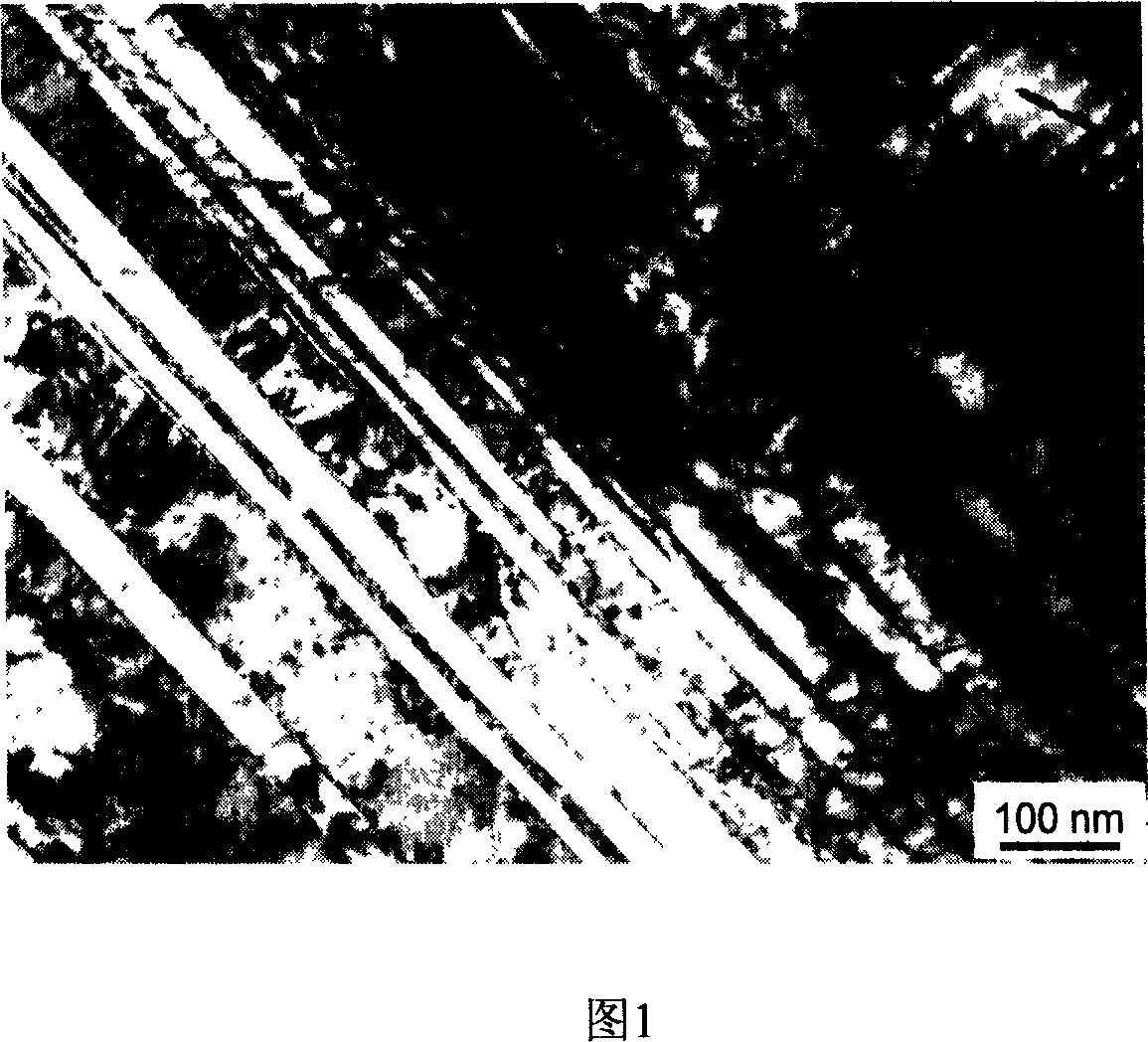

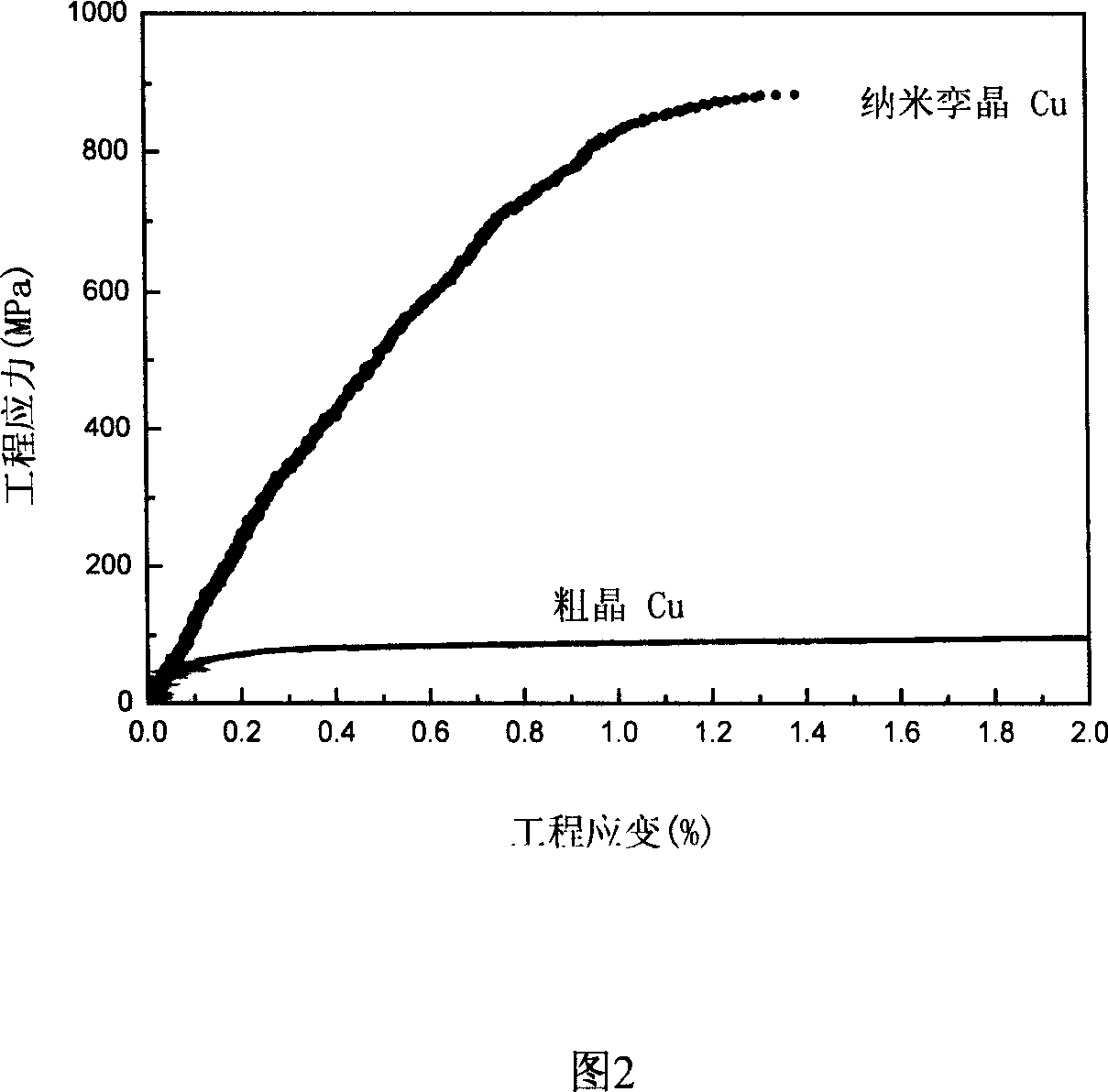

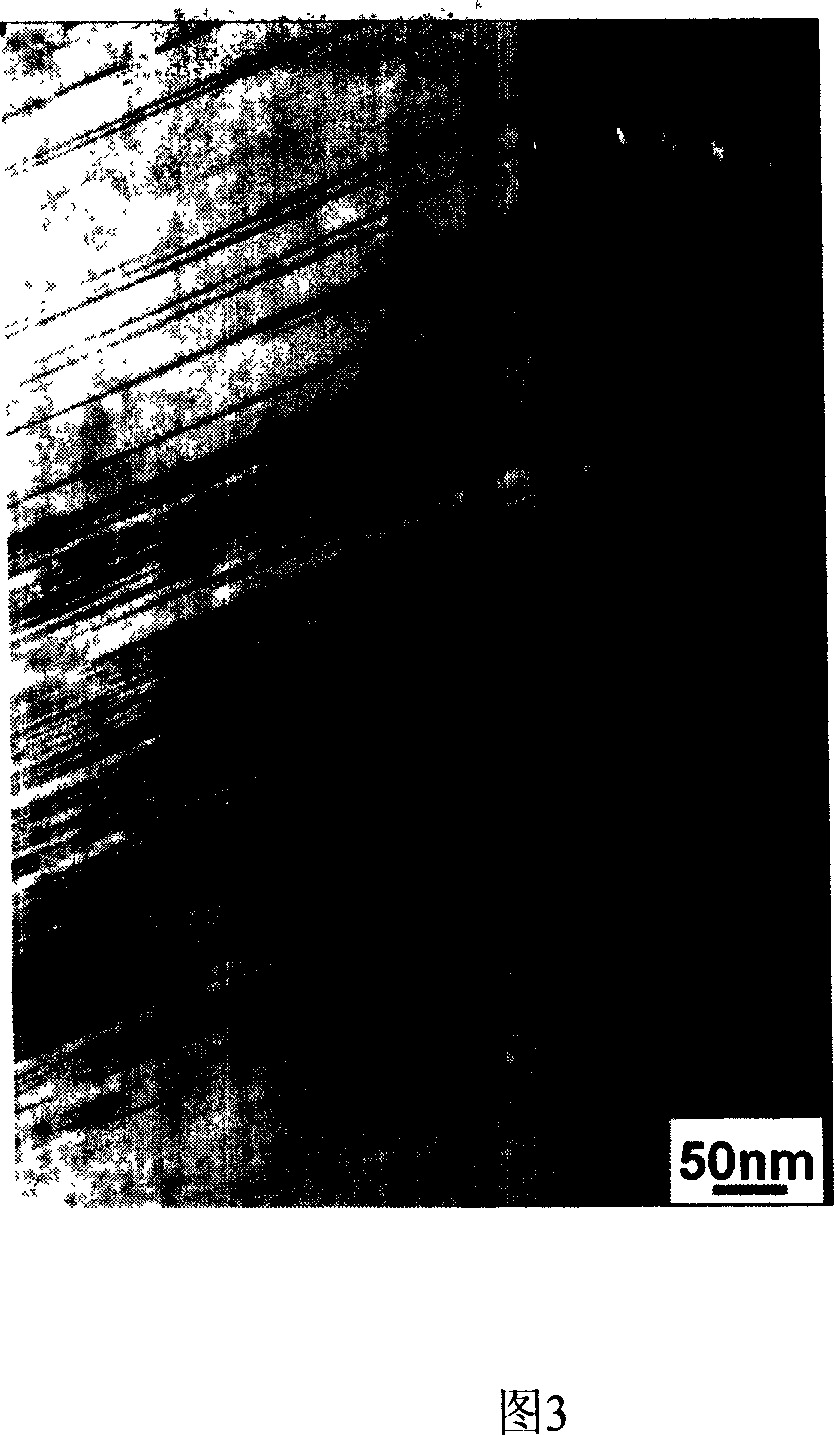

Superhigh strength high conduction block pure copper material and preparation method

This invention relates to an improved technique of nanometer crystal material, particularly relating a metallic pure copper of block high density nanometer twin crystal with super strong intensity, high conductivity and its preparation. Key feature of microstructure of block pure copper is of mechanical twin crystal of fascicularis high density nanometer, average slice thickness of twin crystal is some ten nanometers, length is hundreds nanometers. Both interior of basal body and twin crystal has dislocation with high density, its tensile yield strength is about 750MPa, its resistivity achieves at 1.81*10-8 omega m. Preparation of block pure copper material with super strong intensity, high conductivity is using dynamic high speed transfiguring technique, to carry out many times process of single direction for block pure copper, modified deformation rate: circumscription is 102-104s-1;Modified deformation variance: total deformation variance is more than 1.8 (computing method: epsilon=H0 / H greater than 1.8); deformation temperature: 30deg.C to 200deg.C.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

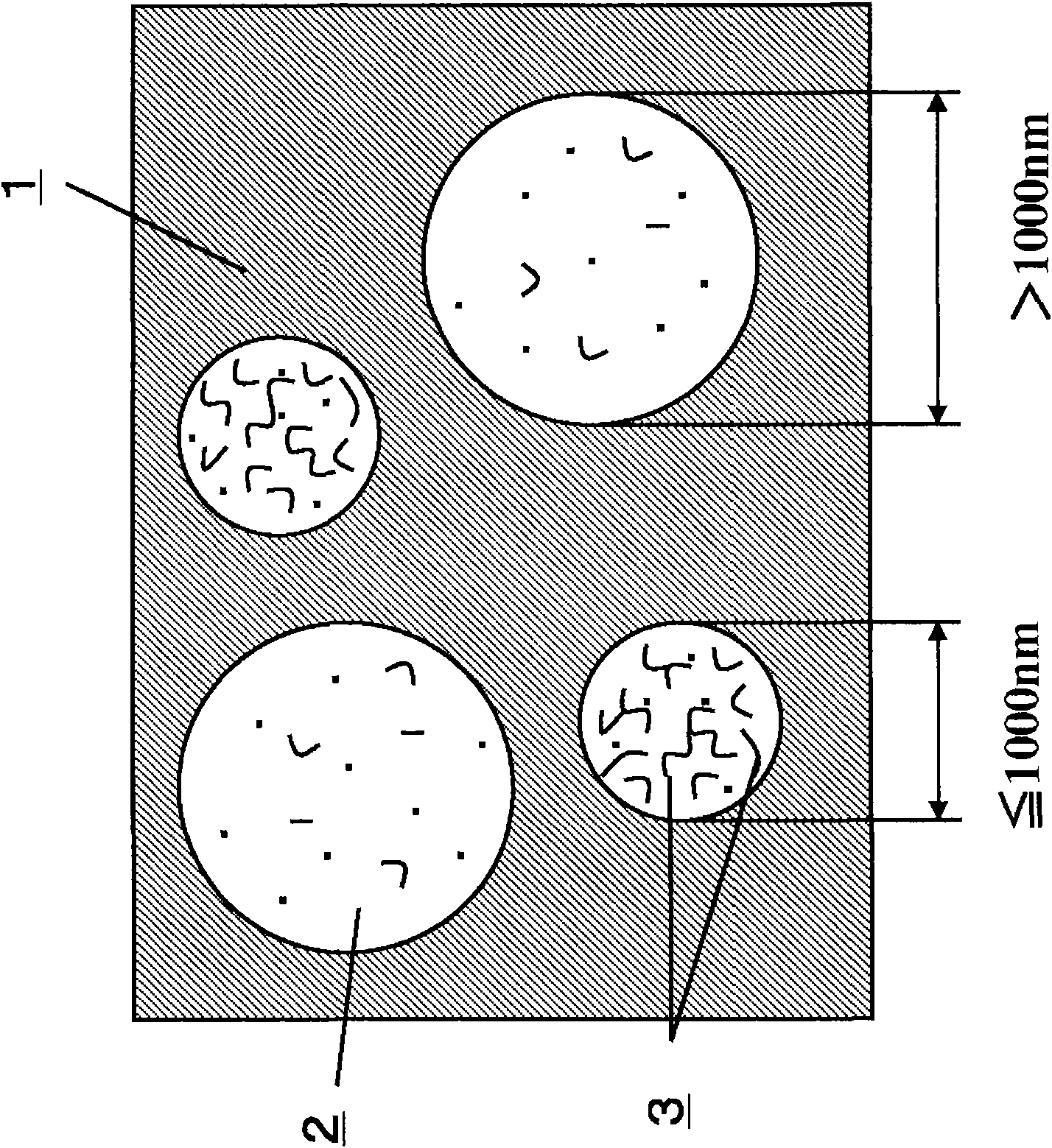

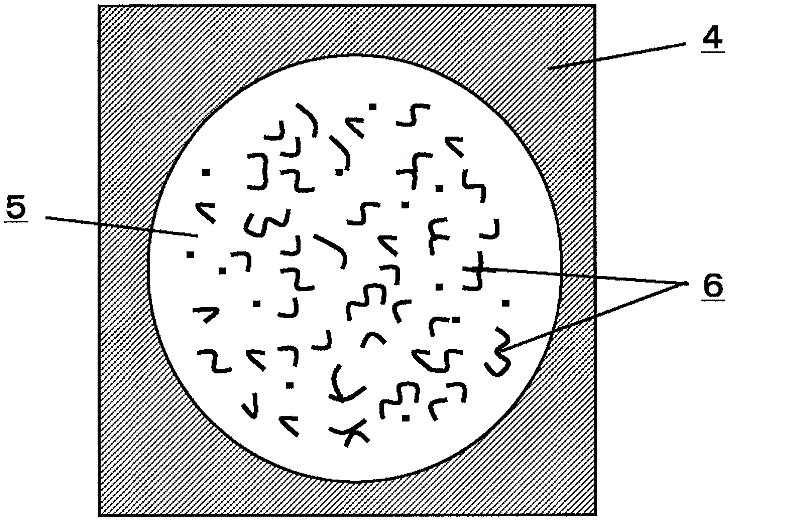

Thermoplastic resin composition, process for producing the same and molding

This invention is a thermoplastic resin composition comprising a thermoplastic resin (A) and a reactive functional group-containing resin (B), which has a specific structure in the morphology of the resin composition observed by transmission electron microscopy tomography, and the relaxation time T1C of each carbon nucleus by the solid NMR measurement of the thermoplastic resin composition containing a polyamide resin is kept in a specific range. The composition is excellent in the balance between contradictory properties such as impact resistance and heat resistance, remarkably exhibits a peculiar viscoelastic behavior not observed in the conventional polymeric materials, and is remarkably excellent in impact energy absorbing performance and vibration energy absorbing performance at the time of high-speed deformation.

Owner:TORAY IND INC

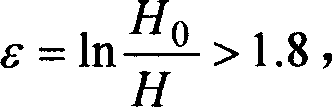

Method for raising metal and alloy strength

This invention relates to a technique that raises strength of metal and alloy, especially provides a method that in the precondition that chemical composition of metal and alloy is not changed, raising strength of metal and alloy by technique of dynamic state plastic deformation. Utilize technique of dynamic state high speed deformation, progress many manipulations with low temperature single direction, deformed strain rate is: 101-104s-1;Deformed strain variable is: total deflection exceed 1(computing method is:epsilon=ln H0 / H>1),epsilon is deflection, H0 is thickness of material without deformation, H is thickness of material with deformation; Deformation temperature is: 30deg.C to -200deg.C. This invention utilizes technique of high speed deformation, preparative method is simple, and it is easy to control parameter of deformation technology and deformation temperature. It can produce metal and alloy with high intensity through necessarily improve orthodox deformation technique, optimize technology parameter and deformation temperature. This invention does not chemical constituent of materials, only through adjust material microstructure to strengthen metal and alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

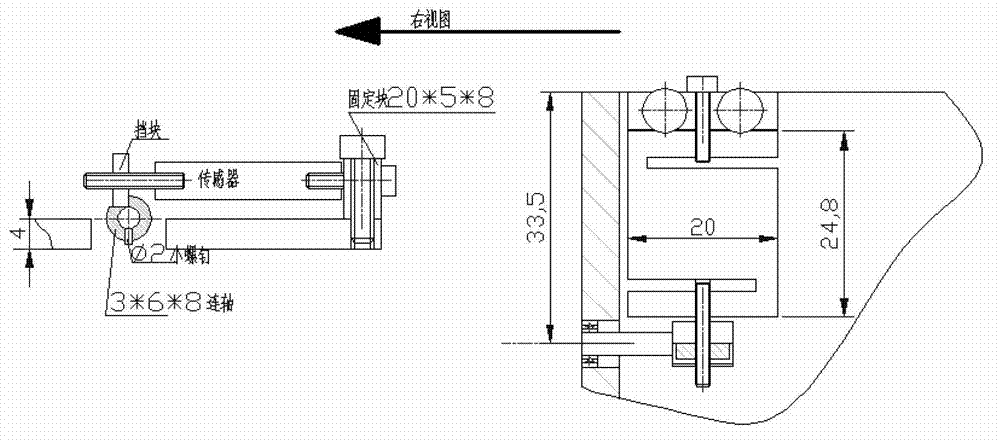

Miniature stretching rheological device for in-situ structure detection of polymer film material, and experimental method thereof

ActiveCN103091181AEasy clampingEasy to replaceInvestigating material ductilityFourier transform on finite groupsSpectrograph

The invention provides a miniature stretching rheological device for in-situ structure detection of a polymer film material, and an experimental method thereof. Accurate temperature control and high-speed deformation of a polymer film sample are achieved in a limited space; strain and strain rate can be accurately controlled and continuously adjusted at the same time; the device adopts a brushless servo motor of a hollow core cup to drive a driving shaft to rotate; a stretching rheological operation is exerted on the sample; the rotating speed and displacement of the motor are accurately controlled by Labview control program combined with a hall sensor and an encoder of a motor; a driven shaft of the device is connected with a miniature tension sensor; and the change of tension in the stretching rheological process is tracked in real time. The miniature stretching rheological device has the advantages of being small in volume, light in weight, convenient to install, suitable for collocation with equipments such as a microfocus X-ray diffraction station, an optical microscope, and a Fourier transform microscopic infrared spectrograph, and is a good device for in-situ research of internal structure change in the high-polymer material stretching rheological process under different temperature conditions.

Owner:UNIV OF SCI & TECH OF CHINA

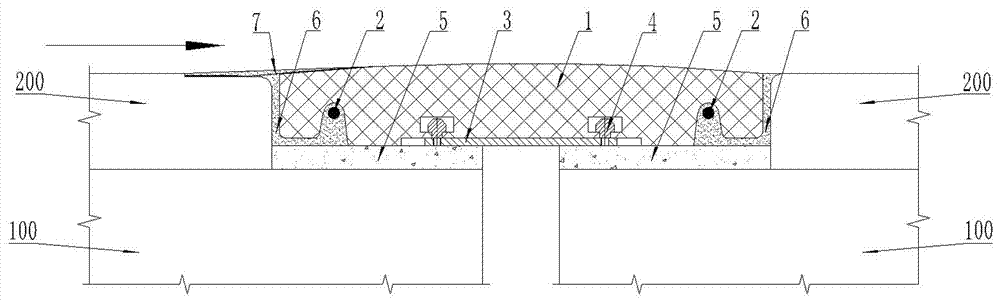

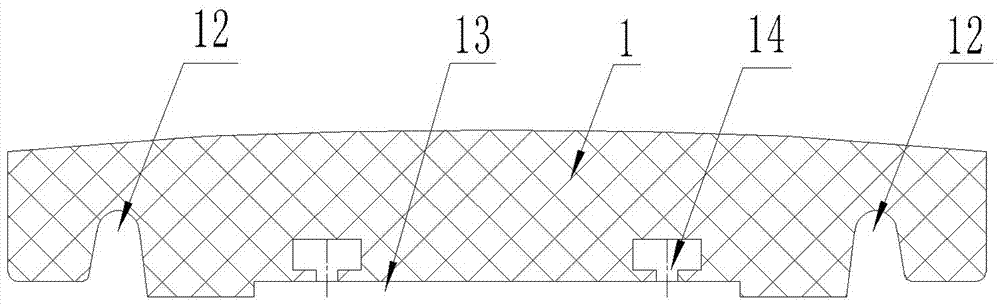

A combined type seamless expansion joint structure used for bridge pavement structures

ActiveCN106906716AEffective bondingMeet the forceClimate change adaptationPaving detailsFiberArchitectural engineering

A combined type seamless expansion joint structure used for bridge pavement structures is disclosed. The expansion joint structure includes a straddle steel plate spanning an expansion joint, and an elastic telescoping component between two pavement structures. The bottom surface of the straddle steel plate is provided with a self-leveling mortar base layer paved on two sides of the top surface of the expansion joint. The elastic telescoping component covers the straddle steel plate and the self-leveling mortar base layer. Bottom two sides of the elastic telescoping component are provided with two mounting slots longitudinally. Fiber rods are disposed in the mounting slots. Anchoring adhesion seams are between the elastic telescoping component and the pavement structures. The anchoring adhesion seam and the mounting slot which are at same side are communicated through a connecting slot in the bottom surface of the elastic telescoping component. The anchoring adhesion seams, the mounting slots and the connecting slots are filled with flexible structural glue. The expansion joint structure has low-temperature toughness, a characteristic of high-speed deformation resilience under heavy loads and a simple structure, and is convenient to construct.

Owner:东莞瑞固工程材料科技有限公司

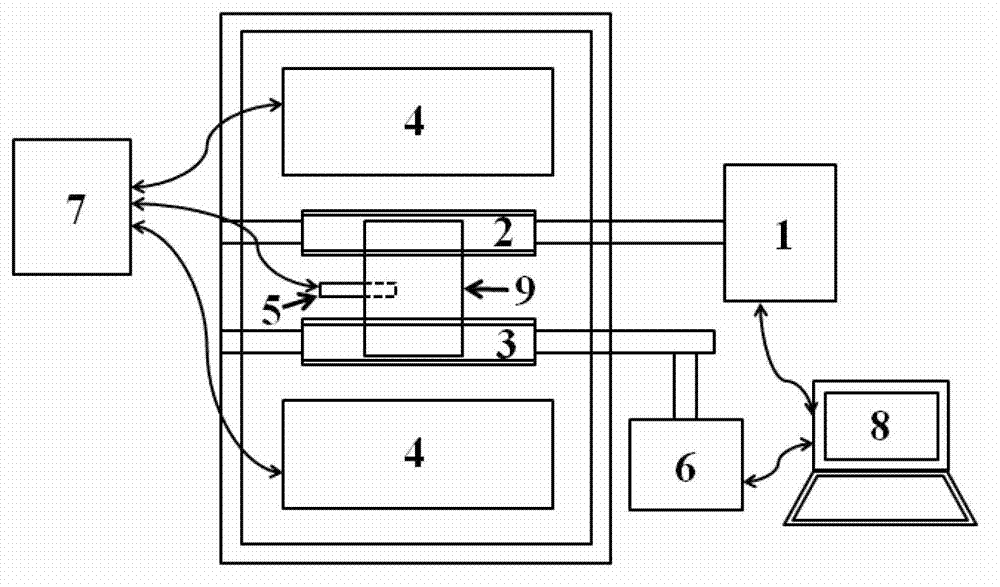

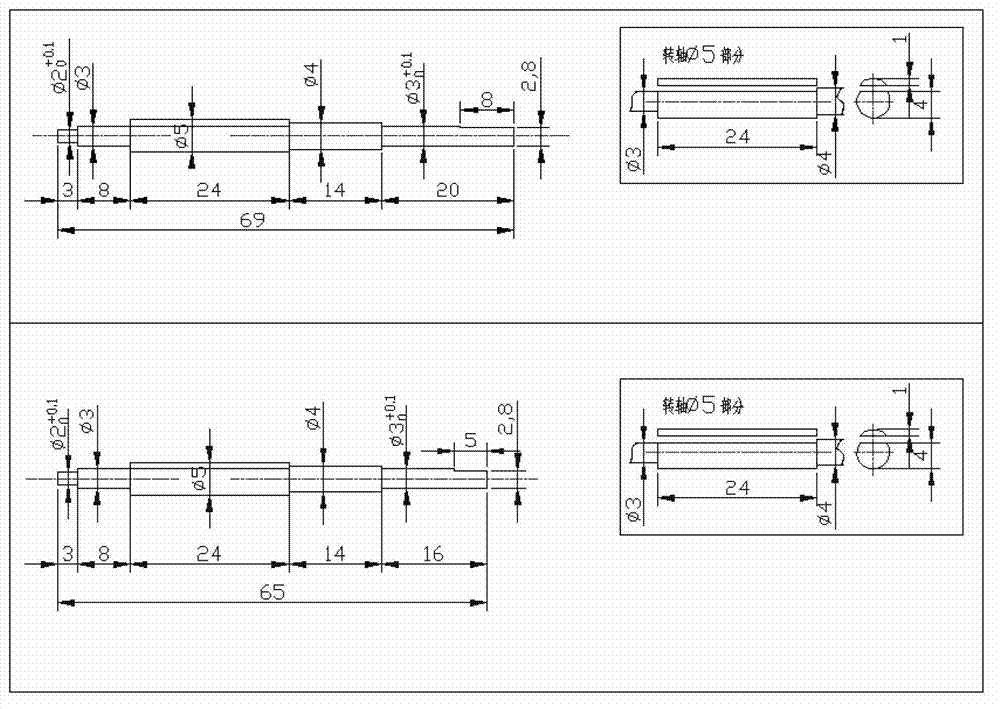

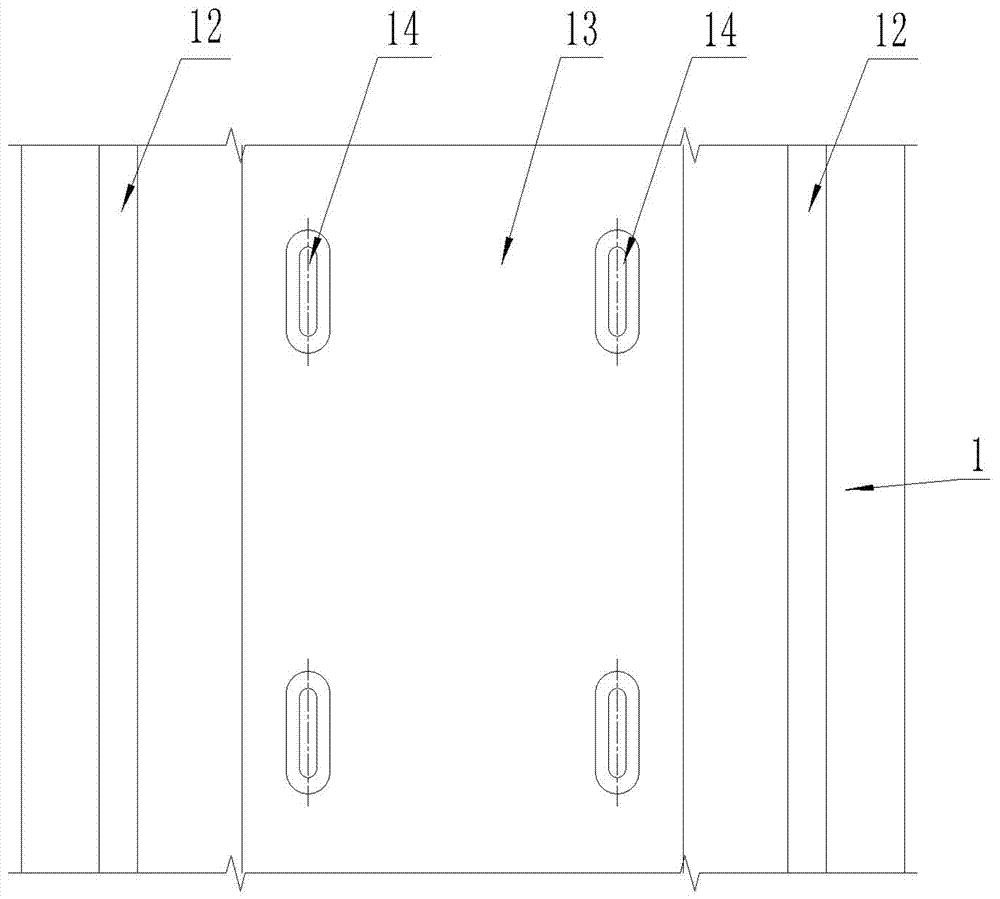

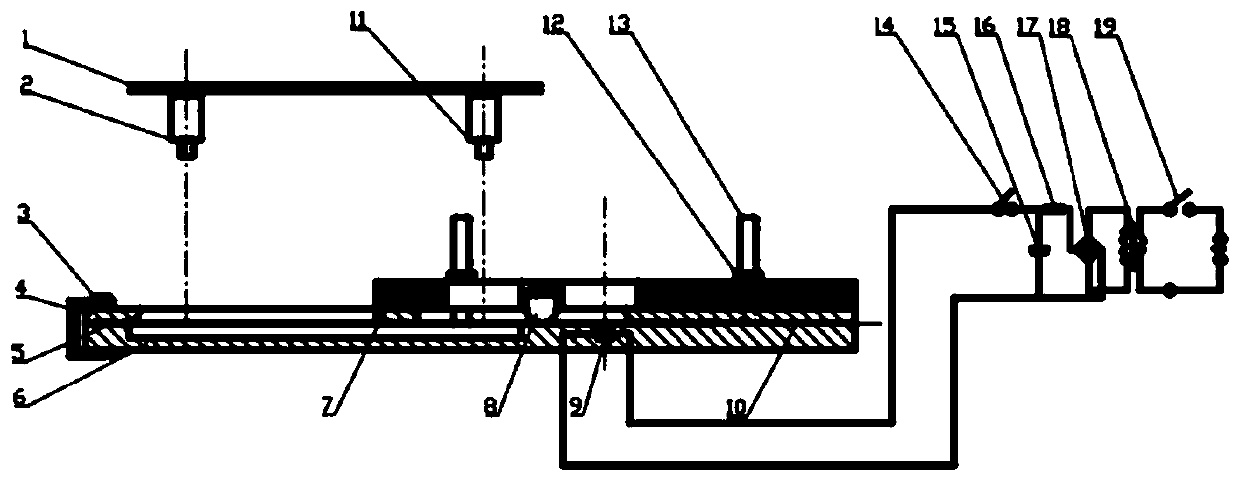

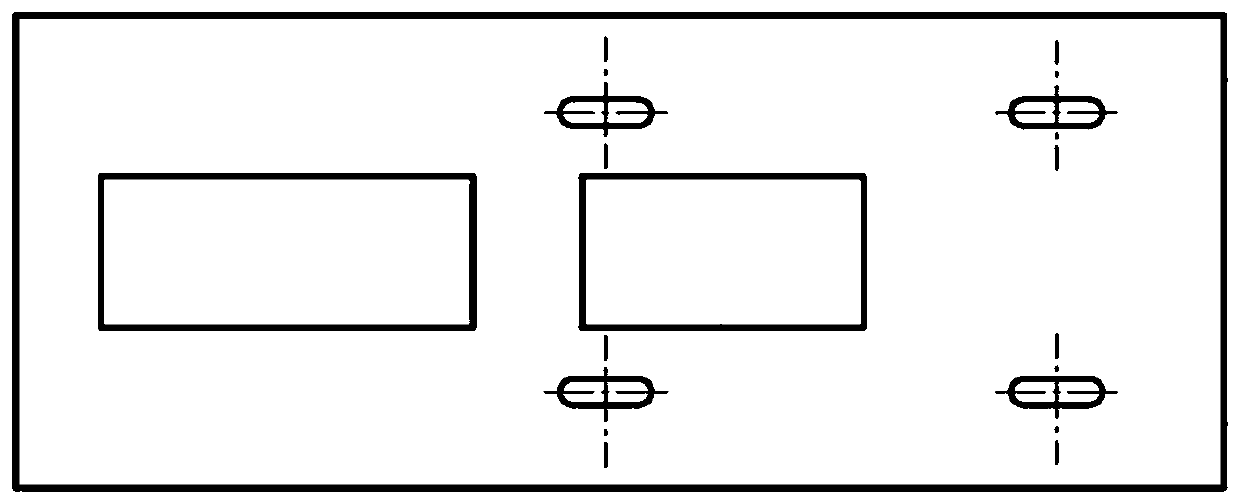

Metal sheet high-speed tensile test device driven by electromagnetic force

ActiveCN110658070AAccurately establishedAccurately getMaterial strength using tensile/compressive forcesClassical mechanicsEngineering

The invention relates to a metal sheet high-speed tensile test device driven by electromagnetic force. The tensile test device comprises a stress shooting camera, an insulating rigid plate, an experimental platform, a strain shooting camera and a power supply unit; a tensile sample is pressed on the experimental platform through the insulating rigid plate; two square holes in the middle of the insulating rigid plate are positioned above two speckle areas of the tensile sample respectively; a groove is formed in the left half part of the upper surface of the experimental platform and located under two speckle areas of the tensile sample, and a coil base in the right half part of the experimental platform is located under the right sides of the two speckle areas of the tensile sample; the power supply unit comprises a coil, and the coil is electrified to generate an electromagnetic force acted on the tensile sample, so that the right side of the tensile sample expands at high speed to drive the left side to generate tensile deformation; and the stress shooting camera and the strain shooting camera face the two speckle areas of the tensile sample respectively to acquire deformation information of the tensile sample. According to the test device, a stress-strain curve of the material in the high-speed deformation process can be quickly and accurately obtained.

Owner:华瞬(深圳)智能装备有限公司

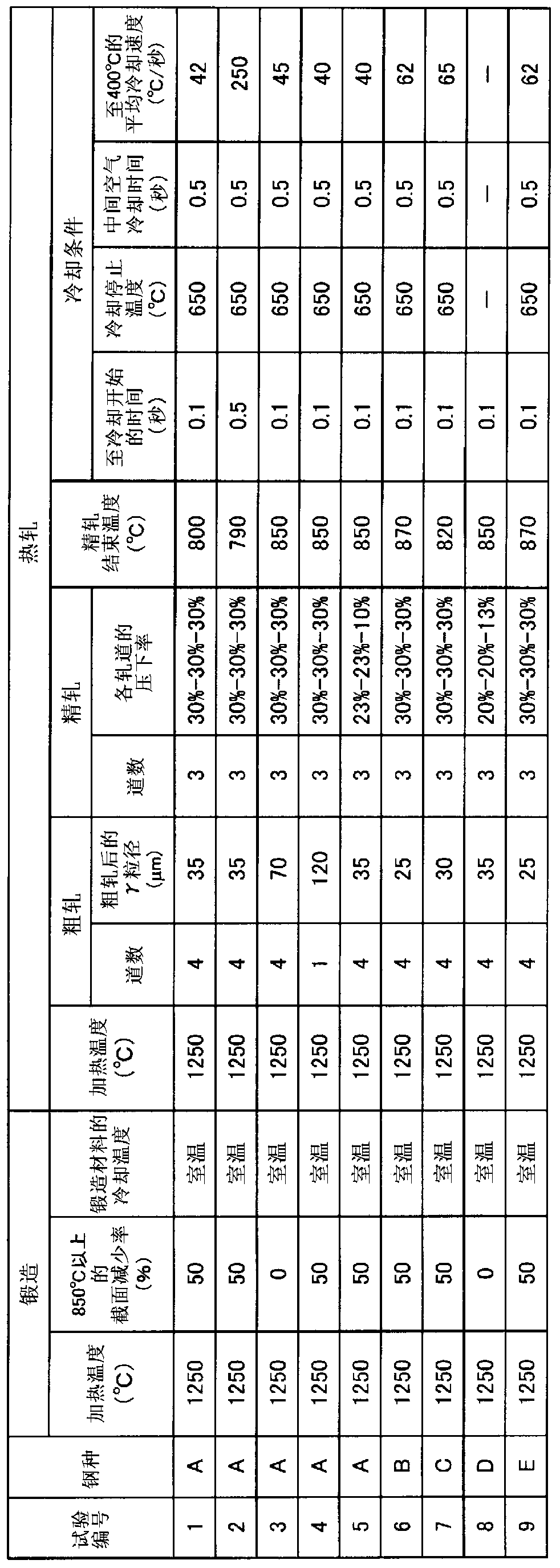

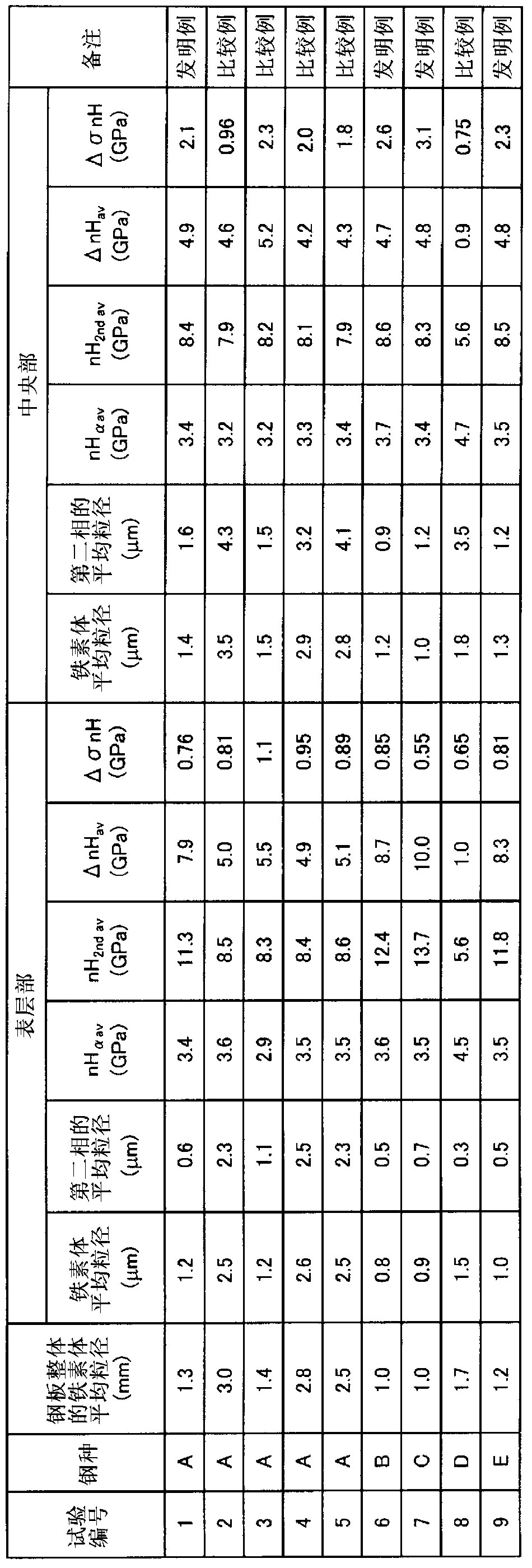

Hot-rolled steel sheet, cold-olled steel sheet, and plated steel sheet each having exellent uniform ductility and local ductility in high-speed deformation

InactiveCN103249853AImprove toughnessImprove crash safetyHot-dipping/immersion processesFurnace typesSurface layerMulti phase

The present invention relates to a hot-rolled steel sheet, a cold-rolled steel sheet, and a plated steel sheet having improved uniform ductility and local ductility at a high strain rate. A multi-phase hot-rolled steel sheet according to one mode of the present invention has a metallurgical structure having a main phase of ferrite with an average grain diameter of at most 3.0 µm and a second phase including at least one of martensite, bainite, and austenite. In the surface layer, the average grain diameter of the second phase is at most 2.0 µm, the difference (”nH av ) between the average nanohardness of the main phase (nH ±av ) and the average nanohardness of the second phase (nH 2nd av ) is 6.0 - 10.0 GPa, the difference (”ÃnH) of the standard deviation of the nanohardness of the second phase from the standard deviation of the nanohardness of the main phase is at most 1.5 GPa, and in the central portion, the difference (”nH av ) between the average nanohardnesses is at least 3.5 GPa to at most 6.0 GPa and the difference (”ÃnH) between the standard deviations of the nanohardnesses is at least 1.5 GPa.

Owner:NIPPON STEEL CORP

Method and device for electromagnetically forming metal pipe fitting in radial and axial loading mode

ActiveCN103406418BAdjustable loading methodMeet the process requirementsPipe fittingAxial compression

The invention discloses a method and a device for electromagnetically forming a metal pipe fitting in a radial and axial loading mode. The device mainly comprises an eddy current coil, magnetic field coils and power systems. The eddy current coil generates induced eddy currents, the magnetic field coils generate radial magnetic fields, and the eddy current coil and the magnetic field coils are powered by the power systems. The method and the device have the advantages that electromagnetic force can be radially and axially loaded simultaneously in a procedure for electromagnetically forming the metal pipe fitting, an electromagnetic force loading mode can be adjusted, and accordingly machining requirements of different workpieces can be met; the axial compression type pipe fitting is electromagnetically expanded, so that the thickness reduction of a pipe wall in an expansion procedure can be effectively reduced, the forming limit of a formed workpiece is increased, and the forming performance of the formed workpiece is improved; high-speed deformation experiment conditions in different load forms can be provided for metal pipe fittings by the method for electromagnetically forming the metal pipe fitting in the radial and axial loading mode, and novel experiment measures are provided for research on high-speed deformation mechanisms of materials.

Owner:湖北继扬电力科技有限公司

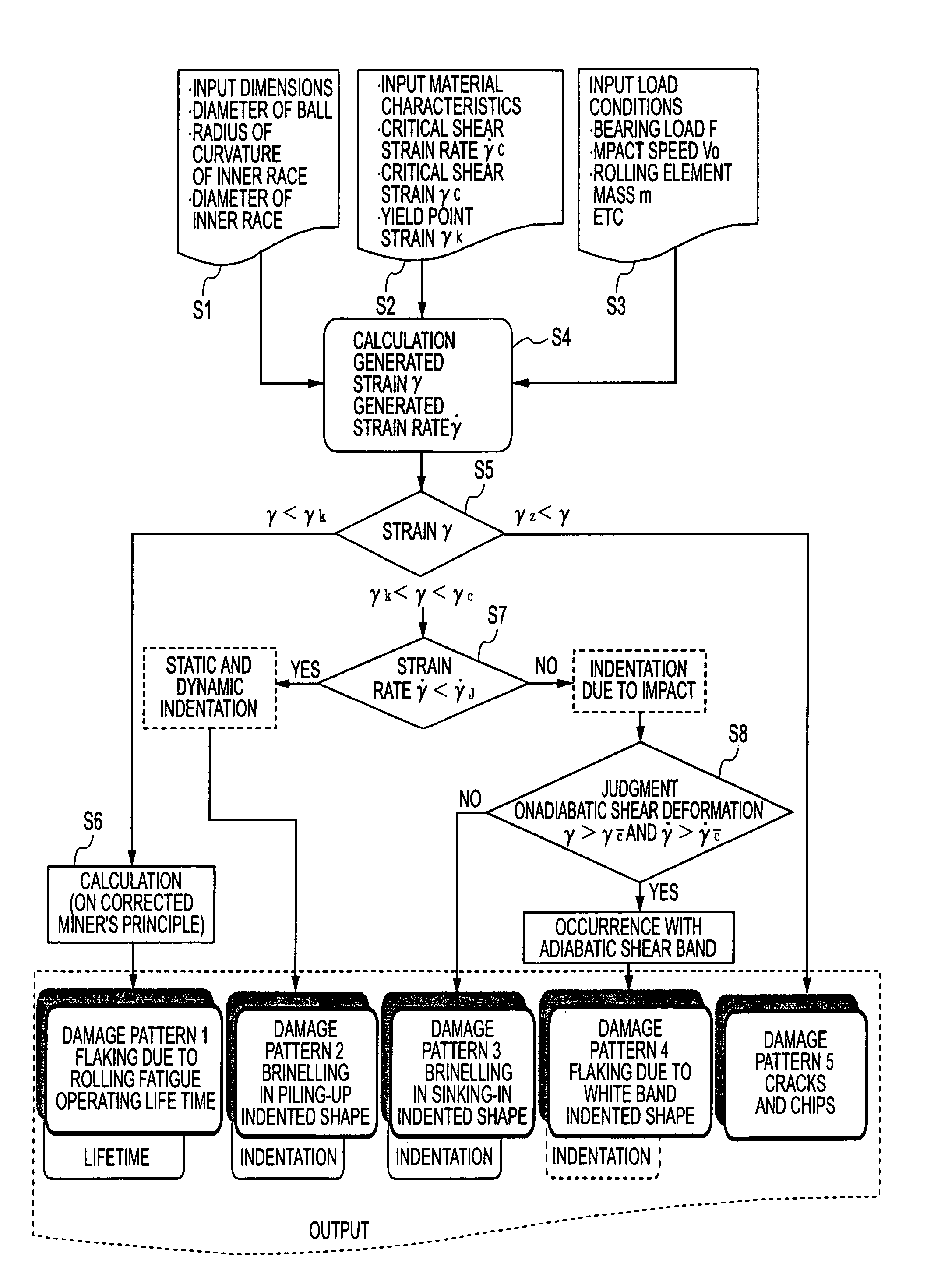

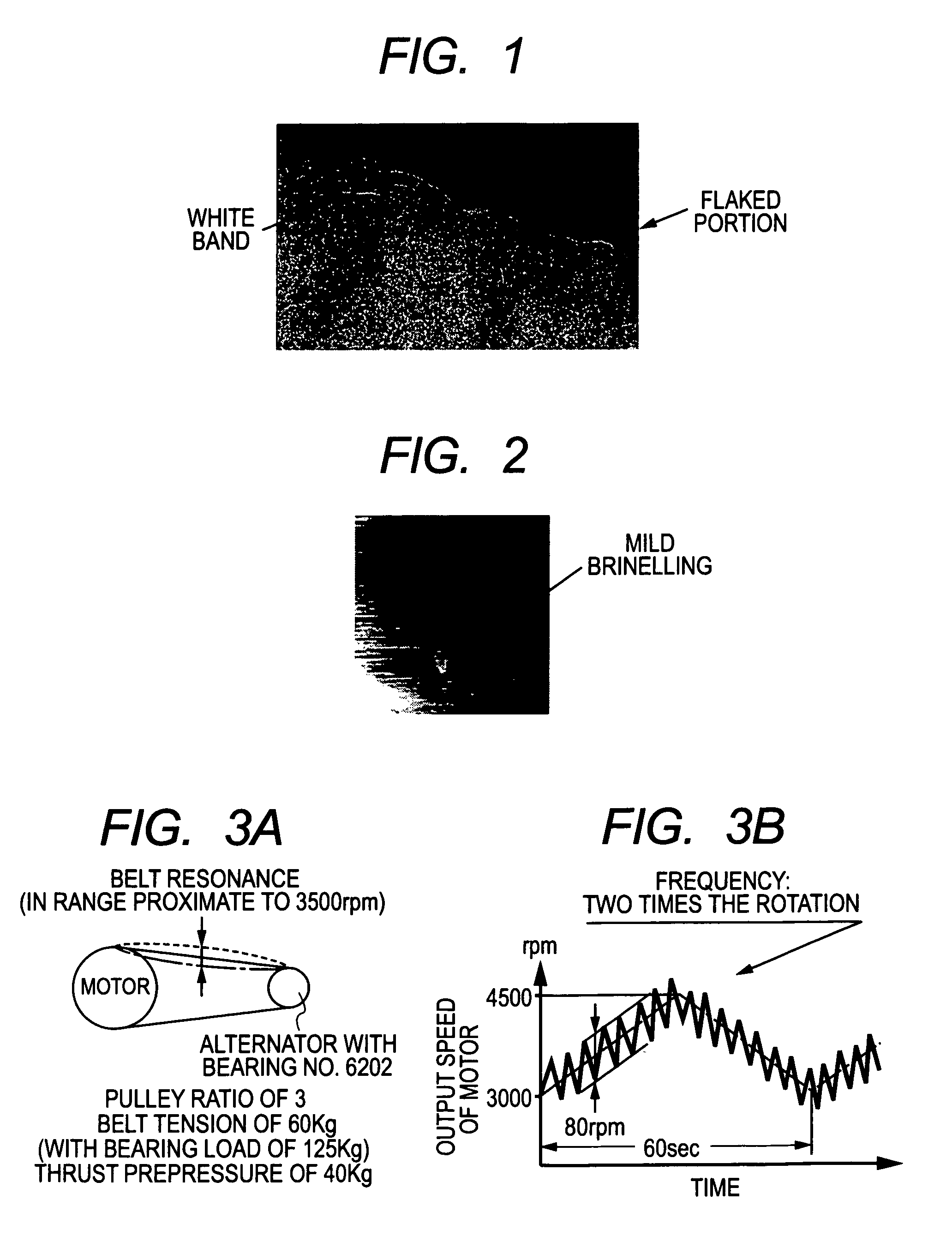

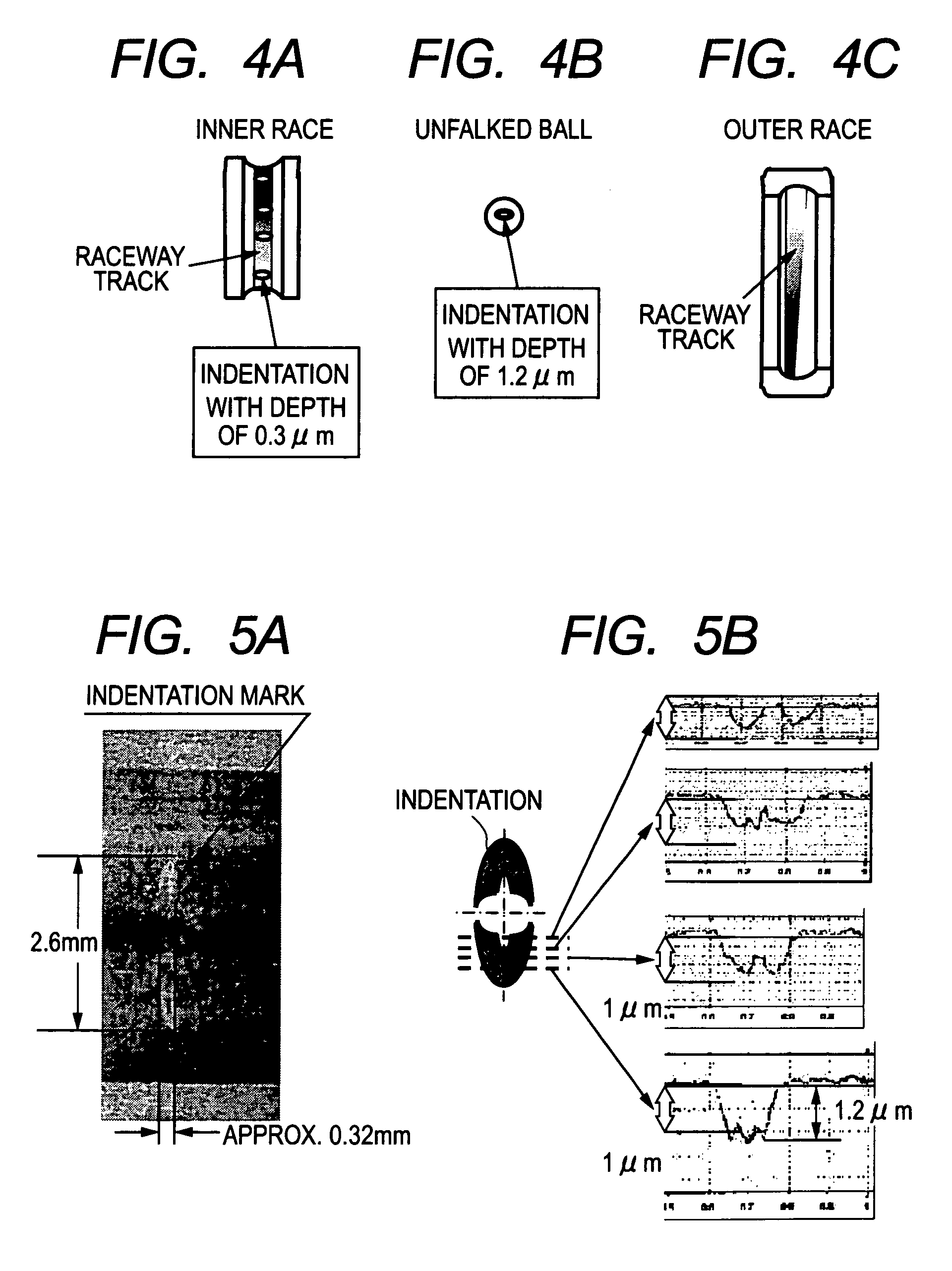

Apparatus and method for determining patterns of damage being caused in rolling contact element

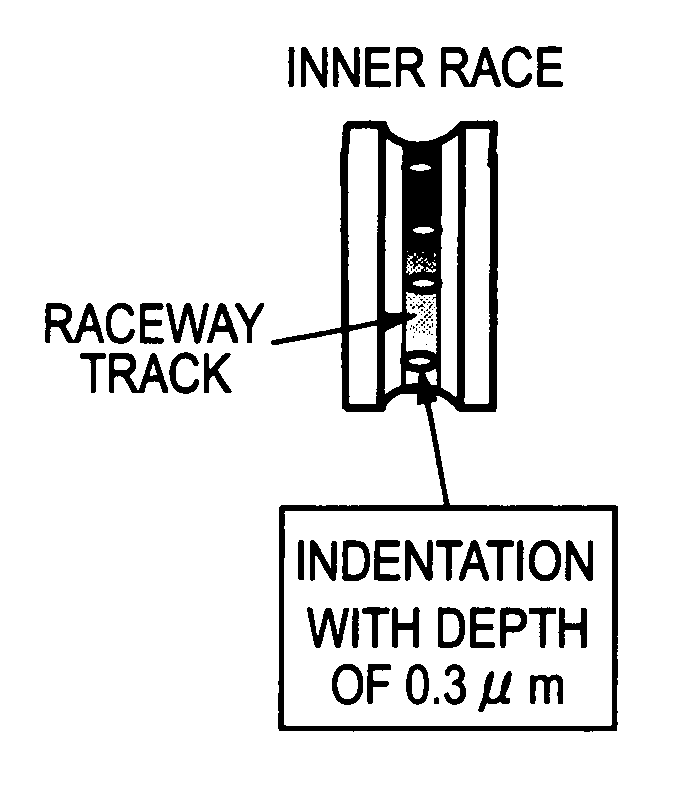

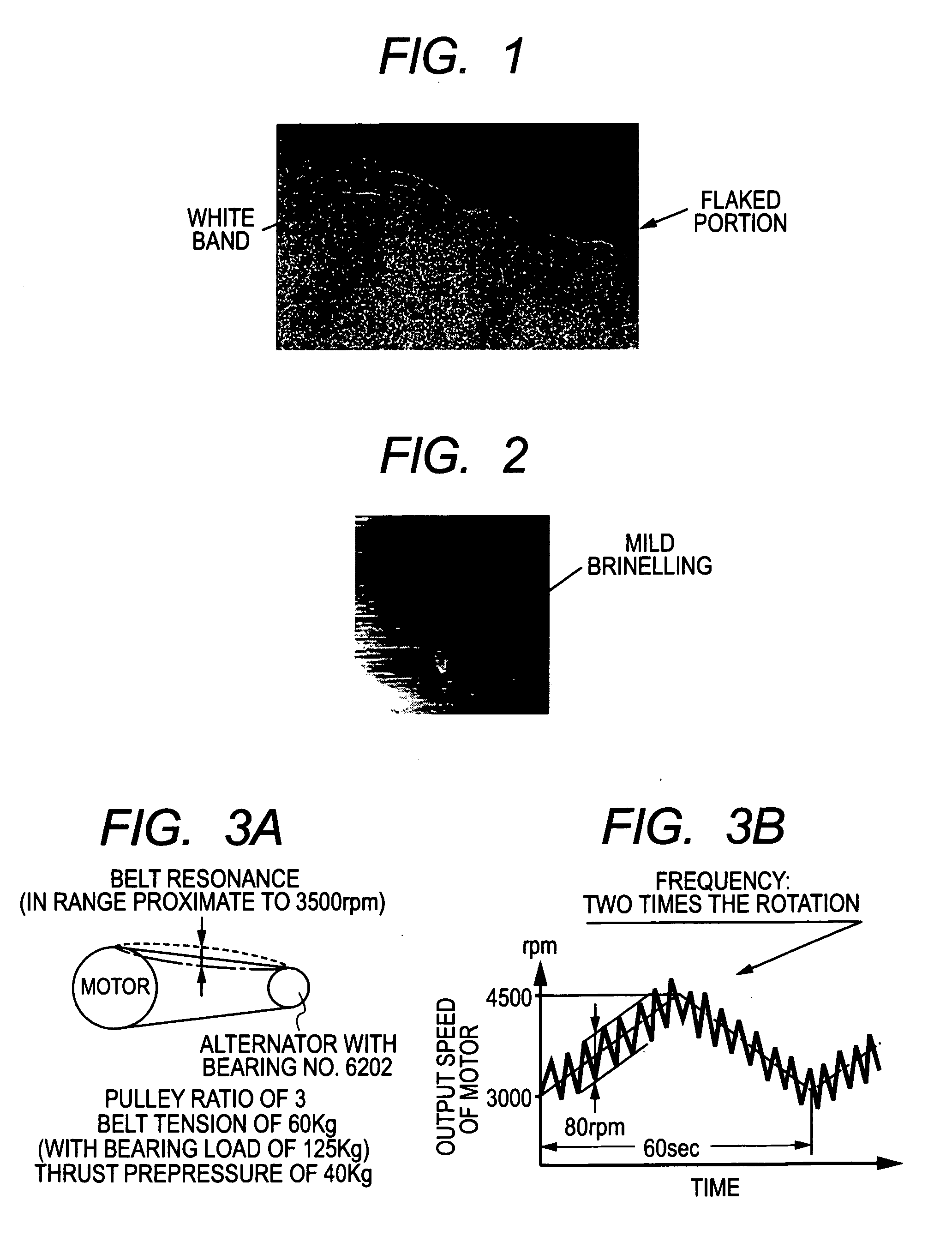

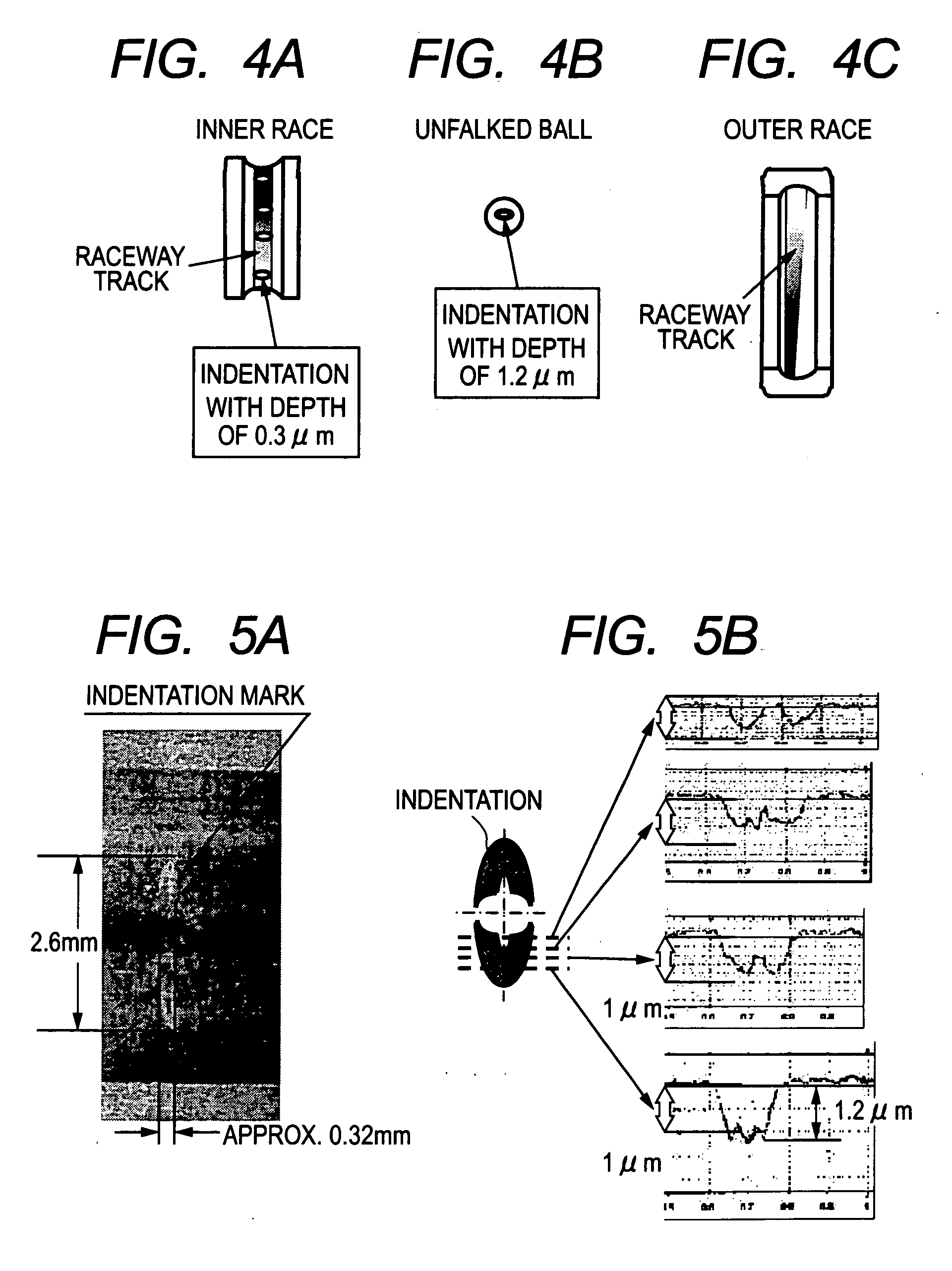

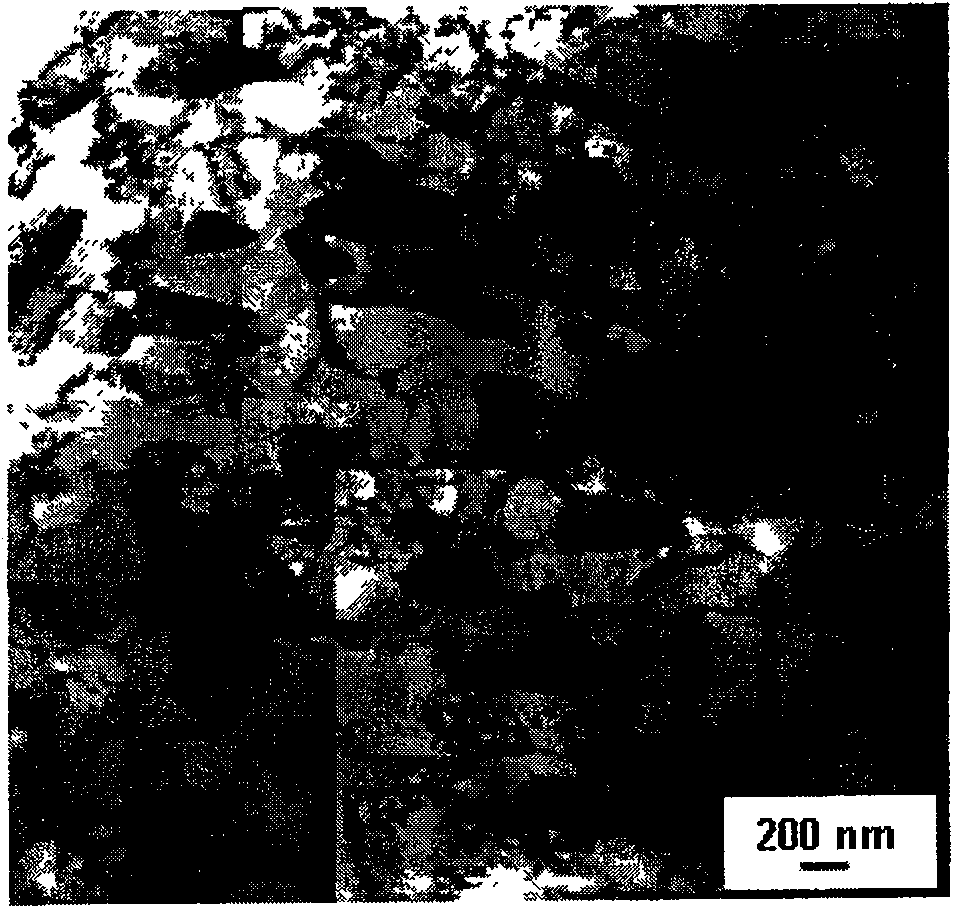

InactiveUS20070044543A1Simple fashionAvoid damagePlug gaugesMachine bearings testingBrinellingAdiabatic shear band

A method of designing a roller bearing is disclosed upon clarifying mechanisms of damage patterns in respect of two kinds of brinelling, involved in the bearing, wherein white-banded flaking (brittle flaking) is a plastic instability phenomenon appearing under high-speed deformation accompanied by adiabatic shear deformation status with the resultant occurrence of adiabatic shear band (also called white band) inside material of the bearing. This enables all of the damage patterns to be determined upon making comparison between shear strain and shear strain rate, occurring inside the bearing, and discriminated values.

Owner:DENSO CORP

High speed processing method for realizing superfine crystal grain structure on metallic material surface

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

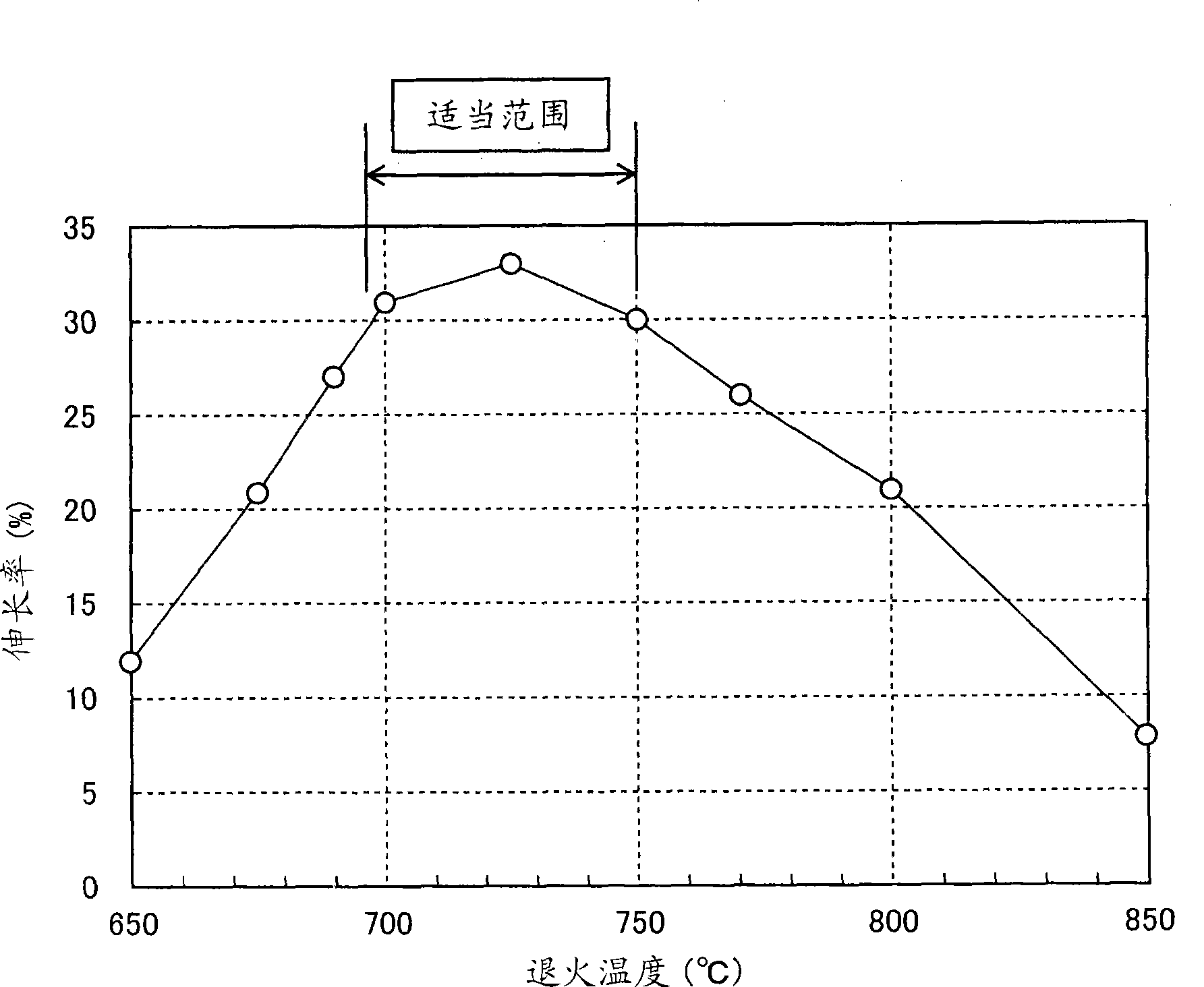

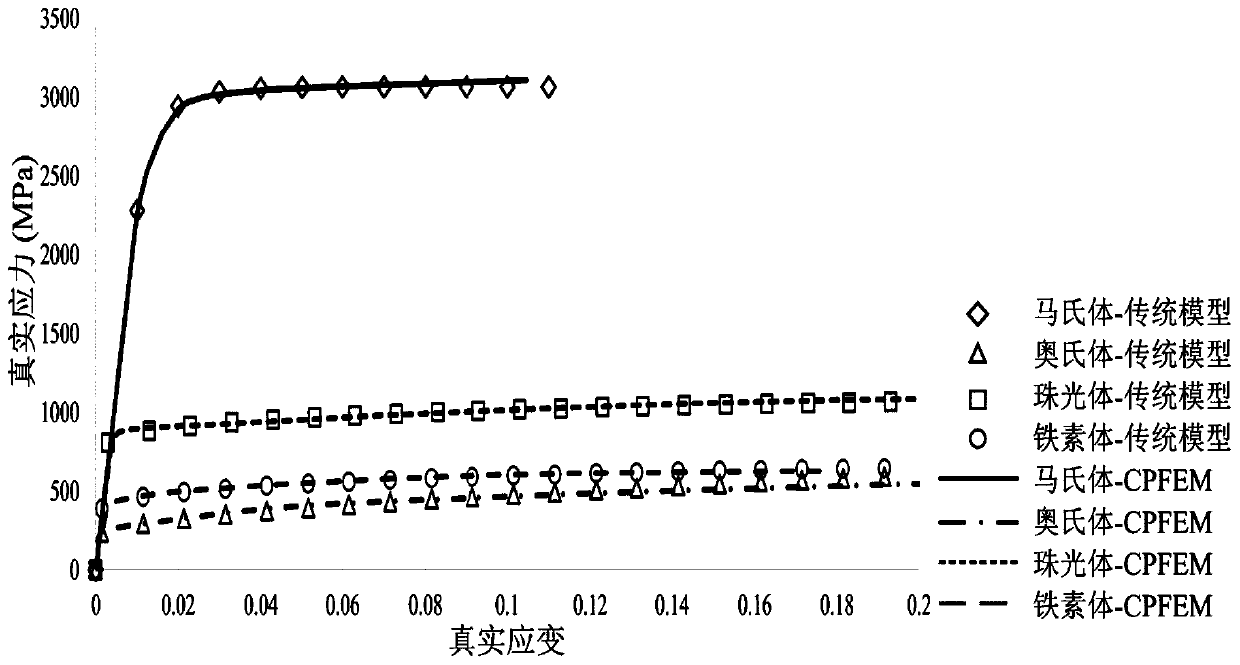

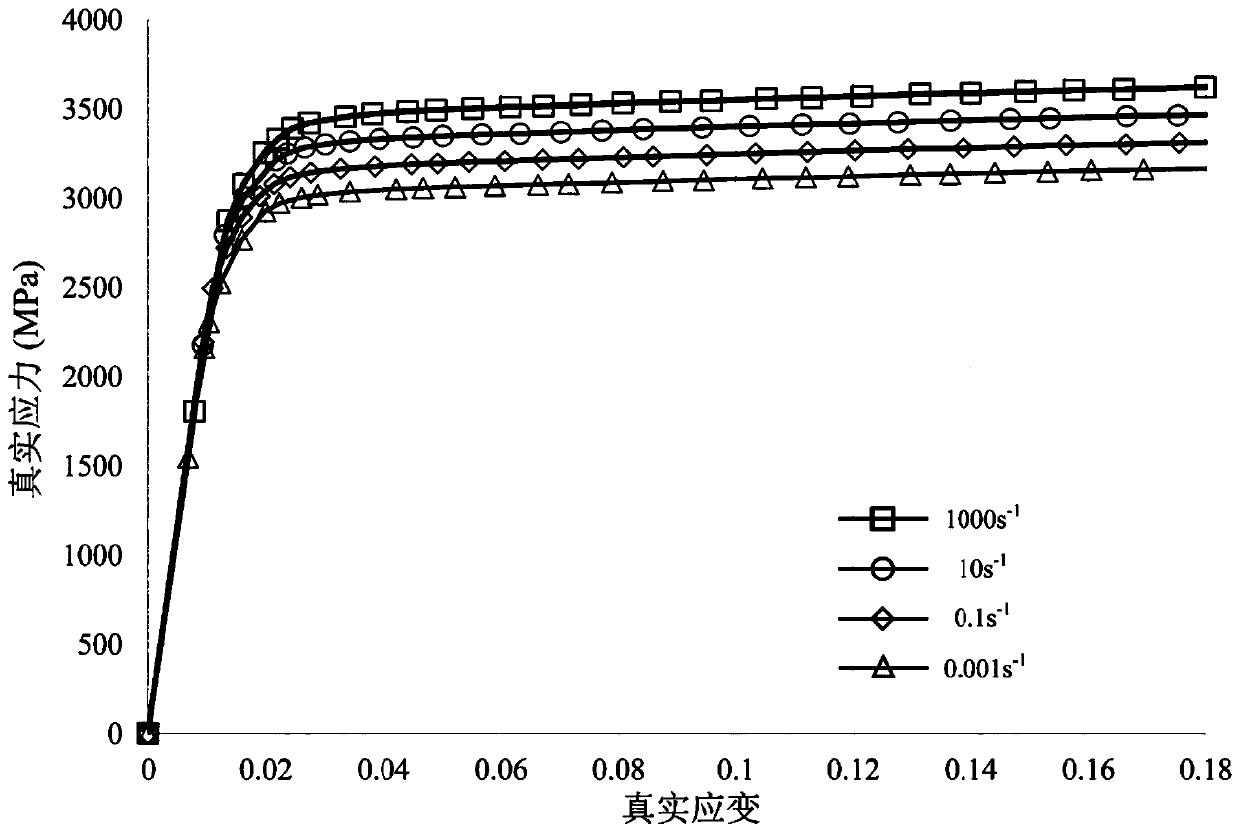

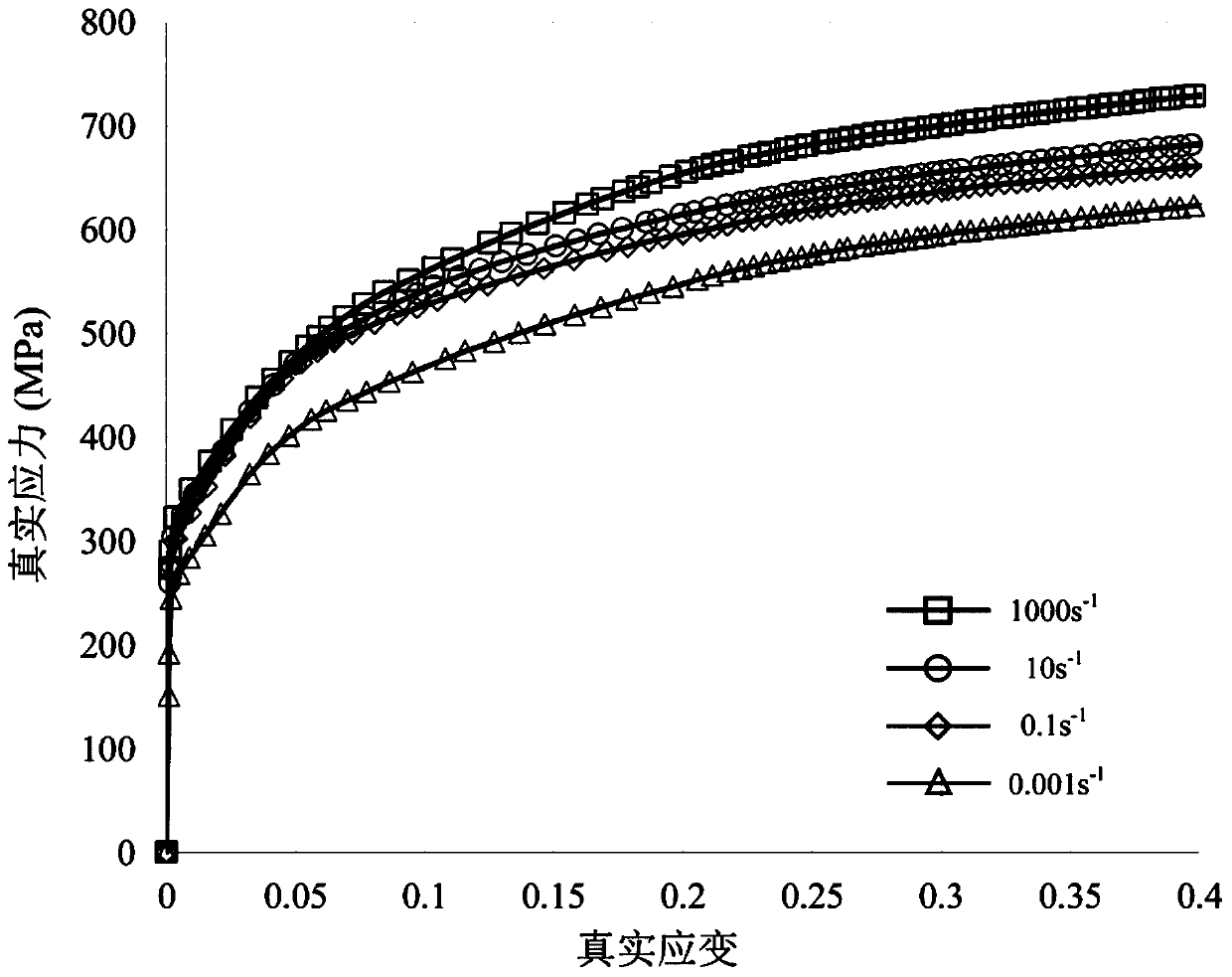

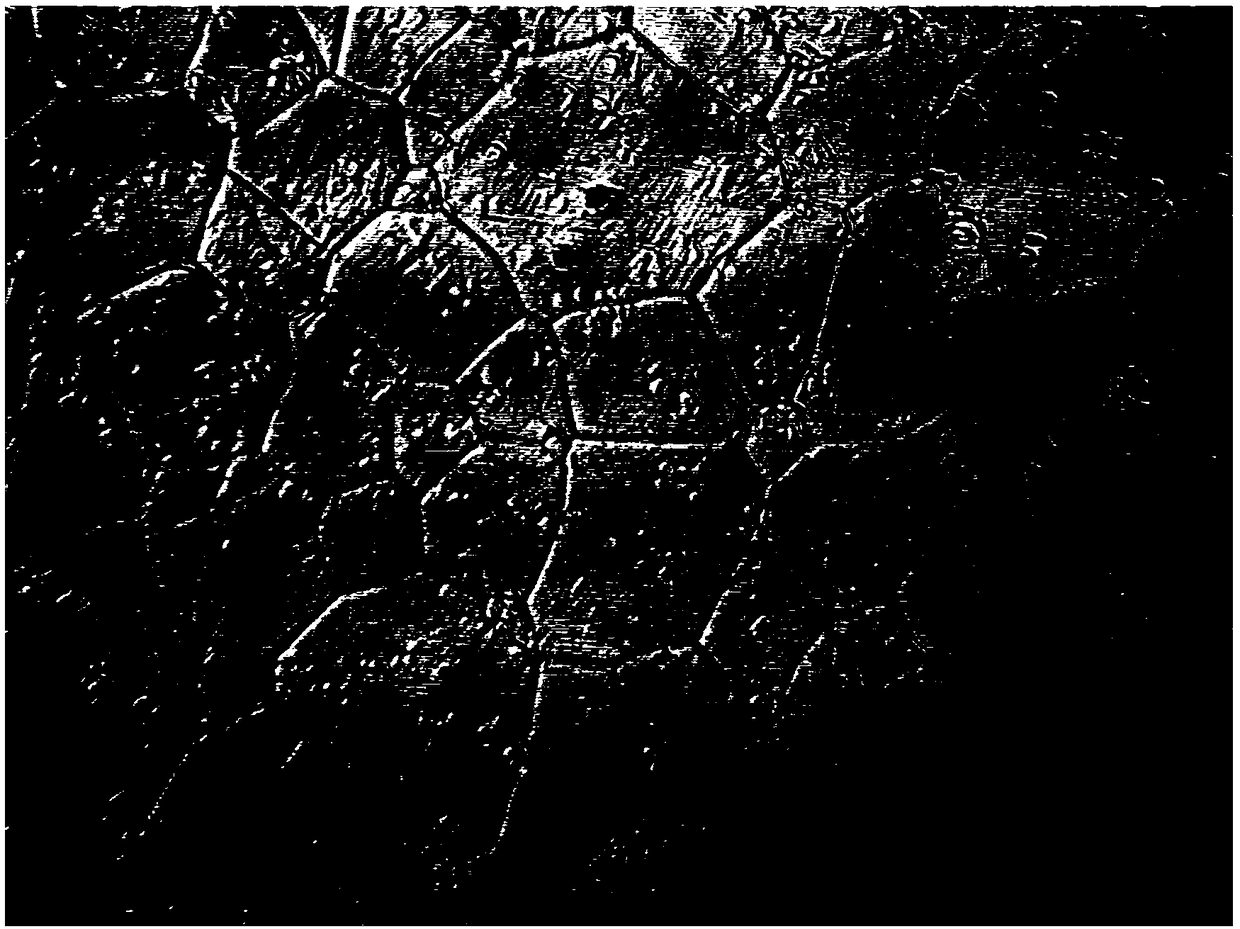

Constitutive behavior construction method for multiphase metal material for high-speed deformation process

ActiveCN111145842AEliminate cumbersomenessReduce testing costsDesign optimisation/simulationComputational materials scienceMacroscopic scaleMetallic materials

The invention discloses a rapid calculation method for constitutive behaviors of a multi-phase metal material for a high-speed deformation process. The method comprises the steps: predicting the mechanical behavior of each single pure phase in the multi-phase material through a crystal plasticity finite element method, and then predicting the macroscopic constitutive behavior shown by the materialin the multi-phase state through metallographic structure measurement and proportional mixing methods. The method can accurately and quickly predict the mechanical behavior of a single phase of the material in a high strain rate state, so that the method can be suitable for deformation processes such as high-speed machining and forging of steel, titanium alloy and other materials with complex phase components. According to the method, the problem that for the same material, after different heat treatments, the mechanical properties are significantly changed due to microstructure changes and the mechanical behaviors of the material need to be measured again is solved, so the cost can be significantly reduced in industrial production practice, the simulation and analysis efficiency can be improved, and the method has important significance for computer-aided analysis and design of the part machining deformation process.

Owner:XI AN JIAOTONG UNIV

Apparatus and method for determining patterns of damage being caused in rolling contact element

InactiveUS7577555B2Avoid mechanical damageNo errorPlug gaugesMachine bearings testingBrinellingAdiabatic shear band

A method of designing a roller bearing is disclosed upon clarifying mechanisms of damage patterns in respect of two kinds of brinelling, involved in the bearing, wherein white-banded flaking (brittle flaking) is a plastic instability phenomenon appearing under high-speed deformation accompanied by adiabatic shear deformation status with the resultant occurrence of adiabatic shear band (also called white band) inside material of the bearing. This enables all of the damage patterns to be determined upon making comparison between shear strain and shear strain rate, occurring inside the bearing, and discriminated values.

Owner:DENSO CORP

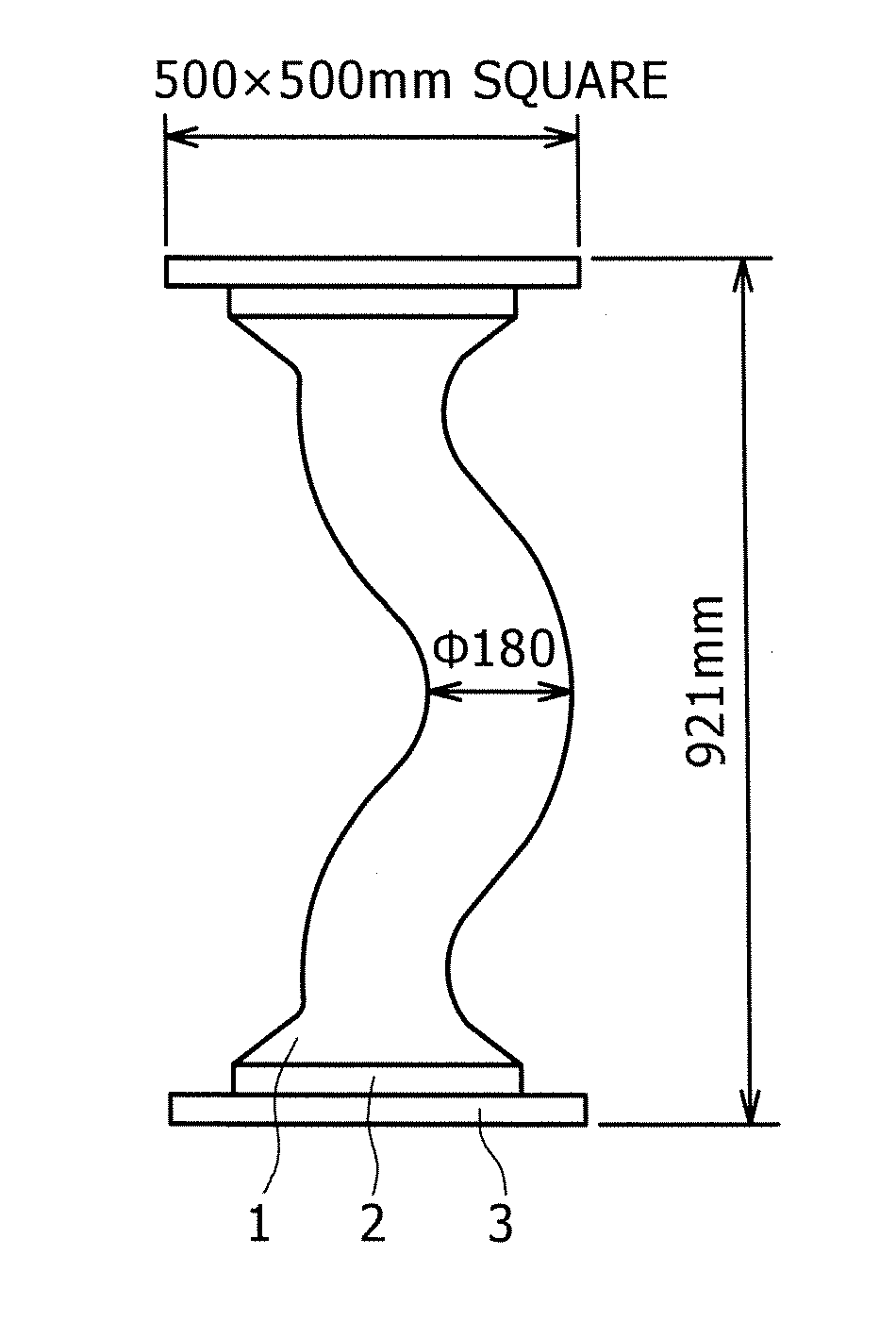

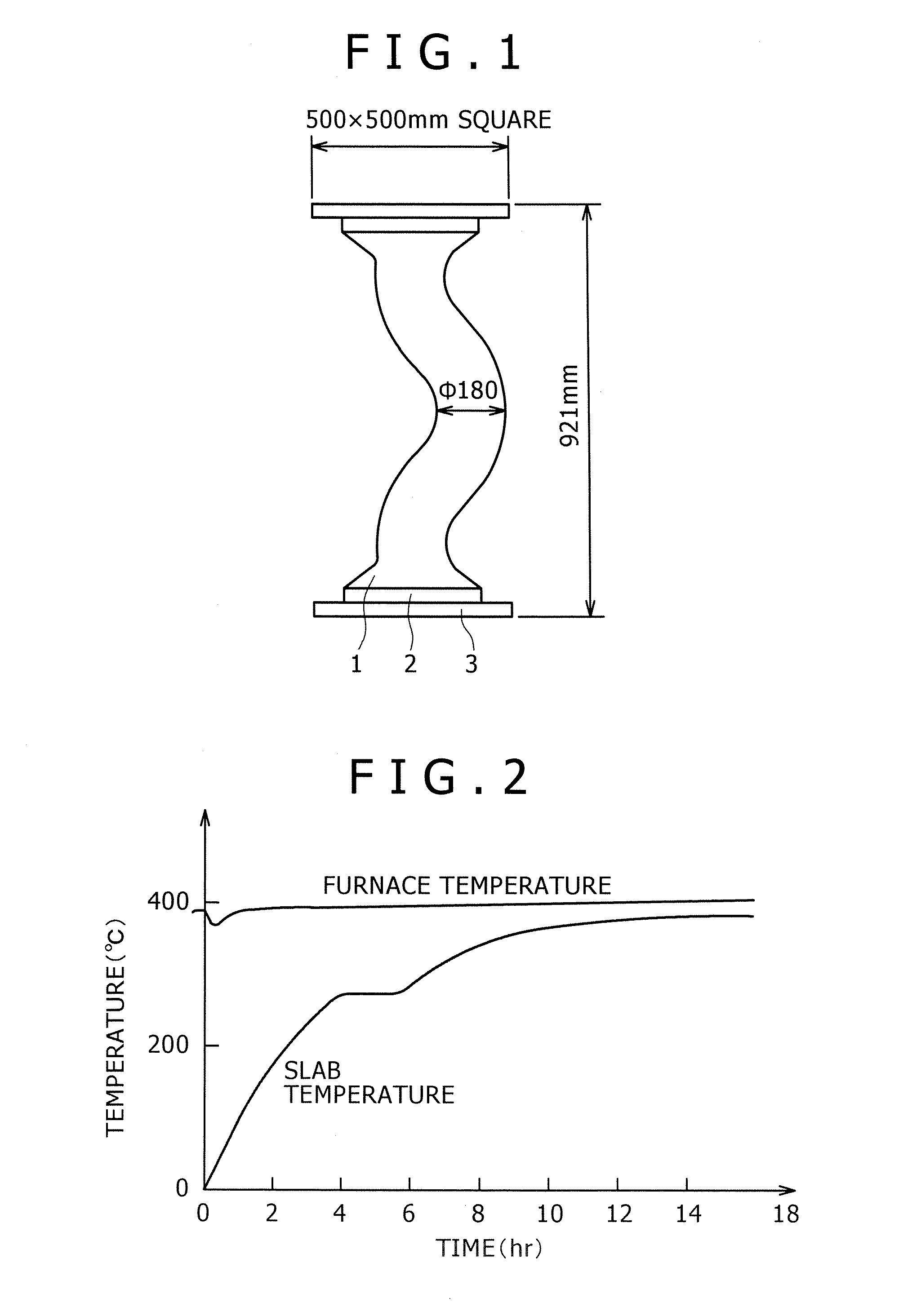

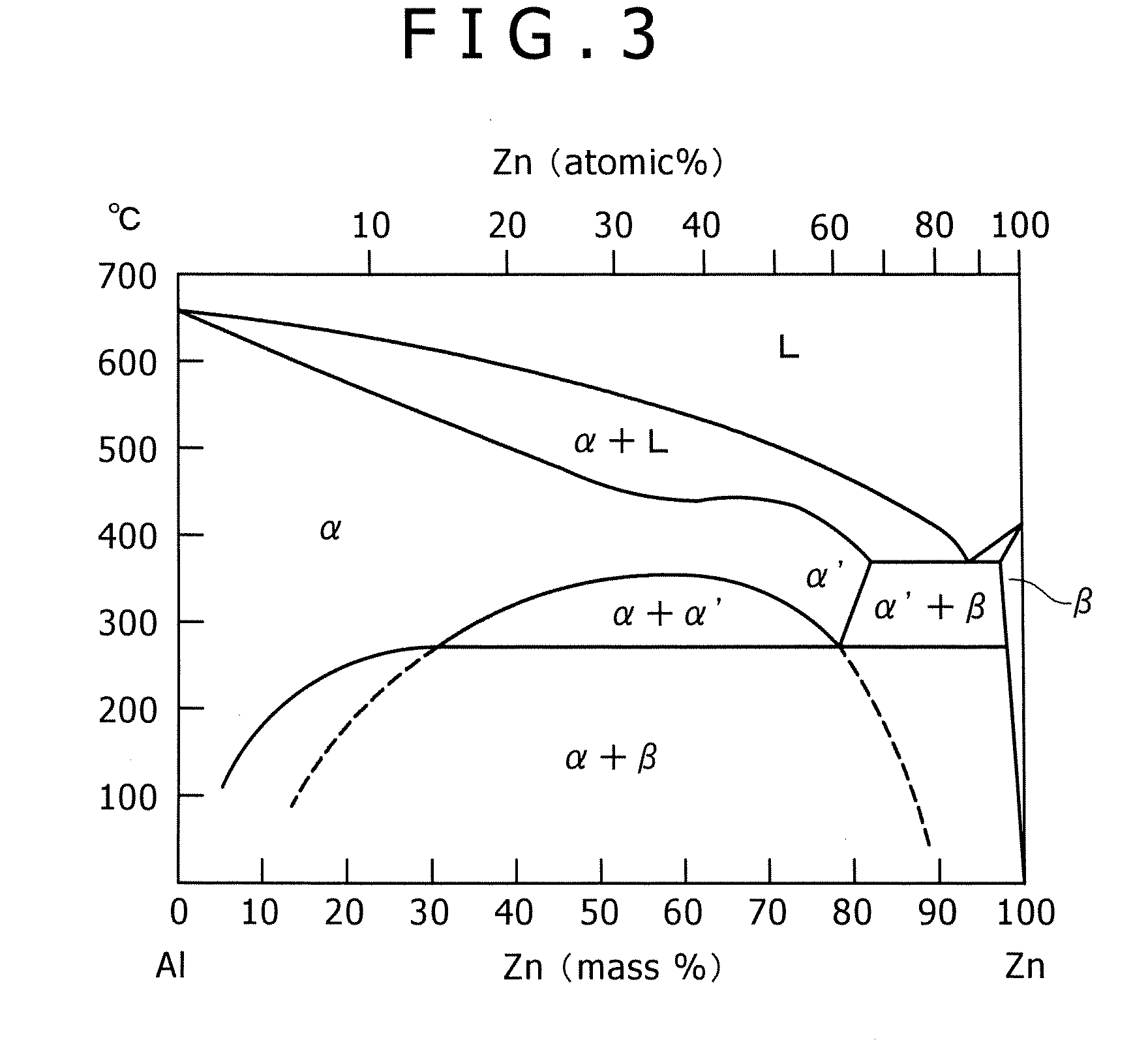

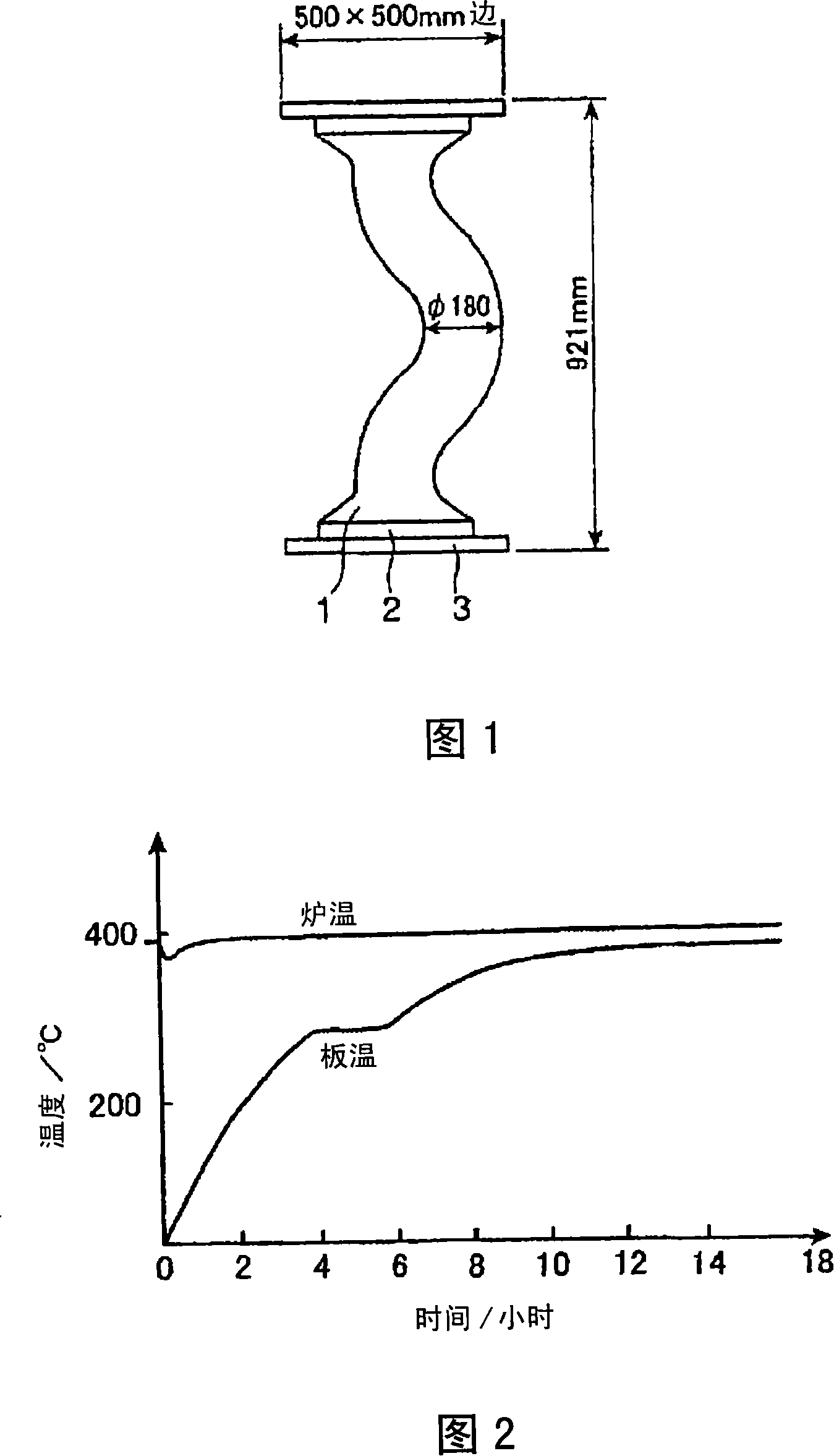

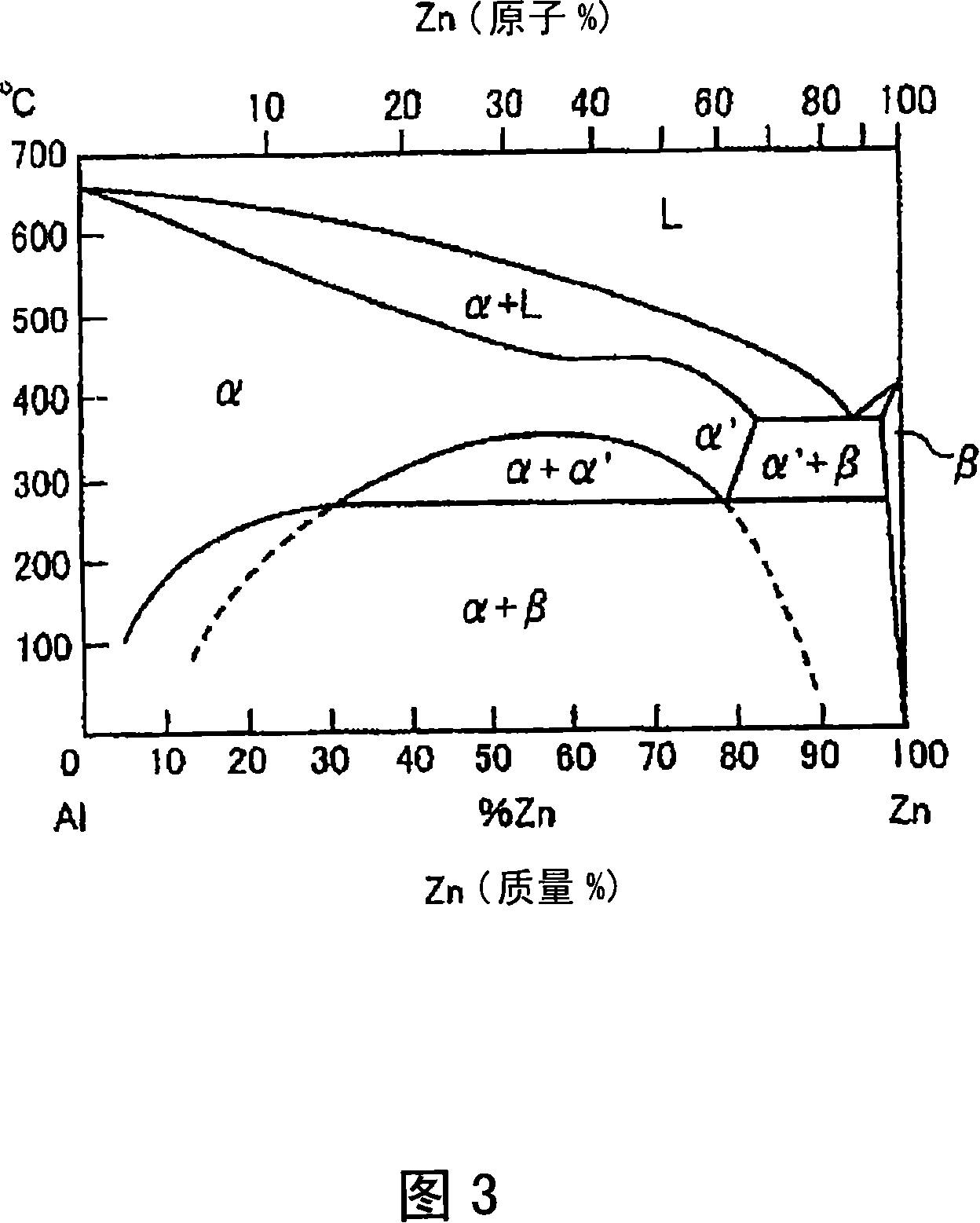

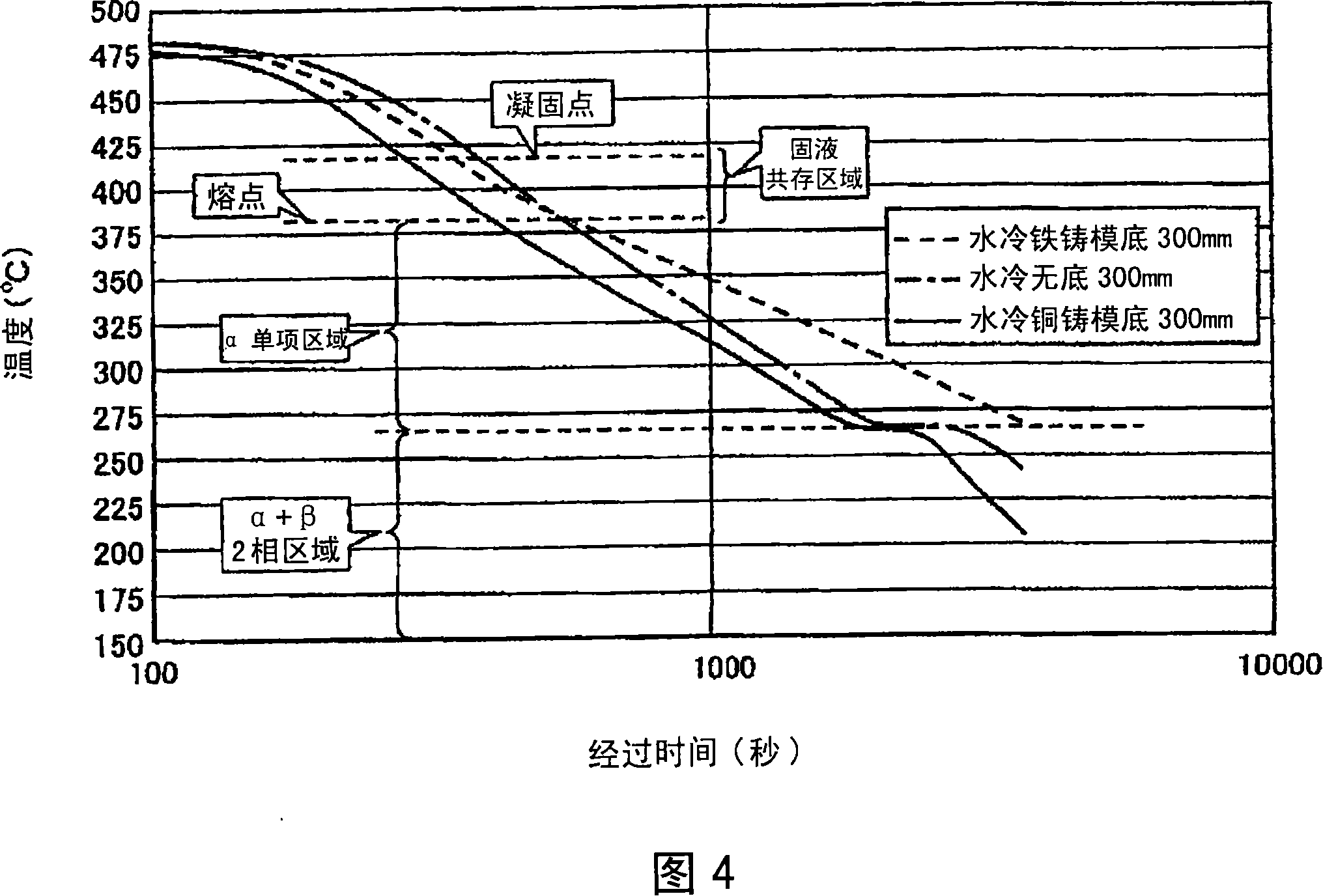

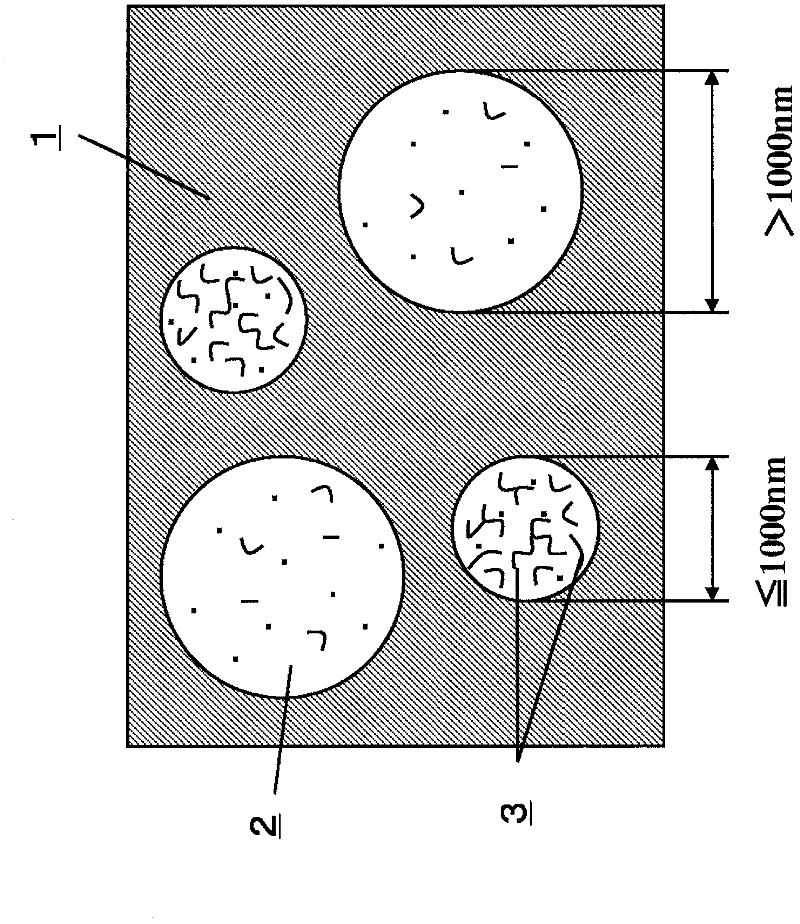

Zn-Al Alloy Having Excellent High-Speed Deformation Properties and Process For Producing the Same

A Zn—Al alloy excellent in static deformability as well as dynamic deformability and applicable to large-sized structures, and a method for production thereof. The alloy contains 30-99% Zn, with the remainder being Al and inevitable impurities, and has a metallographic structure in which the α phase or α′ phase having an average grain size no larger than 5 μm contains the β phase finely dispersed therein, the Al inclusions have a maximum equivalent circle diameter no larger than 50 μm and are free of pores no smaller than 0.5 mm in terms of equivalent circle diameter, and the macrosegregation of Al is less than 3.0% and the microsegregation of Al is less than 2.0%. (% means mass %.)

Owner:KOBE STEEL LTD

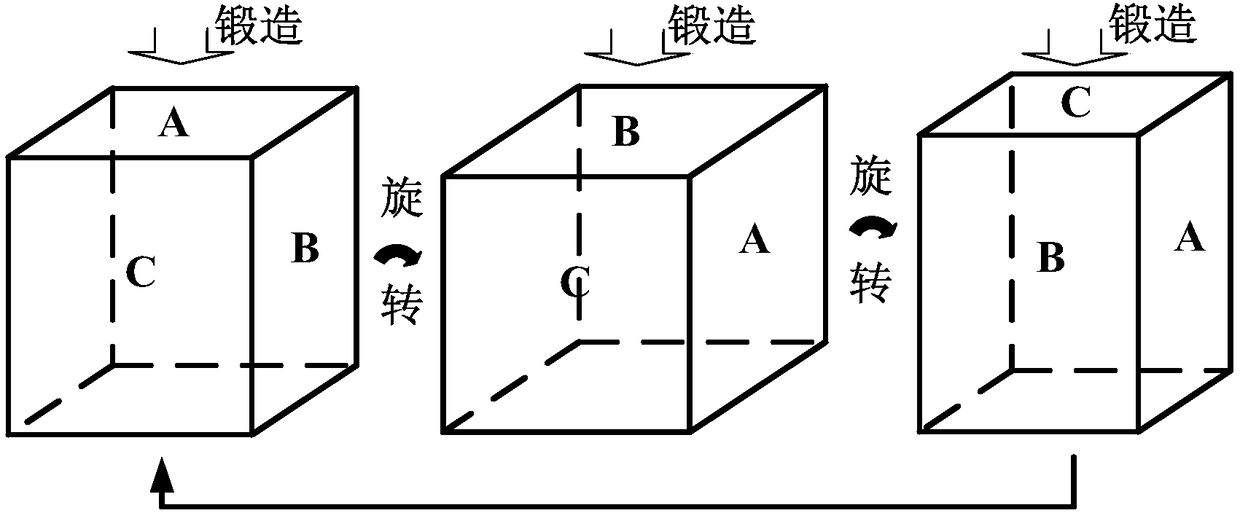

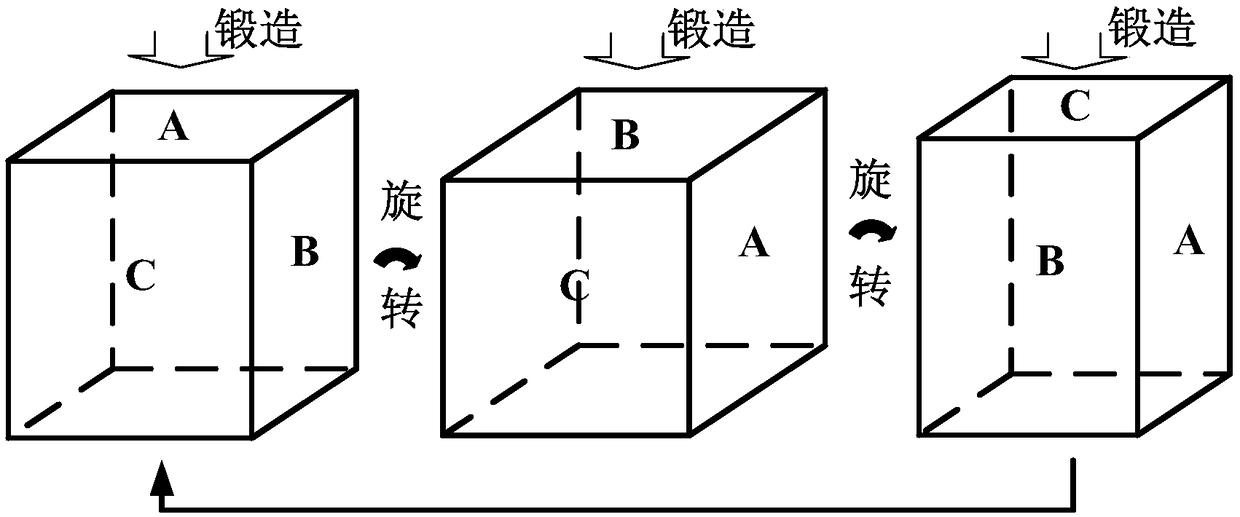

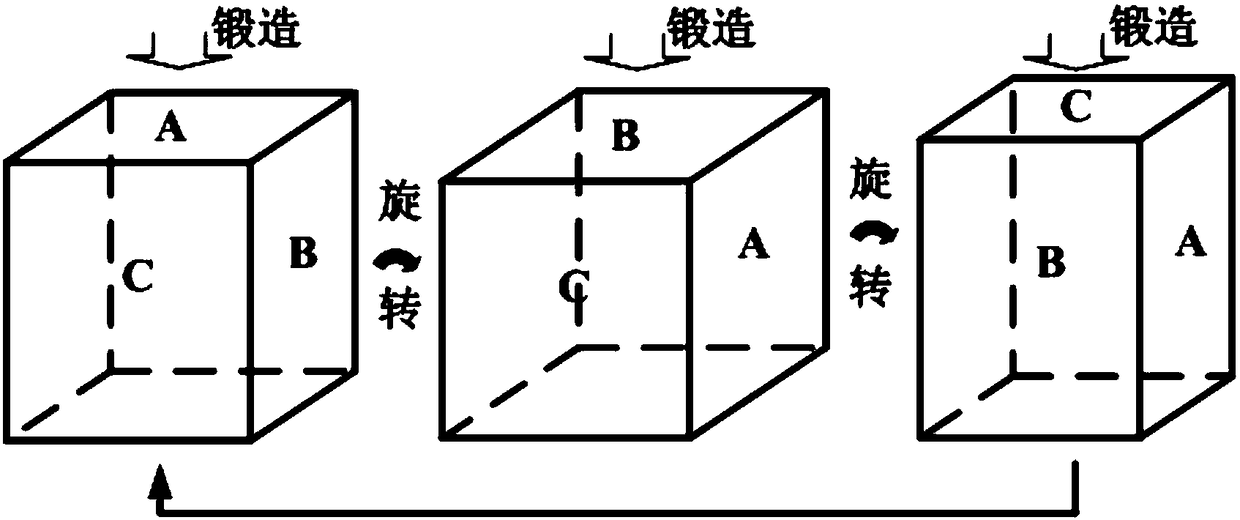

Preparation method of ultra-fine grain AZ61 magnesium alloy bulk material

InactiveCN108531837AGuaranteed plastic formabilityConsistent temperatureMetal-working apparatusUltra fineINCREASED EFFECT

A preparation method of an ultra-fine grain AZ61 magnesium alloy bulk material comprises thermal treating and thermal processing of the alloy, wherein the temperature in the thermal treating of the alloy is maintained at 400+ / -5 DEG C, and the temperature is maintained for 10+ / -0.5 hours; the alloy is cooled by air; the temperature in the thermal processing of the alloy is 250+ / -5 DEG C, and the temperature is maintained for 10+ / -1min before thermal processing; the thermal processing mode is a small-pass-straining high-strain-rate three-way forging mode; a pneumatic hammer is used as a forgingdevice; passes are heated without repeating, and the pass strain capacity is 10+ / -0.5%; 12 deformation passes are provided; and the cooling mode is realized by air cooling. According to the method, asimilar solid solution structure is obtained by high-temperature short-time thermal treating; a large number of twin crystals can be produced by high-speed deformation and are induced to dynamicallyrecrystallized, and thus the alloy structure can be rapidly refined; and meanwhile, the temperature decrease caused by heat dissipating is compensated by temperature increase effect of high-speed deformation, and passes are not heated. The method is suitably used for preparing the ultra-fine grain AZ61 magnesium alloy bulk material.

Owner:HUNAN INST OF TECH

Zn-Al alloy having excellent high-speed deformation properties and its making method

InactiveCN101194035AExcellent static deformationExcellent dynamic deformation abilityMaximum diameterAlloy

This invention provides a Zn-Al alloy, which is excellent in static deformability, as well as in dynamic deformability, and can be applied to a large structure, and a process useful for producing the Zn-Al alloy. The Zn-Al alloy comprises Zn: 30 to 99% (% by mass; the same shall apply hereinafter) with the balance consisting of Al and unavoidable impurities, wherein the Zn-Al alloy has a texture comprising a ss phase finely dispersed in an a phase or a' phase having an average grain diameter of not more than 5 [mu]m, the maximum diameter of Al-based inclusions is not more than 50 [mu]m, and, at the same time, pores having a equivalent circle diameter of not less than 0.5 mm are absent, and the macrosegregation of Al is less than 3.0%, and the microsegregation of Al is less than 2.0%.

Owner:KOBE STEEL LTD

Thermoplastic resin composition, process for producing the same and molding

This invention relates to a thermoplastic resin composition comprising a thermoplastic resin (A) and a reactive functional group-containing thermoplastic resin (B), which has a specific structure in the morphology of the resin composition observed by transmission electron tomography, and the relaxation time T1C of each carbon nucleus by the solid NMR measurement of the thermoplastic resin composition containing a polyamide resin is kept in a specific range. The composition is excellent in the balance between contradictory properties such as impact resistance and heat resistance, remarkably exhibits a peculiar viscoelastic behavior not observed in the conventional polymeric materials, and is remarkably excellent in impact energy absorbing performance and vibration energy absorbing performance at the time of high-speed deformation.

Owner:TORAY IND INC

High-speed metal pipe wall punching device and method

InactiveCN104438544AAchieve high-speed punchingUniform and reliable application of forcePulse loadPunching

The invention discloses a high-speed metal pipe wall punching device and method and belongs to the field of machine manufacturing. The device and method solve the problem that in the prior art, during mechanical punching, the shape and quality of a peripheral pipe wall are affected due to the fact that a gap exists between a male die and a female die. According to the scheme of the high-speed metal pipe wall punching device, one output end of a pulse power supply is connected with one terminal of a coil, the other terminal of the coil is connected with the other output end of the pulse power supply, two half dies are embedded in a jacket die, a pipe to be punched is arranged in the two half dies, and the coil is arranged in the pipe to be punched. According to the scheme of the high-speed metal pipe wall punching method, the coil, the pipe to be punched, the half dies and the jacket die are assembled, outer grid voltage is connected with a high voltage switch after being boosted through a high voltage transformer, a pulse load enables the pipe to be punched to be subjected to the high-speed deformation process including expansion, shearing and breakage in sequence along the edge of a hole formed by the two half dies through hindrance of the two half dies, and then punching is achieved. The device and method are used for punching metal pipes.

Owner:HARBIN INST OF TECH

Measurement method of three-dimensional speckle strain measurement device

ActiveCN101655352BHigh measurement accuracySimplify requirementsUsing optical meansVibration measurementFull field

The invention discloses a three-dimensional speckle strain measurement method, comprising: (1) speckle preparation; (2) camera calibration; (3) state information acquisition; (4) computational domain designation; (5) initial point setting; (6) speckle matching; (7) three-dimensional reconstruction; and (8) strain computation. By the above operation steps, the invention provides a three-dimensional speckle strain measurement method, which can effectively obtain high preciseness measurement results in measurements of material characteristic parameters such as full-field vibration measurement, dynamic strain measurement, high speed deformation measurement, fracture mechanics, impact excitation and dynamic material experiments. The invention has the characteristics of convenient measurement operation, high automation degree, exact and reliable results, high efficiency and non-contact measurement.

Owner:XI AN JIAOTONG UNIV

Short-process preparation method of ultra-fine grain Mg-3Al-1Zn alloy

InactiveCN108642417AUniform equiaxed grain structureNo heat treatment requiredFoundry mouldsFoundry coresUltra fineAlloy

A short-process preparation method of an ultra-fine grain Mg-3Al-1Zn alloy comprises the steps of alloy casting and hot processing. A square water cooling copper mold is adopted as an alloy casting mold, the molding size of the mold is 150mm*150mm*150mm, the capacity of mold cooling water is 300+ / -10 ml, and the flow speed of the cooling water is 3+ / -0.5 L / min; and the alloy hot processing temperature is 250+ / -5 DEG C, the soaking time before hot processing is 10+ / -1 min, the hot processing manner is small-pass-strain high-strain-rate triaxial forging, an air hammer is adopted as forging equipment, heating is not repeated between passes, the pass strain capacity is 10+ / -0.5%, strain passes are 12 passes, and air cooling is adopted as the cooling manner. According to the method, uniform andequiaxial casting structures similar to solid solutions are prepared through the water cooling copper mold, a large number of twin crystals are generated through high-speed deformation, dynamic recrystallization is induced through the twin crystals, and the alloy structure is refined fast; and the method is suitable for preparing ultra-fine grain Mg-3Al-1Zn alloy bulk materials.

Owner:HUNAN INST OF TECH

High-speed deformation aircraft

The invention relates to a high-speed deformation aircraft. The high-speed deformation aircraft comprises an aircraft head, an aircraft body and a power device; the power device is mounted at the tail of the aircraft body; the aircraft body comprises a shell; the shell is formed by winding memory metal plates; observing in the axial direction of the aircraft body, the shell is of a coiled spiral ellipse; the spiral ellipse has a high-temperature phase shape and a low-temperature phase shape; in a high temperature state, the ratio of the long radius to the short radius of the outermost layer of the spiral ellipse is greater than that in a low temperature state; the space between adjacent memory metal plates is filled with a buffering heat conducting layer; a working cabin, a control cabin and a supply cabin are arranged in a sizing shell; the control cabin is electrically connected with the power device. The aircraft is novel and unique in structure; the external shape of the aircraft body can be adjusted intelligently according to different flight speeds, so that the resistance of the aircraft is reduced, the temperature rising caused by friction is reduced, and favourable conditions are provided for increasing the speed of the aircraft.

Owner:安徽百舸争流信息科技股份有限公司

Preparation method of bimodal tissue Mg-6Zn-0.45Zr alloy

InactiveCN108396214AGuaranteed plastic formabilityImprove continuous malleabilityHot workingGrain distribution

The invention discloses a preparation method of a bimodal tissue Mg-6Zn-0.45Zr alloy. The method comprises alloy heat treatment and alloy hot working, wherein the preservation temperature of the alloyheat treatment is 330 + / -5 DEG C, the heat preservation time of the alloy is 10 + / -0.5 hours, and the cooling mode is air cooling; and the temperature of the alloy hot working is 250 + / -5 DEG C, theheat preservation time before the alloy hot working is 10 + / -1 minutes, the alloy hot working mode adopts small-pass strain high-strain-rate three-direction forging, the forging equipment is an air hammer, secondary heating is not repeated among the passes, the pass strain capacity is 10 + / -0.5%, the deformation pass is 24 passes, and the cooling mode is the air cooling. According to the preparation method, the bimodal tissue Mg-6Zn-0.45Zr alloy with controllable crystalline grain distribution can be prepared, and the bimodal tissue Mg-6Zn-0.45Zr alloy has excellent comprehensive mechanical properties; the temperature drop caused by heat dissipation is made up by utilizing the temperature rise effect of high-speed deformation, no heating is needed among the passes, and the method is shortin machining period and is suitable for producing large-size block body of the Mg-6Zn-0.45Zr alloy.

Owner:HUNAN INST OF TECH

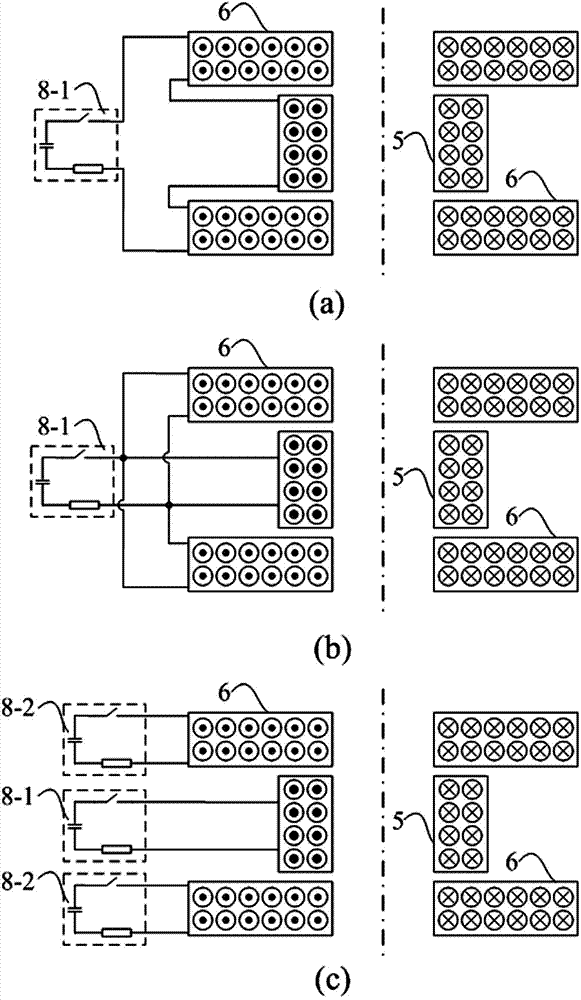

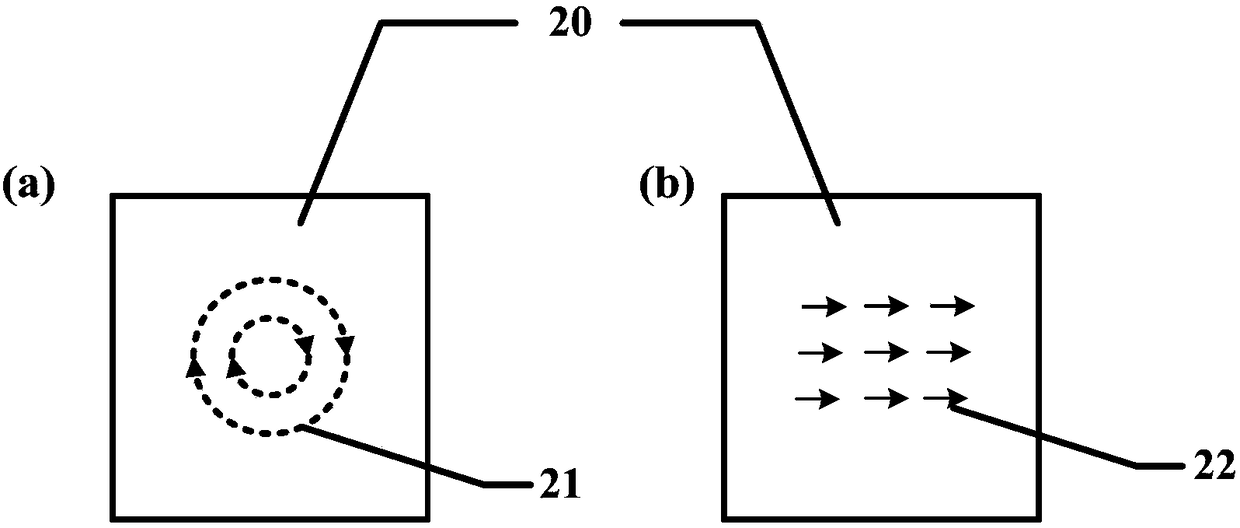

Electromagnetic pulse forming device and method for sheet metal

ActiveCN107127243BSolve the problem of insufficient forming forceIncrease currentVehicle componentsElectromagnetic pulseEngineering

The invention discloses an electromagnetic pulse forming device and method for a metal sheet. The electromagnetic pulse forming method includes the steps that S1, when the metal sheet to be formed is arranged between a forming die and a forming coil, pressure equipment is used for applying pressure through a blank holder, and accordingly a metal sheet flange area can be prevented from being wrinkled; S2, a first power module is used for supplying a current to the forming coil, and the powered-on forming coil generates a pulsed magnet field at a metal sheet area; a second power module is used for supplying a current to the metal sheet, so that a pulse current is generated in the metal sheet; and the pulse current and the pulsed magnet field act with each other to generate electromagnetic force used for driving the metal sheet to be subjected to high-speed deformation; and S3, the metal sheet to be formed can be deformed through the electromagnetic force. According to the electromagnetic pulse forming device and method, in the mode of directly loading the currents, the current magnitude in the metal sheet can be increased obviously, the influence on the current magnitude by electrical resistivity is small, and the problem of being insufficient in forming force due to the fact that the induced eddy current of a low electric conductivity material is small can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com