Patents

Literature

48 results about "White band" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

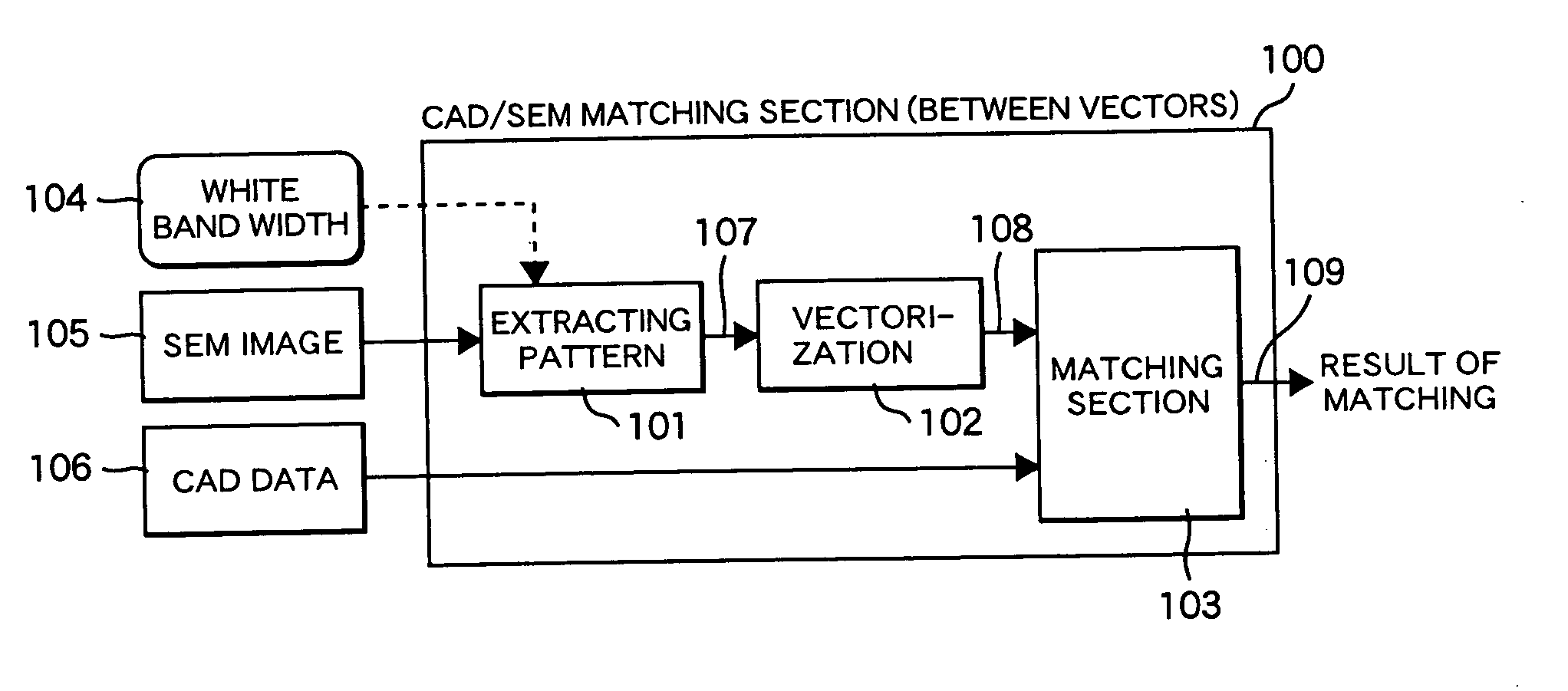

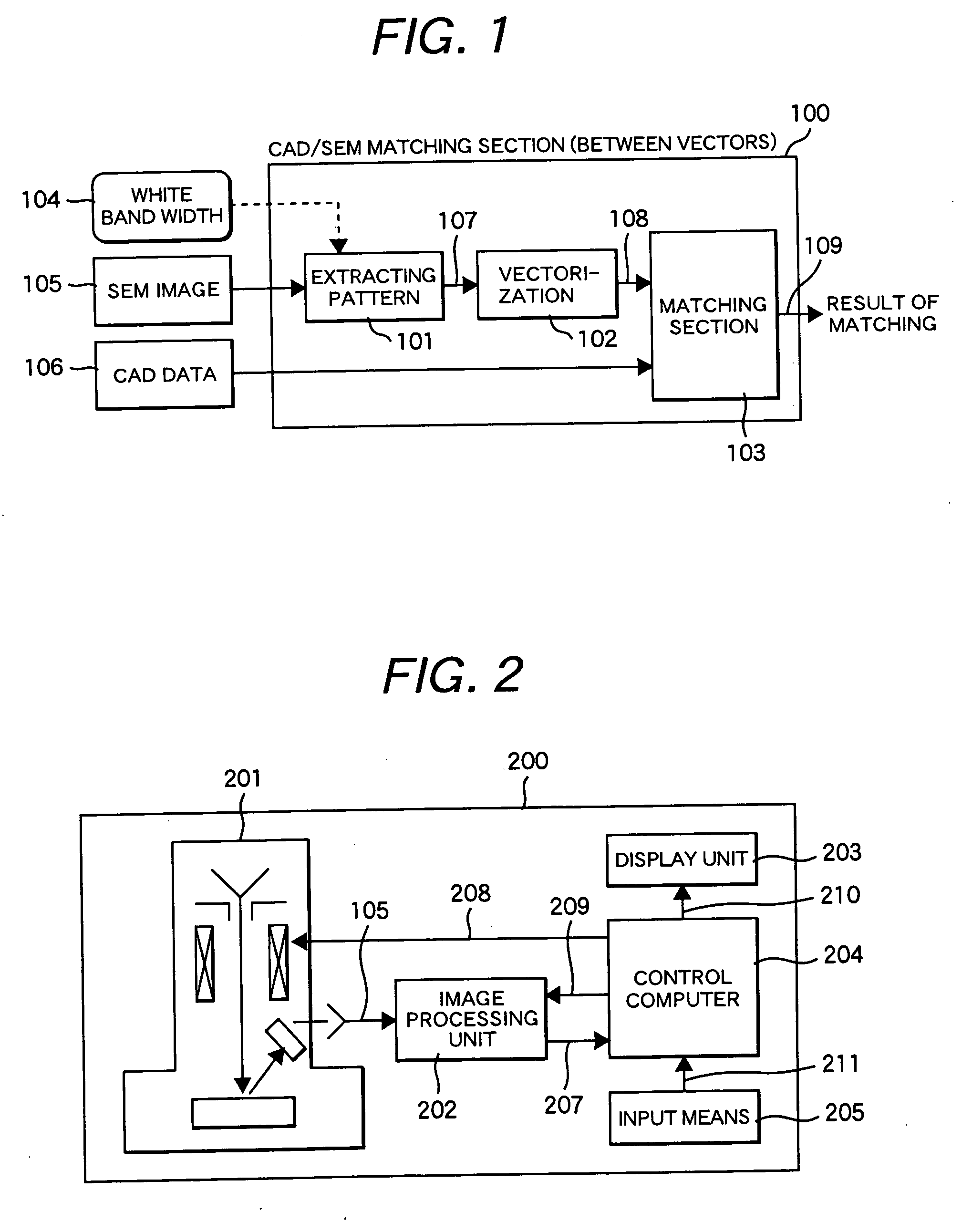

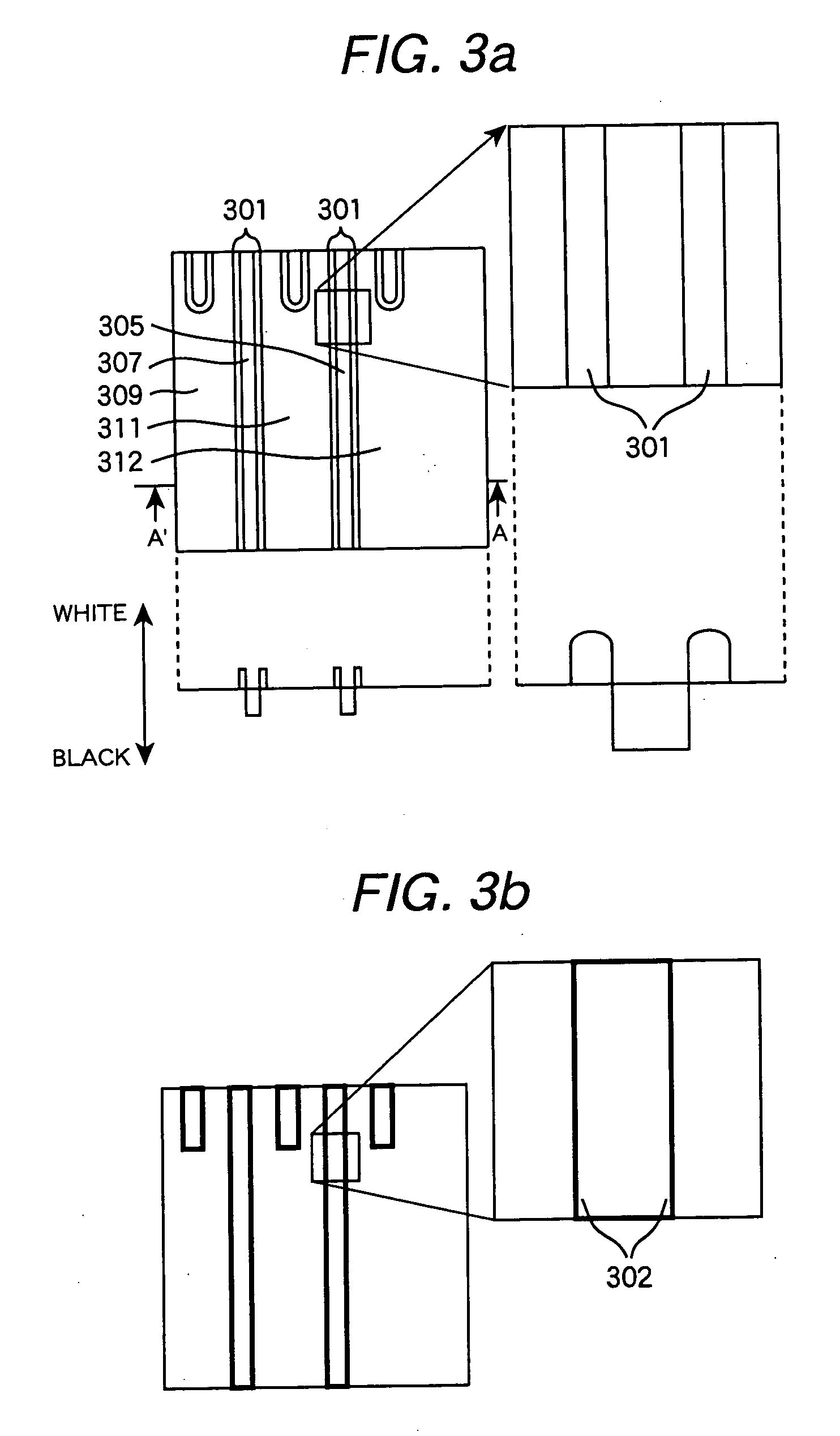

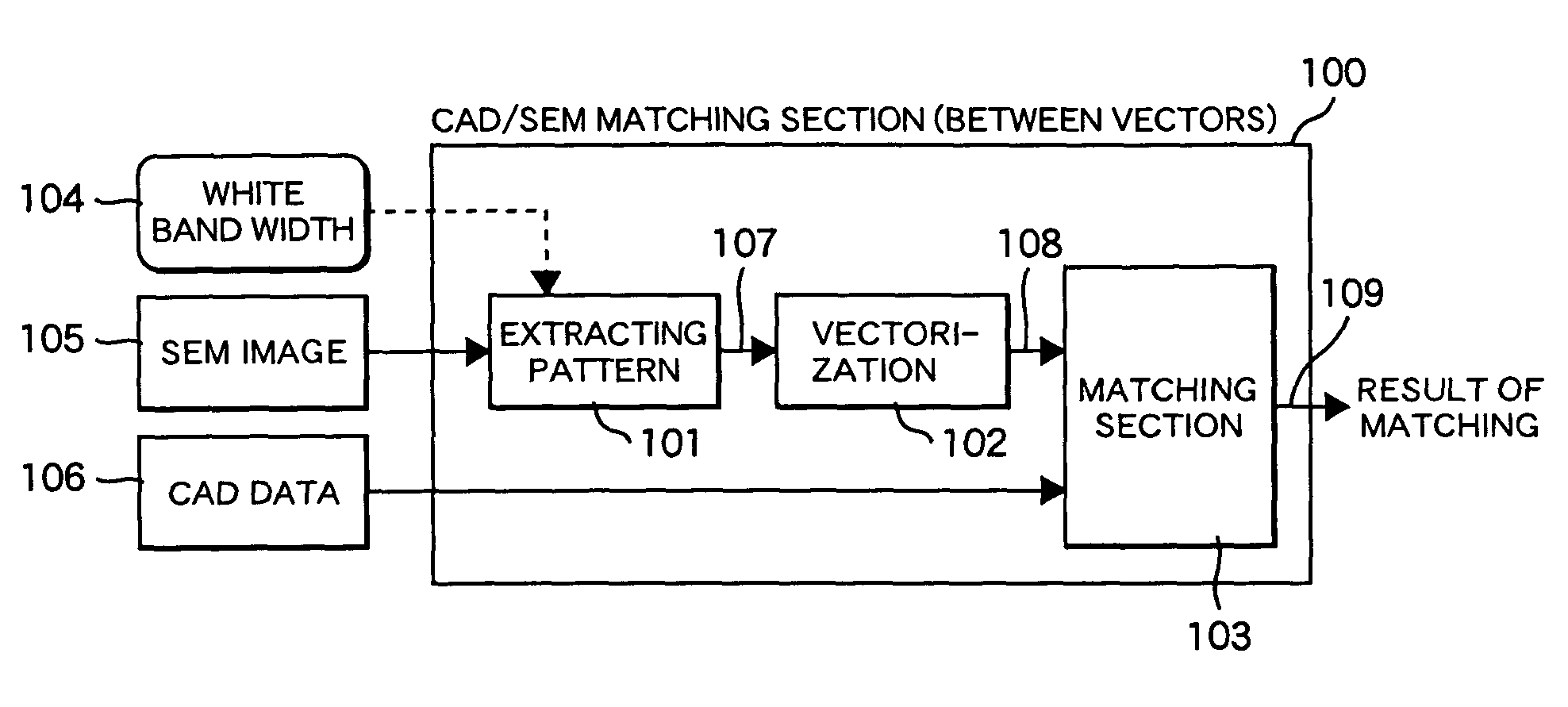

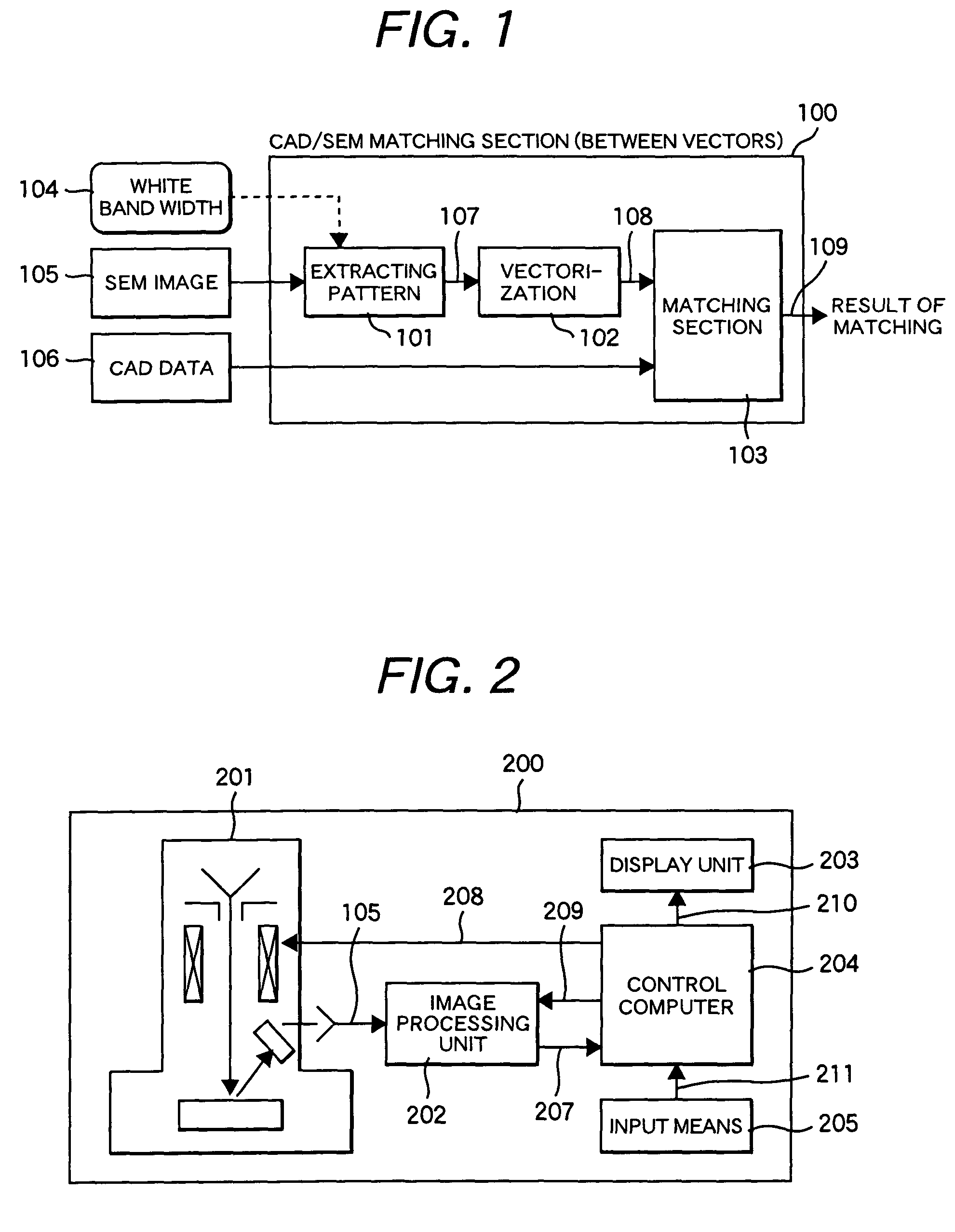

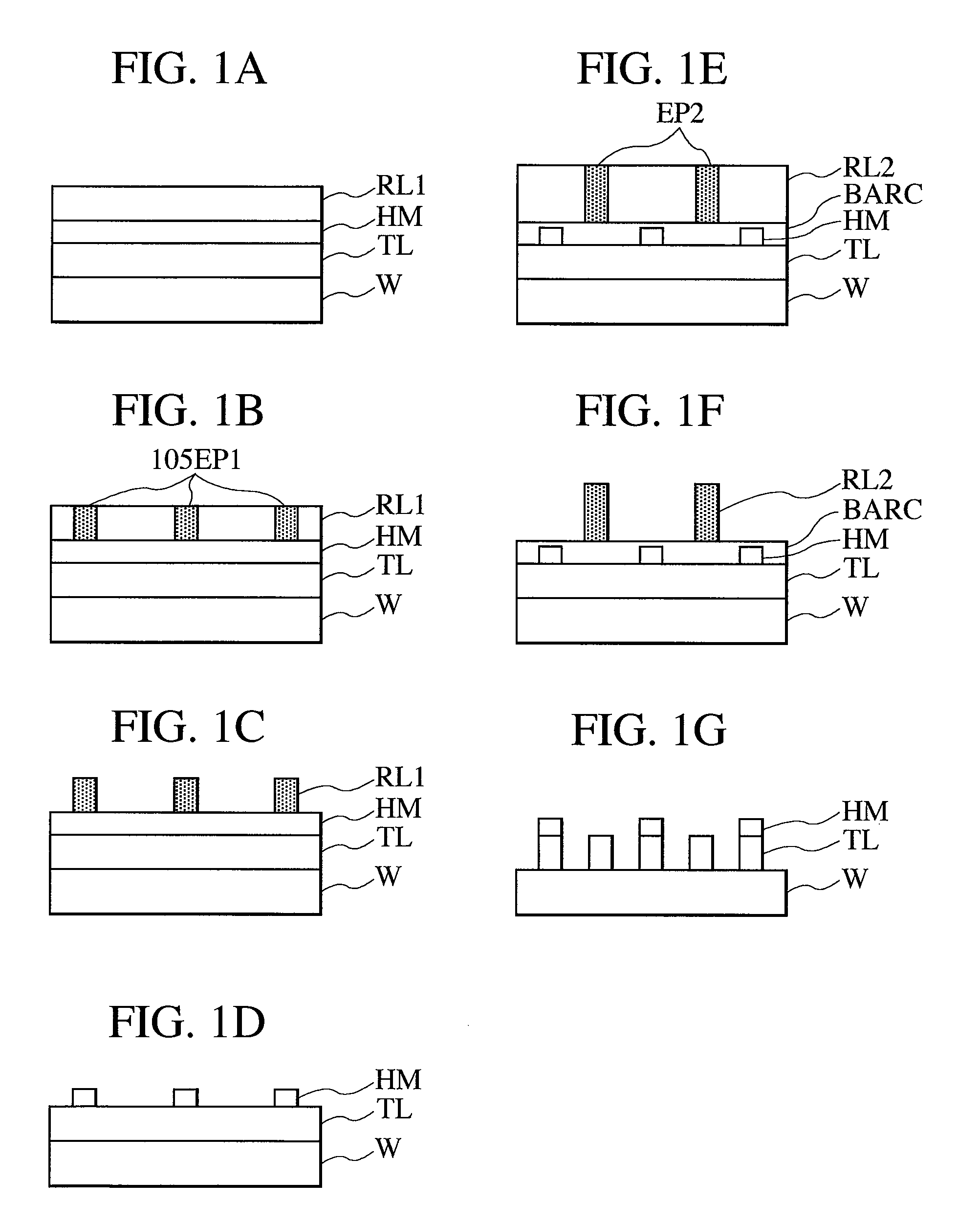

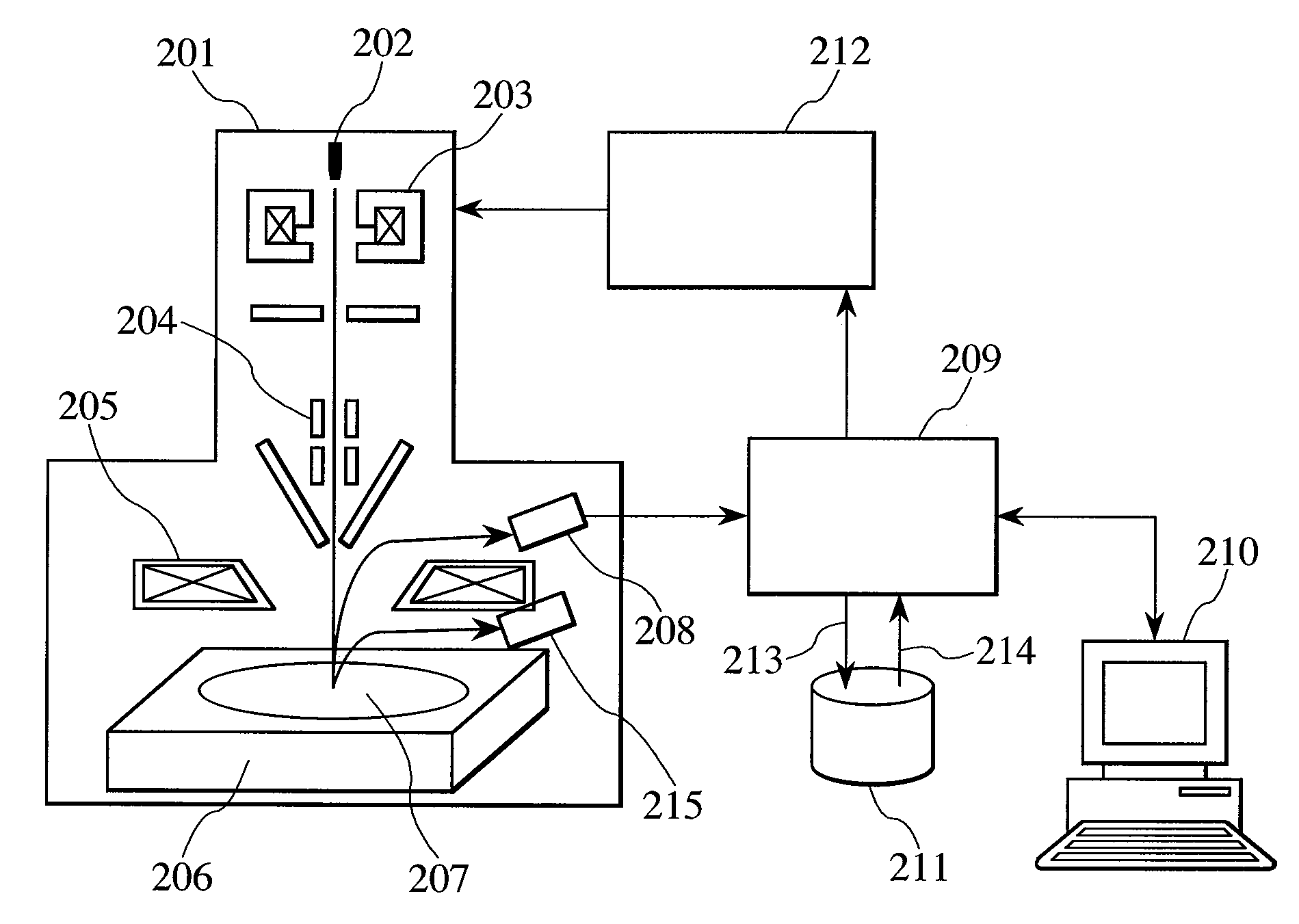

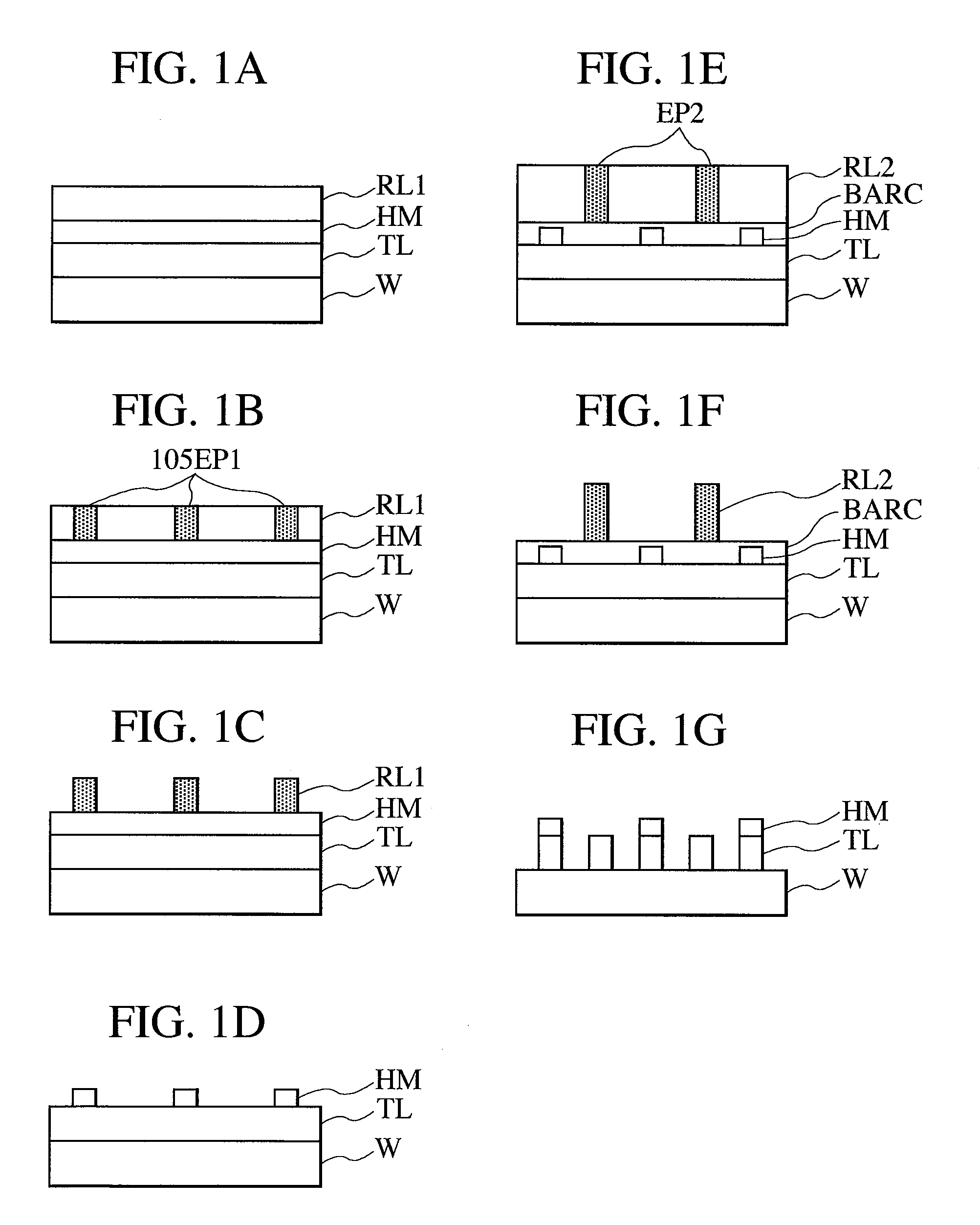

Pattern matching apparatus and scanning electron microscope using the same

ActiveUS20060045326A1Accurate isolationAccurate extractionImage enhancementImage analysisPattern matchingScanning tunneling microscope

A pattern matching apparatus comprising: means for storing photographed image data of a semiconductor device; means for storing CAD data of said semiconductor device; an information input means for inputting information on the white band width contained in said image data; a pattern extracting means for extracting a pattern on the semiconductor device from said image data by using the white band width information; and a matching means for matching said pattern with the CAD data.

Owner:HITACHI HIGH-TECH CORP

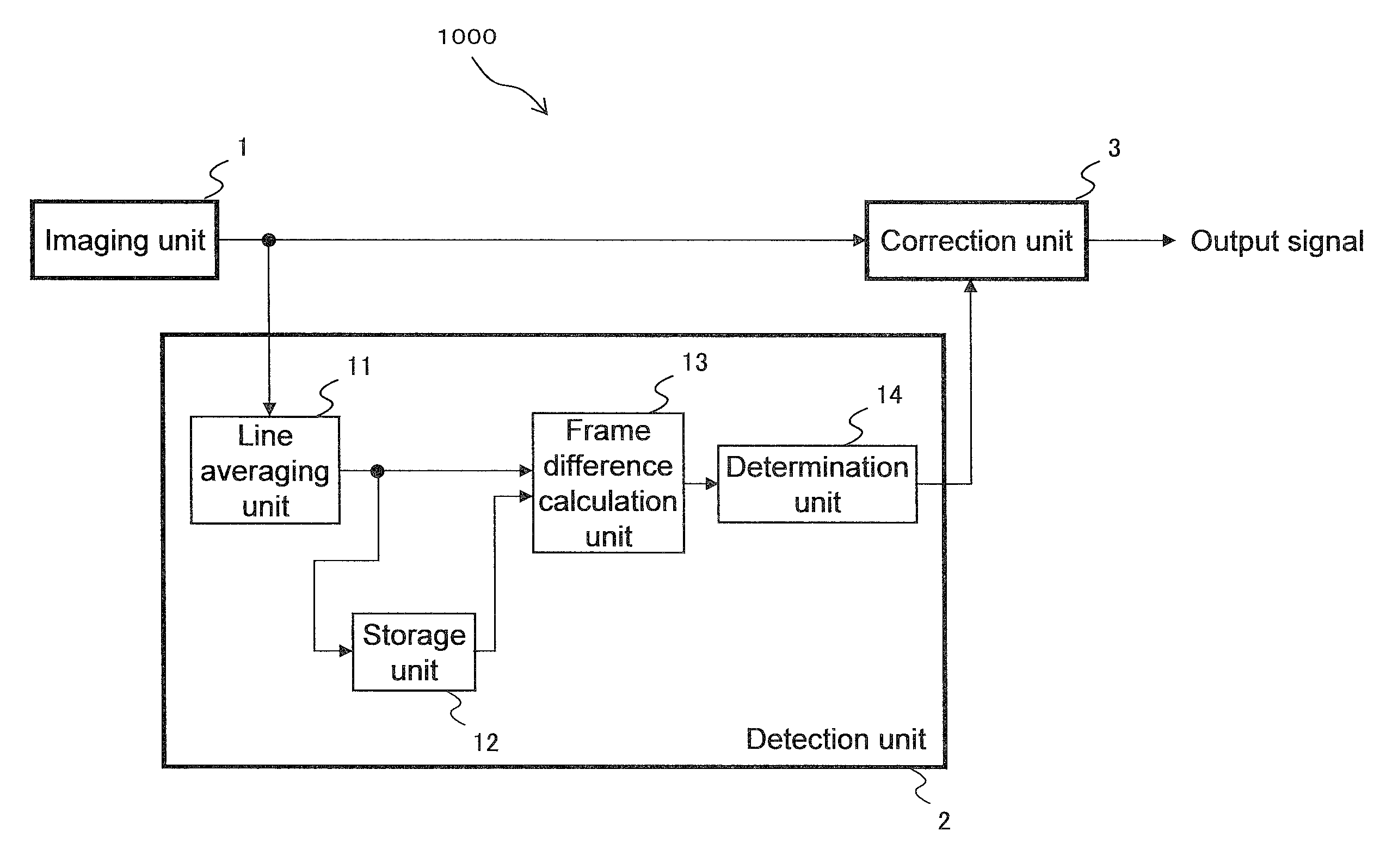

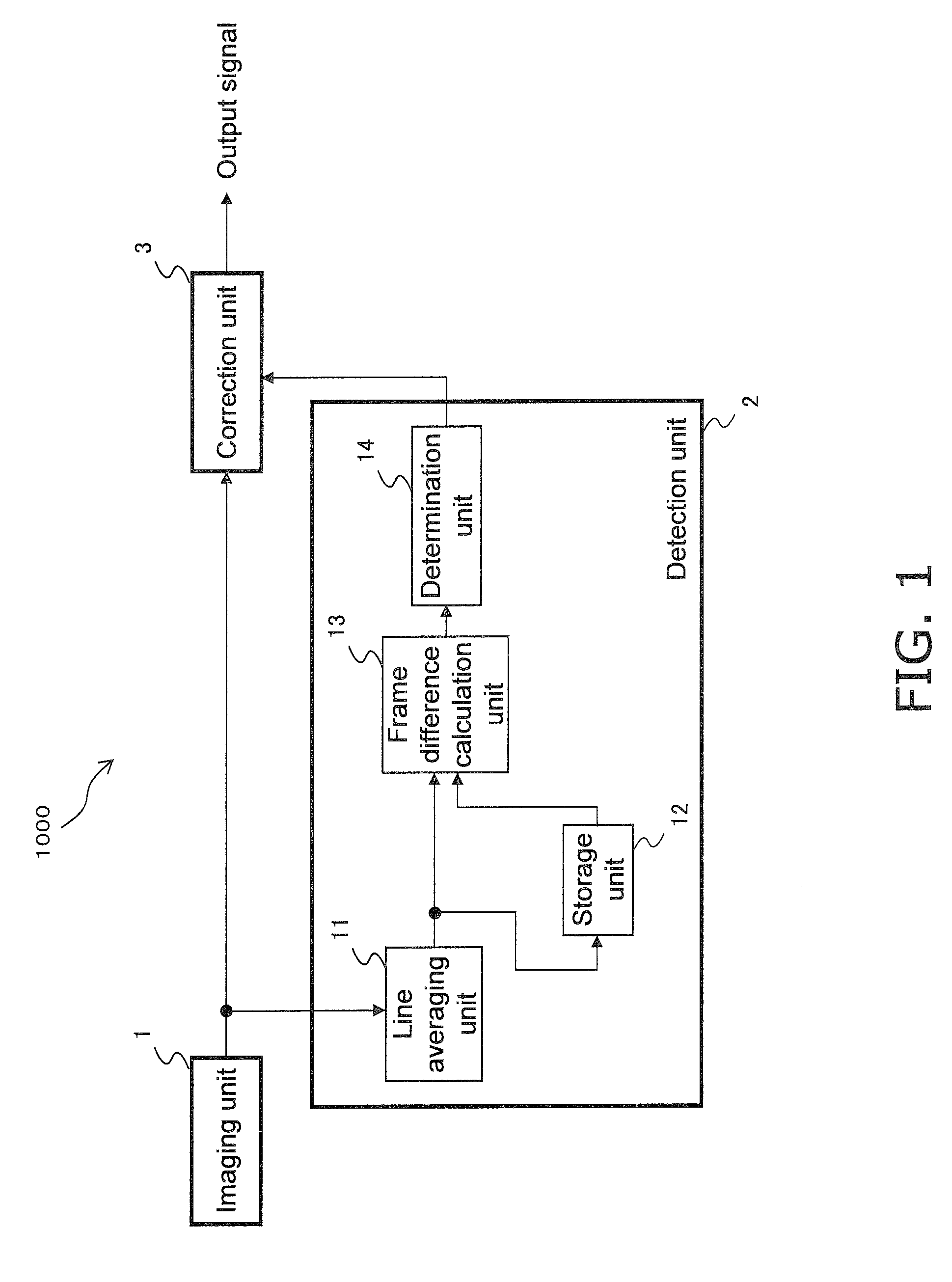

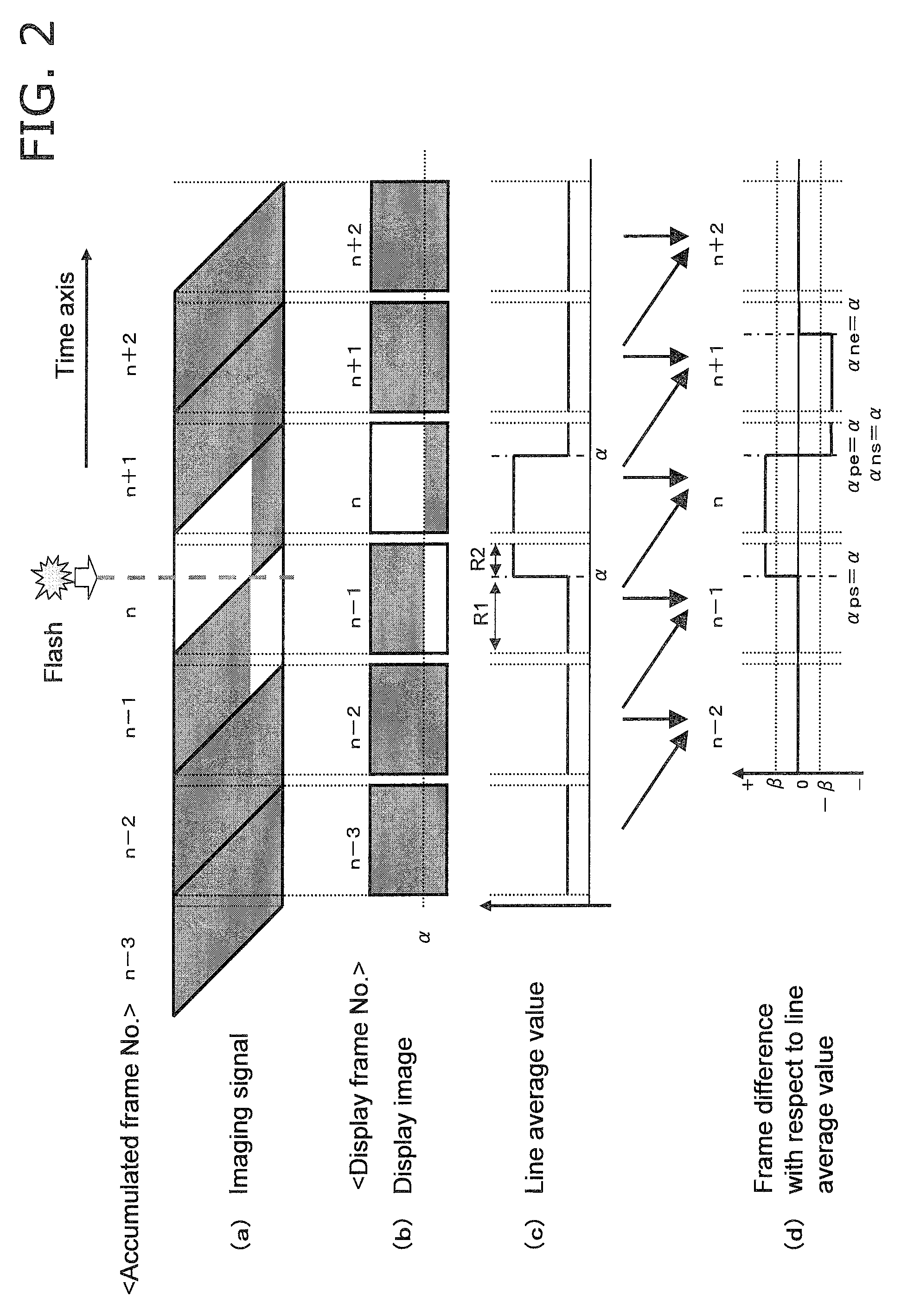

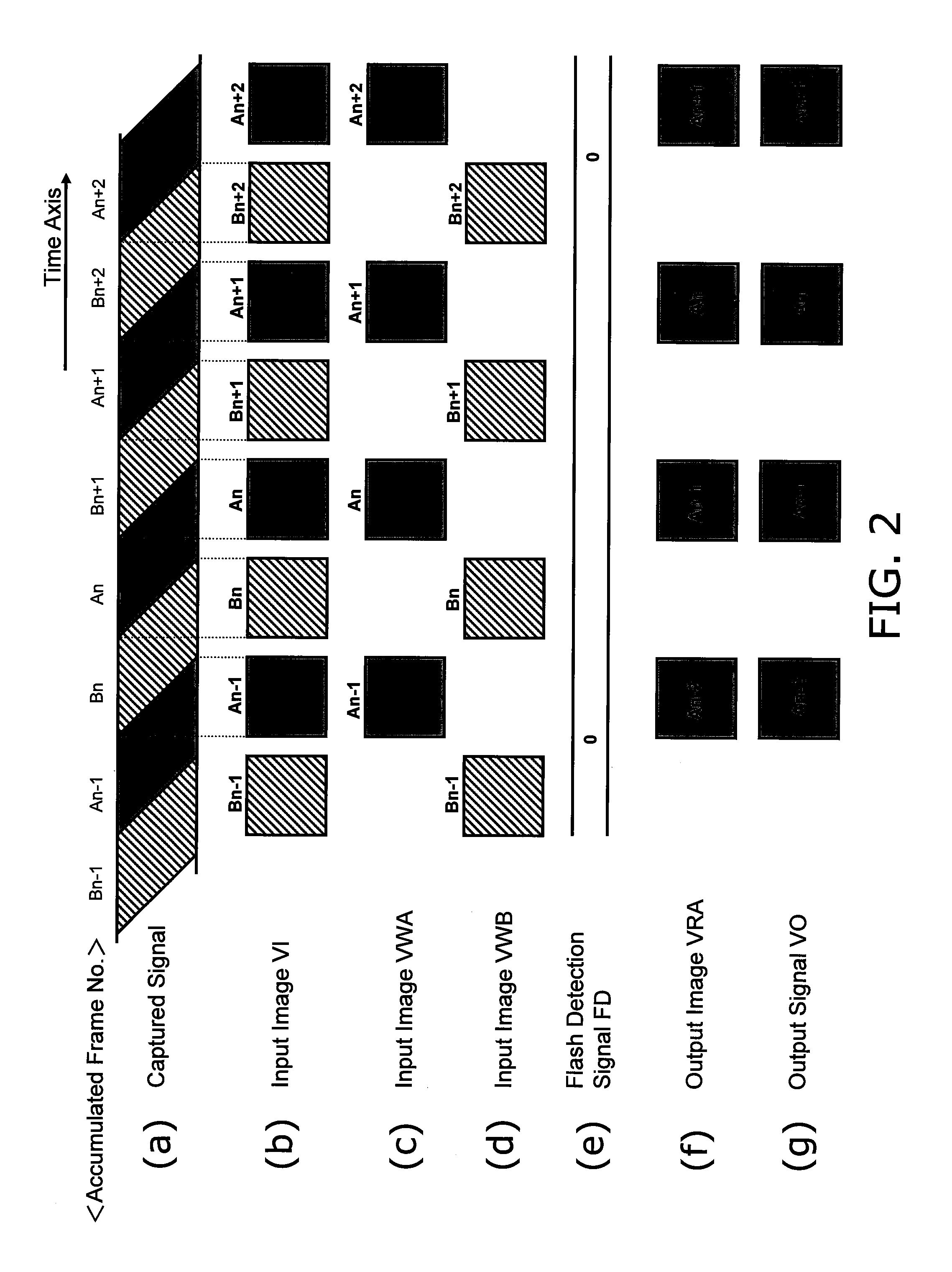

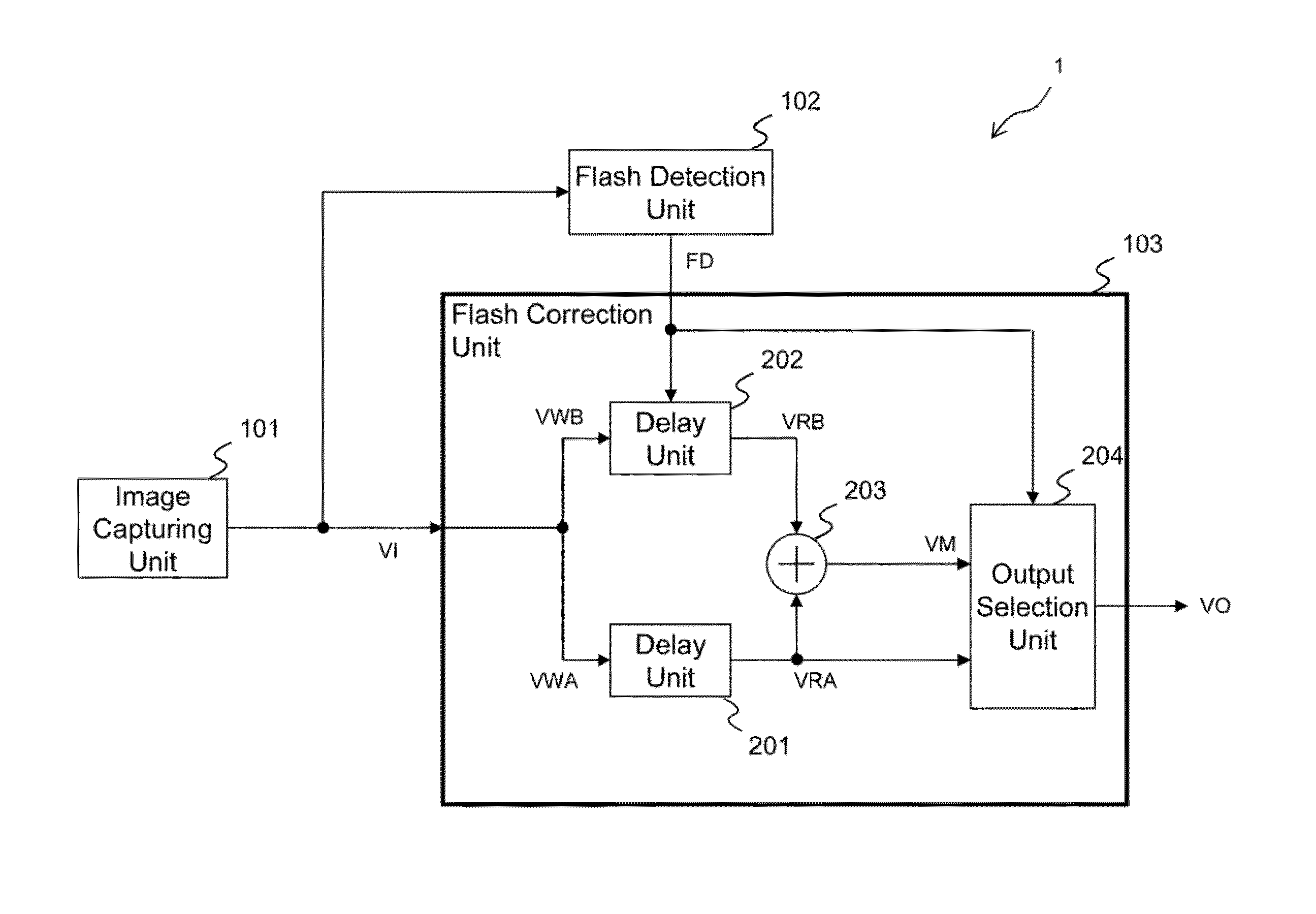

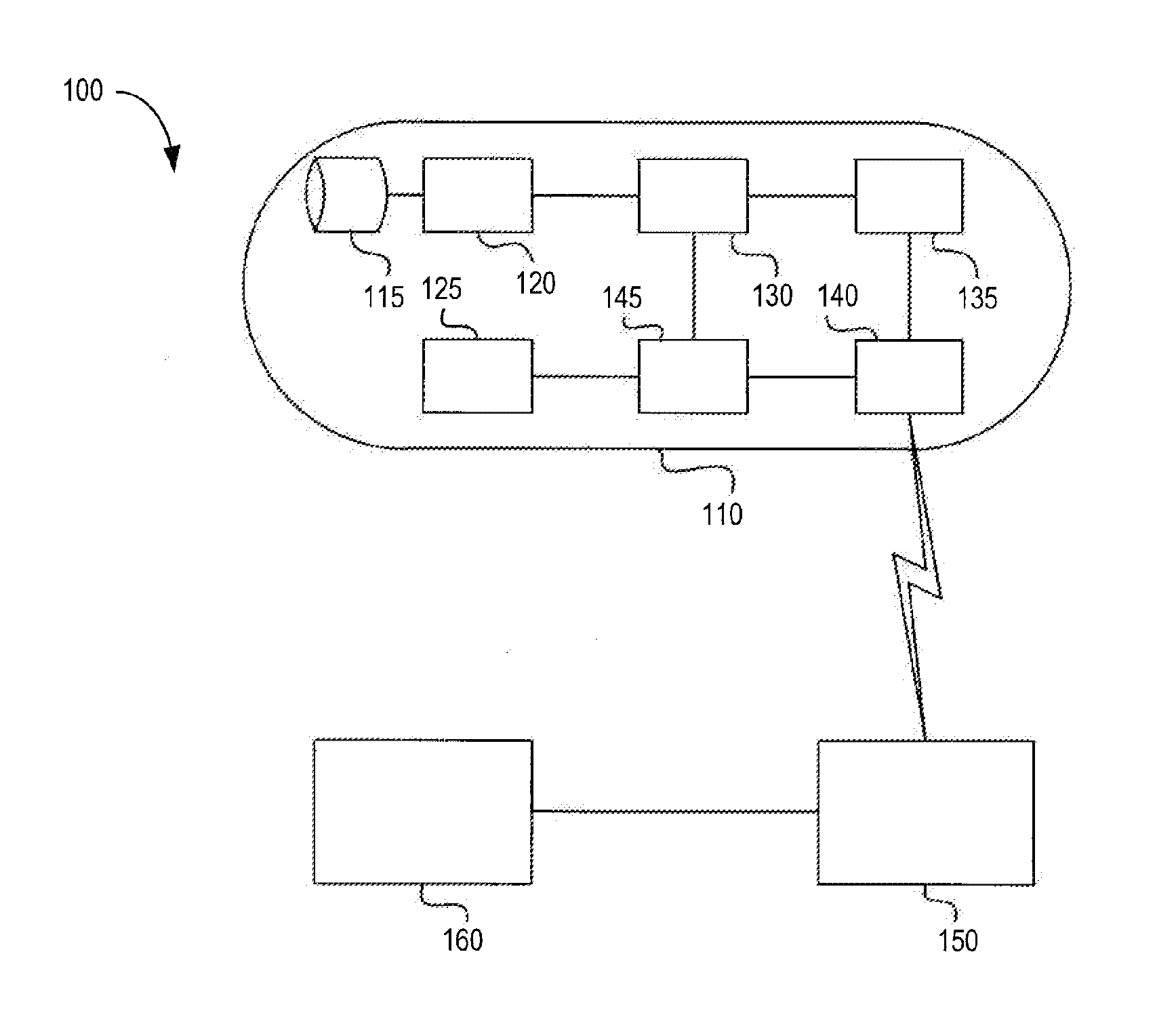

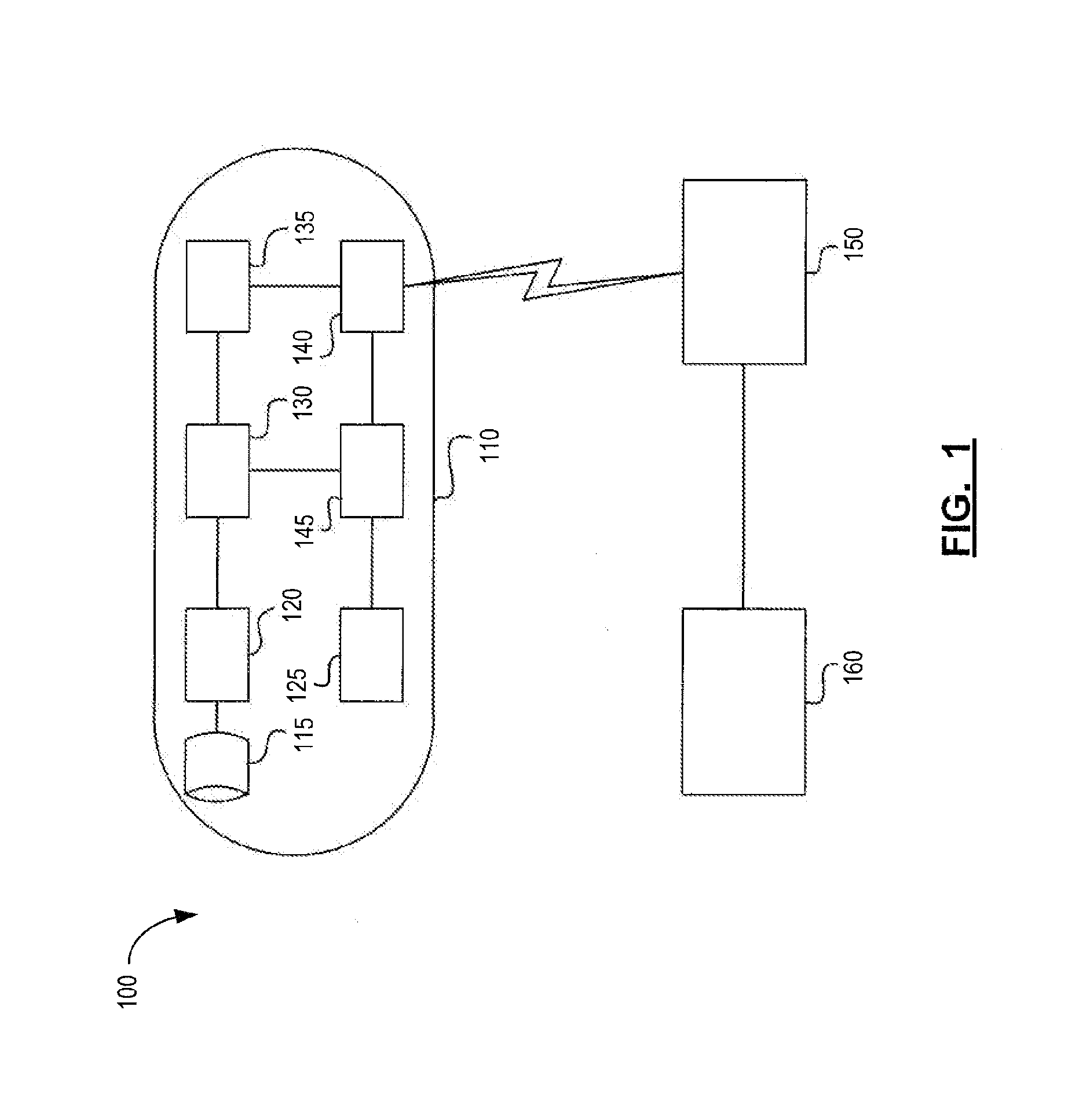

Imaging device, external flash detection method, program, and integrated circuit

ActiveUS20120026359A1Reliably determinedIncrease in circuit scaleTelevision system detailsImage analysisFrame differenceCMOS

When capturing images of a subject with an imaging device that uses a CMOS image sensor, a white band-shaped artifact appears in the imaging signal due to the influence of a rolling shutter operation performed when an external flash has been emitted. Manipulating or removing images in which such an artifact appears requires specifying the frames in which the artifact appears. A line averaging unit (11) calculates the average luminance level of each line in the imaging signal, the average luminance levels are temporarily stored by a storage unit (12), and thereafter a frame difference calculation unit (13) calculates the difference between the line average luminance levels and the line average luminance levels of the next frame. These frame difference values are compared with a reference value, and it is determined that the influence of an external flash is present if a portion of interest with high values is continuous for one frame period.

Owner:PANASONIC CORP

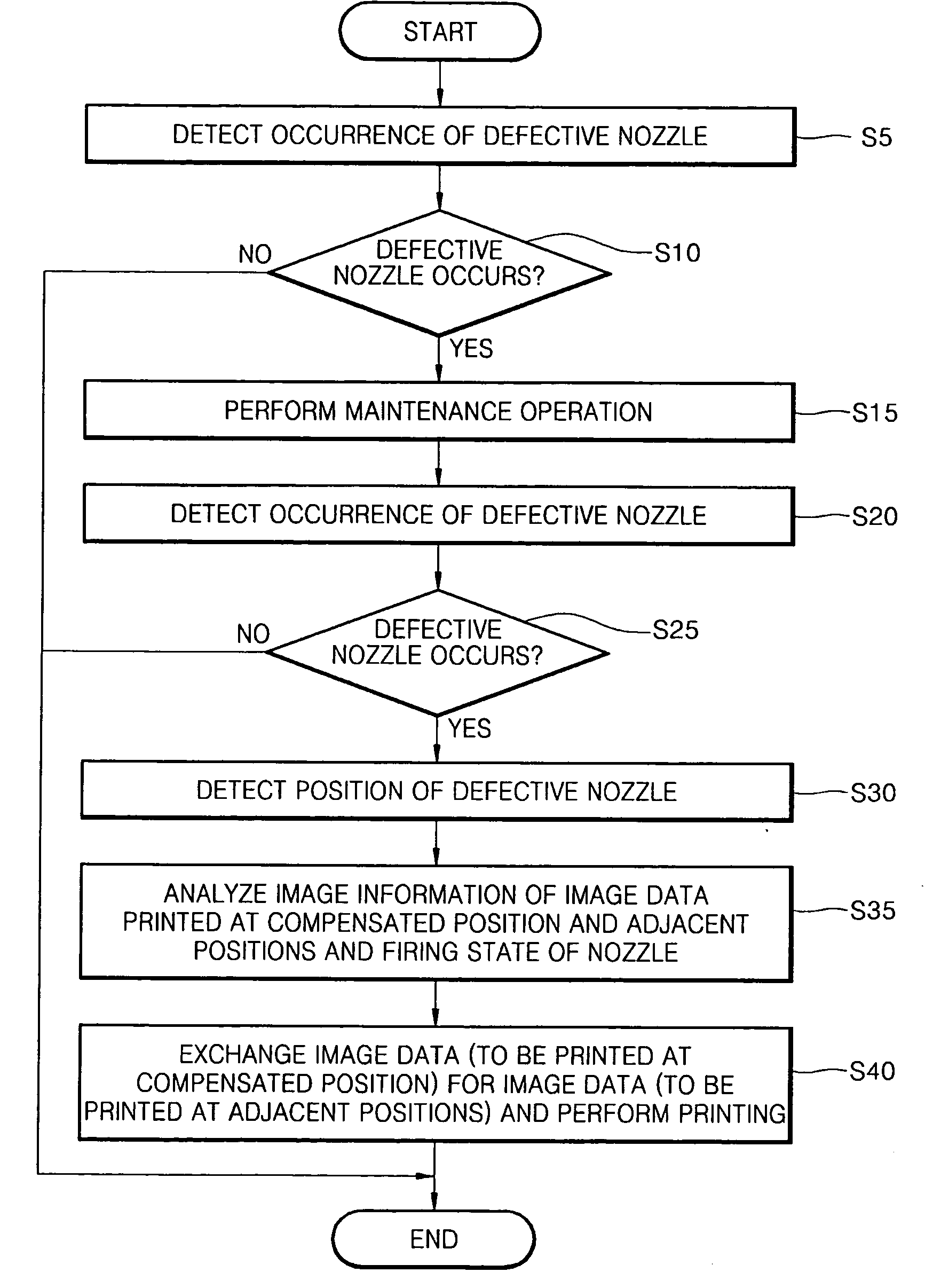

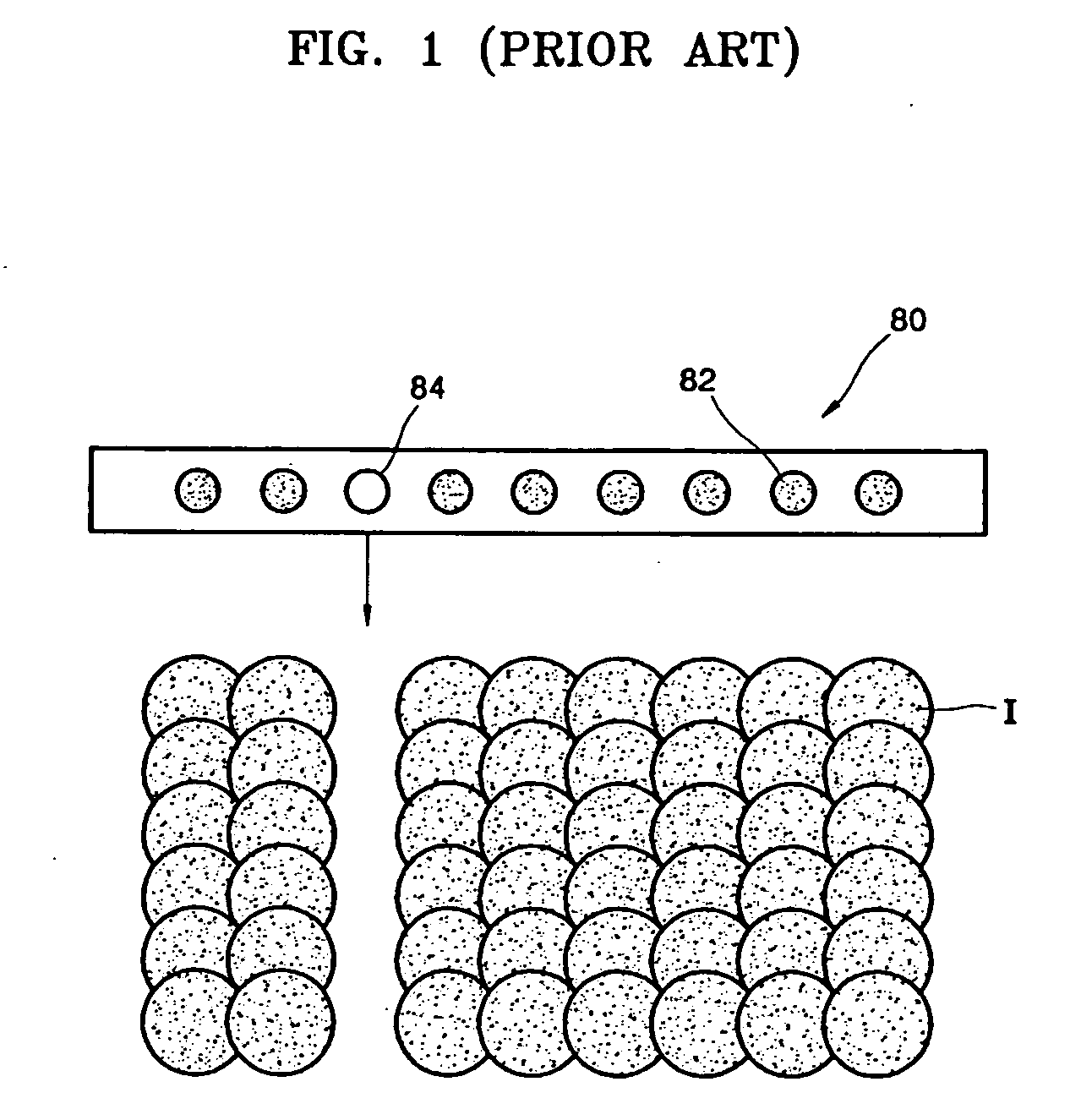

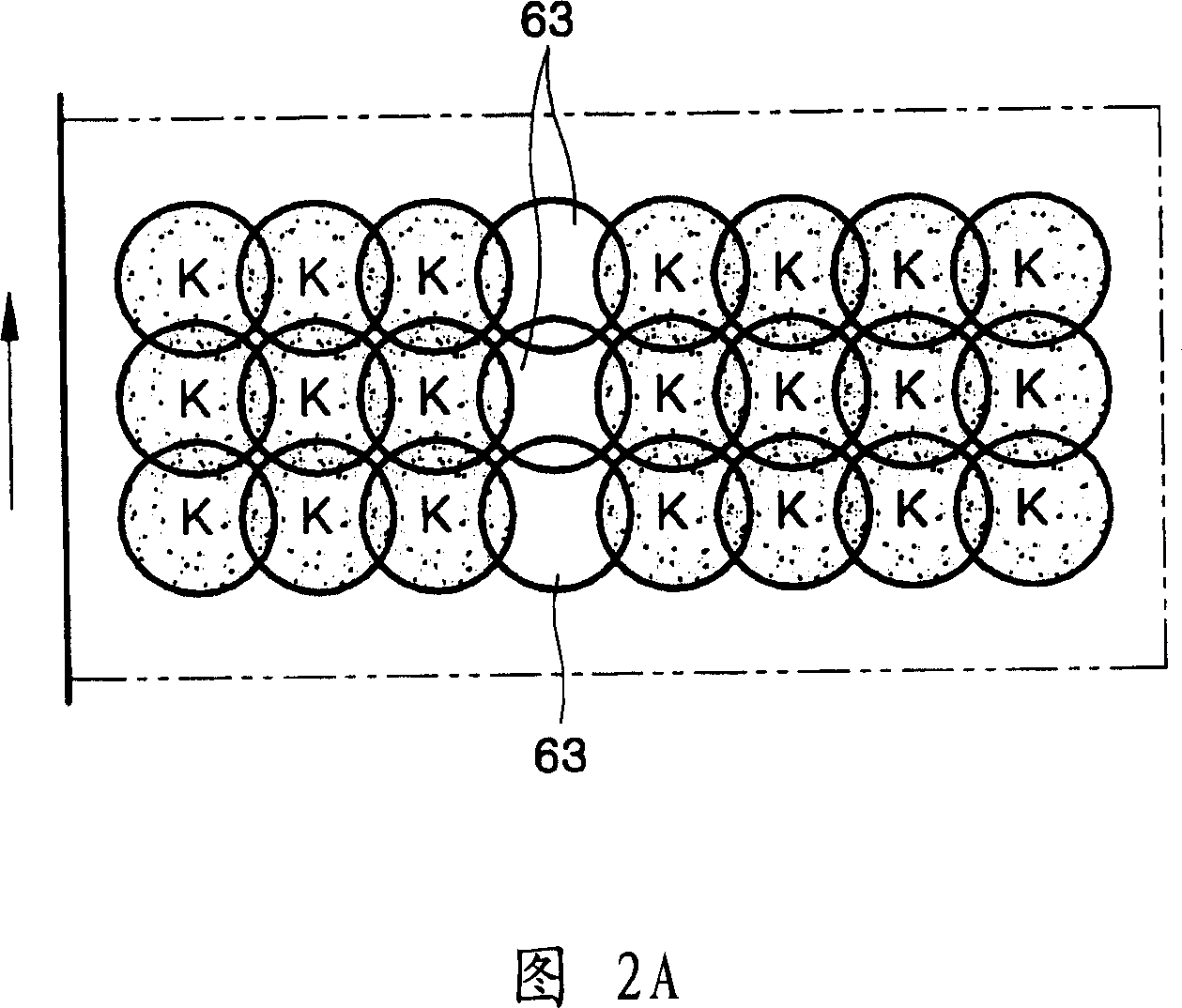

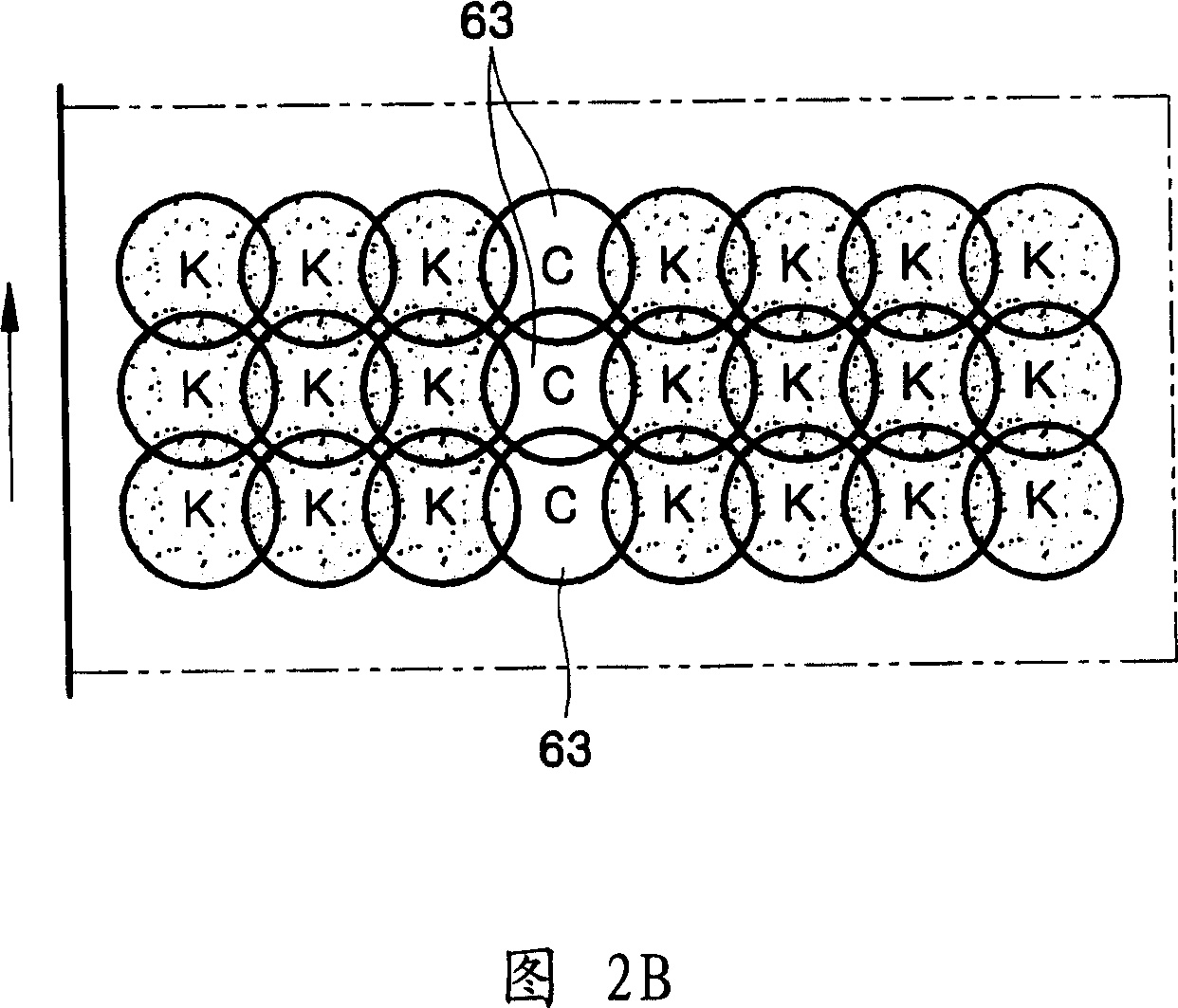

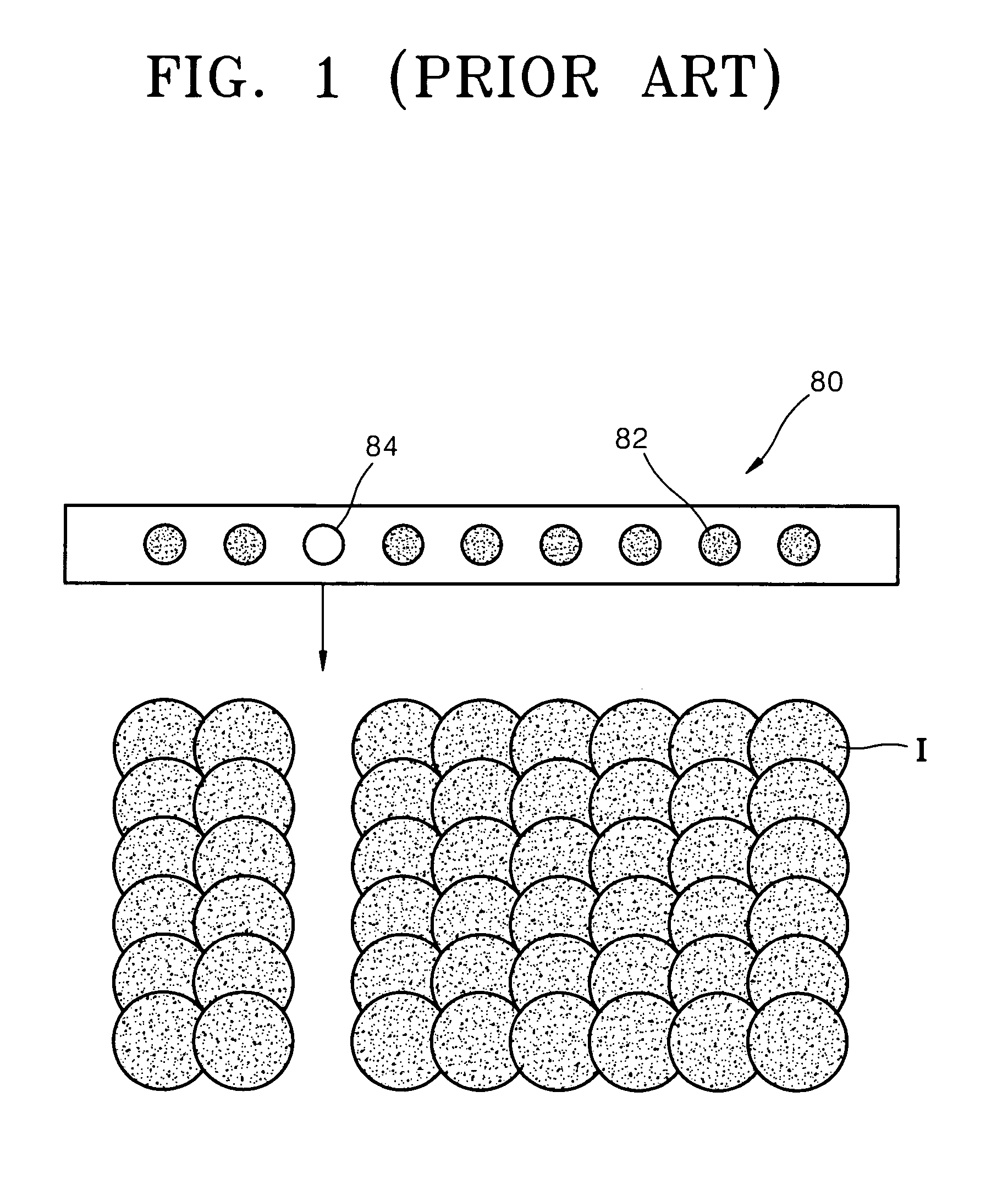

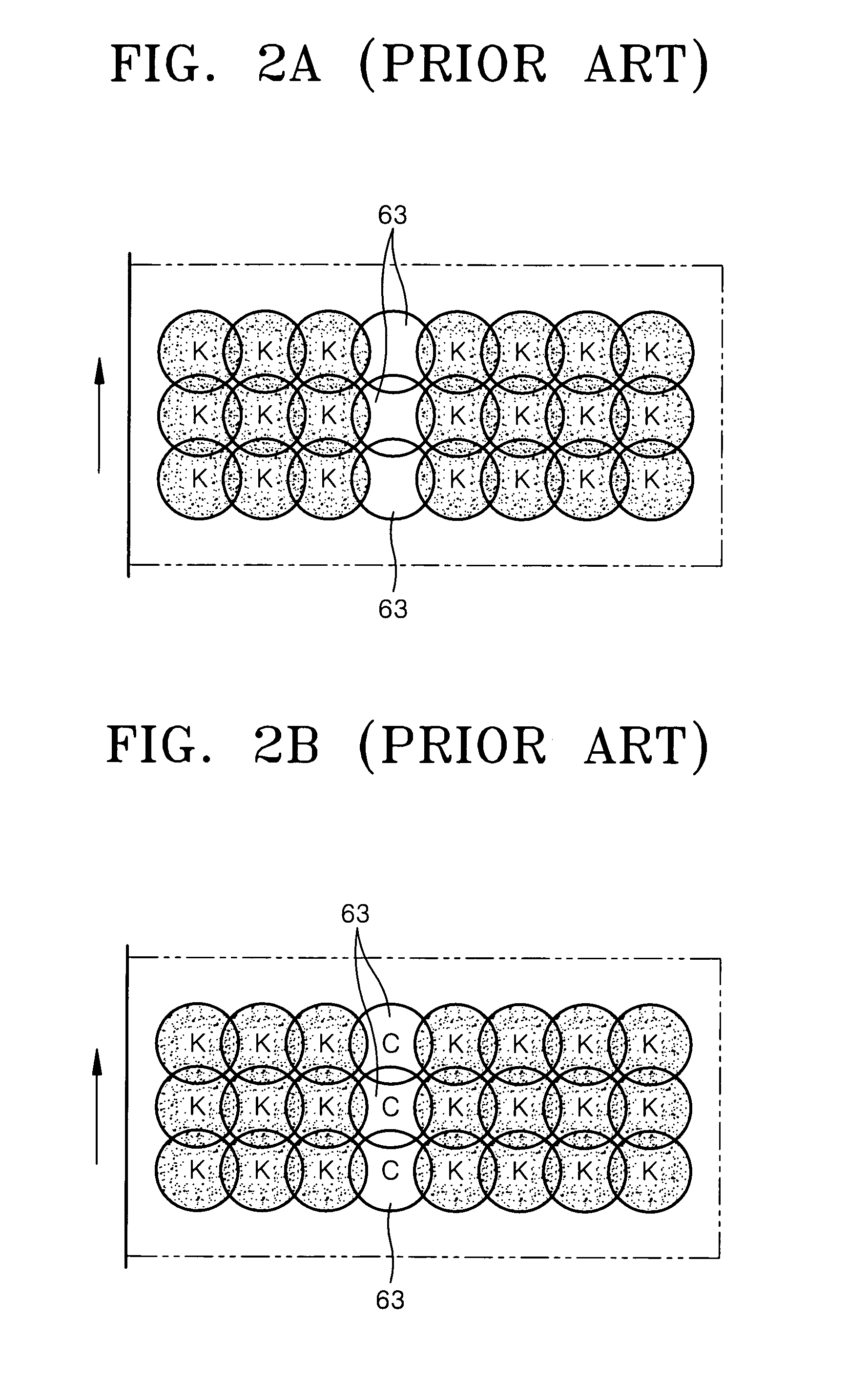

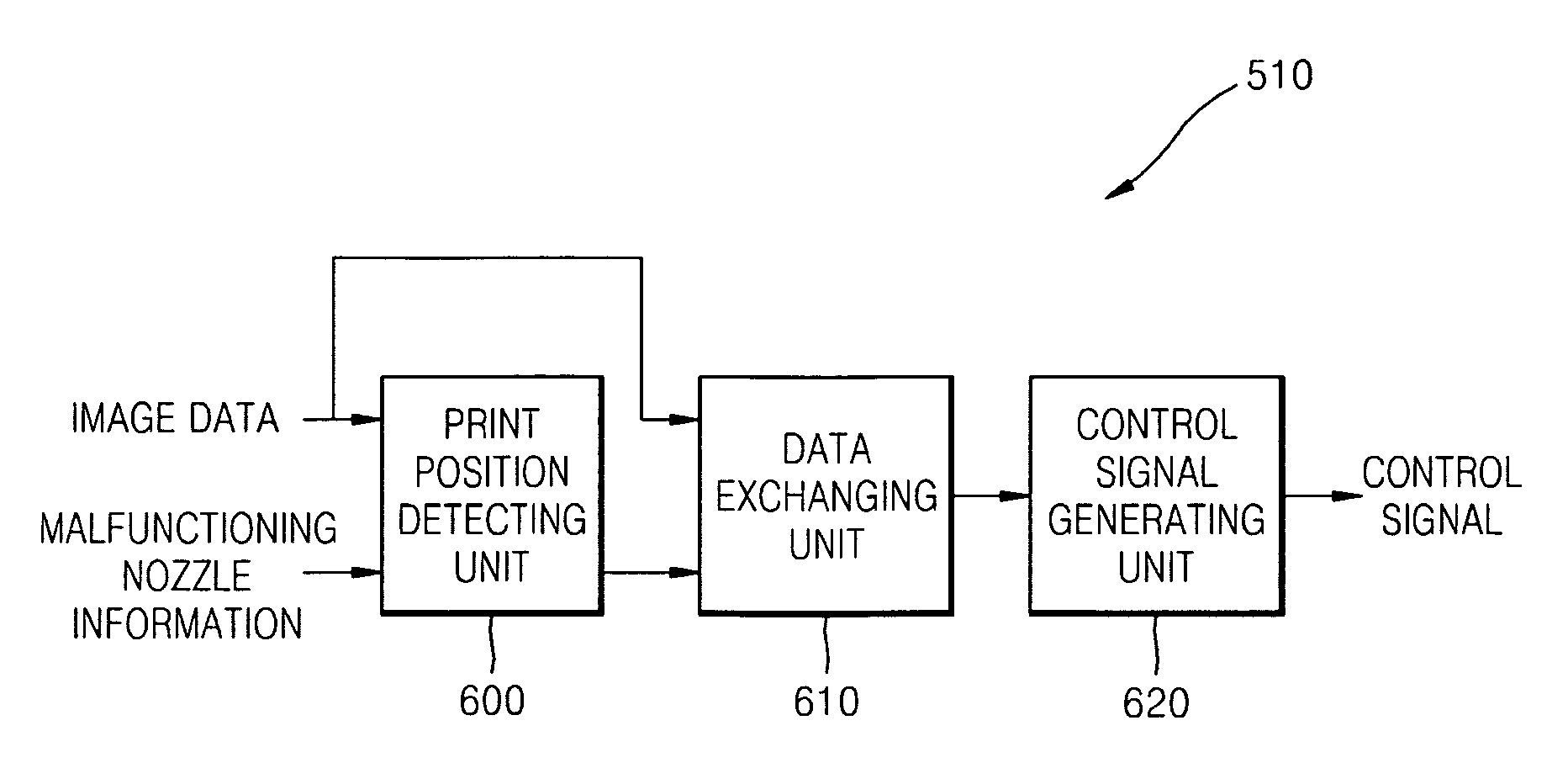

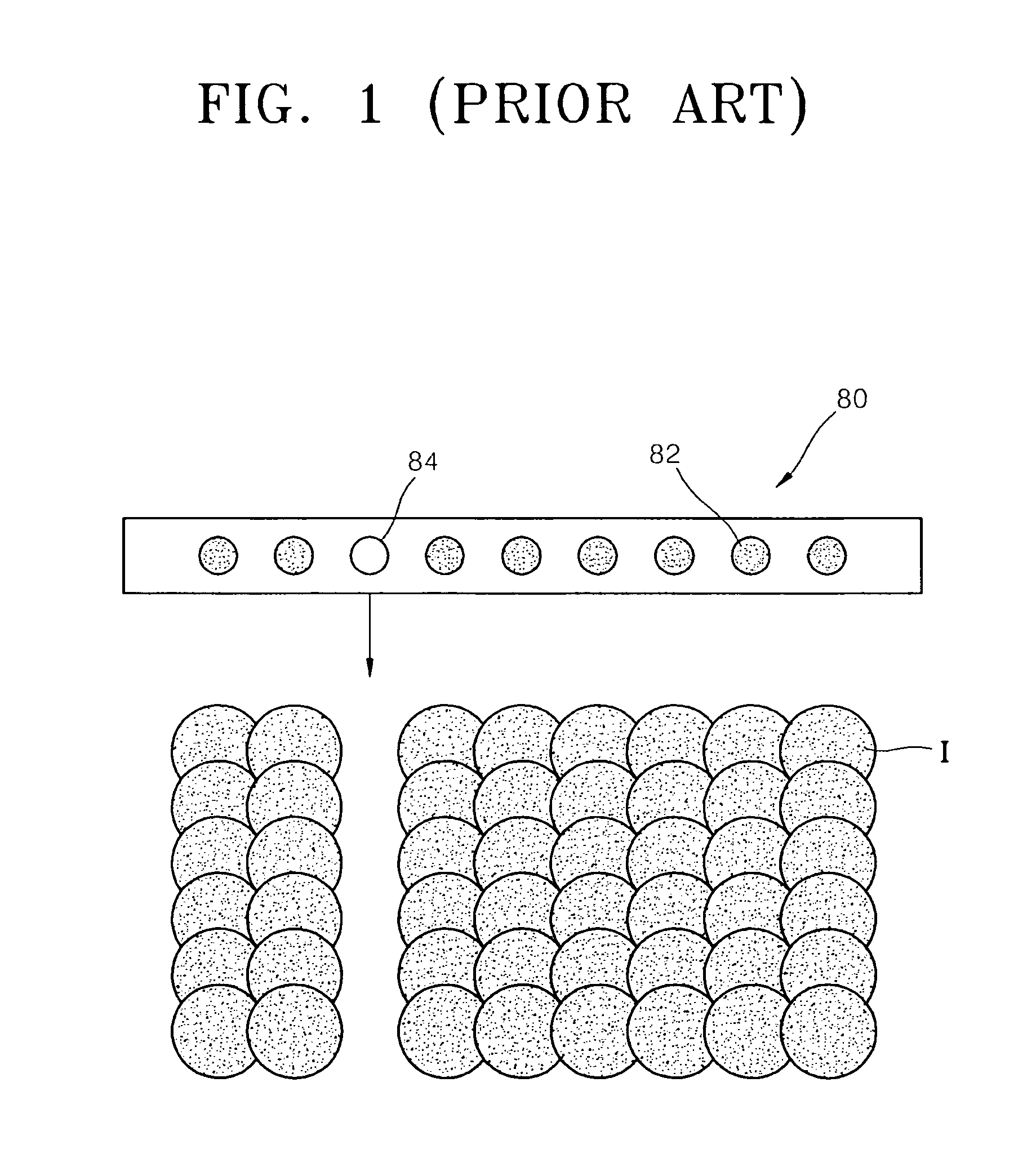

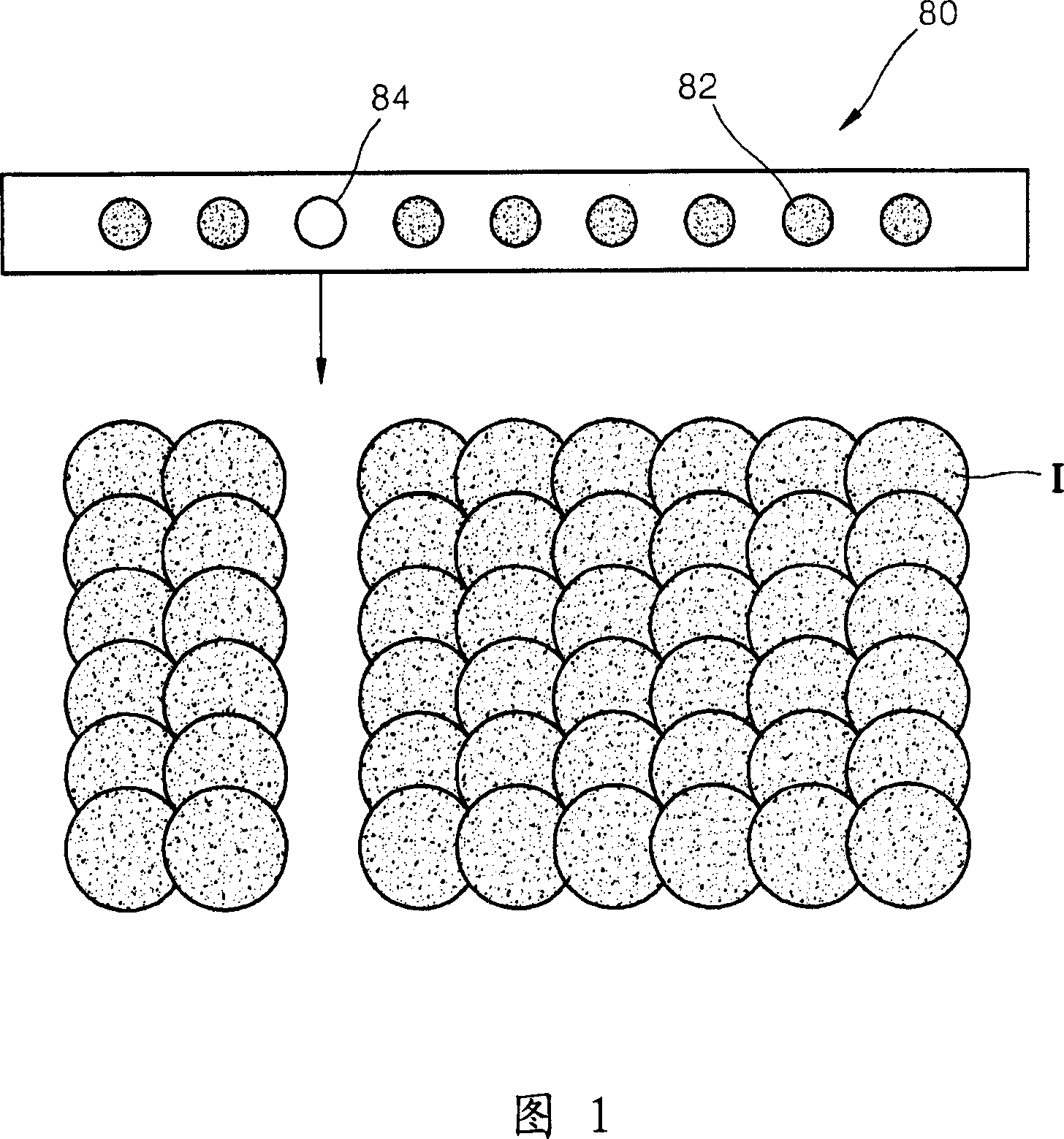

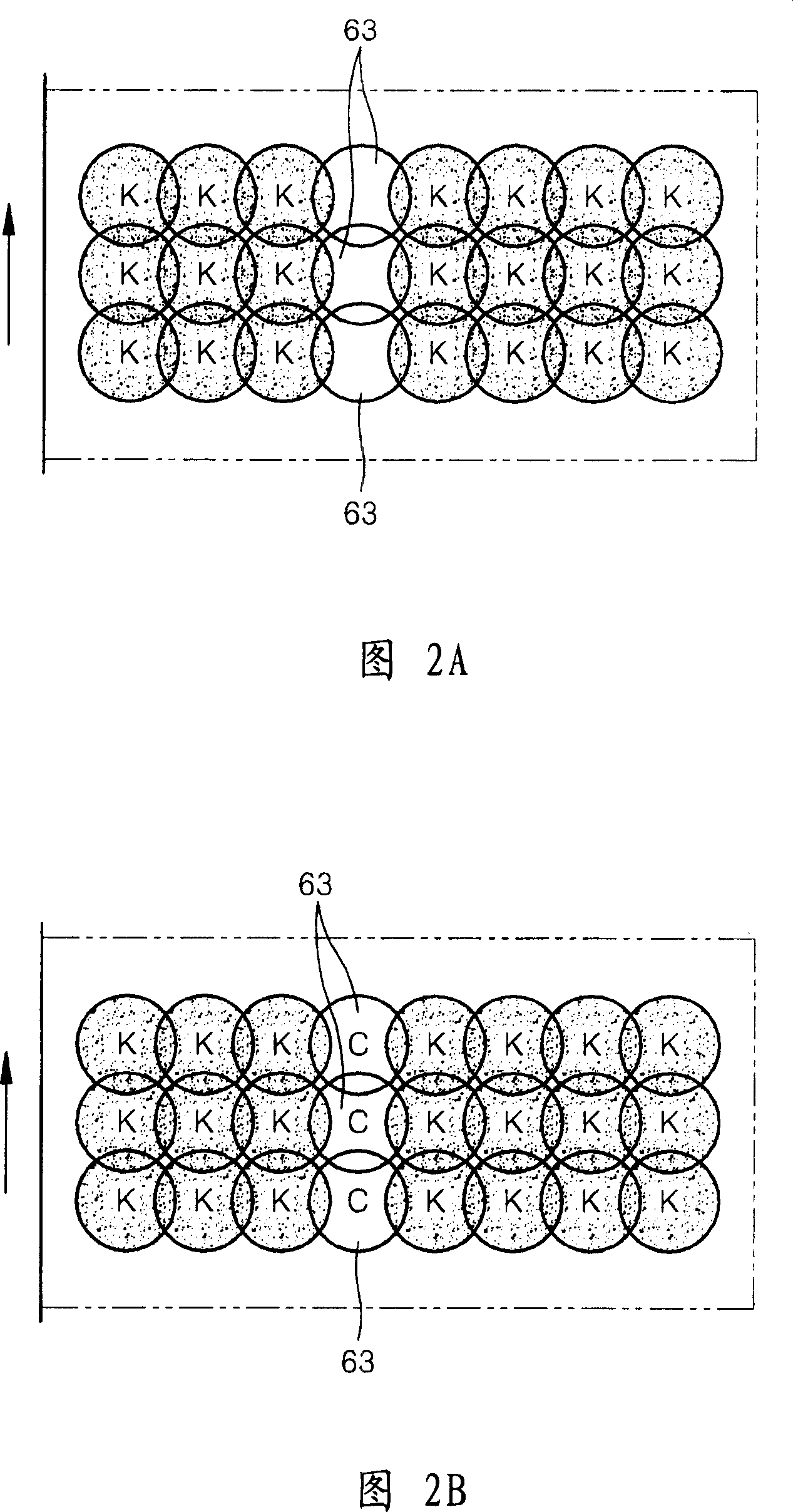

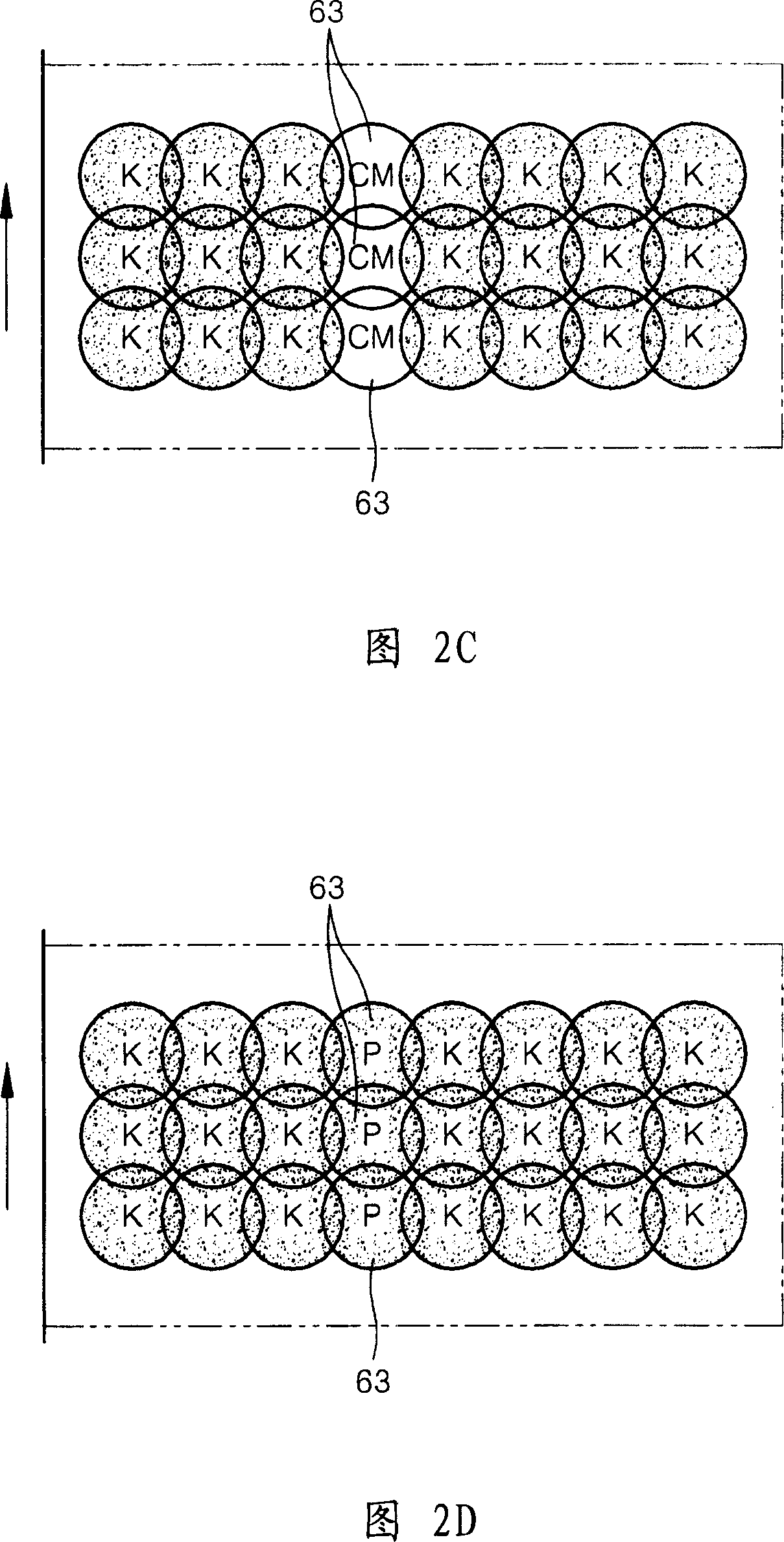

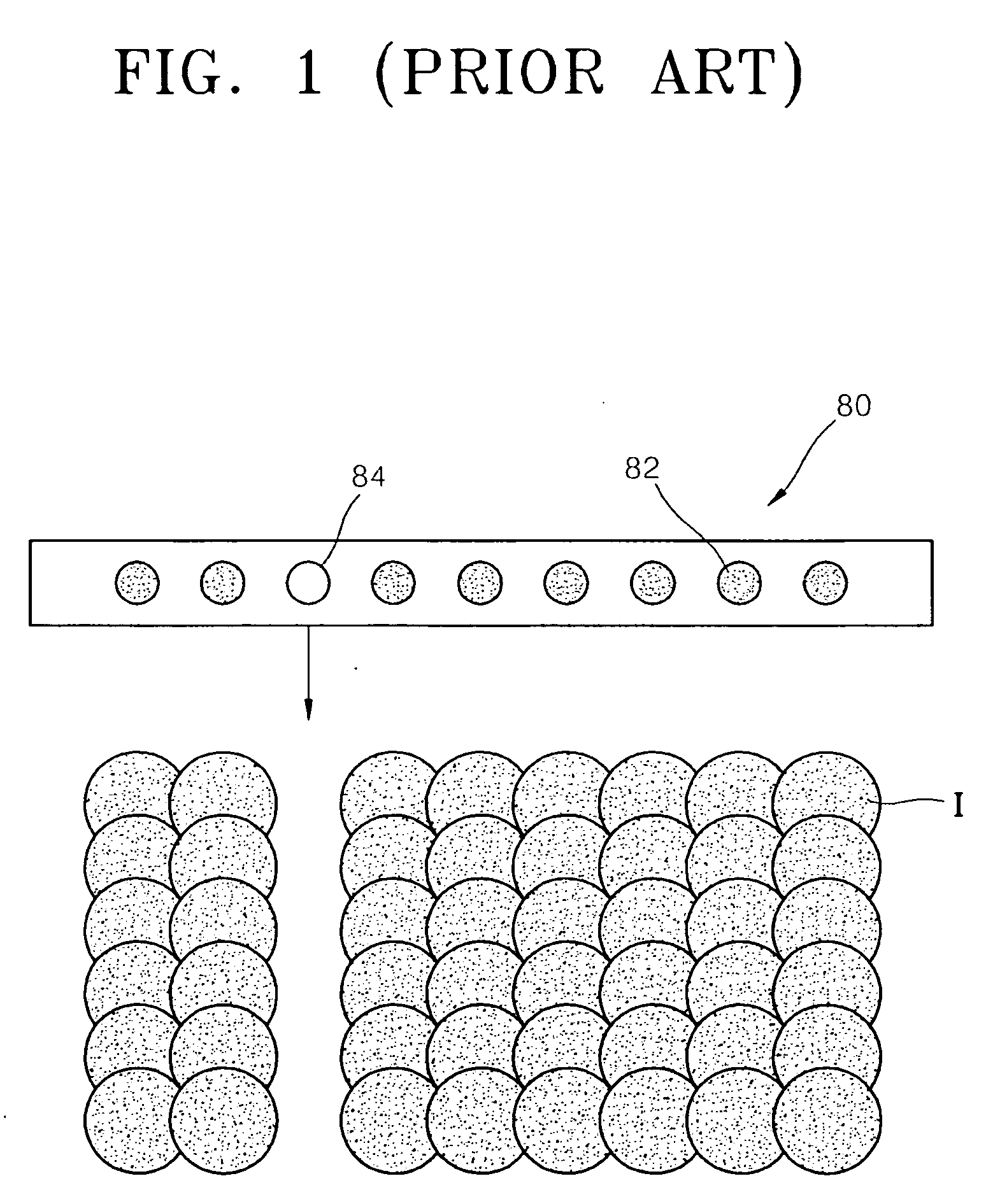

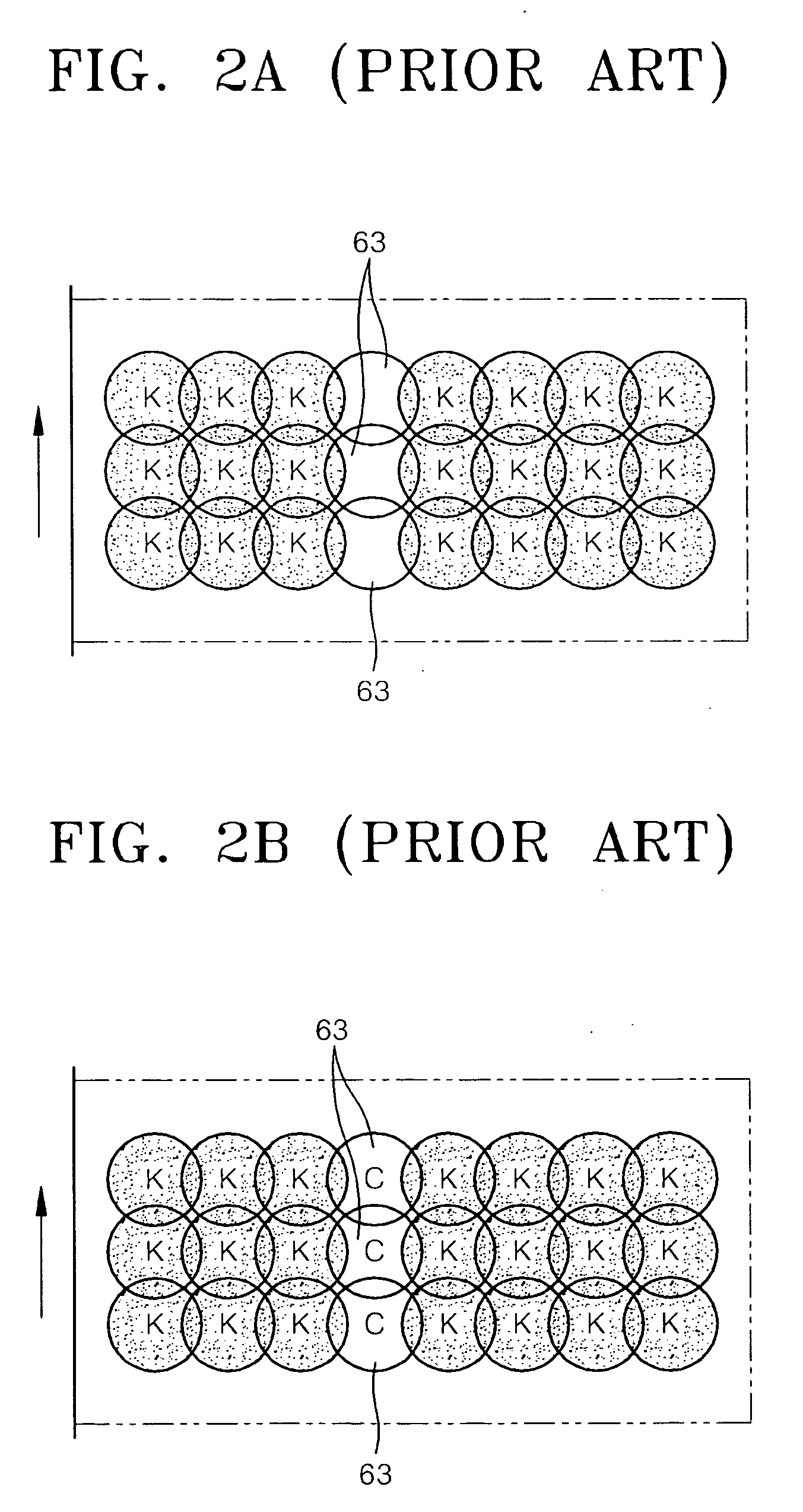

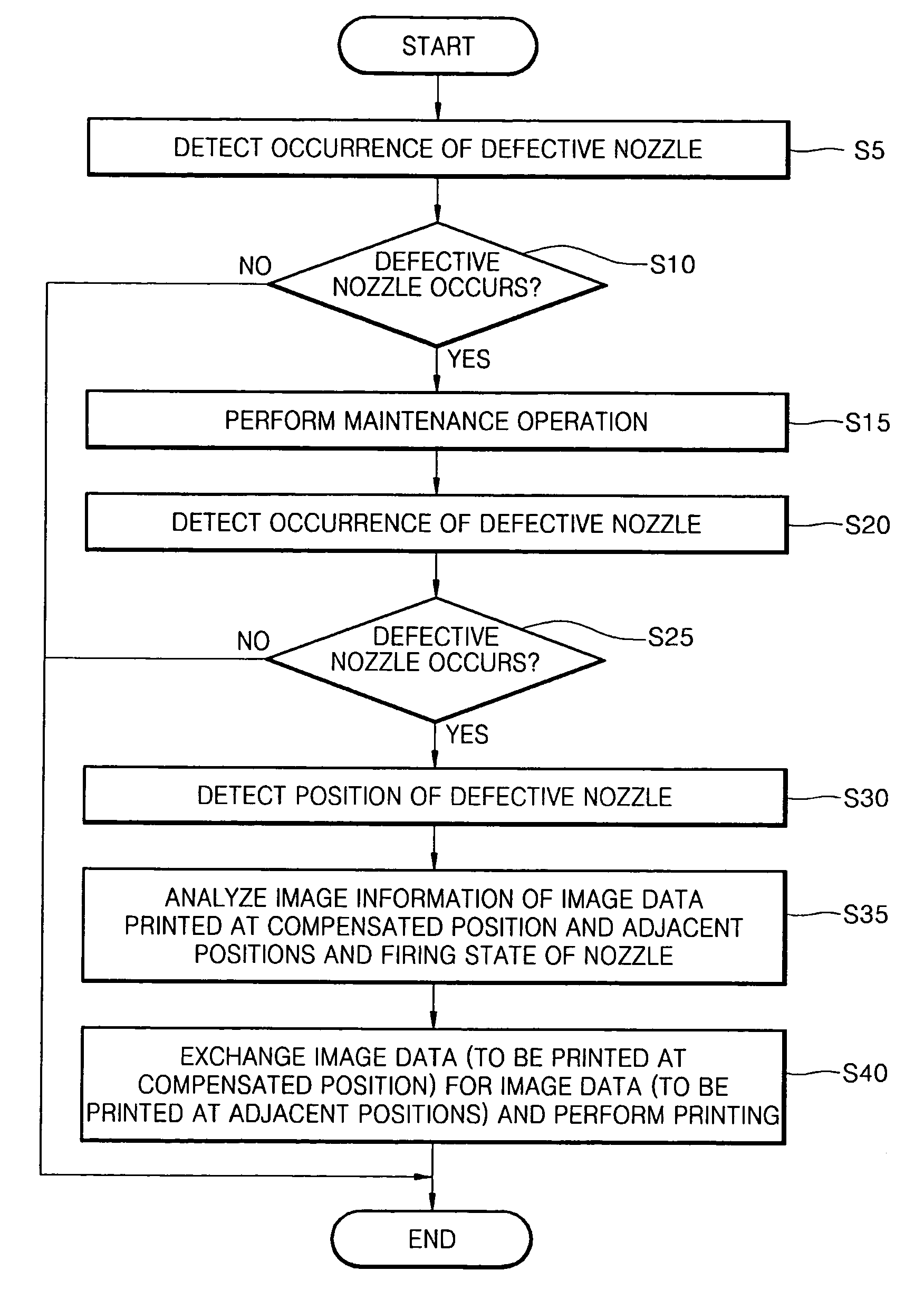

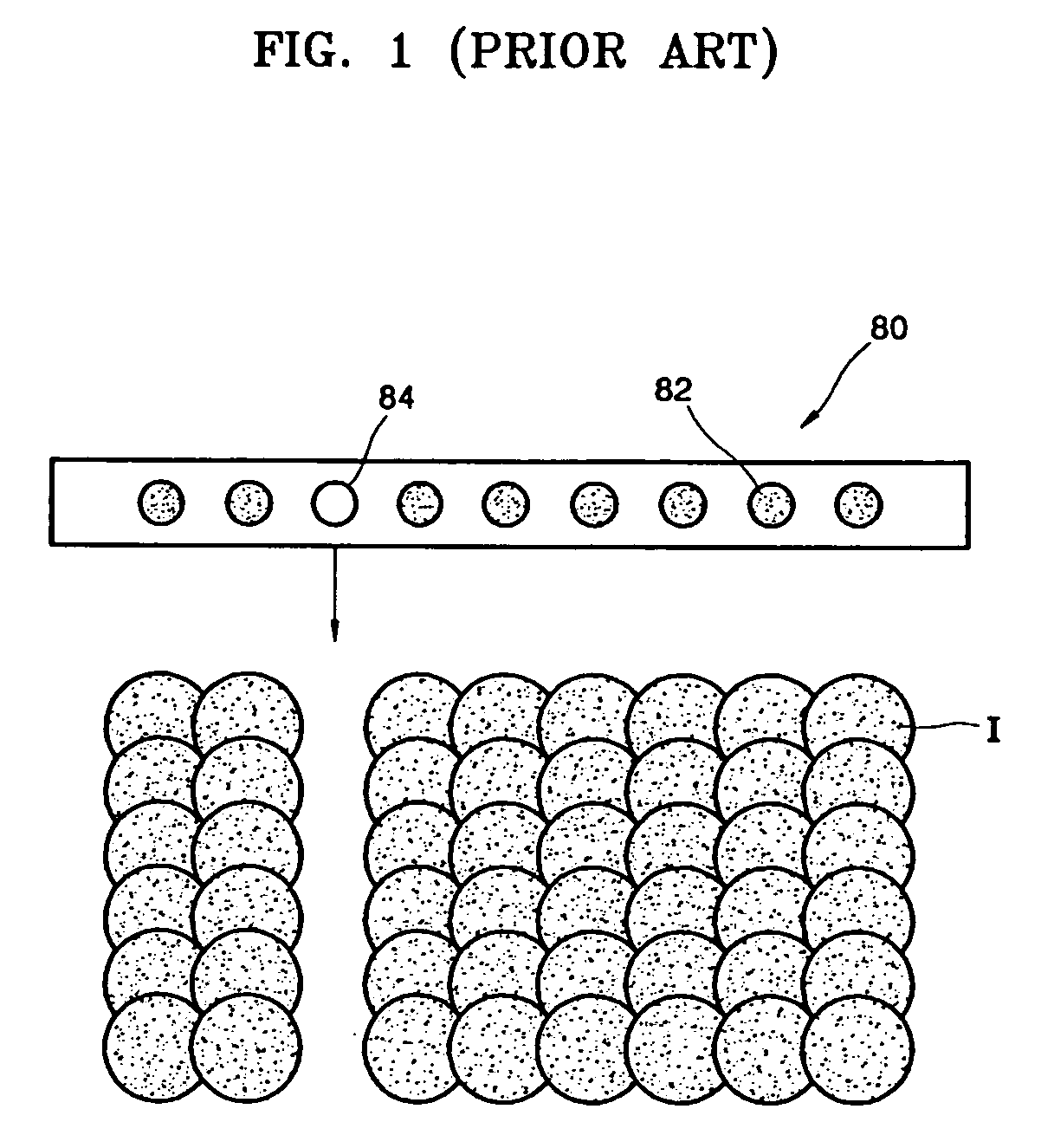

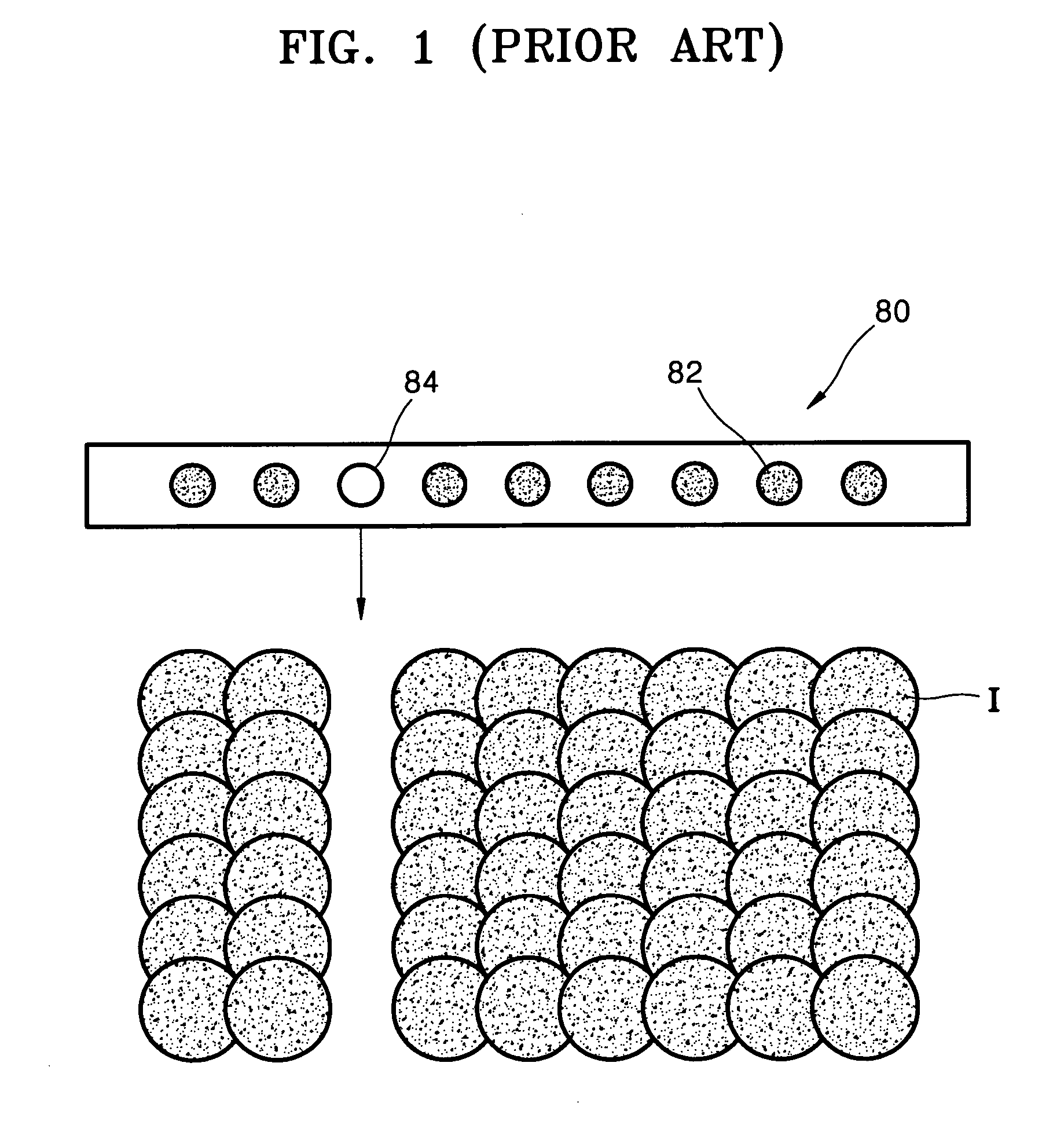

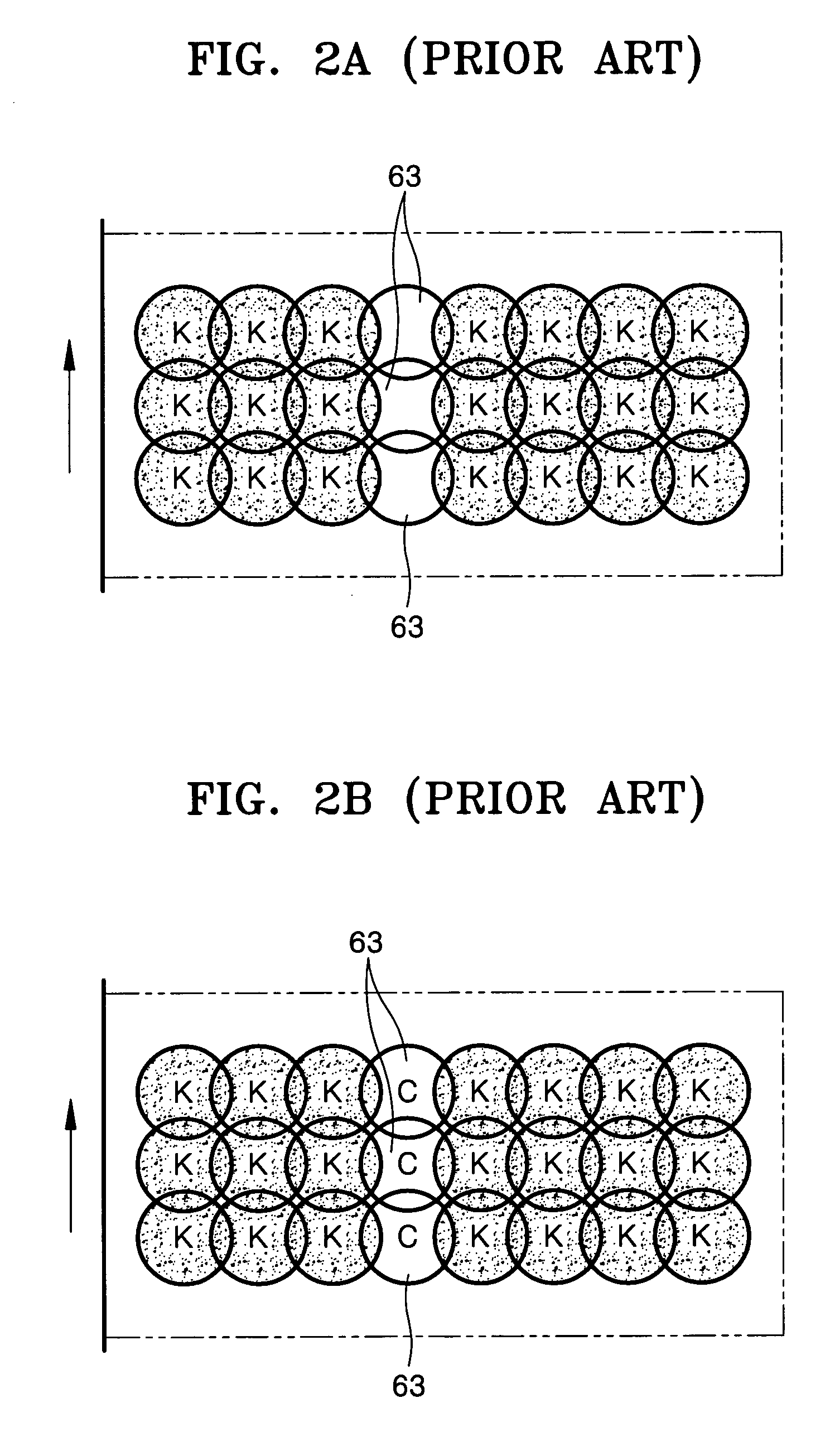

Inkjet image forming apparatus and method of compensating for defective nozzle thereof

InactiveUS20070070111A1Improve image qualityMinimize impactOther printing apparatusImaging qualityEngineering

An inkjet image forming apparatus and a method of defective nozzle compensation in the inkjet image forming apparatus. The method includes detection of an occurrence and a position of the defective nozzle in a nozzle unit, when the defective nozzle is detected, analyzing image information on image data which are to be printed at a compensated position which is a position printed with the defective nozzle and image data which are to be printed at positions adjacent to the compensated position, and exchanging the image data which are to be printed at the compensated position for image data which are to be printed at one of the adjacent positions according to the analyzed image information and performing printing. Missing dots caused by the defective nozzle are compensated by exchanging image data and performing printing. Accordingly, since the image data are exchanged and printed, it is possible to prevent deterioration in image quality such as a white band which can be easily perceived by a user.

Owner:HEWLETT PACKARD DEV CO LP

Ink jet image forming apparatus, and method for compensating defective nozzle thereof

InactiveCN1955001AVisual representation by matrix printersOther printing apparatusImaging qualityEngineering

An inkjet image forming apparatus and a method of defective nozzle compensation in the inkjet image forming apparatus. The method includes detection of an occurrence and a position of the defective nozzle in a nozzle unit, when the defective nozzle is detected, analyzing image information on image data which are to be printed at a compensated position which is a position printed with the defective nozzle and image data which are to be printed at positions adjacent to the compensated position, and exchanging the image data which are to be printed at the compensated position for image data which are to be printed at one of the adjacent positions according to the analyzed image information and performing printing. Missing dots caused by the defective nozzle are compensated by exchanging image data and performing printing. Accordingly, since the image data are exchanged and printed, it is possible to prevent deterioration in image quality such as a white band which can be easily perceivedby a user.

Owner:HEWLETT PACKARD DEV CO LP

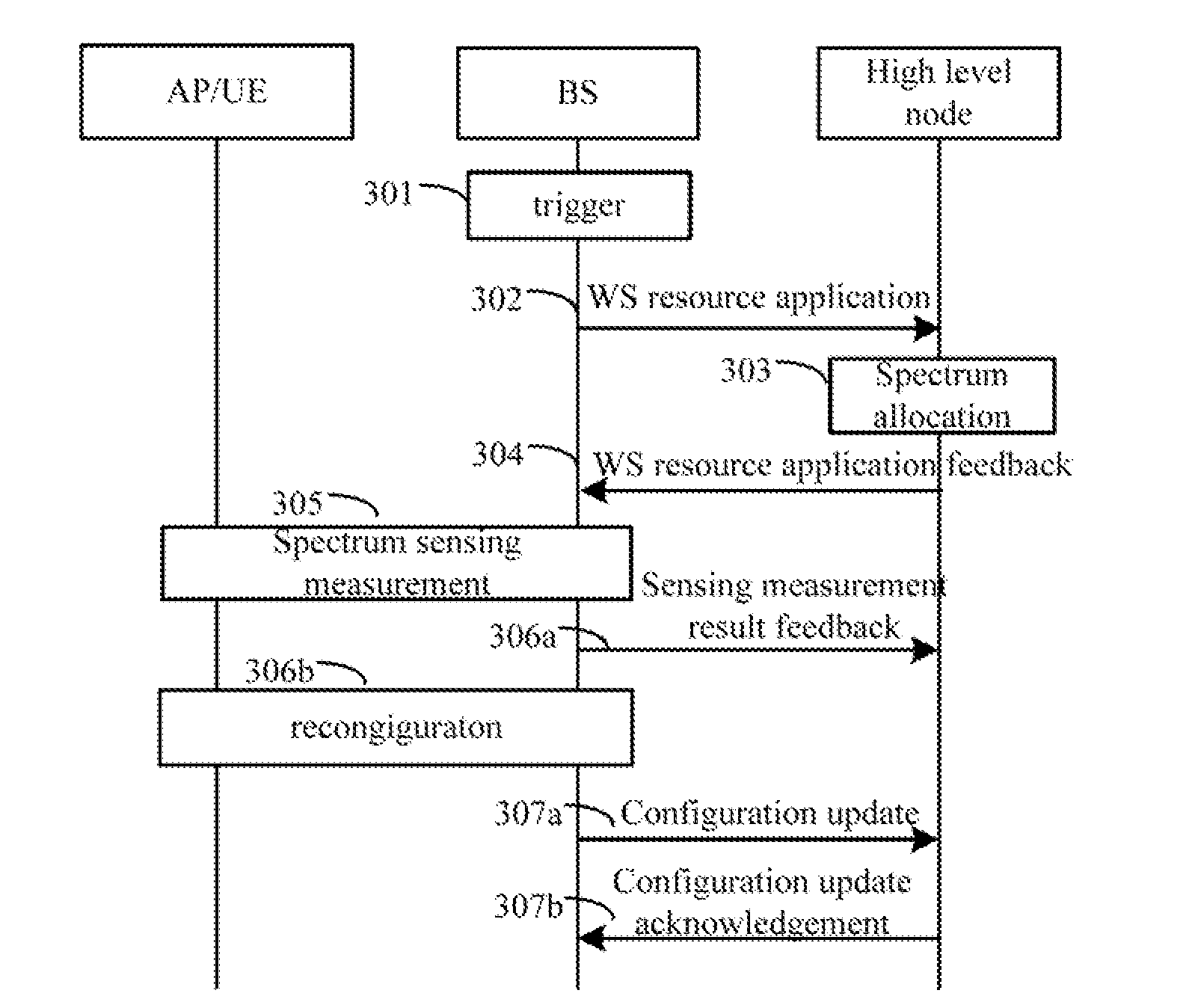

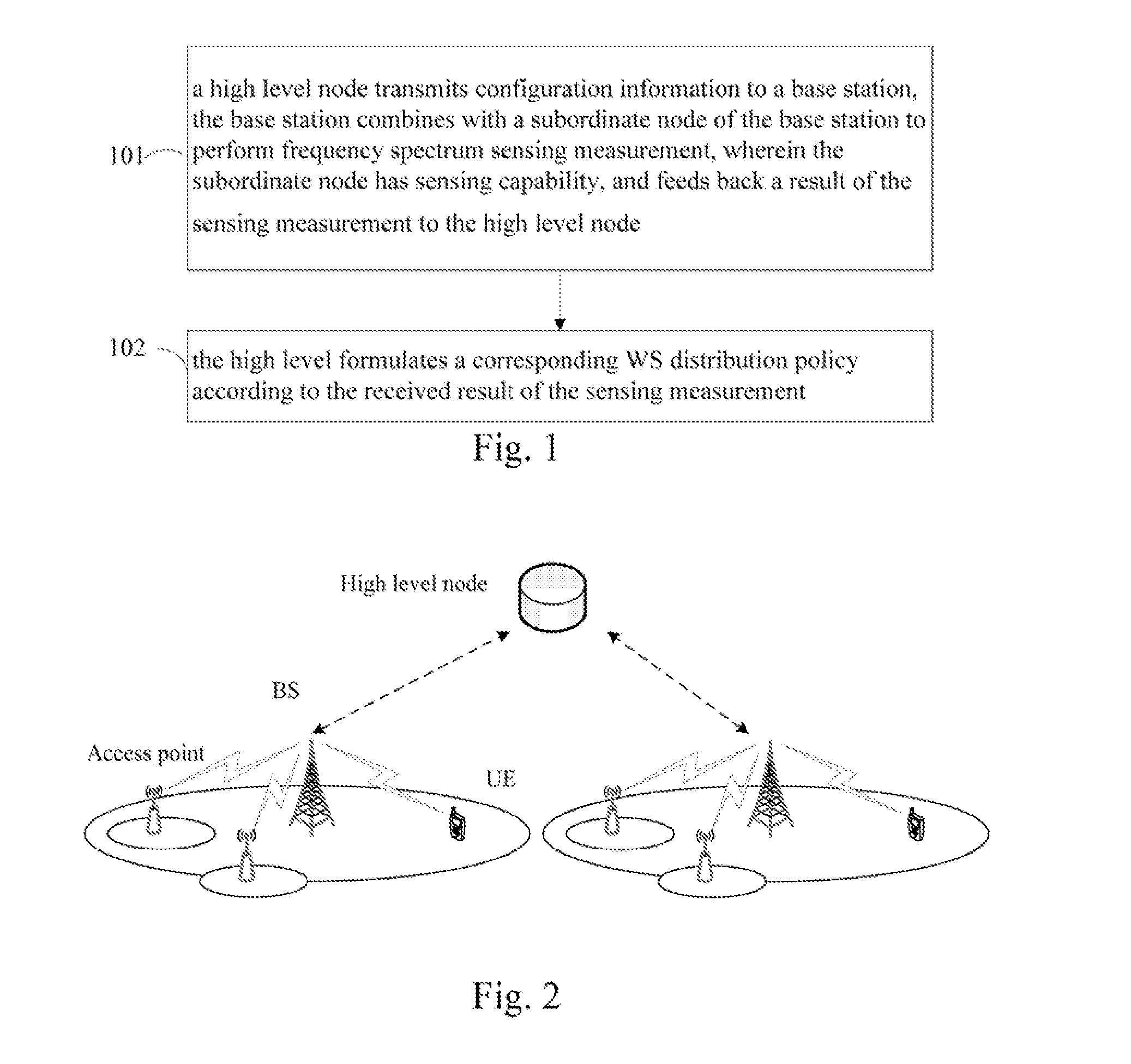

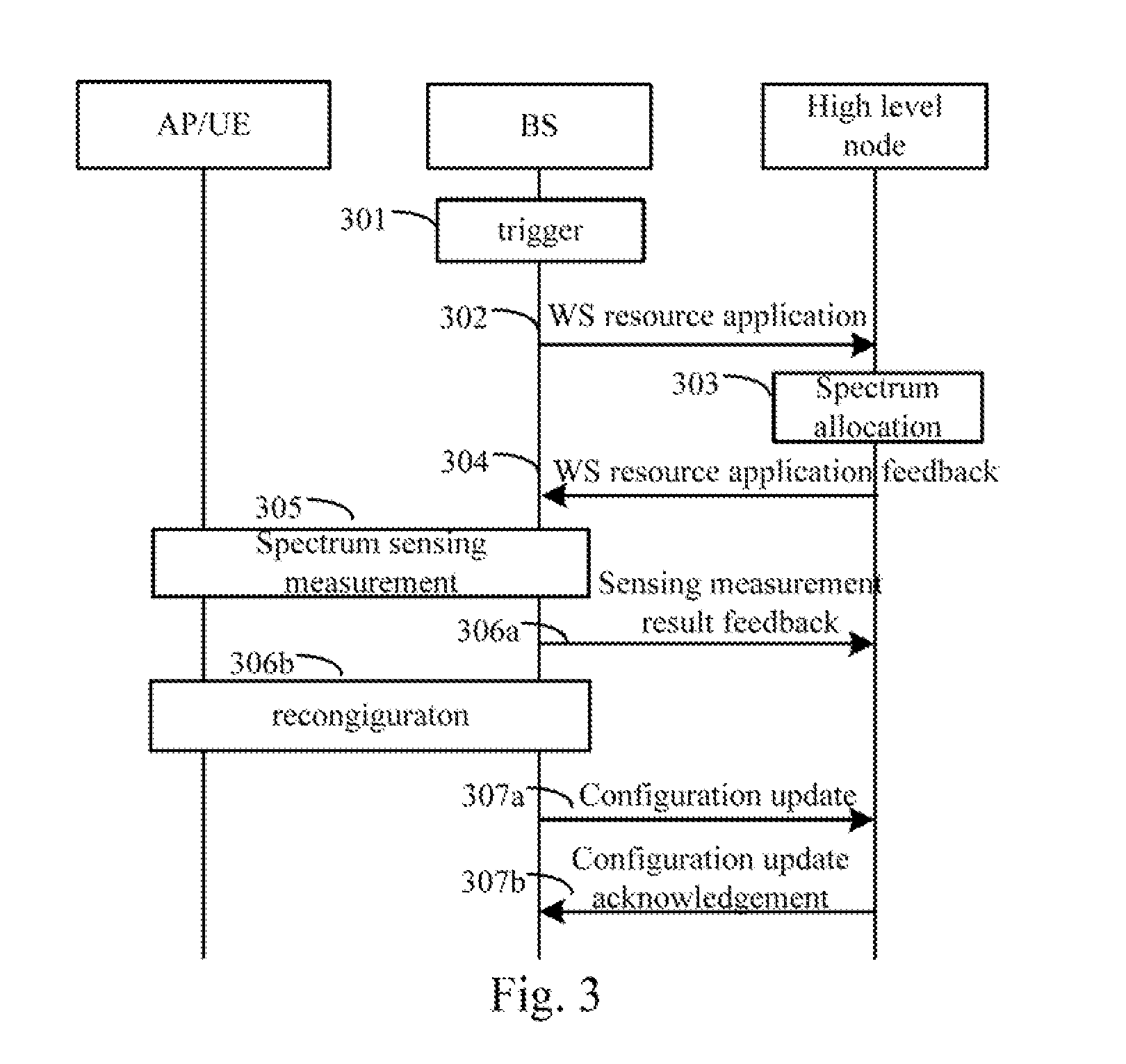

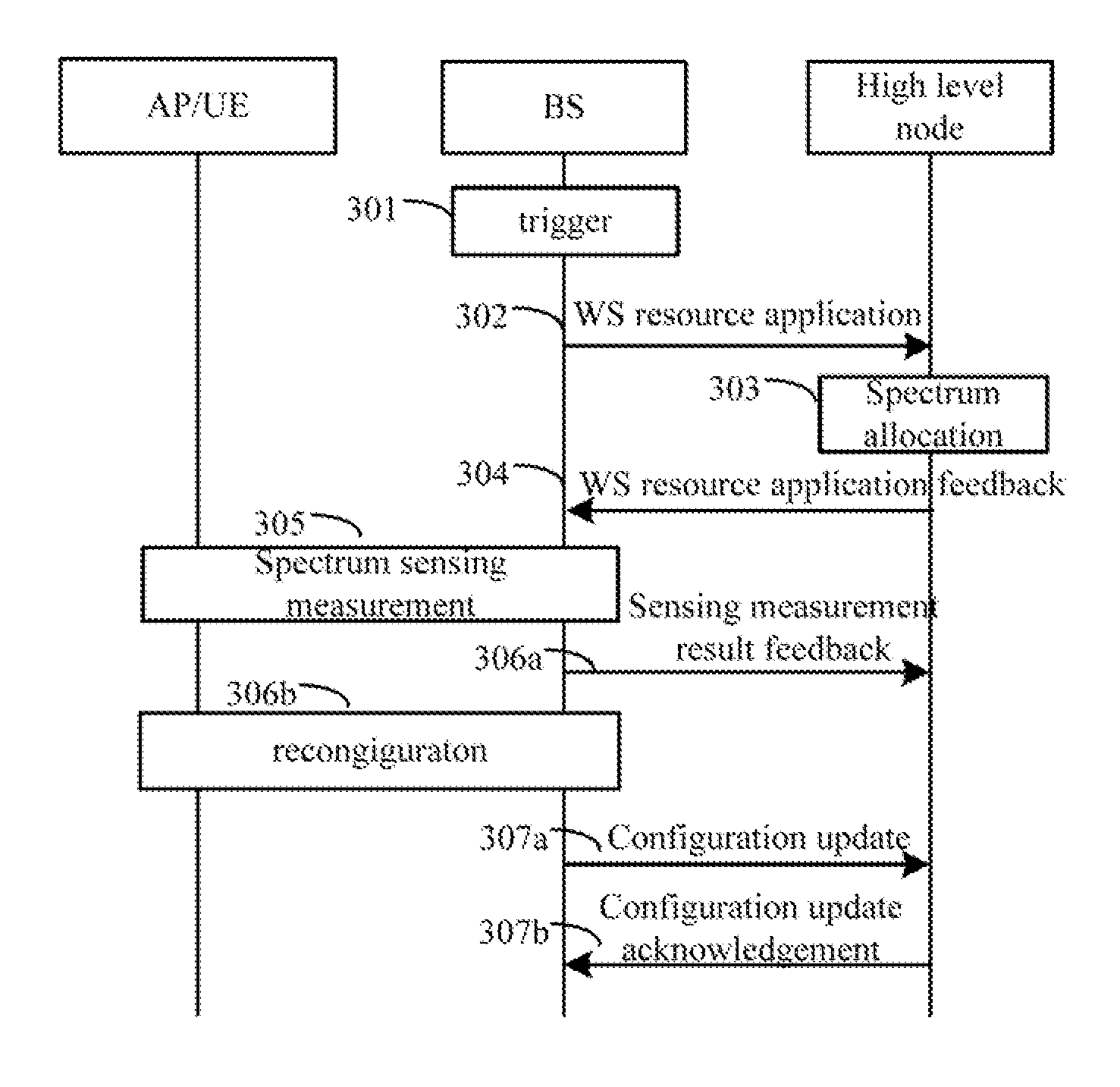

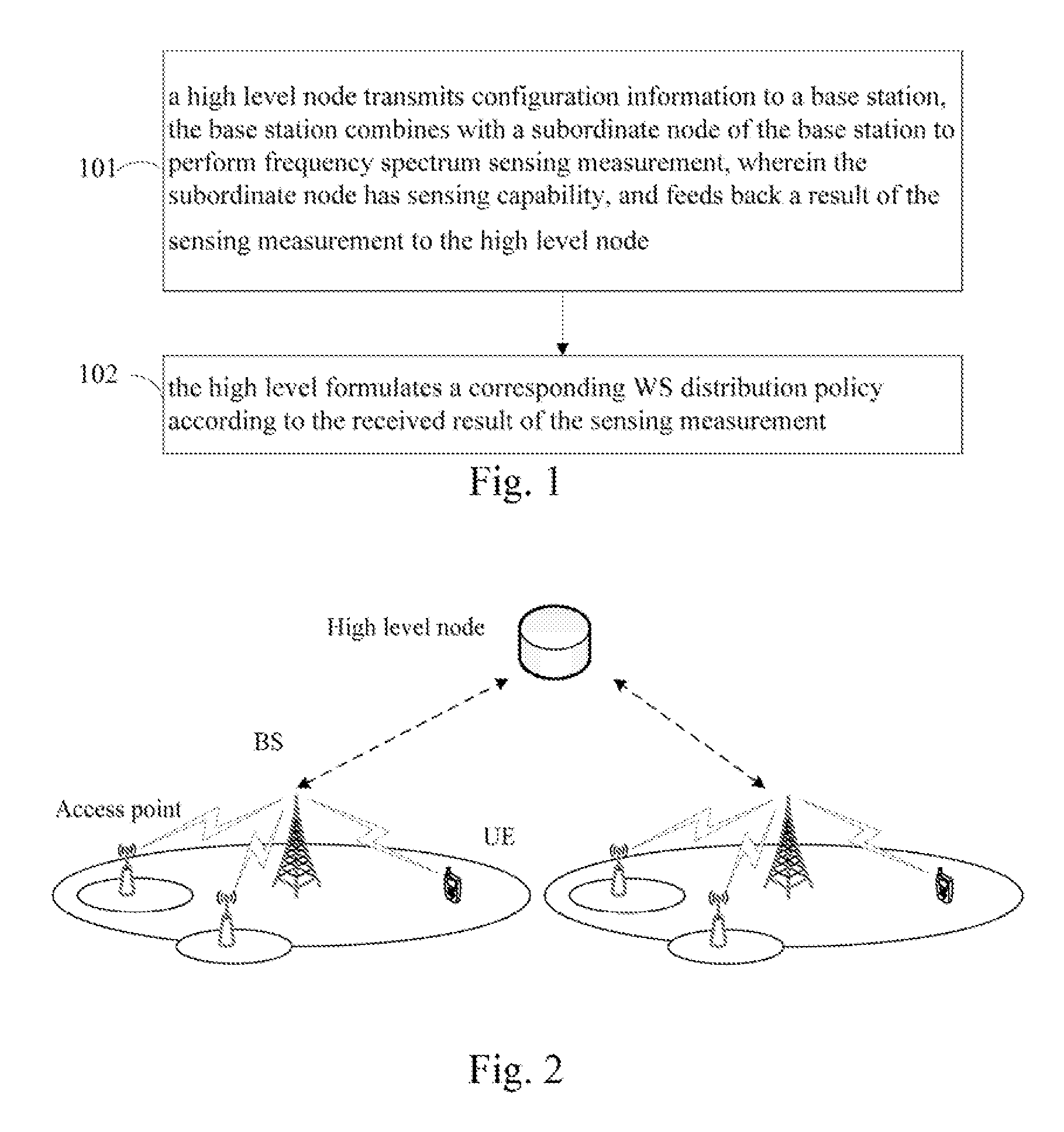

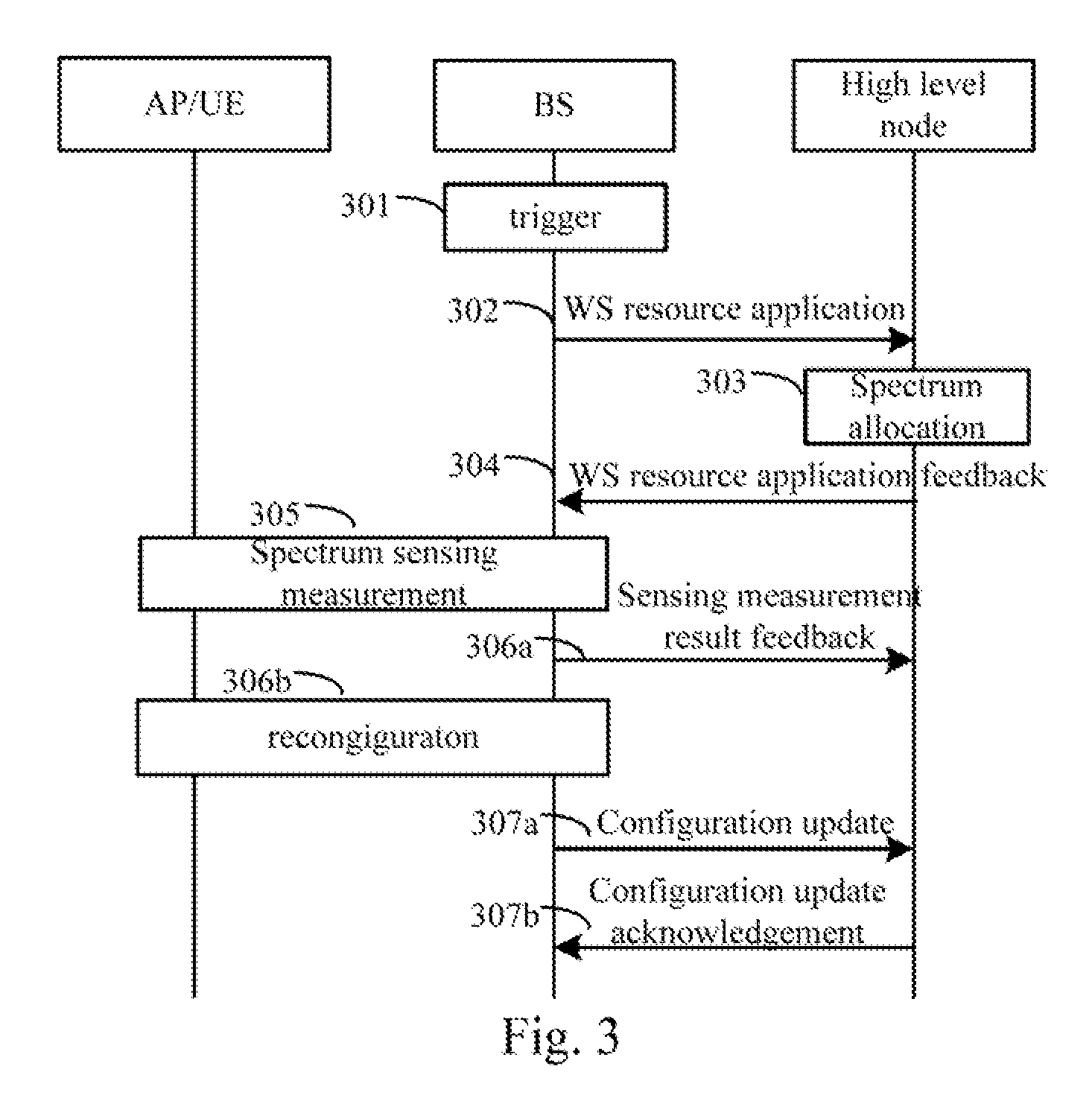

Sensing aiding method and system for cognitive radio

ActiveUS20130310062A1Reduce probabilityReduce overheadWireless commuication servicesNetwork planningFrequency spectrumCognitive radio

The disclosure discloses a sensing aiding method for cognitive radio. The method includes the following steps. a high level node transmits configuration information to a base station; the base station combines with a subordinate node of the base station to perform frequency spectrum sensing measurement, in which the subordinate node has sensing capability, and feeds back a result of the sensing measurement to the high level node; and the high level node formulates a corresponding WS allocation policy according to the received result of the sensing measurement. The disclosure also discloses a system. By the method and the system of the disclosure, the high level node transmits the configuration information to the base station; the base station performs the spectrum sensing measurement in combination with the subordinate node having the sensing capability of the base station in a designated frequency band and feeds the result of the sensing measurement back to the high level node; and the high level node formulates the corresponding WS allocation policy according to the result of the sensing measurement. Available white band resources are acquired; the probability of base station configuration failure is reduced, and the overhead caused by configuration failures is reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

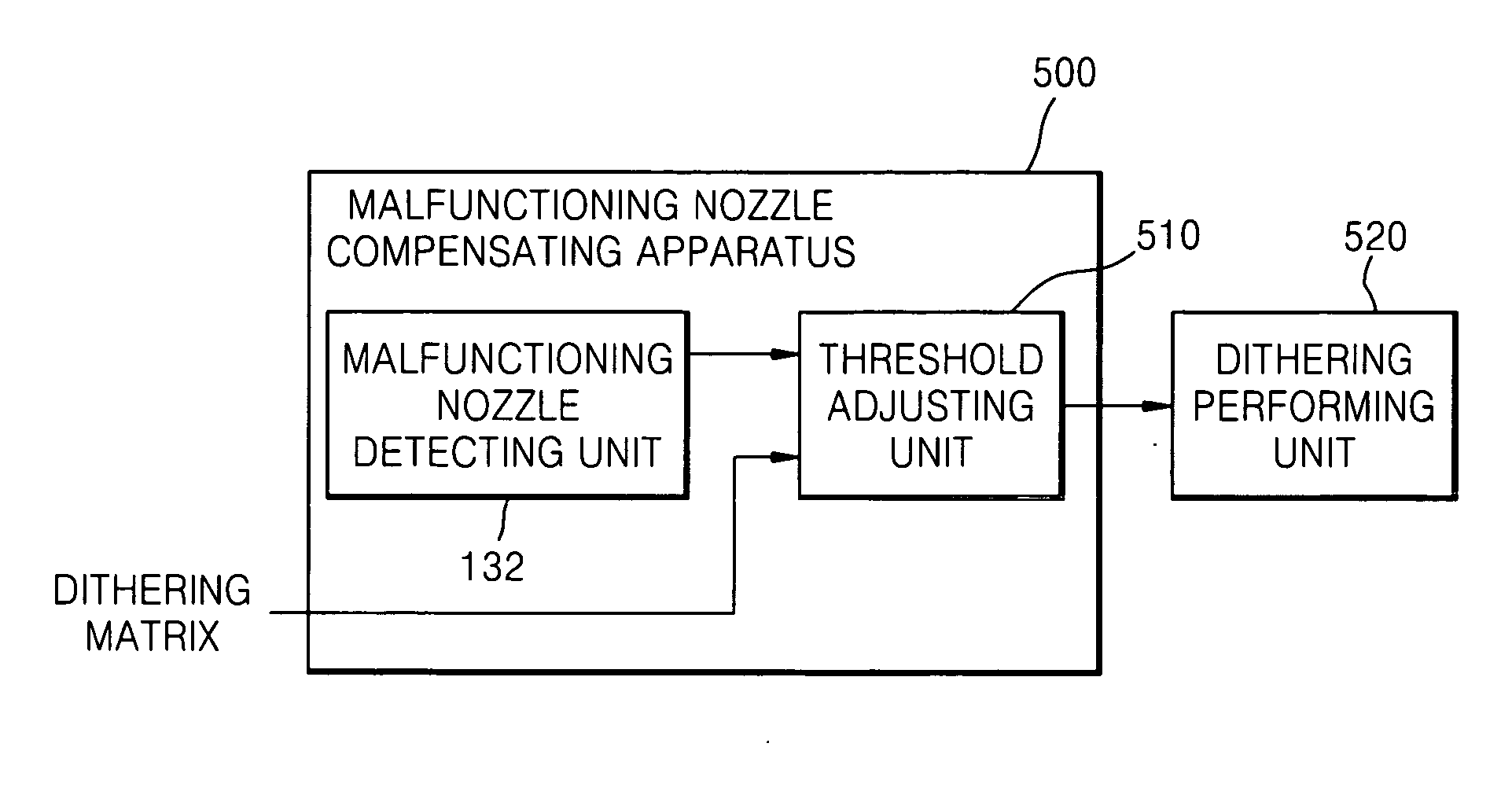

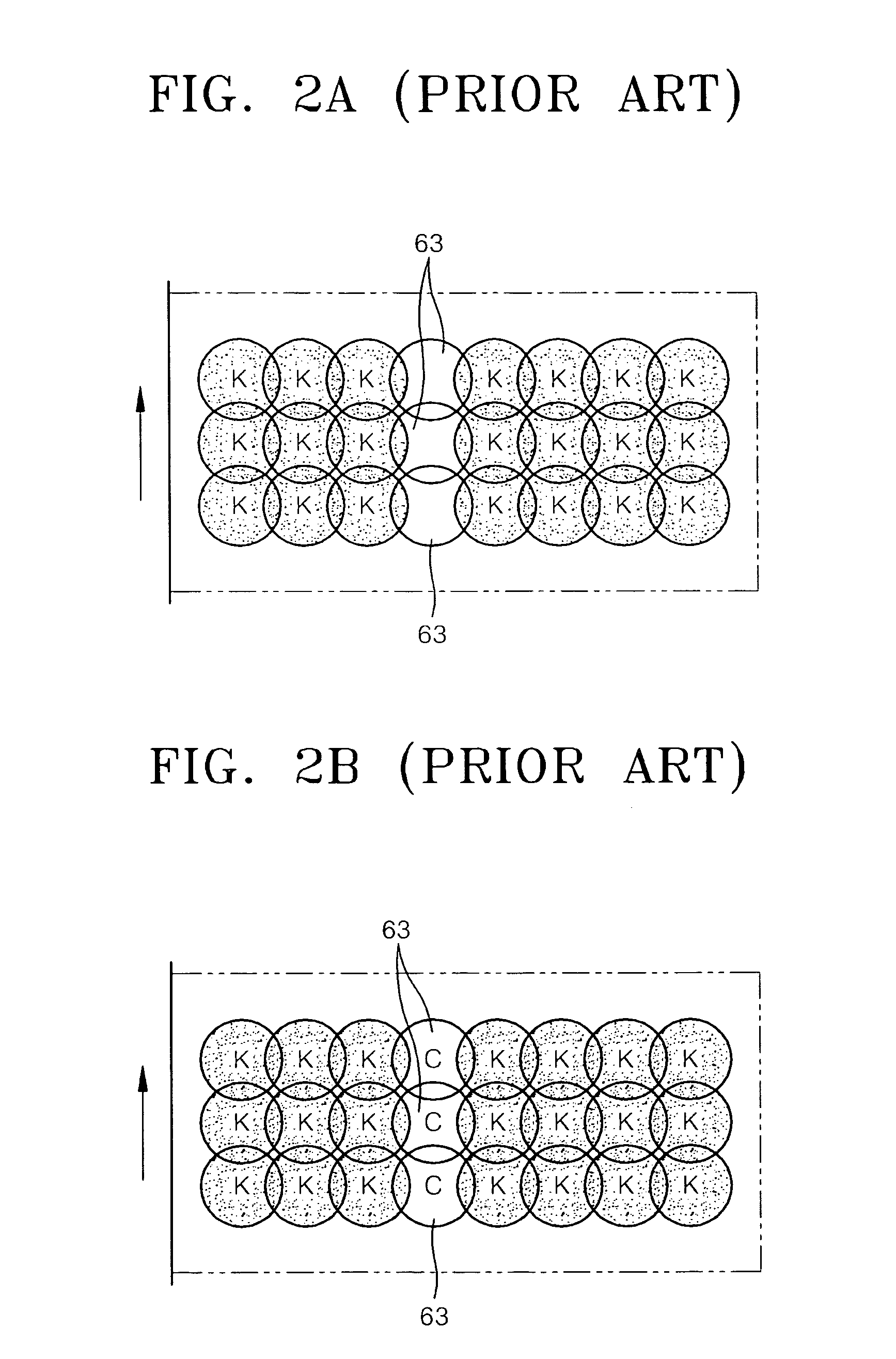

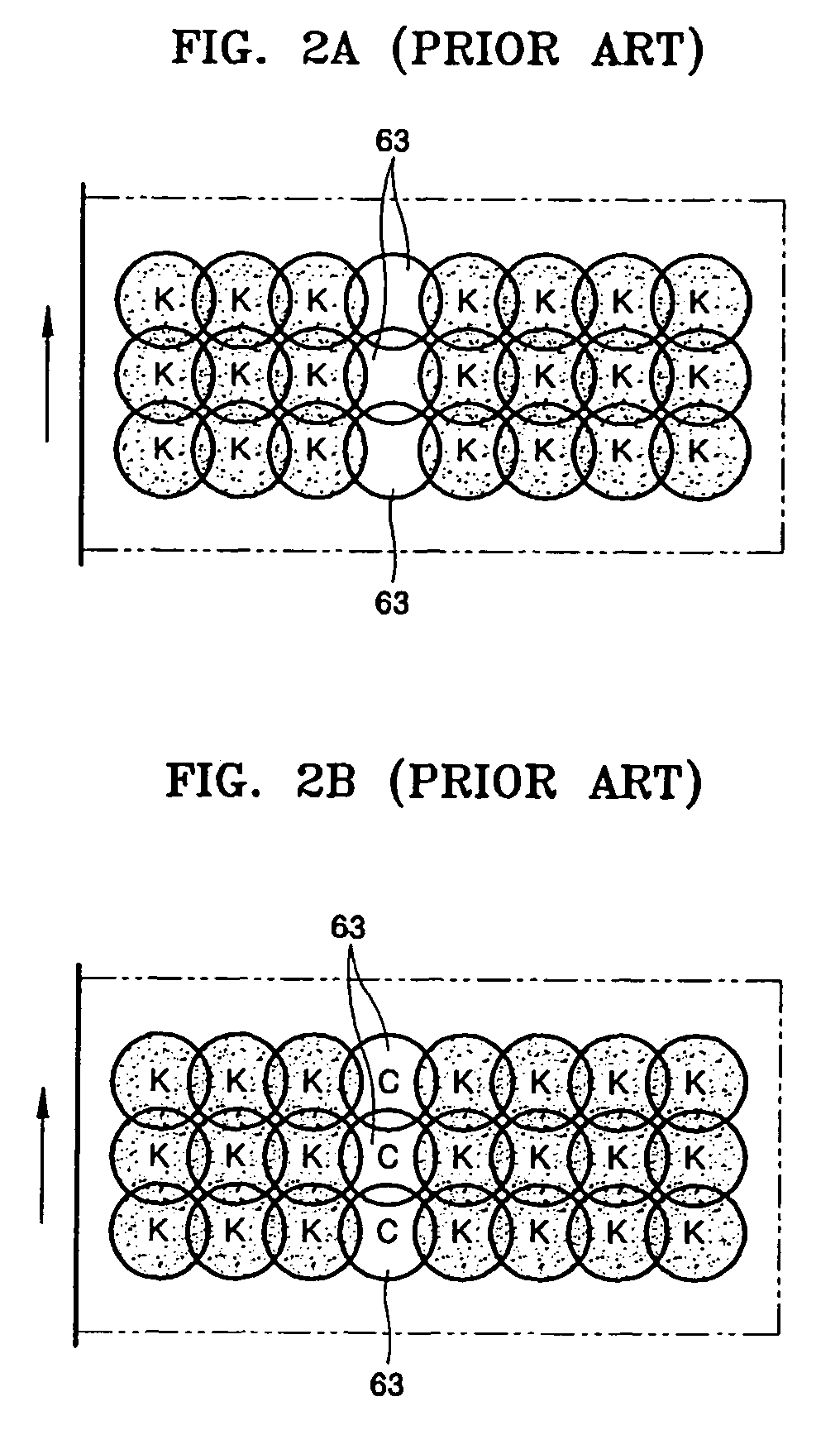

Method and apparatus for compensating for malfunctioning nozzle of inkjet image forming apparatus

InactiveUS20070115507A1Improve printing qualityGood colorImage enhancementVisual presentationEngineeringHue

Provided are a method and apparatus for compensating for the degradation of a print image due to a malfunctioning nozzle that irregularly ejects ink. The method includes detecting a malfunctioning nozzle among nozzles installed in an inkjet image forming apparatus and increasing a dithering threshold of an adjacent position to a compensation position printed by the detected malfunctioning nozzle. The method adjusts a dithering threshold of a print position of the malfunctioning nozzle or a dithering threshold of an adjacent print position, and thus performs a halftoning transaction and prints an image. Accordingly, the degradation of print quality such as a visible white band can be prevented and the lifetime of the printhead can be lengthened.

Owner:S PRINTING SOLUTION CO LTD

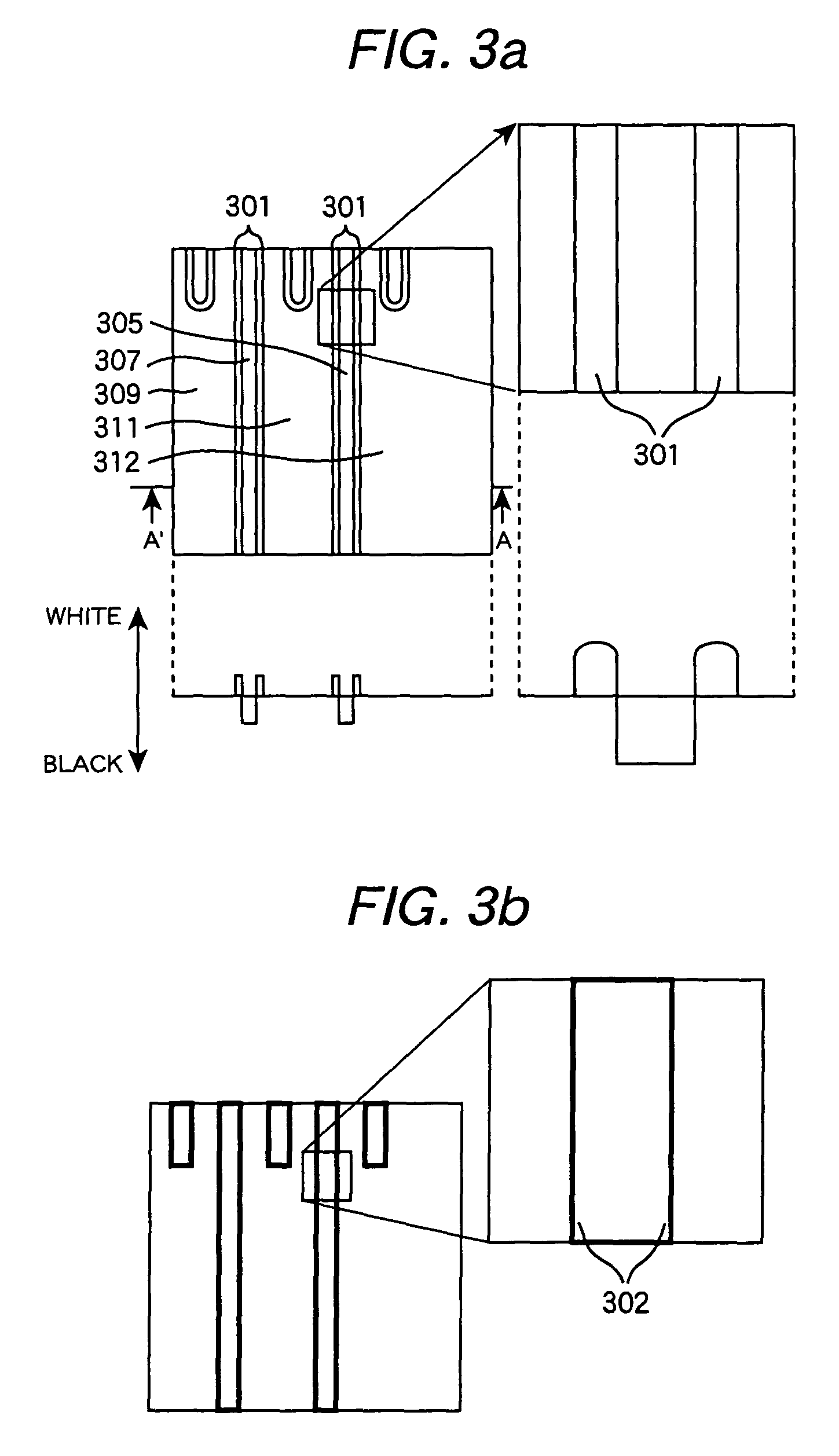

Pattern matching apparatus and scanning electron microscope using the same

ActiveUS8041104B2Accurate isolationAccurate extractionImage enhancementImage analysisPattern matchingScanning tunneling microscope

A pattern matching apparatus comprising: means for storing photographed image data of a semiconductor device; means for storing CAD data of said semiconductor device; an information input means for inputting information on the white band width contained in said image data; a pattern extracting means for extracting a pattern on the semiconductor device from said image data by using the white band width information; and a matching means for matching said pattern with the CAD data.

Owner:HITACHI HIGH-TECH CORP

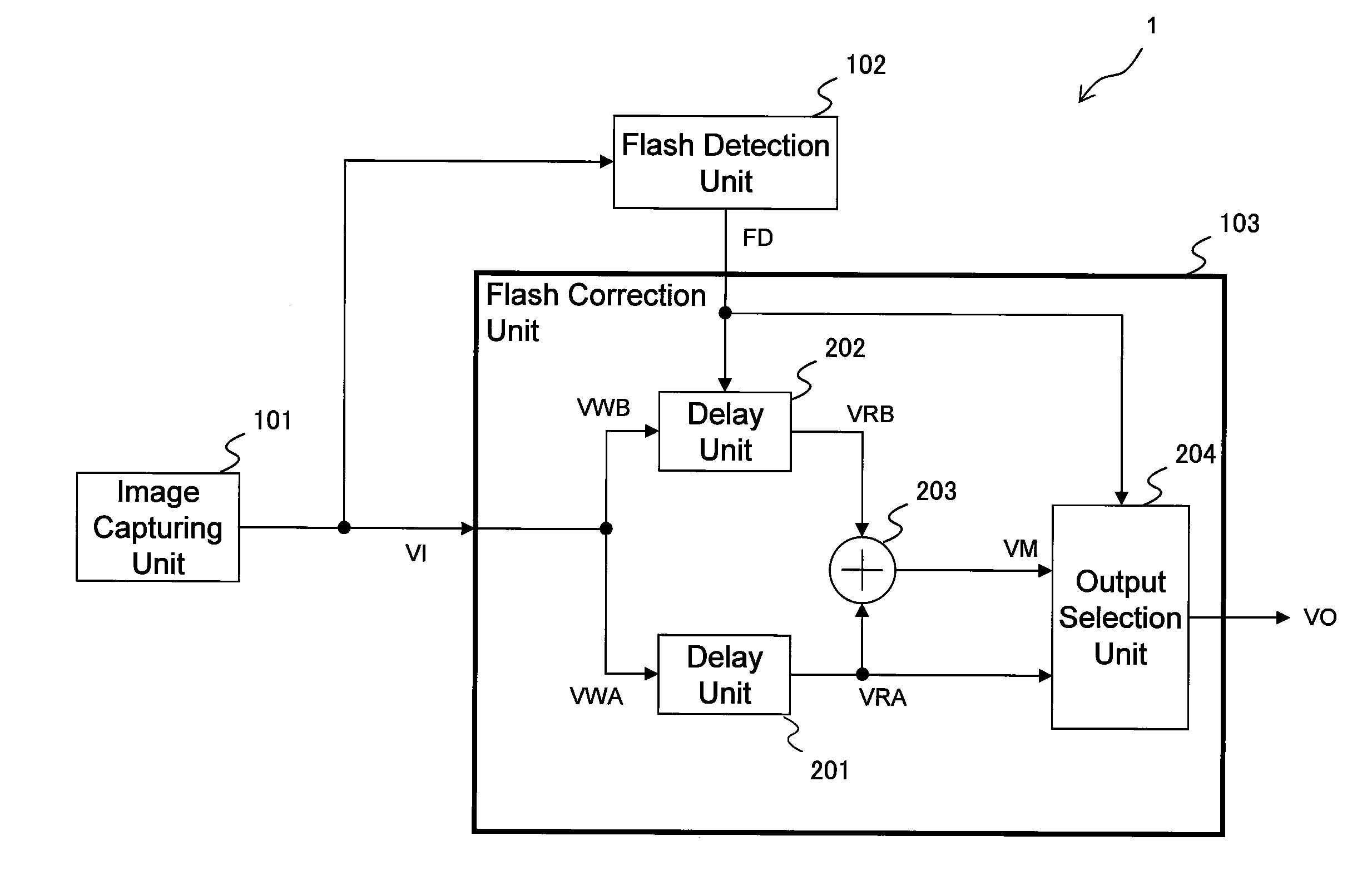

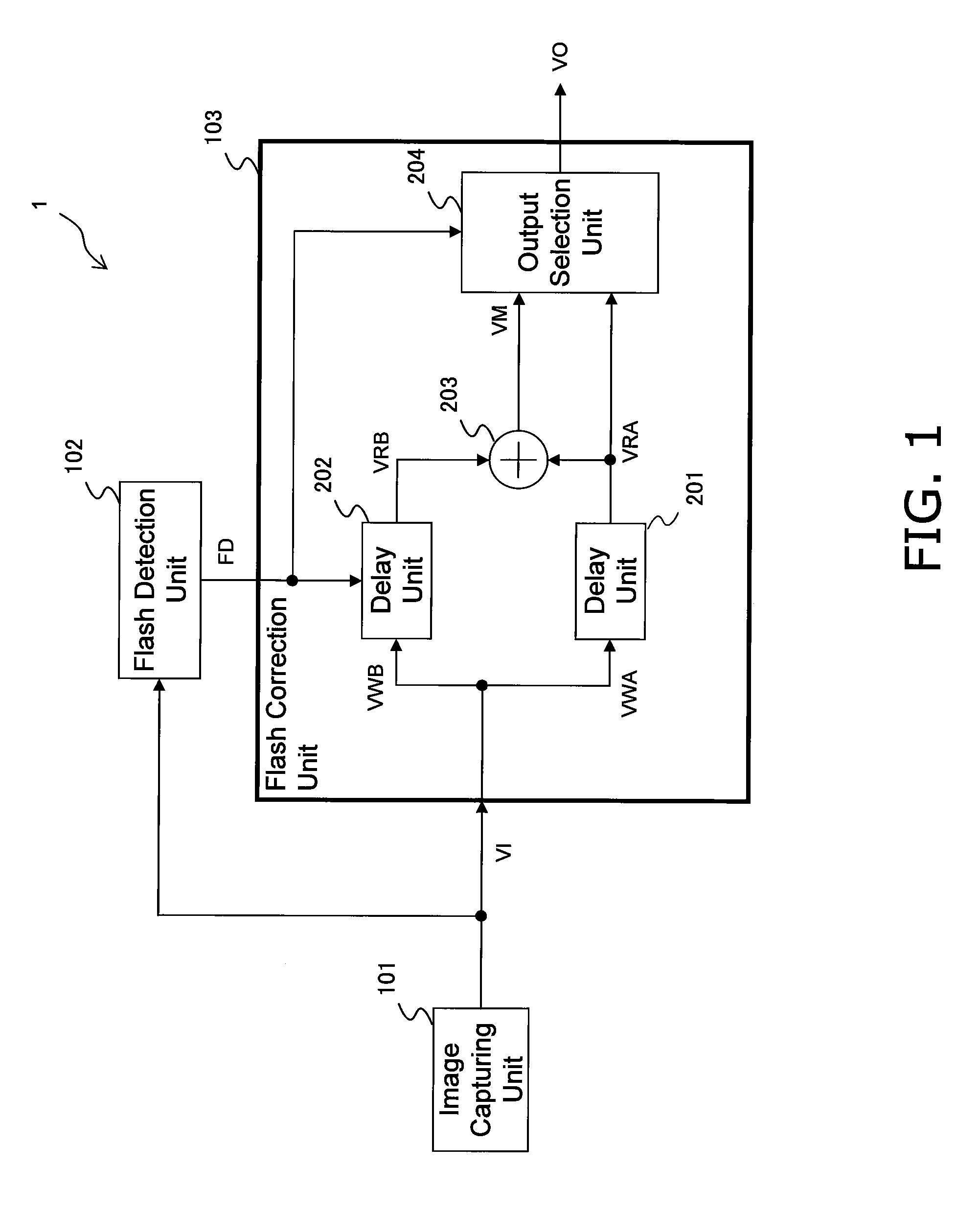

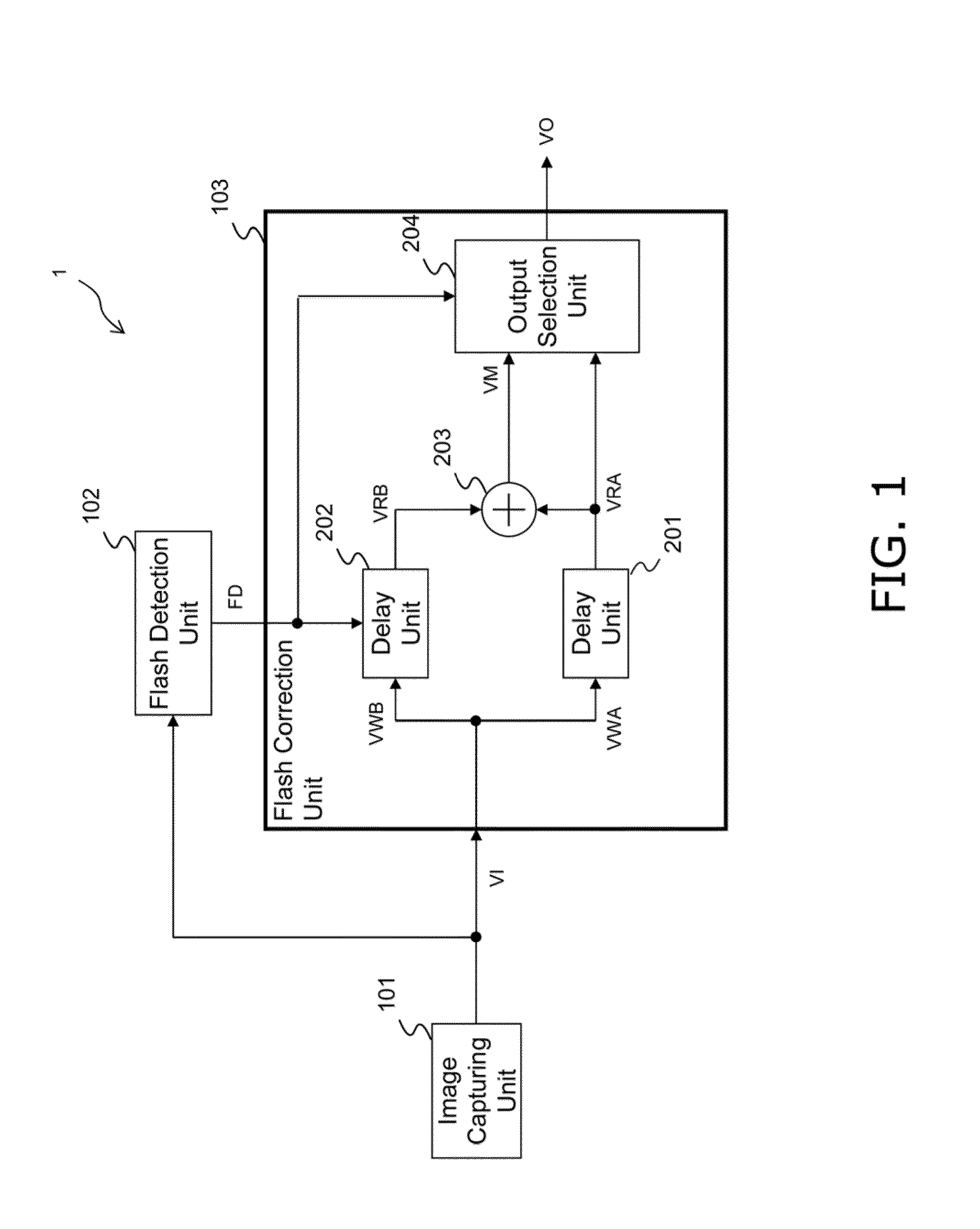

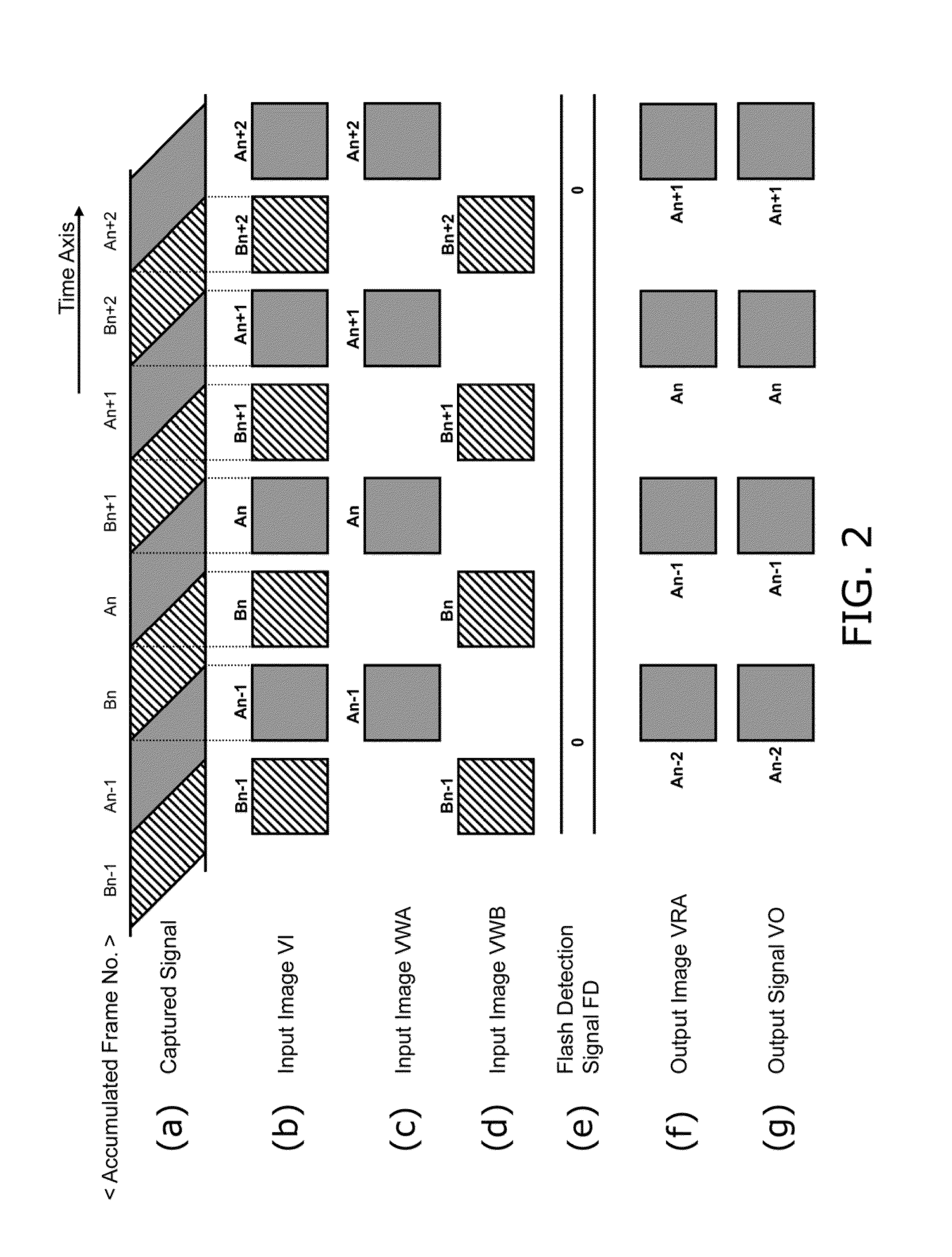

Imaging apparatus, external flash correction method, recording medium, and integrated circuit

ActiveUS20110273591A1Suppress interferenceTelevision system detailsColor television detailsCorrection methodElectron

In the case where a subject is captured by an imaging apparatus that employs a CMOS image sensor, white band interference appears in the captured signal due to the influence of rolling shutter operations when an external flash such as a camera flash has occurred; the present technique obtains an image in which that interference has been corrected even during electronic shutter imaging.An image capturing unit outputs both a valid video signal (a primary video signal) and an unnecessary video signal (a secondary video signal) as an output signal; a flash detection unit detects white band interference caused by an external flash; and a flash correction unit delays the valid video signal using a first delay unit and delays the unnecessary video signal using a second delay unit. When white band interference has occurred, the outputs of the respective delay units are added together by an adding unit, generating a corrected signal. An output selection unit selects and outputs the signal from the first delay unit in normal times, and when interference caused by an external flash has occurred, selects and outputs the corrected signal.

Owner:PANASONIC CORP

Method for producing wear-resistant steel by employing plate blank secondary-cooling area electromagnet to stir

The invention discloses a method for producing wear-resistant steel by employing a plate blank secondary-cooling area electromagnet to stir. The method comprises the following steps of firstly, pre-processing molten iron; and secondly, performing smelting to obtain vacuum degassing molten steel by a converter, and performing continuous casting after the molten steel is refined to obtain the wear-resistant steel. The size of a current is reduced during the stirring process of the electromagnet, a pull speed is adjusted according to the size requirement of a fraction surface of the wear-resistant steel and an action position of electromagnetic stirring, and a pair of electromagnetic stirring rollers is employed. In the wear-resistant steel fabricated by the method, a frame segregation or white band negative segregation band phenomenon is eliminated, the problem of quality of the wear-resistant steel during the application process is not occurred, and the quality of the wear-resistant steel is greatly improved.

Owner:NANJING IRON & STEEL CO LTD

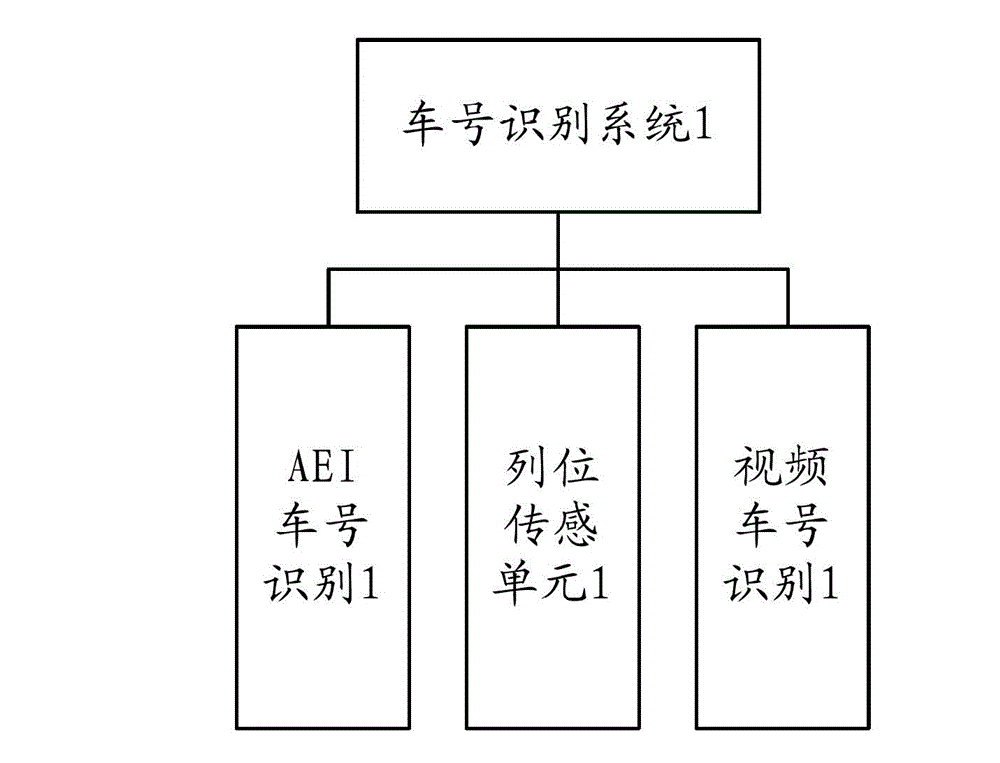

Method and system for monitoring shutting safety for vehicle inspection and maintenance

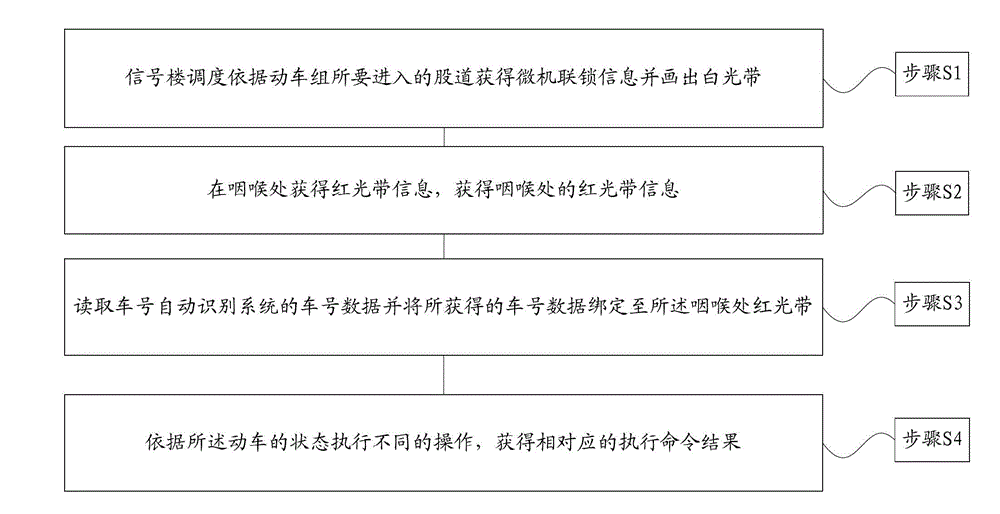

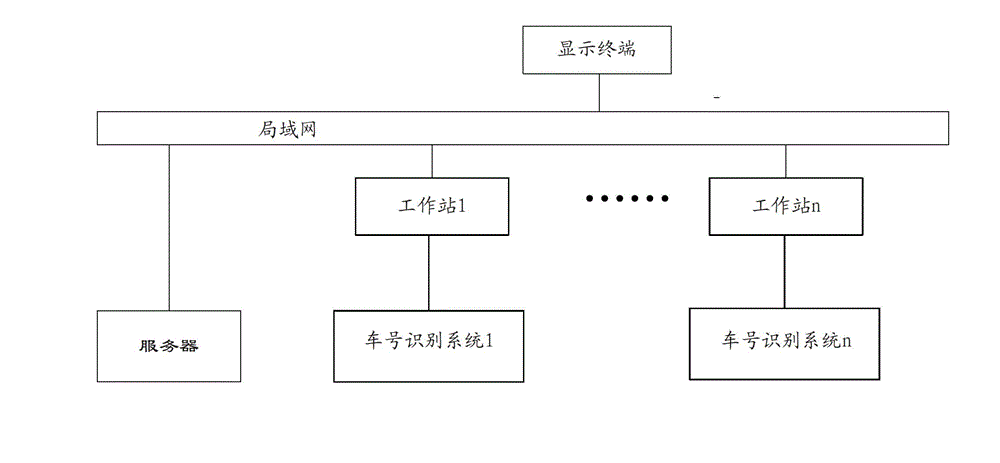

InactiveCN102745212ASolve the real-time tracking of the entry and exit of EMUsResolve entry and exit situationsRailway signalling and safetyMicrocomputerThroat

The invention provides a method and system for monitoring shutting safety for vehicle inspection and maintenance. The method for monitoring shutting safety for vehicle inspection and maintenance comprises the steps of: S1, obtaining microcomputer interlock information according to a station track where a motor train unit enters into by signal cabin dispatching and drawing a white band; S2, obtaining red band information at a throat; S3, reading vehicle number data of a vehicle number automatic identification system and binding the vehicle number data obtained to the red band information at the throat; and S4, executing different operations to obtain corresponding execution command results according to the state of the motor train unit. The method and system provided by the invention overcome the deficiency that in-and-out conditions of the motor train unit cannot be tracked and the vehicle number and end position information of the motor train unit cannot be displayed in current reexamination systems.

Owner:北京铁龙恒通车辆装备有限公司

Method and apparatus for compensating for malfunctioning nozzle and inkjet image forming apparatus using the same

Owner:S PRINTING SOLUTION CO LTD

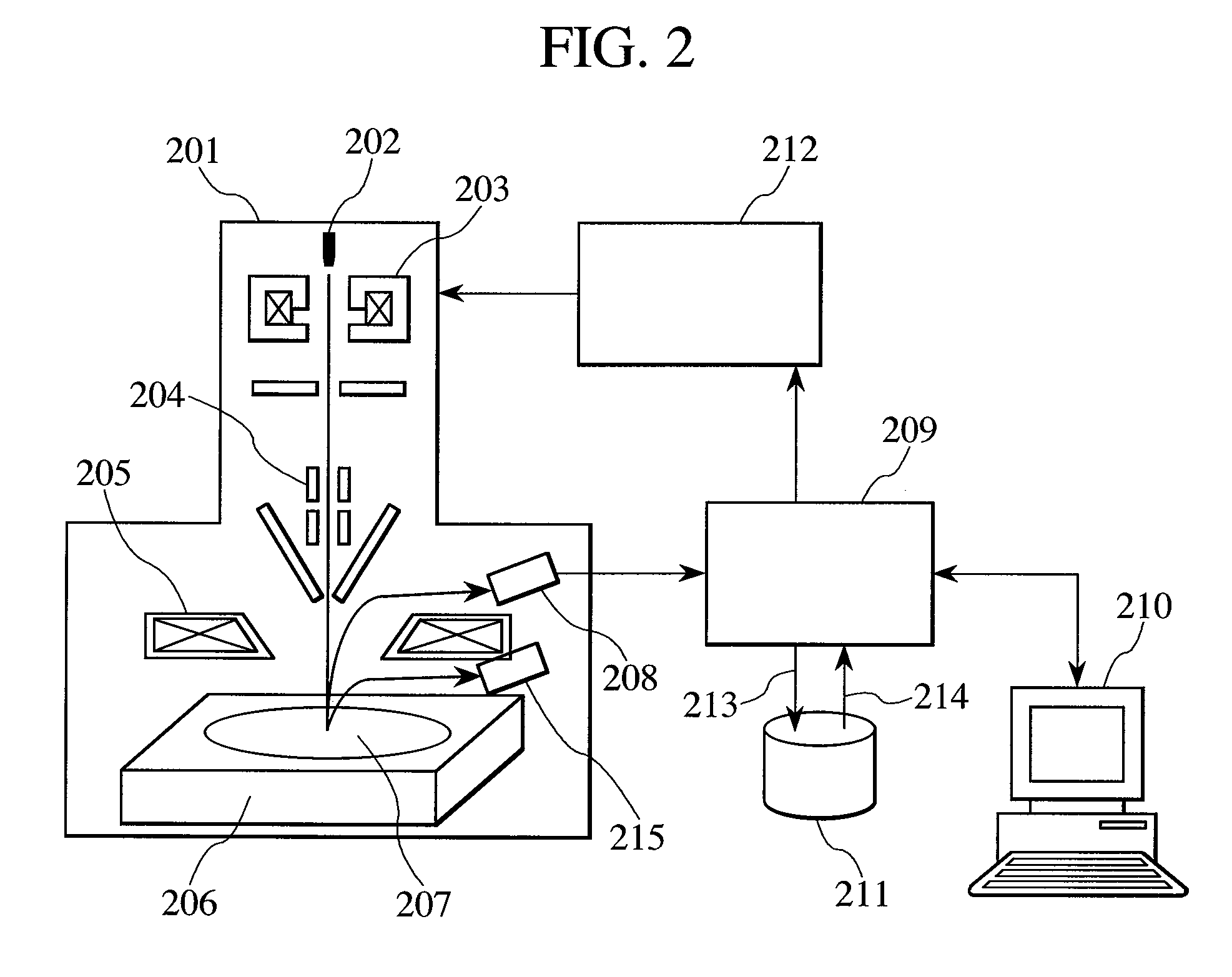

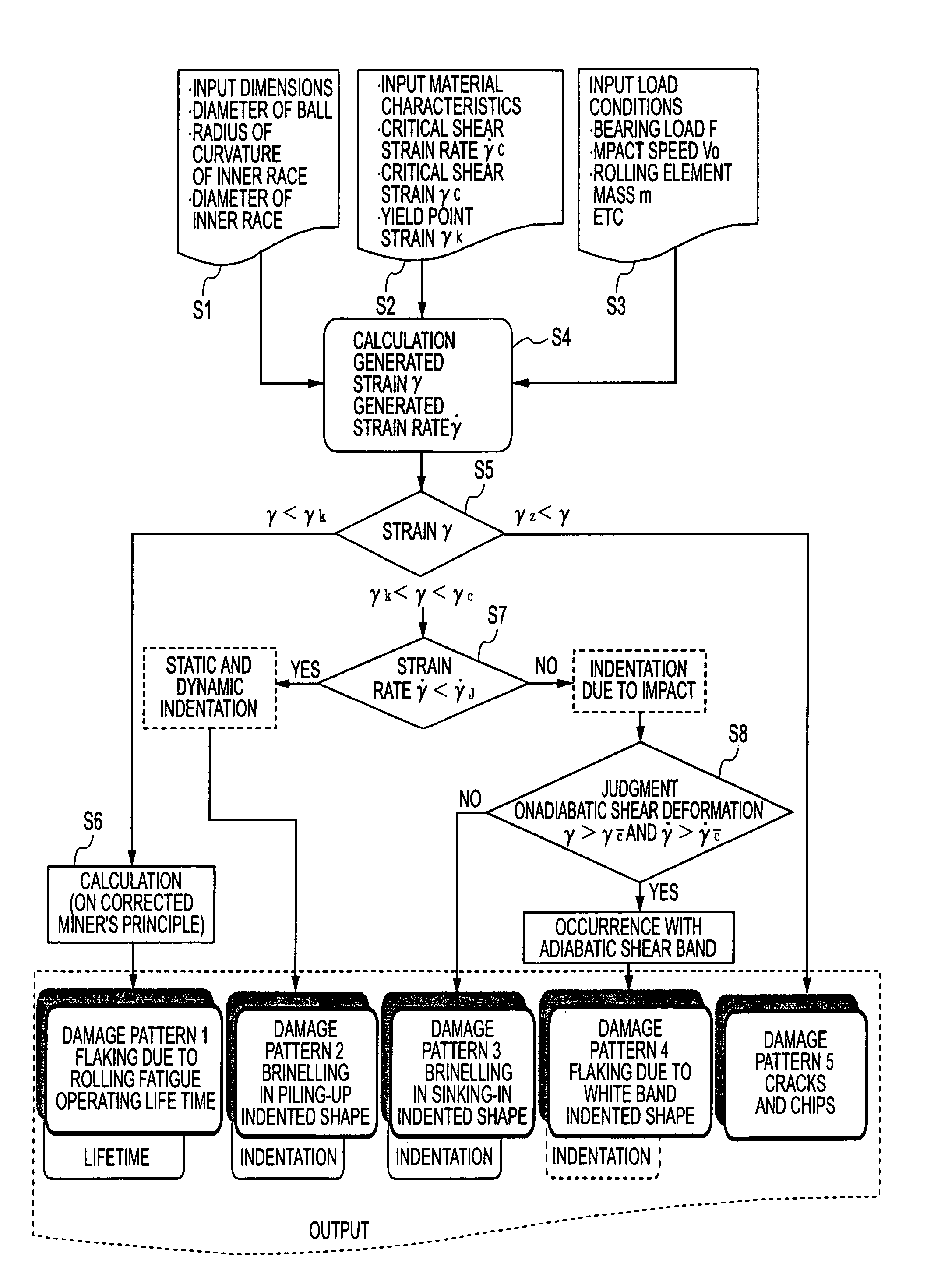

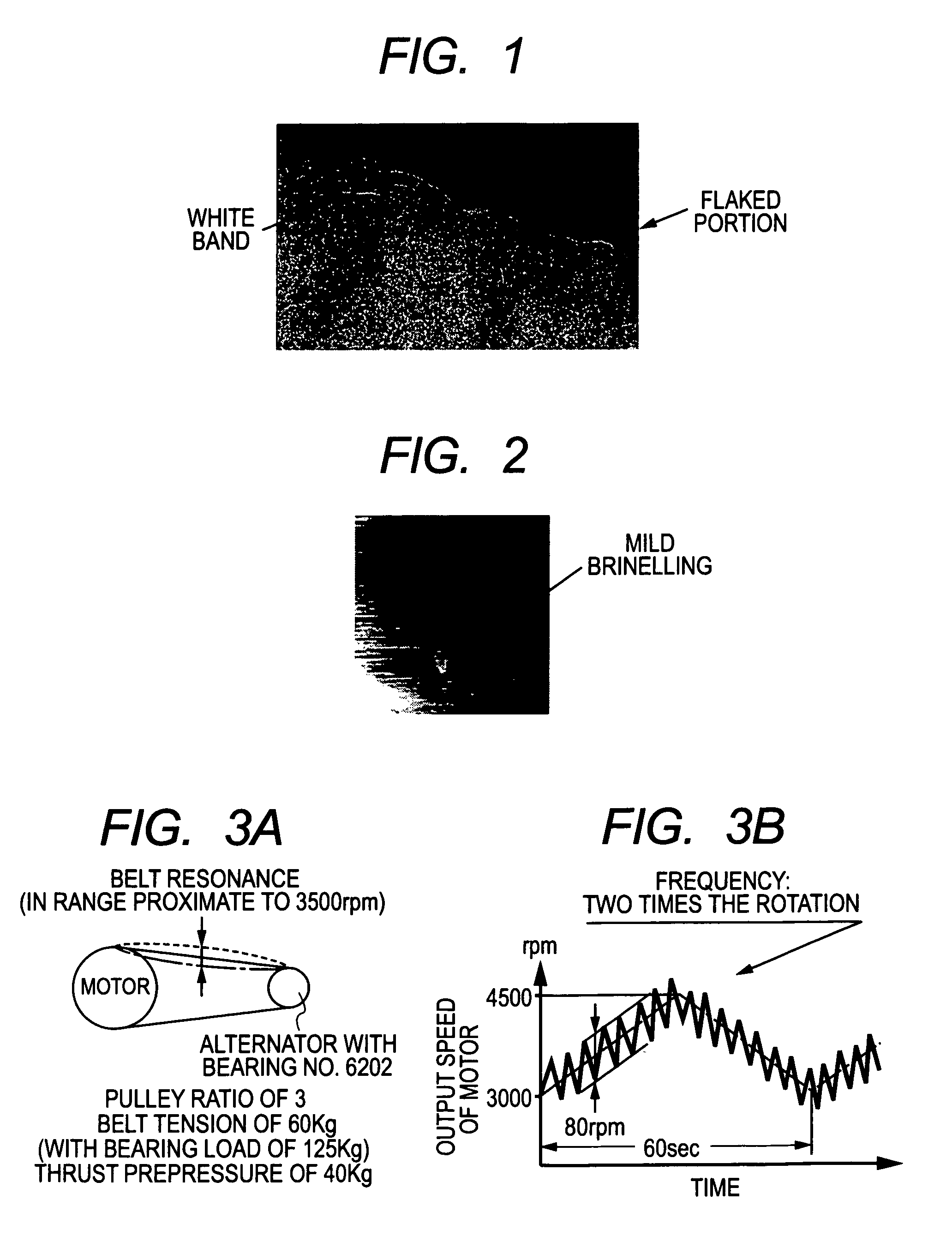

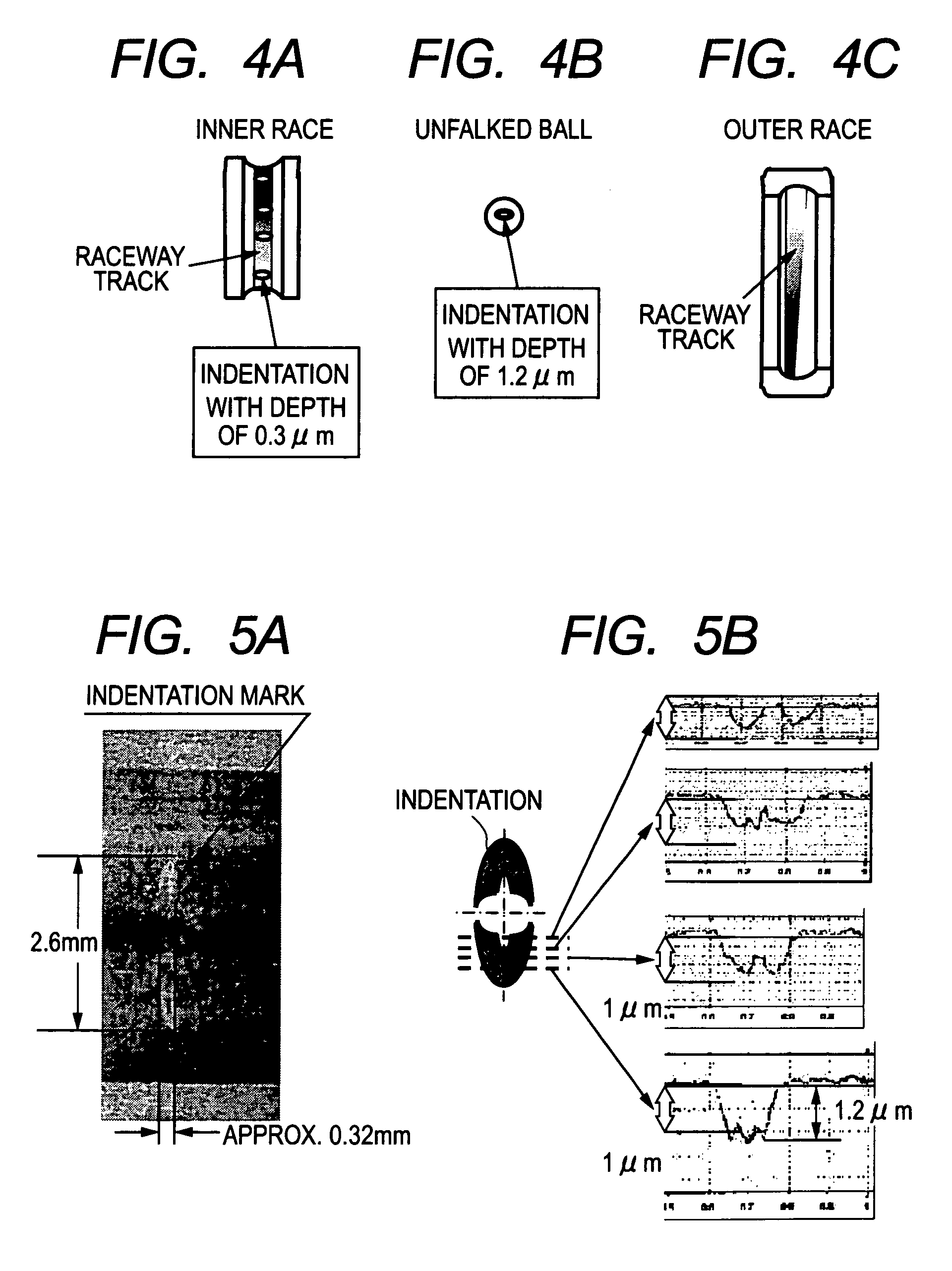

Apparatus and method for determining patterns of damage being caused in rolling contact element

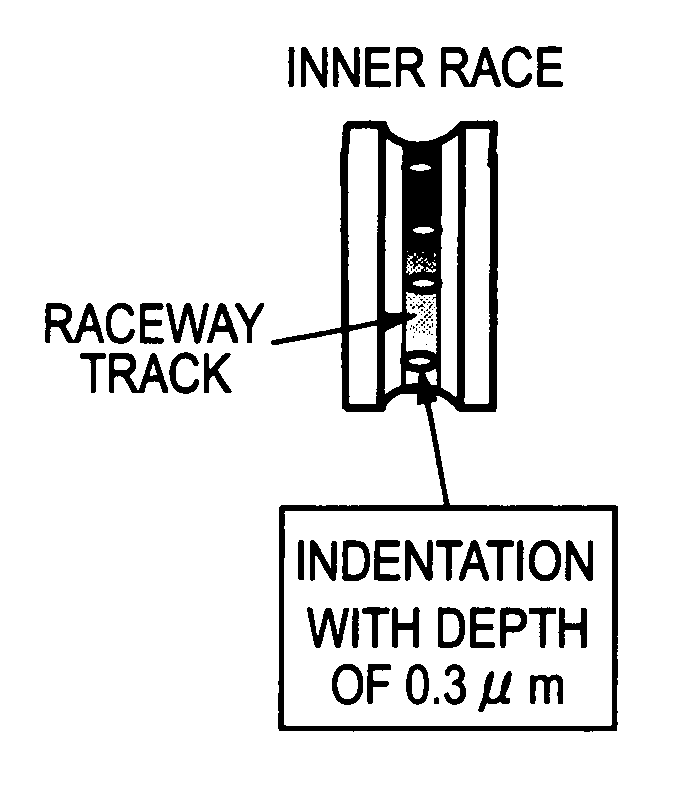

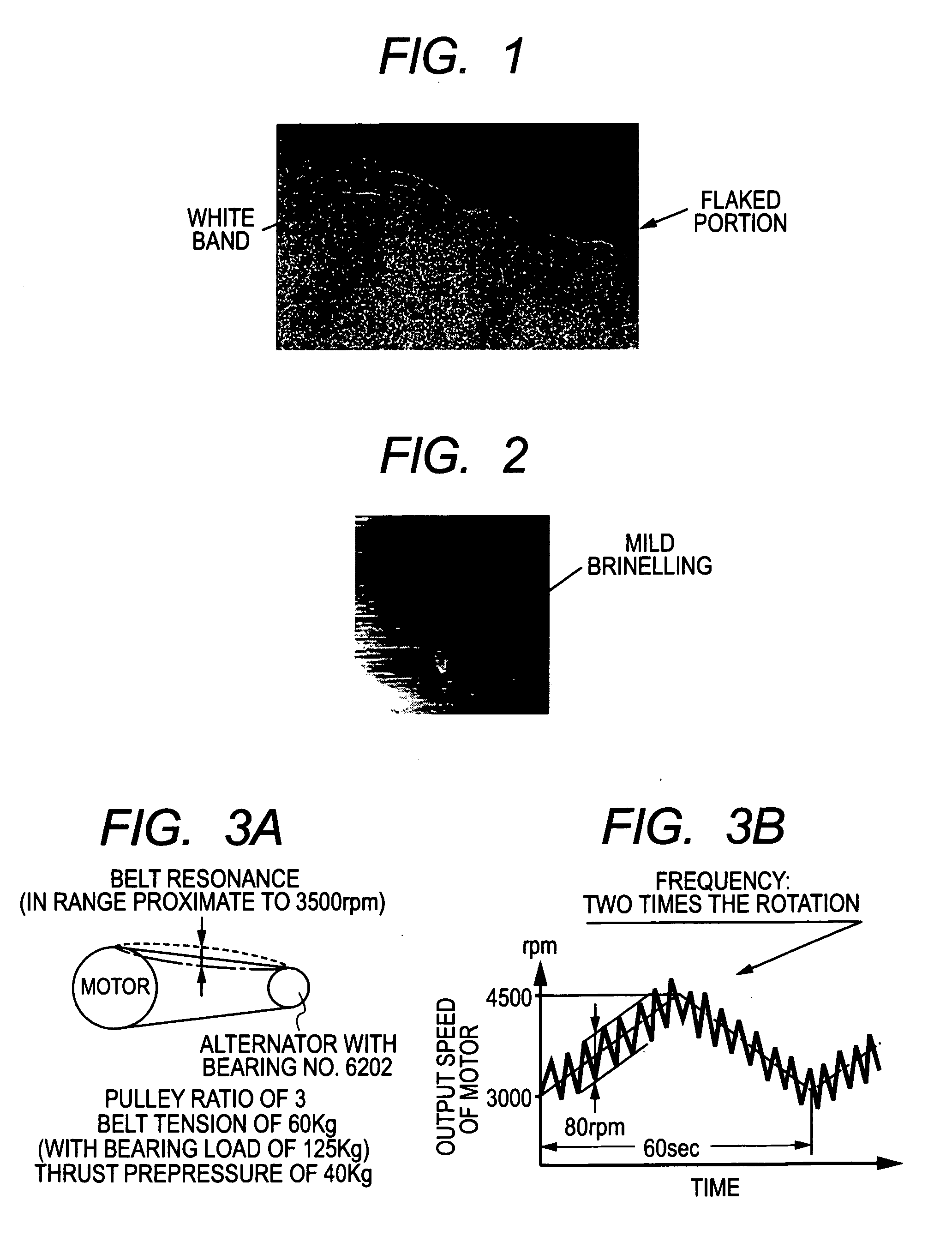

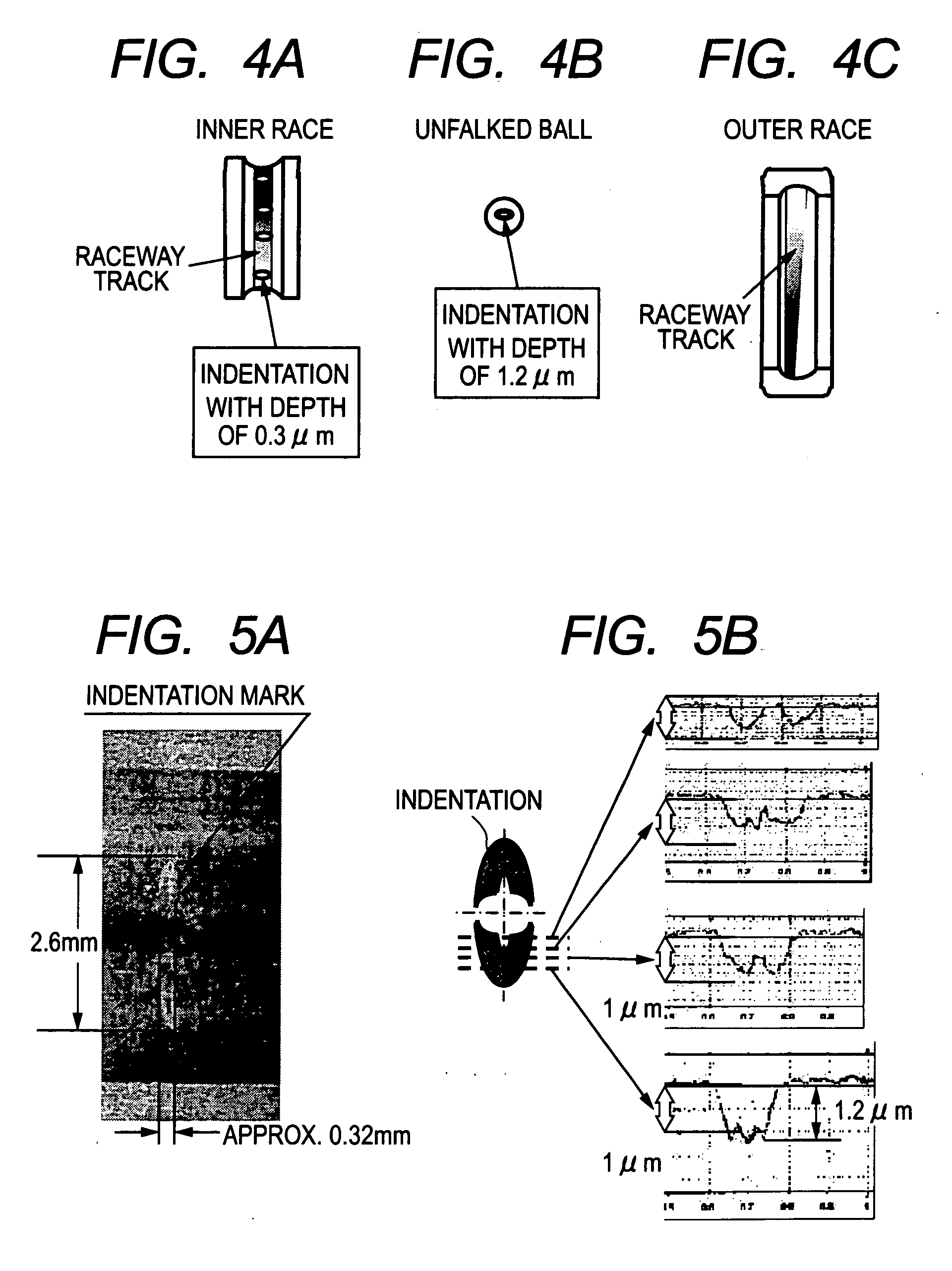

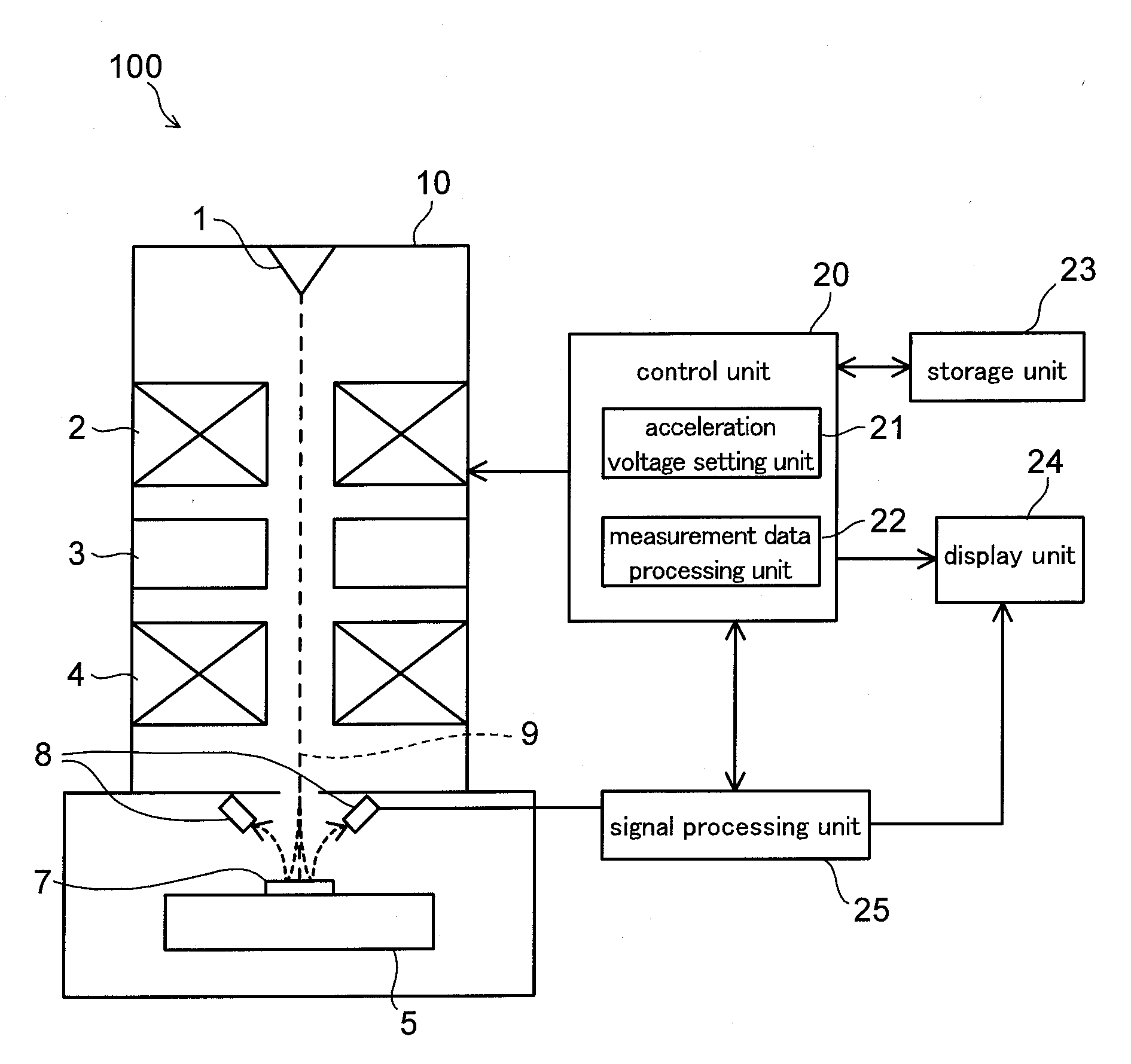

InactiveUS20070044543A1Simple fashionAvoid damagePlug gaugesMachine bearings testingBrinellingAdiabatic shear band

A method of designing a roller bearing is disclosed upon clarifying mechanisms of damage patterns in respect of two kinds of brinelling, involved in the bearing, wherein white-banded flaking (brittle flaking) is a plastic instability phenomenon appearing under high-speed deformation accompanied by adiabatic shear deformation status with the resultant occurrence of adiabatic shear band (also called white band) inside material of the bearing. This enables all of the damage patterns to be determined upon making comparison between shear strain and shear strain rate, occurring inside the bearing, and discriminated values.

Owner:DENSO CORP

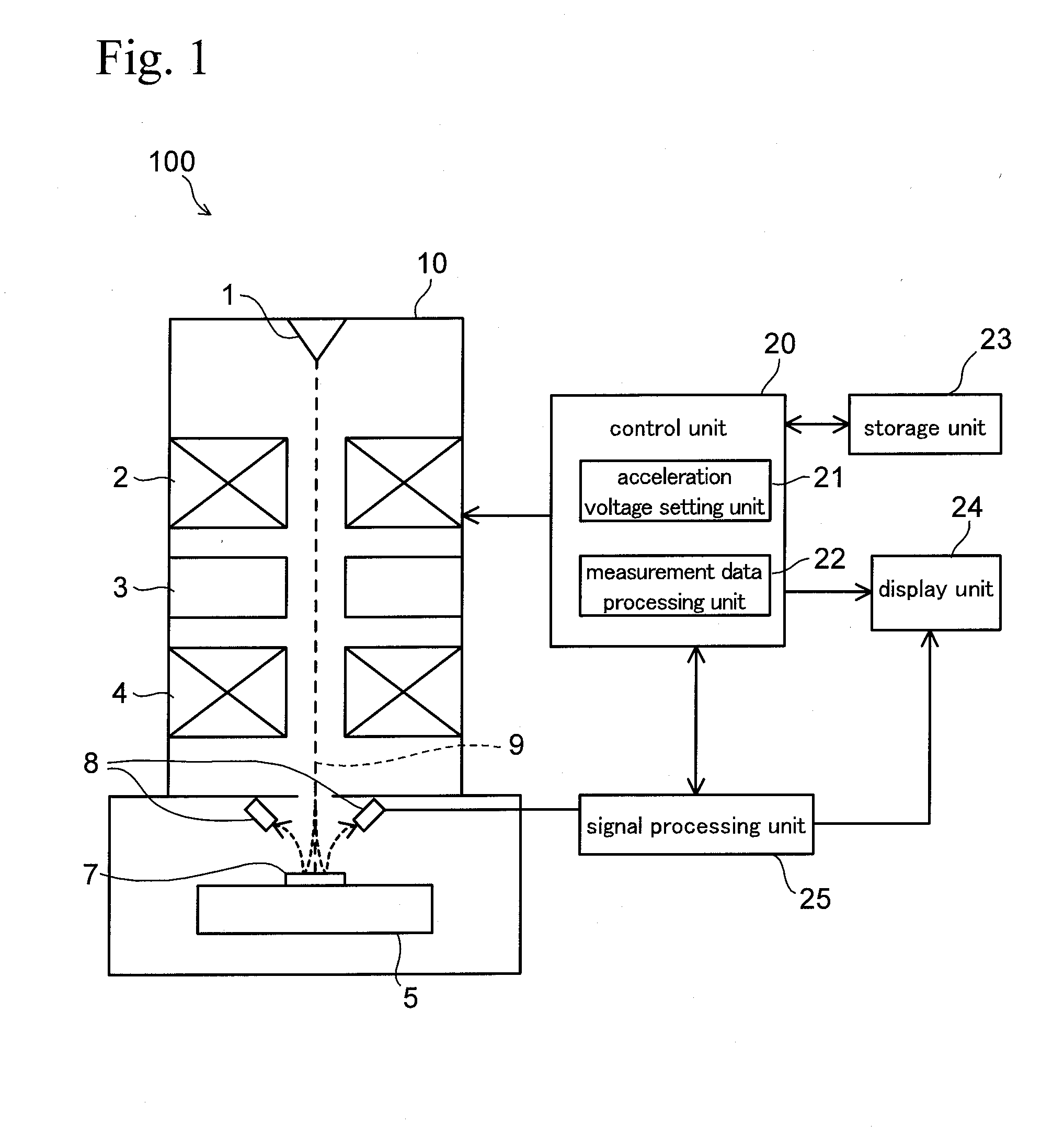

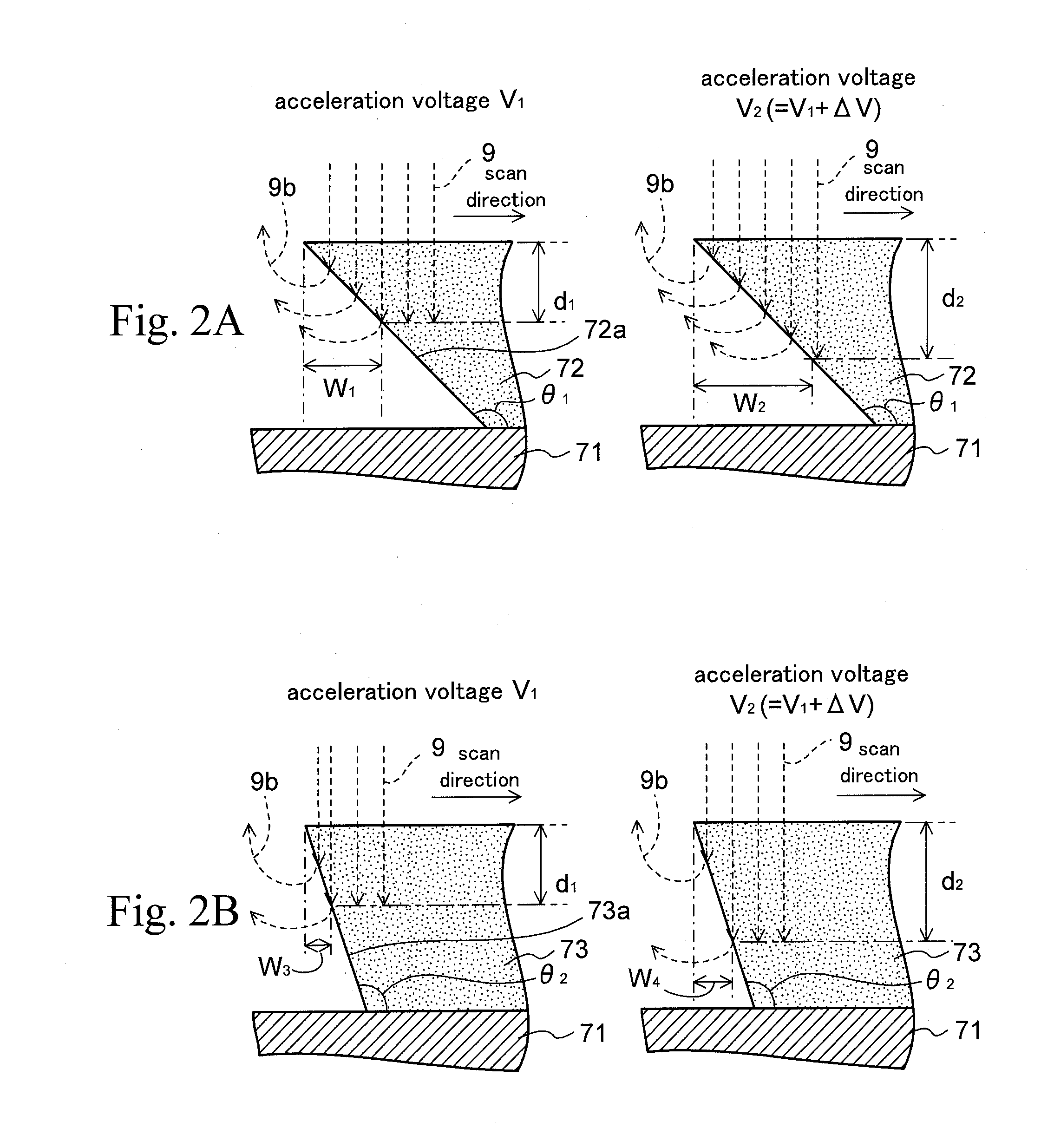

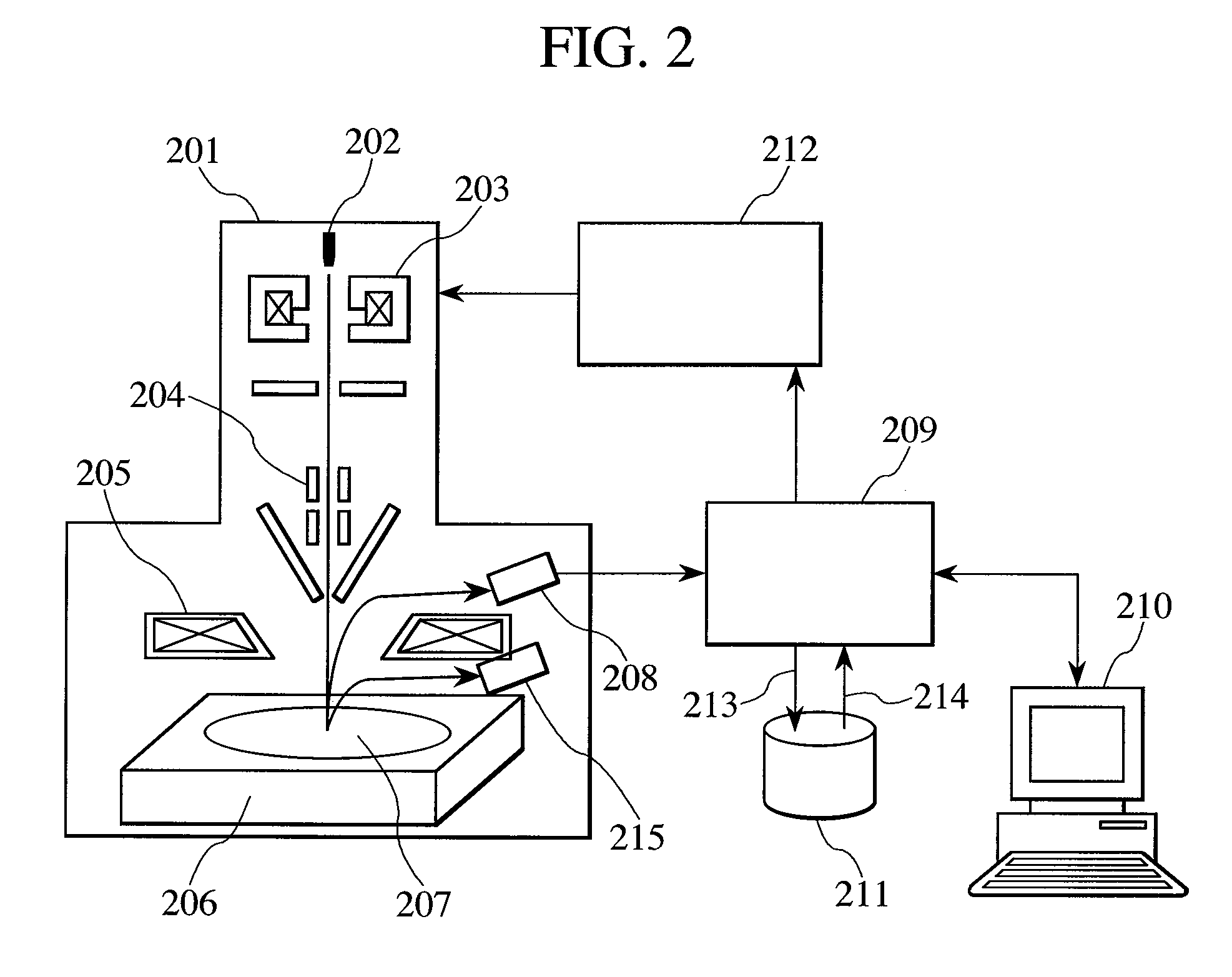

Pattern measurement method and pattern measurement apparatus

InactiveUS20130264480A1Material analysis using wave/particle radiationElectric discharge tubesScanning tunneling microscopeElectron microscope

A pattern measurement method and a pattern measurement apparatus which use a scanning electron microscope are provided. SEM images of a measurement target pattern are respectively acquired at least two predetermined acceleration voltages. White band widths of the measurement target pattern are detected from the acquired SEM images. Then, an amount of change in the white band width between the predetermined acceleration voltages is calculated. A side wall angle of the measurement target pattern is calculated on the basis of a relation between an amount of change in a white band width and a side wall angle experimentally obtained in advance by using a sample with a known side wall angle.

Owner:ADVANTEST CORP +1

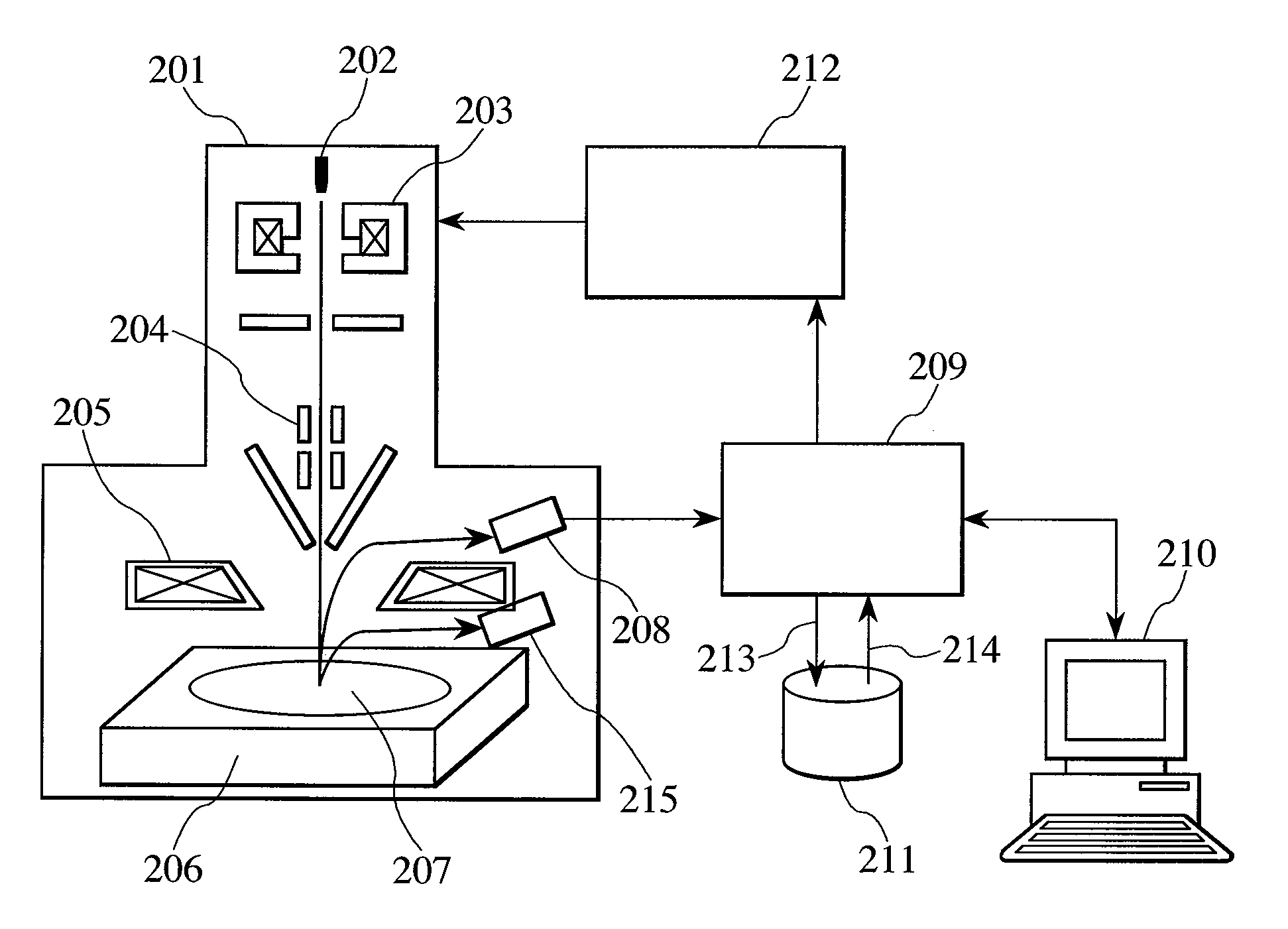

Electron beam measurement apparatus

The present invention provides an electron beam measurement technique for measuring the shapes or sizes of portions of patterns on a sample, or detecting a defect or the like. An electron beam measurement apparatus has a unit for irradiating the patterns delineated on a substrate by a multi-exposure method, and classifying the patterns in an acquired image into multiple groups according to an exposure history record. The exposure history record is obtained based on brightness of the patterns and a difference between white bands of the patterns.

Owner:HITACHI HIGH-TECH CORP

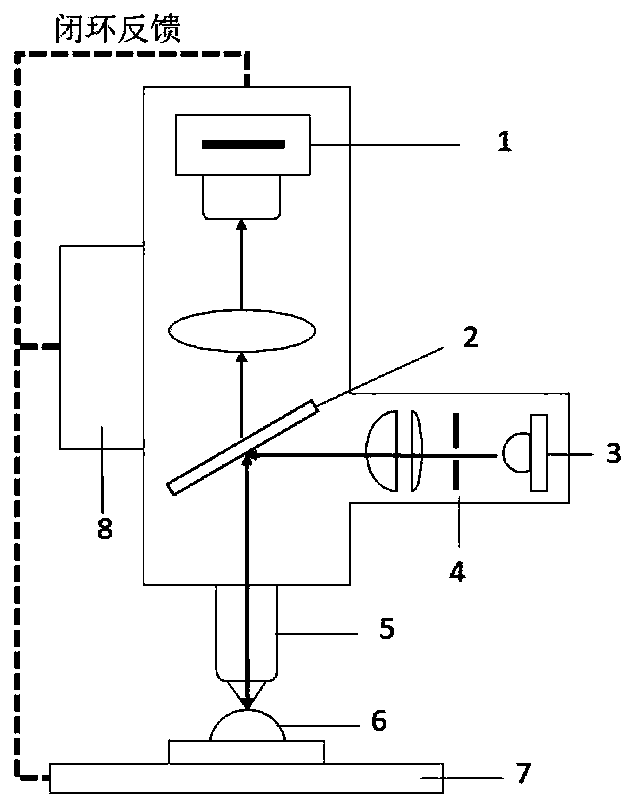

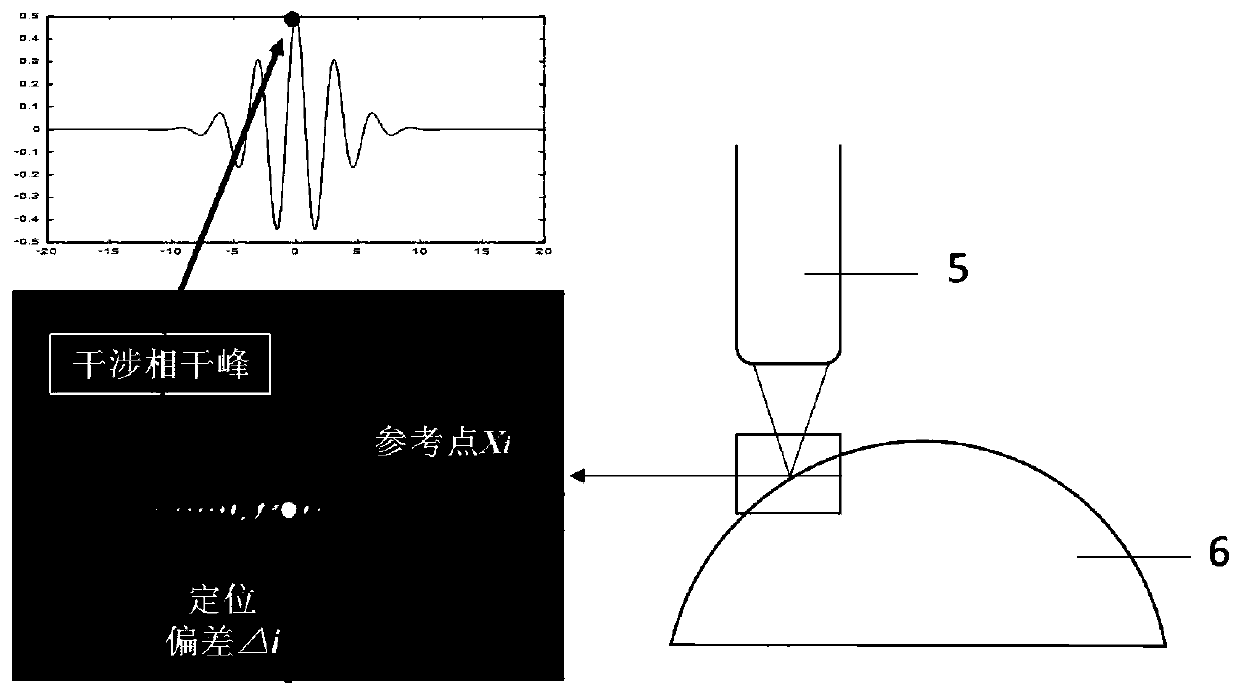

Line white light surface profile measuring method

ActiveCN111412861ARealize large curvature low frequency surface profile measurementUsing optical meansVisual field lossField of view

Owner:TIANJIN UNIV

Electron beam measurement apparatus

The present invention provides an electron beam measurement technique for measuring the shapes or sizes of portions of patterns on a sample, or detecting a defect or the like. An electron beam measurement apparatus has a unit for irradiating the patterns delineated on a substrate by a multi-exposure method, and classifying the patterns in an acquired image into multiple groups according to an exposure history record. The exposure history record is obtained based on brightness of the patterns and a difference between white bands of the patterns.

Owner:HITACHI HIGH-TECH CORP

Apparatus and method for determining patterns of damage being caused in rolling contact element

InactiveUS7577555B2Avoid mechanical damageNo errorPlug gaugesMachine bearings testingBrinellingAdiabatic shear band

A method of designing a roller bearing is disclosed upon clarifying mechanisms of damage patterns in respect of two kinds of brinelling, involved in the bearing, wherein white-banded flaking (brittle flaking) is a plastic instability phenomenon appearing under high-speed deformation accompanied by adiabatic shear deformation status with the resultant occurrence of adiabatic shear band (also called white band) inside material of the bearing. This enables all of the damage patterns to be determined upon making comparison between shear strain and shear strain rate, occurring inside the bearing, and discriminated values.

Owner:DENSO CORP

Method and apparatus for compensating for malfunctioning nozzle of inkjet image forming apparatus

InactiveCN1970297ACompensate for image deteriorationImprove printing qualityVisual representation by matrix printersOther printing apparatusEngineeringColor tone

Provided are a method and apparatus for compensating for the degradation of a print image due to a malfunctioning nozzle that irregularly ejects ink. The method includes detecting a malfunctioning nozzle among nozzles installed in an inkjet image forming apparatus and increasing a dithering threshold of an adjacent position to a compensation position printed by the detected malfunctioning nozzle. The method adjusts a dithering threshold of a print position of the malfunctioning nozzle or a dithering threshold of an adjacent print position, and thus performs a halftoning transaction and prints an image. Accordingly, the degradation of print quality such as a visible white band can be prevented and the lifetime of the printhead can be lengthened.

Owner:HEWLETT PACKARD DEV CO LP

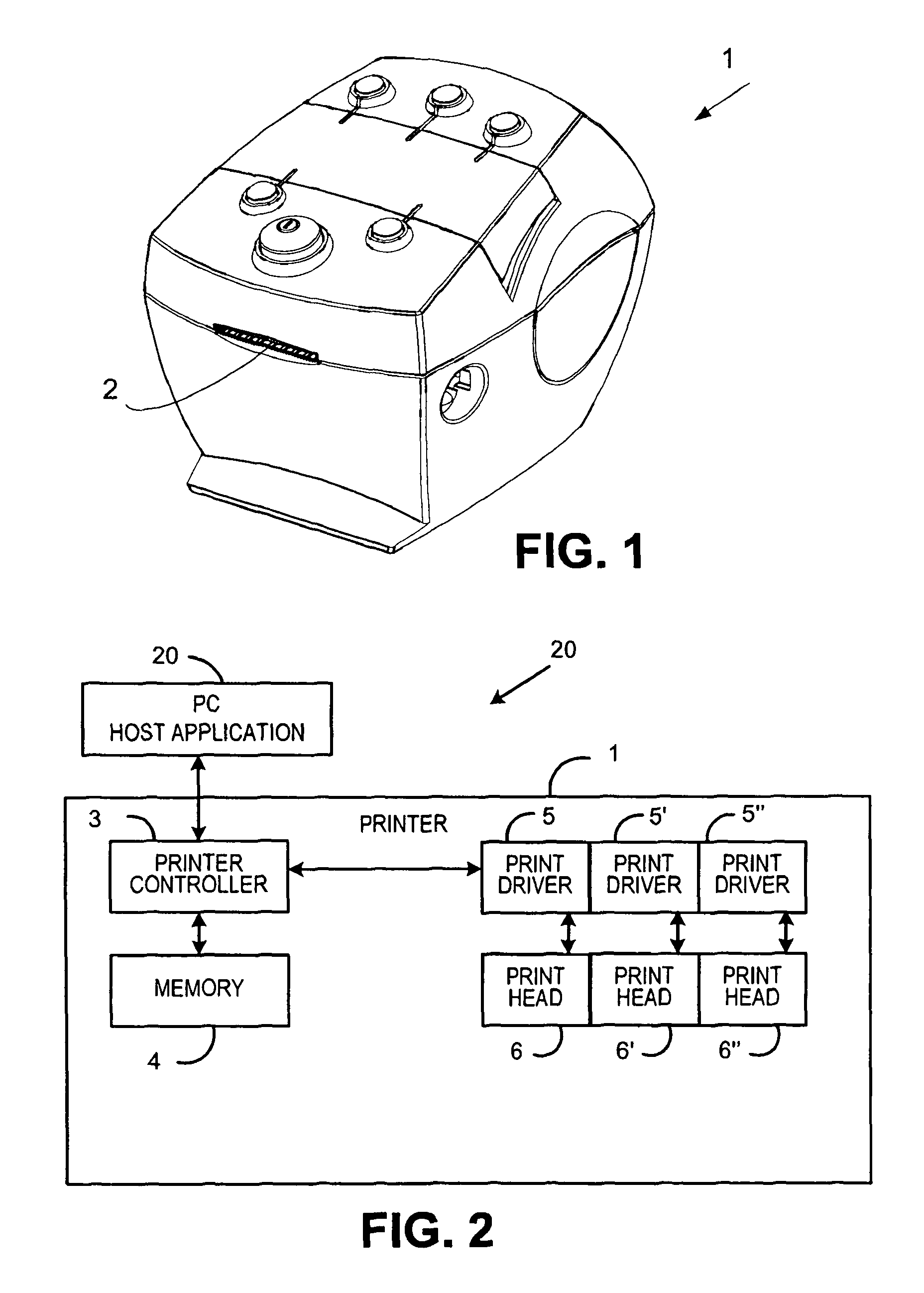

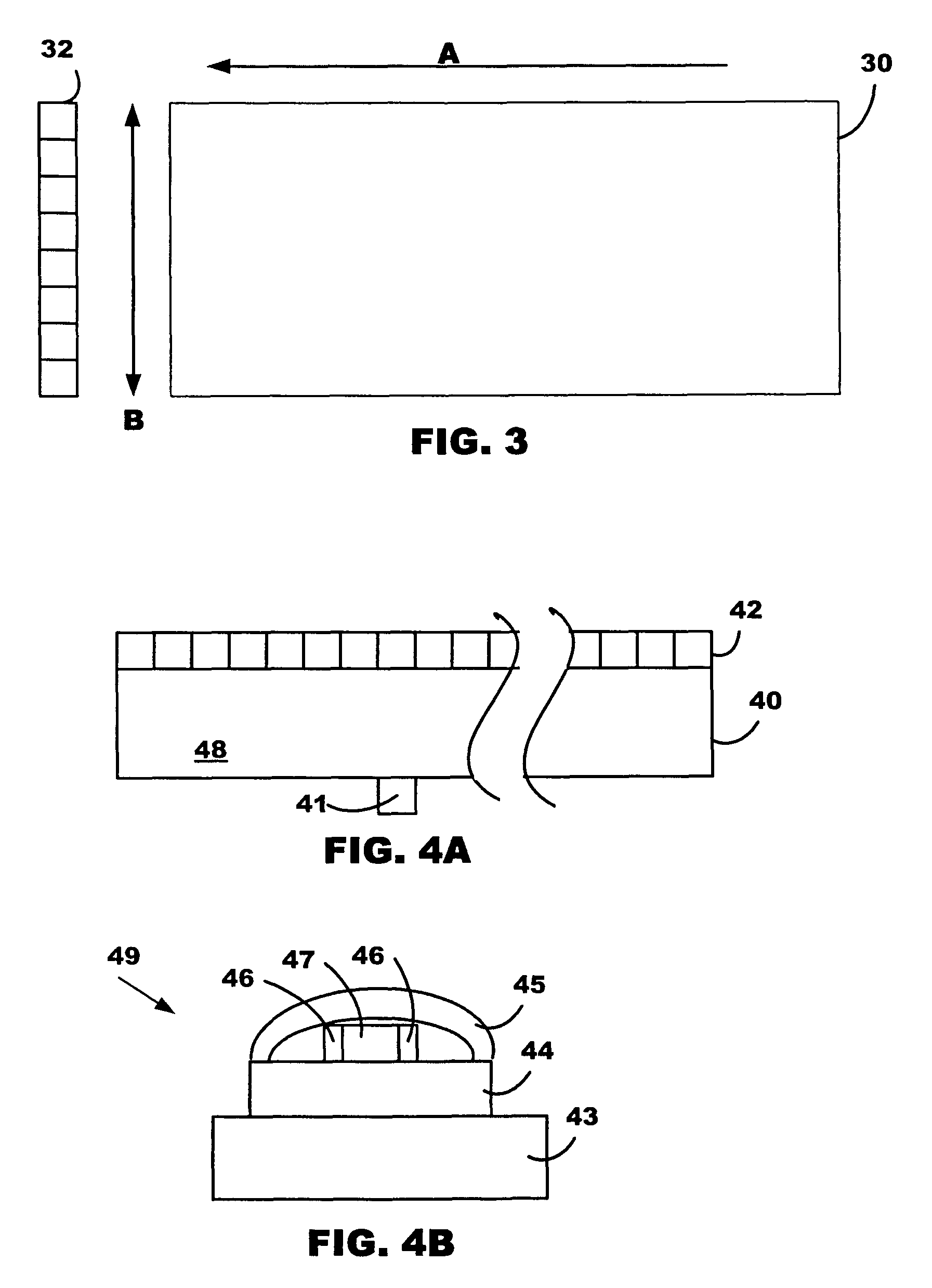

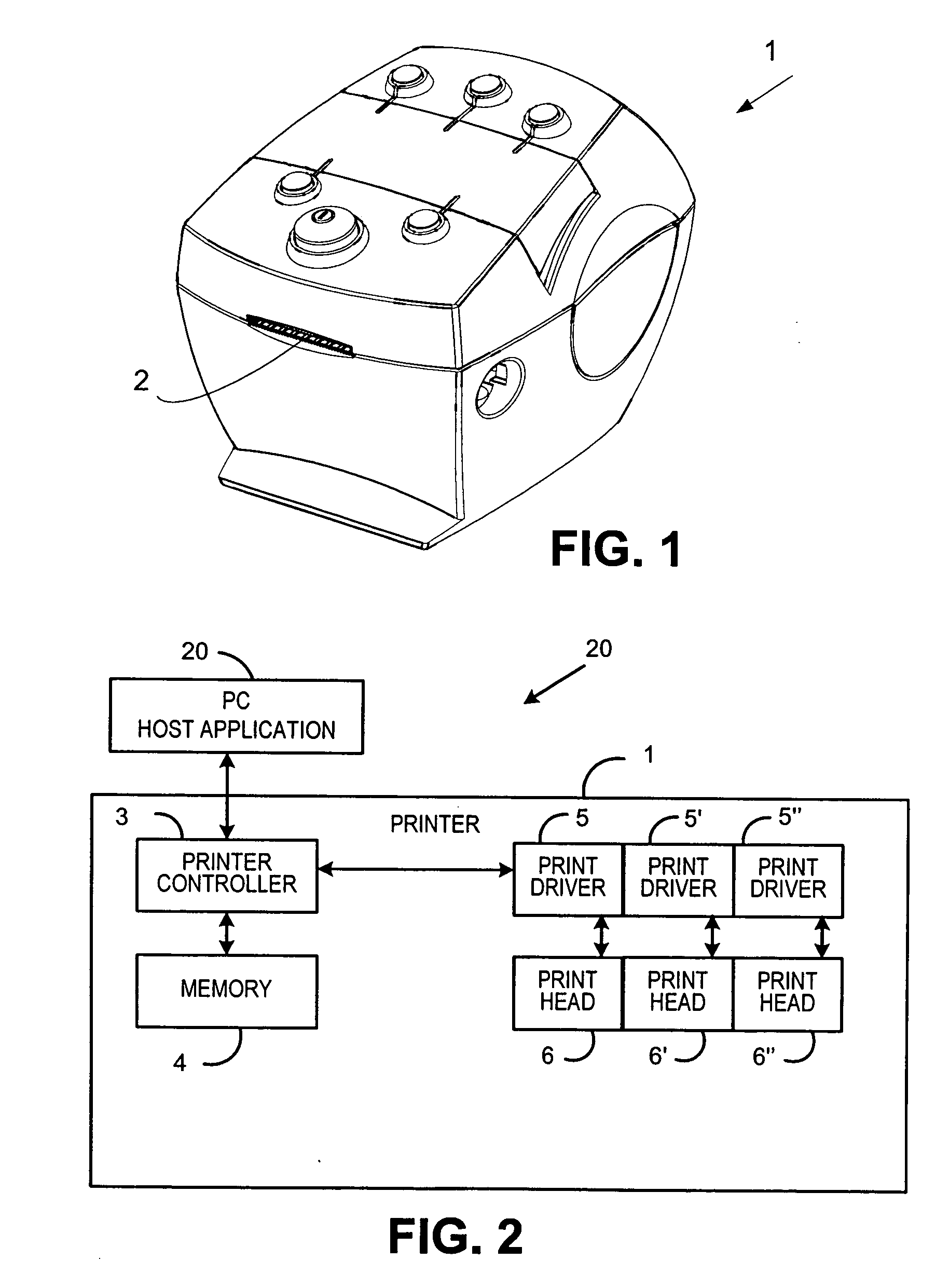

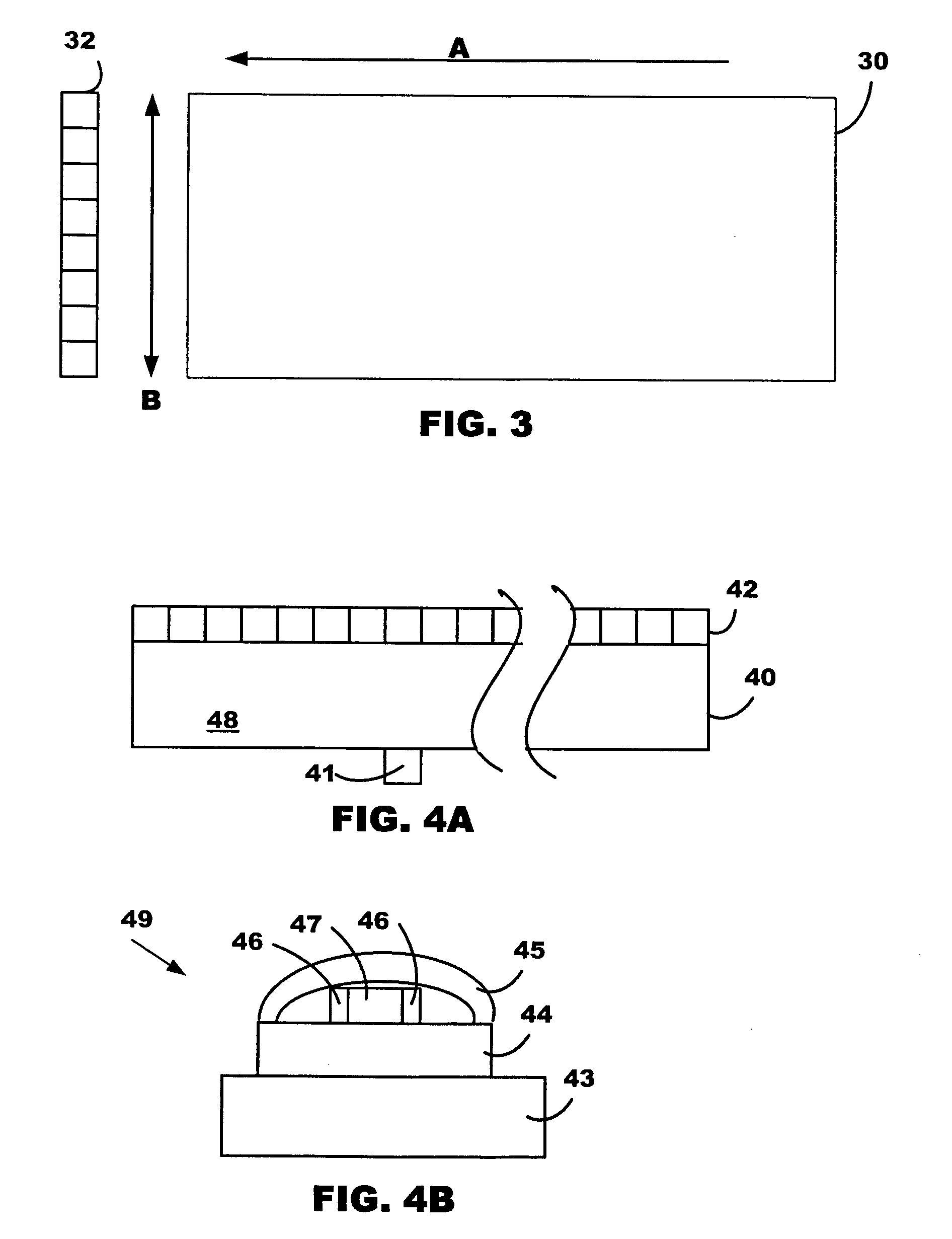

Method for printing address labels using a secure indicia printer

Printing methods and systems that provide both a secure value label printing mode of operation and a non-secure mode of operation that allows generic printing of non-value items without compromising the security feature of the secure printing mode are described. If the printing system determines the image is a non-secure image such as an address label or other non-value graphic, the printing system utilizes the non-secure mode and disables the use certain printhead elements. In such a system, the enforced print disabled white bands are enforced in non-secure mode such as by actually disabling the print drive mechanism that allows a row to be printed or by populating certain regions of the print buffer with zero values.

Owner:PITNEY BOWES INC

Method and apparatus for compensating for malfunctioning nozzle and inkjet image forming apparatus using the same

A method and apparatus are provided for compensating for the degradation of a print image due to a malfunctioning nozzle that irregularly ejects ink. A malfunctioning nozzle is detected among nozzles installed in an inkjet image forming apparatus, and image data of a print position adjacent to a compensation position printed by the malfunctioning nozzle is exchanged for image data of a print position in an interest or inspection region near the compensation position. Accordingly, degradation of print quality, such as, for example, an unintended visible white band, can be prevented and the lifetime of the printhead can be lengthened.

Owner:S PRINTING SOLUTION CO LTD

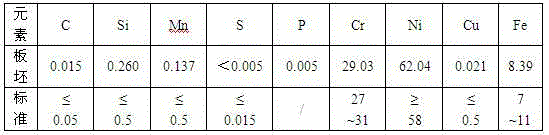

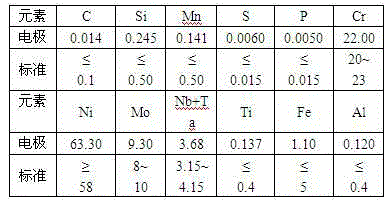

Slag system for ingot stripping and electroslag remelting of nickel-based alloy plate blank

The invention belongs to the technical field of special alloy refinement and in particular relates to a slag system for ingot stripping and electroslag remelting of a nickel-based alloy plate blank. The slag system comprises the following components in percentage by weight: 60%-65% of CaF2, 15%-20% of Al2O3, 13%-15% of CaO and 6%-10% of SiO2; the melting point of the slag system is 1,100-1,150 DEG C, the viscosity at 1600 DEG C is 0.04-0.07Pa.s, and the slag resistance at 1600 DEG C is 0.27-0.3 ohm.cm. The nickel-based alloy plate blank subjected to ingot stripping and electroslag remelting, produced by adopting the slag system is good in surface quality and free of remarkable defects such as double skin and slag inclusions; the interior quality of the plate blank is detected according to GB / T1979-2001 standards, the defects of looseness, segregation, white bands, subsurface bubbles, residual shrinkage cavities, skull patch, fish eyes, axial intercrystalline cracks, interior bubbles, non-metallic inclusions, slag inclusions, dissimilar metal inclusions and the like are not discovered, and the interior quality of steel ingot is good.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Method for printing address labels using a secure indicia printer

Printing methods and systems that provide both a secure value label printing mode of operation and a non-secure mode of operation that allows generic printing of non-value items without compromising the security feature of the secure printing mode are described. If the printing system determines the image is a non-secure image such as an address label or other non-value graphic, the printing system utilizes the non-secure mode and disables the use certain printhead elements. In such a system, the enforced print disabled white bands are enforced in non-secure mode such as by actually disabling the print drive mechanism that allows a row to be printed or by populating certain regions of the print buffer with zero values.

Owner:PITNEY BOWES INC

Inkjet image forming apparatus and method of compensating for defective nozzle thereof

InactiveUS7887154B2Improve image qualityMinimize impactOther printing apparatusImaging qualityImage formation

An inkjet image forming apparatus and a method of defective nozzle compensation in the inkjet image forming apparatus. The method includes detection of an occurrence and a position of the defective nozzle in a nozzle unit, when the defective nozzle is detected, analyzing image information on image data which are to be printed at a compensated position which is a position printed with the defective nozzle and image data which are to be printed at positions adjacent to the compensated position, and exchanging the image data which are to be printed at the compensated position for image data which are to be printed at one of the adjacent positions according to the analyzed image information and performing printing. Missing dots caused by the defective nozzle are compensated by exchanging image data and performing printing. Accordingly, since the image data are exchanged and printed, it is possible to prevent deterioration in image quality such as a white band which can be easily perceived by a user.

Owner:HEWLETT PACKARD DEV CO LP

Imaging apparatus, external flash correction method, recording medium, and integrated circuit

ActiveUS8767095B2Suppress interferenceTelevision system detailsColor television detailsCorrection methodComputer science

An image capturing unit outputs both a valid video signal (a primary video signal) and an unnecessary video signal (a secondary video signal) as an output signal; a flash detection unit detects white band interference caused by an external flash; and a flash correction unit delays the valid video signal using a first delay unit and delays the unnecessary video signal using a second delay unit. When white band interference has occurred, the outputs of the respective delay units are added together by an adding unit, generating a corrected signal. An output selection unit selects and outputs the signal from the first delay unit in normal times, and when interference caused by an external flash has occurred, selects and outputs the corrected signal.

Owner:PANASONIC CORP

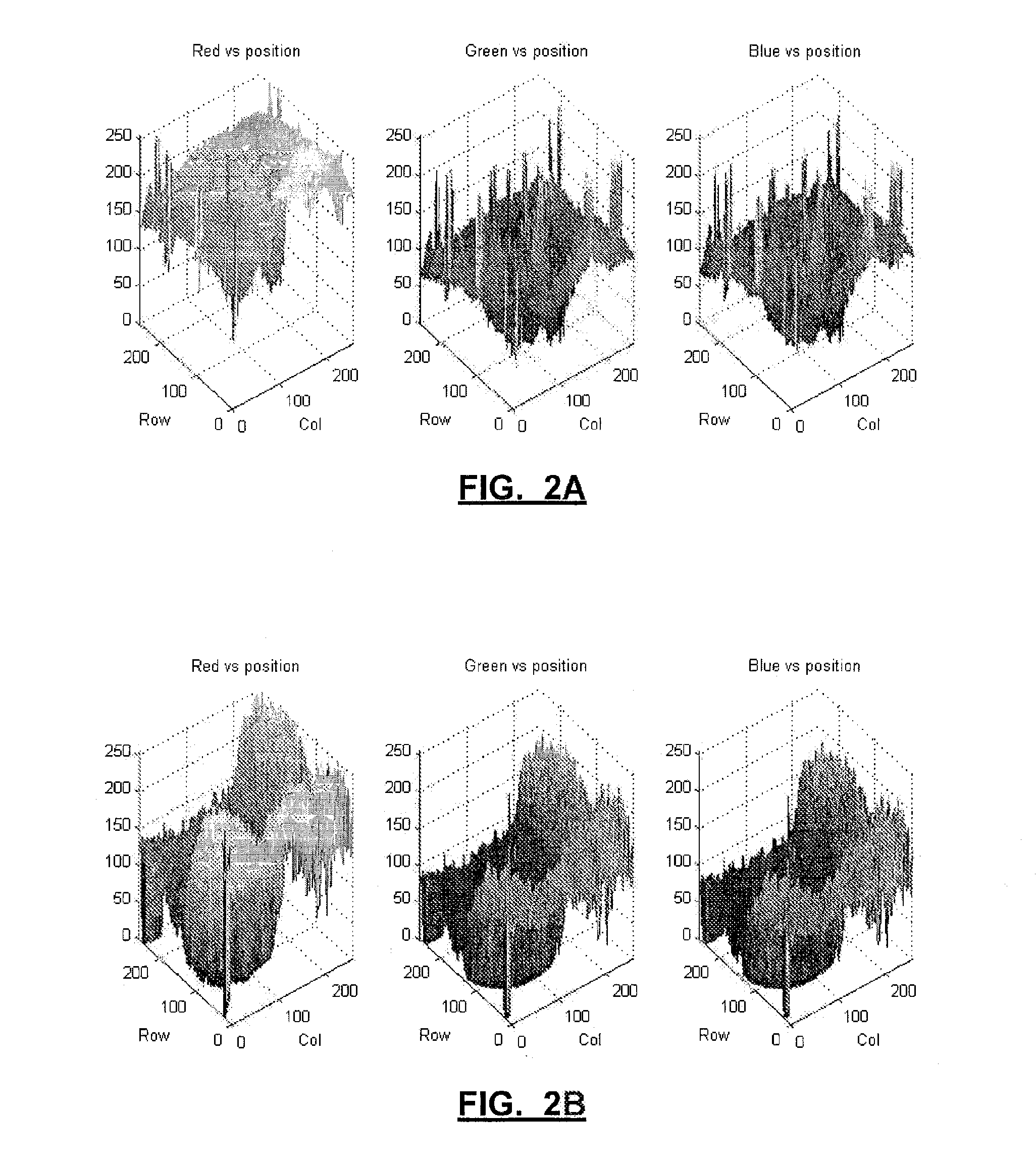

Methods and apparatus for image processing in wireless capsule endoscopy

ActiveUS20130271585A1Television system detailsColor television detailsImaging processingWireless capsule endoscope

Methods and apparatus for image processing suitable for use in wireless capsule endoscopy are provided. The image processing techniques exploit characteristic features of endoscopic images to enable low complexity compression. A color space conversion, coupled with lossless predictive coding and variable length coding are employed. Sub-sampling and clipping may also be used. The described image processing can be used both with both white-band imaging and narrow-band-imaging.

Owner:UNIVERSITY OF SASKATCHEWAN

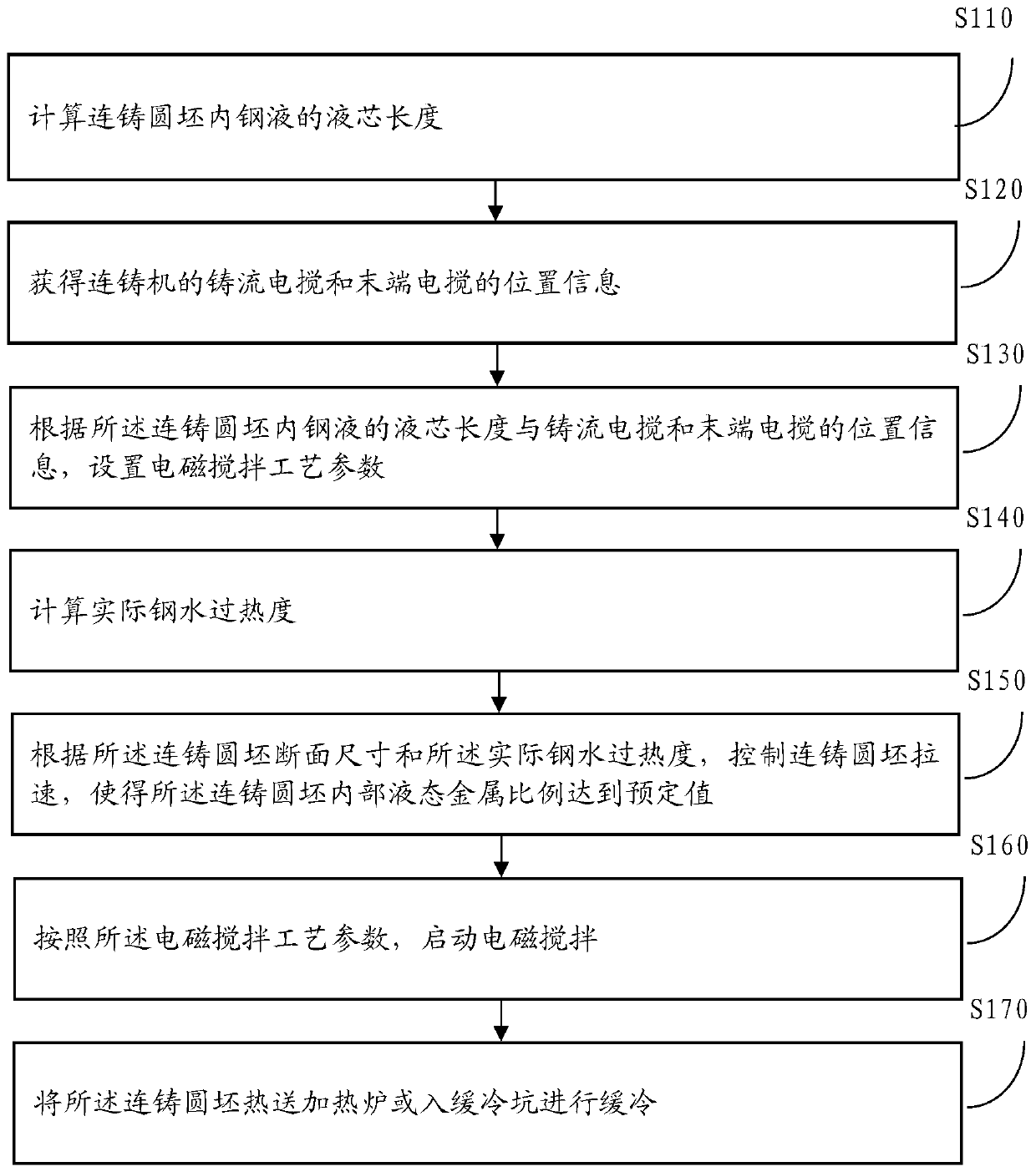

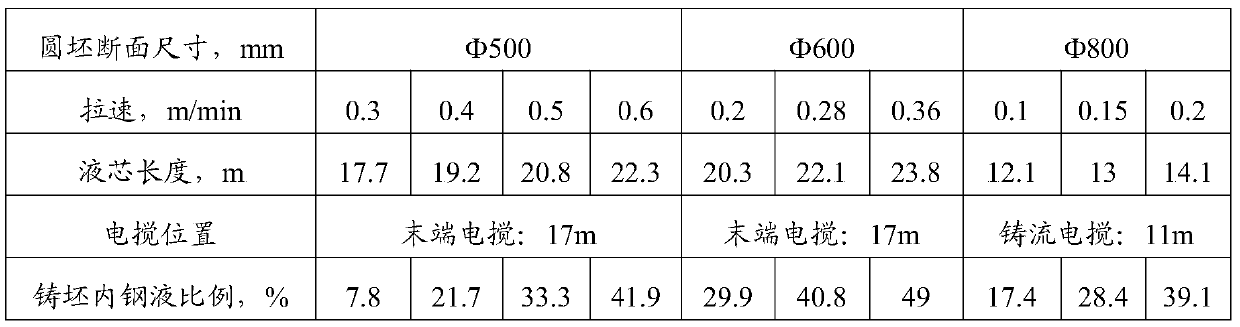

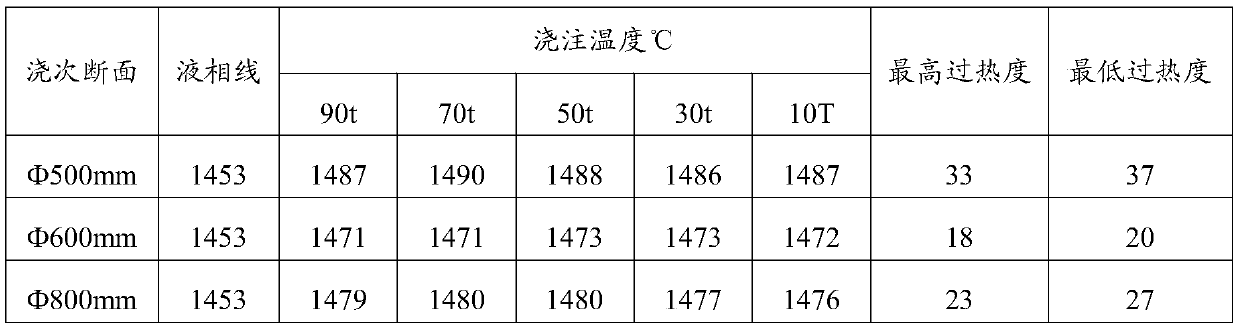

Method for producing large-section high-carbon-manganese-chromium steel continuous casting round billet

The invention discloses a method for producing a large-section high-carbon-manganese-chromium steel continuous casting round billet. The method comprises the following steps of calculating the liquidcore length of molten steel in a continuous casting round billet; obtaining position information of a casting flow electromagnetic stirrer and a tail end electromagnetic stirrer of a continuous casting machine; setting electromagnetic stirring process parameters according to the liquid core length of the molten steel in the continuous casting round billet and the position information of the casting flow electromagnetic stirrer and the tail end electromagnetic stirrer; calculating an actual superheat degree of the molten steel; according to the section size of the continuous casting round billet and the actual superheat degree of the molten steel, controlling a drawing speed of the continuous casting round billet to enable the proportion of liquid metal in the continuous casting round billet to reach a preset value; starting electromagnetic stirring according to the electromagnetic stirring process parameters; and sending the continuous casting round billet to a heating furnace or a slow cooling pit for slow cooling. The method achieves the technical effect of reducing the C segregation of the center of the continuous casting round billet, eliminating the macrostructure white band of the casting blank, improving the defects of the internal loosening, shrinkage porosity, internal cracking and the like, and improving the macrostructure quality of the casting blank.

Owner:JIANGSU LIANFENG ENERGY EQUIP

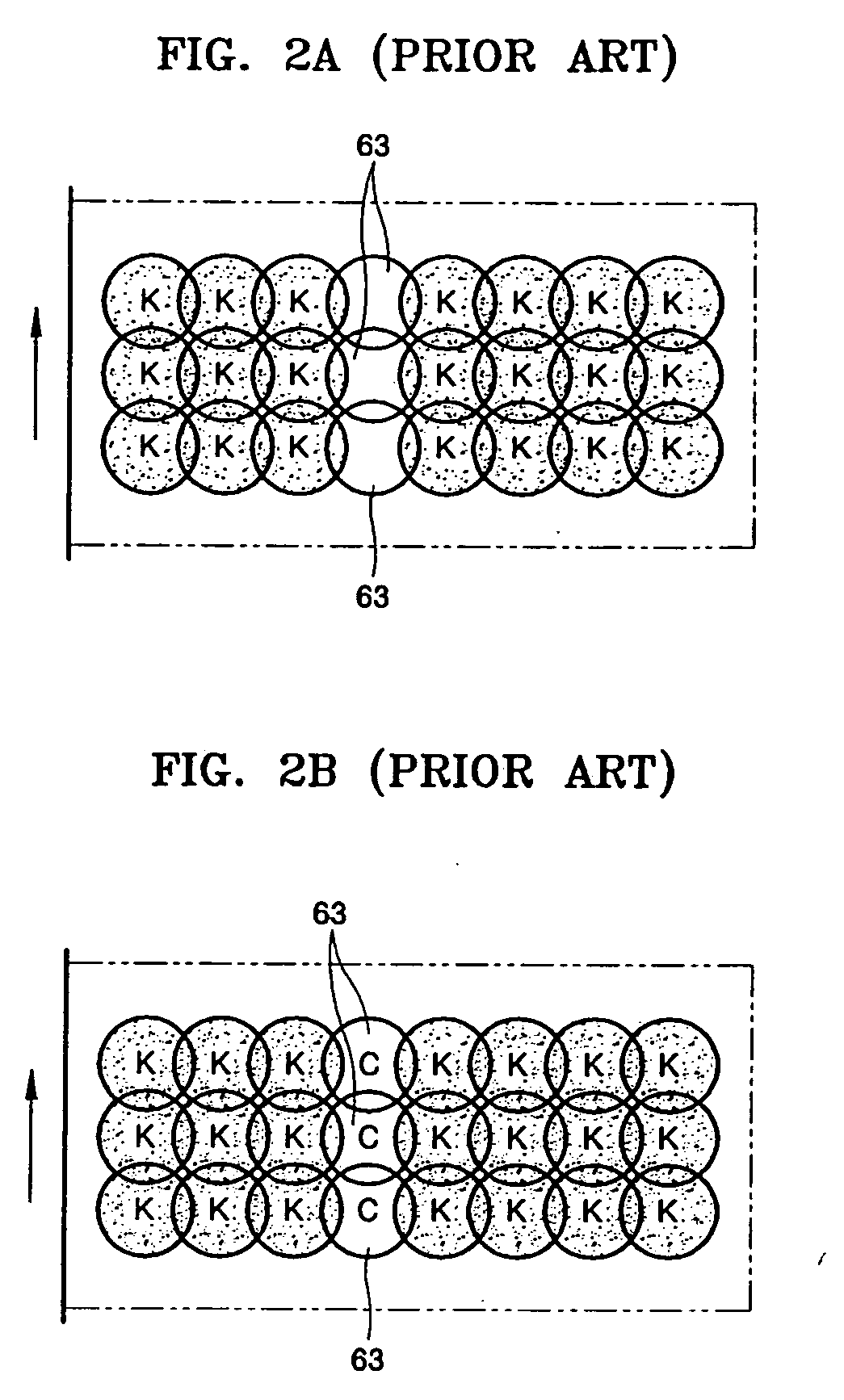

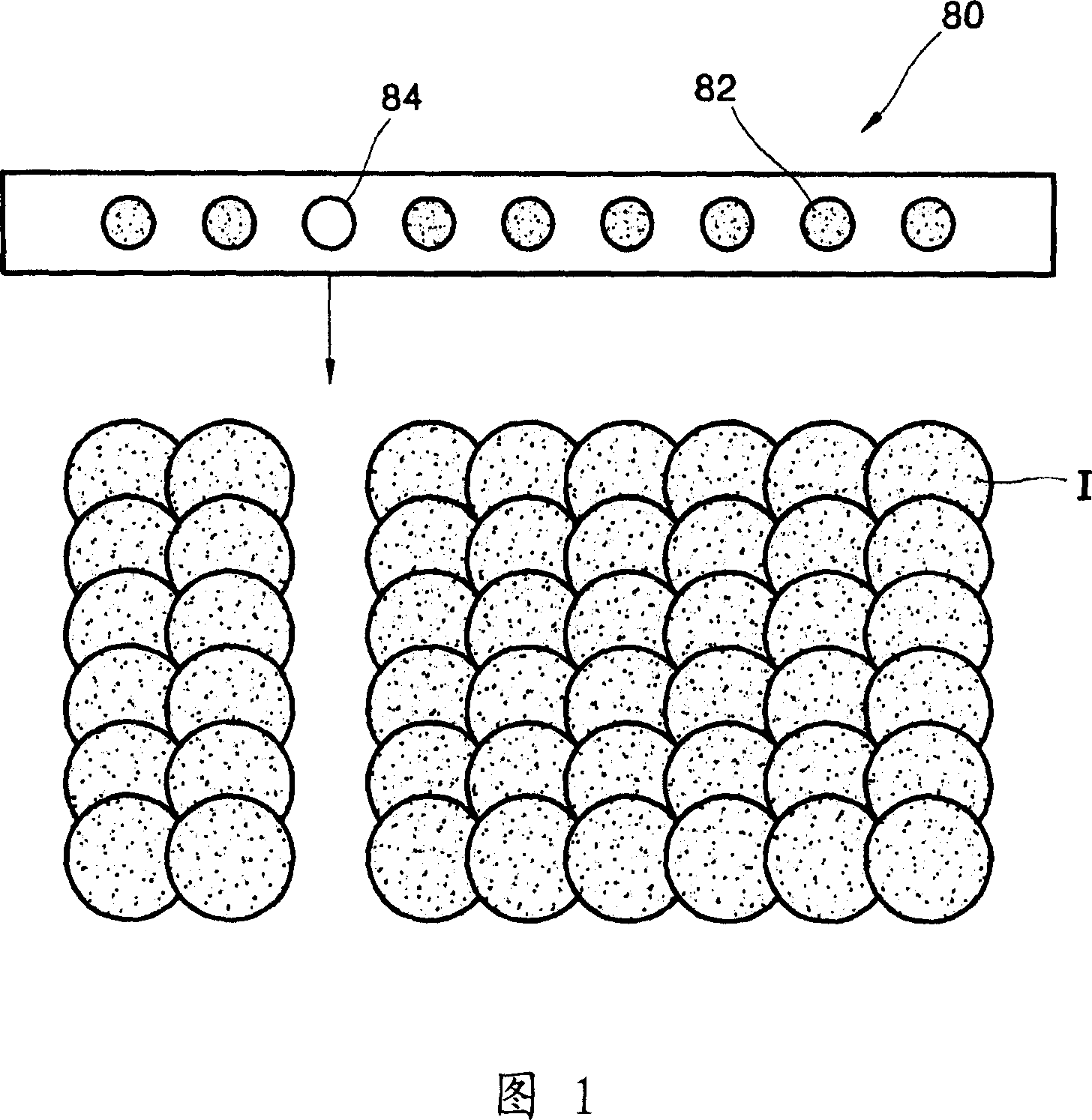

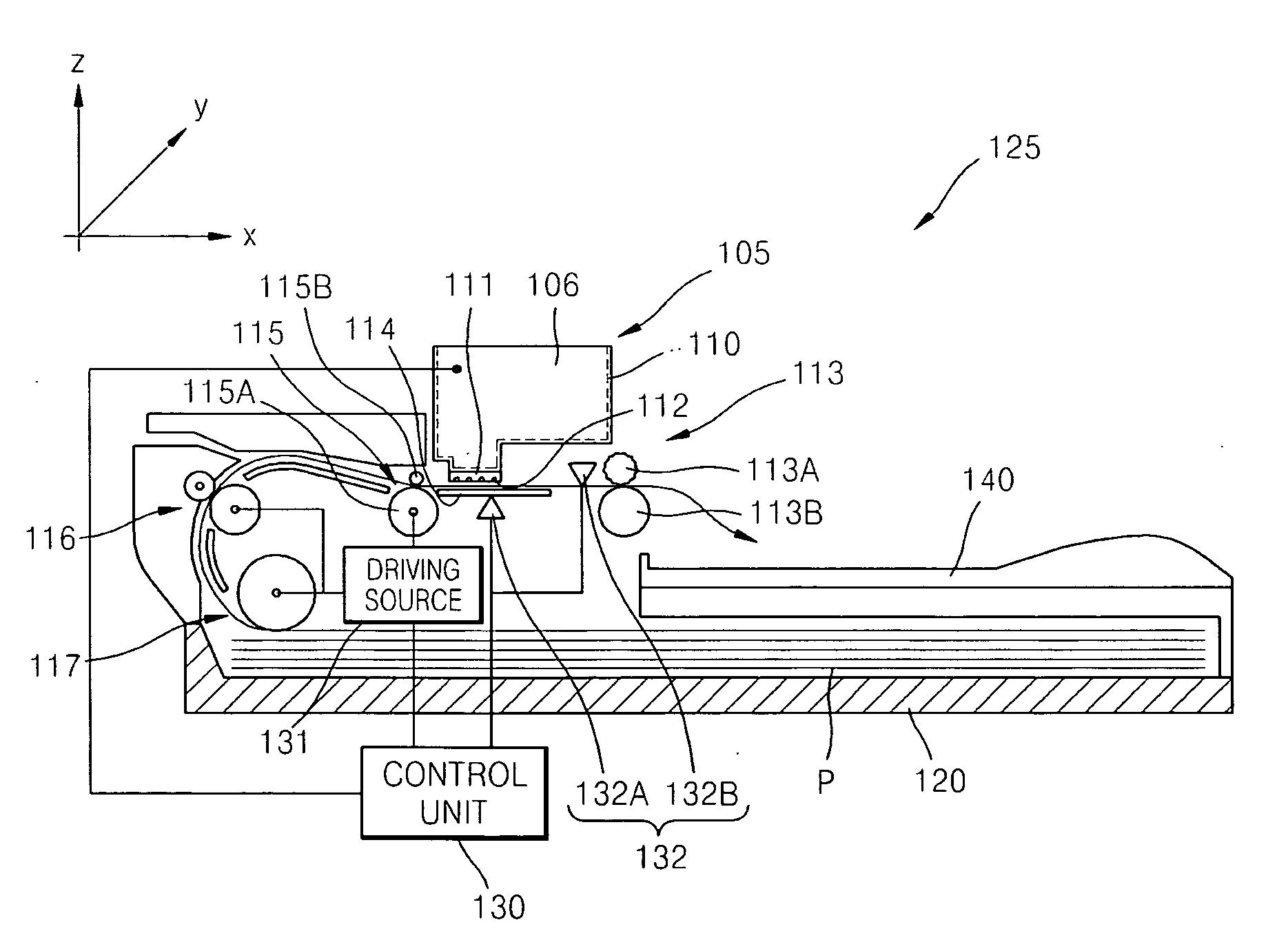

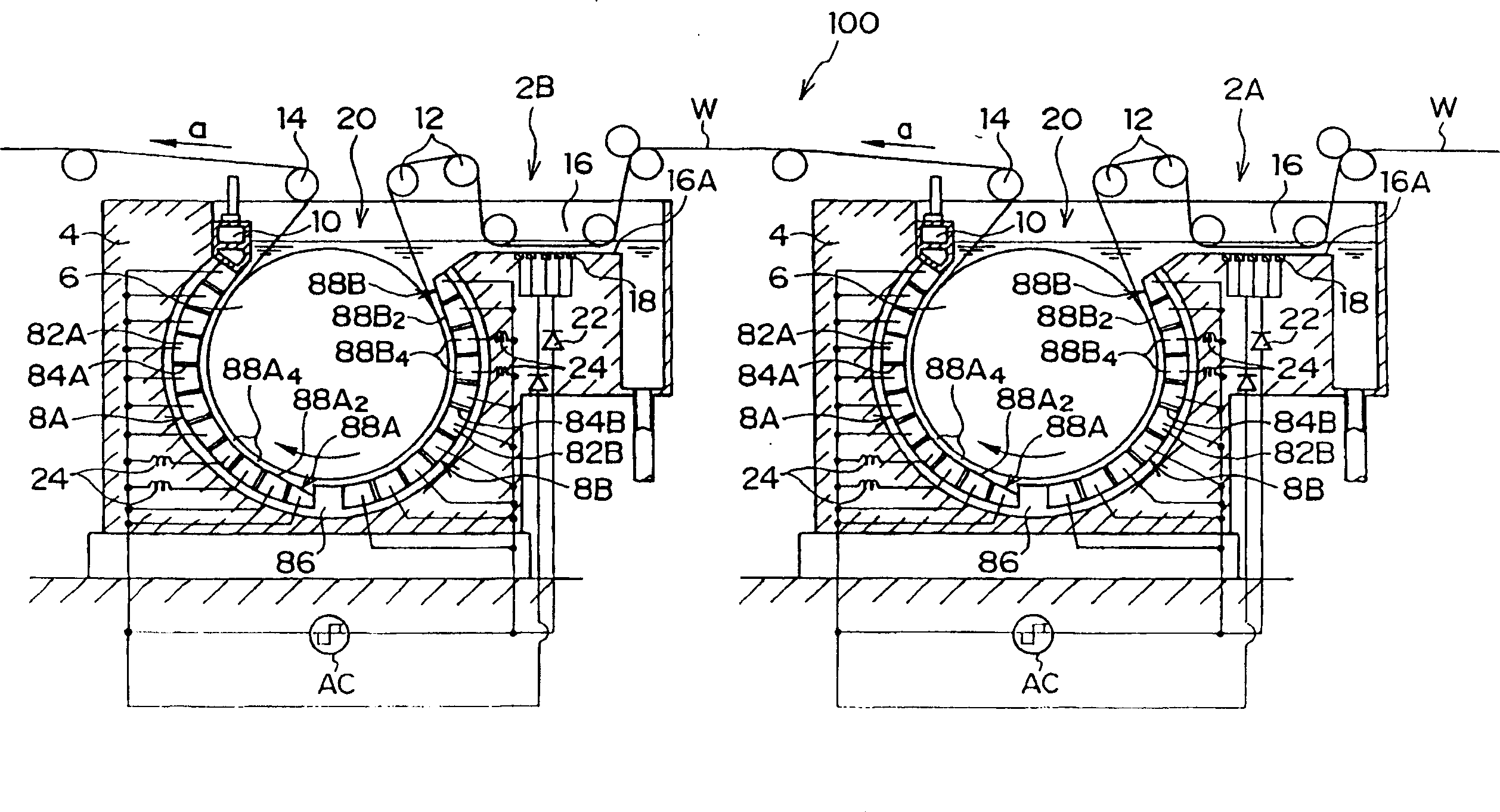

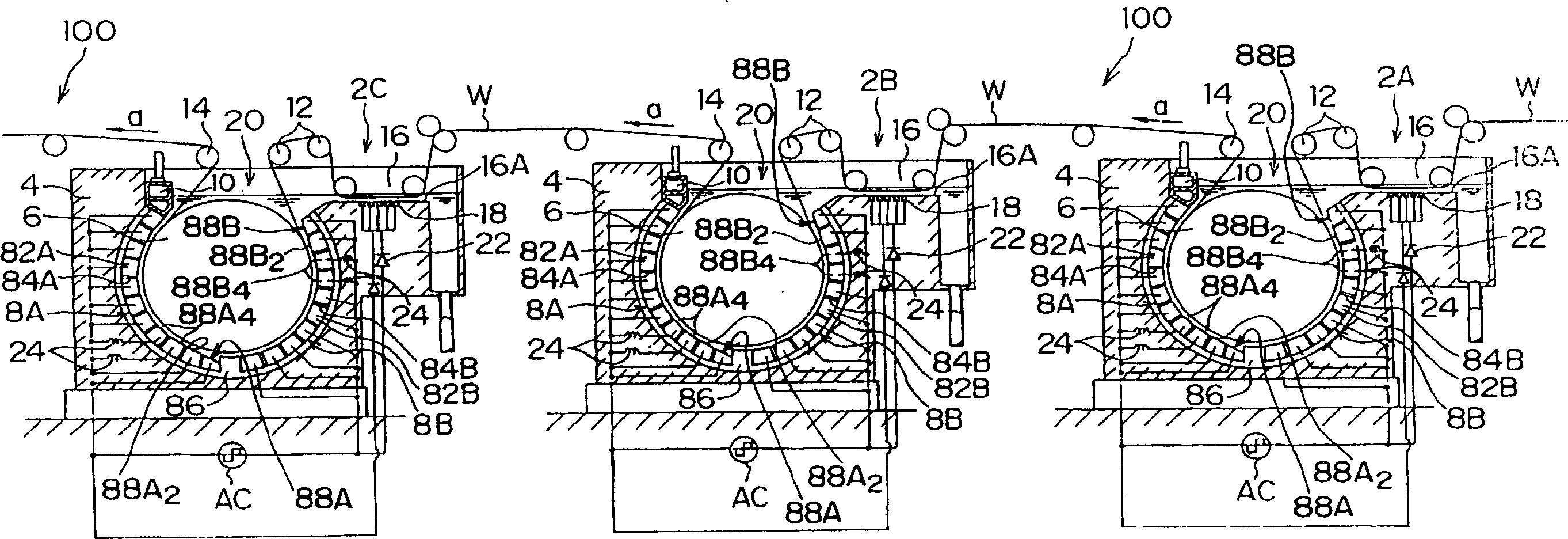

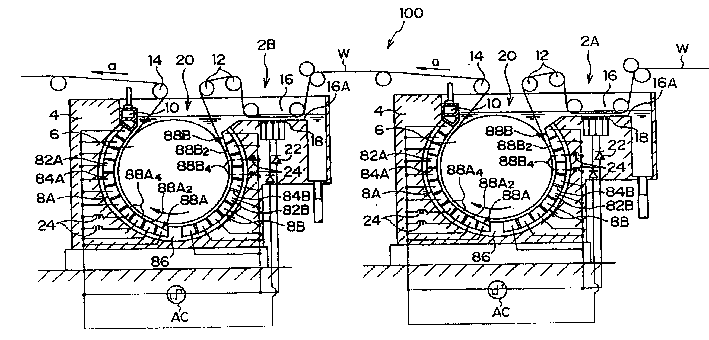

Electrolyzing apparatus

An object of the present invention is to provide an electrolysis apparatus that can prevent formation of surface defects such as white bands on an obtained aluminum support for a planographic printing plate even when electrolyzing an aluminum strip at a high current density while conveying the aluminum strip at a high conveyance velocity. The electrolysis apparatus is used for electrolyzing a metal strip conveyed in one direction. The apparatus includes a plurality of electrolysis cells arranged in series, wherein the metal strip is electrolyzed in an acidic electrolyte by applying an alternating current. In an electrolysis cell disposed in the downstream-most position with respect to the conveyance direction of the metal strip, electrolysis is carried out at a lower current density than in an electrolysis cell disposed in an upstream electrolysis cell with respect to the conveyance direction.

Owner:FUJIFILM CORP

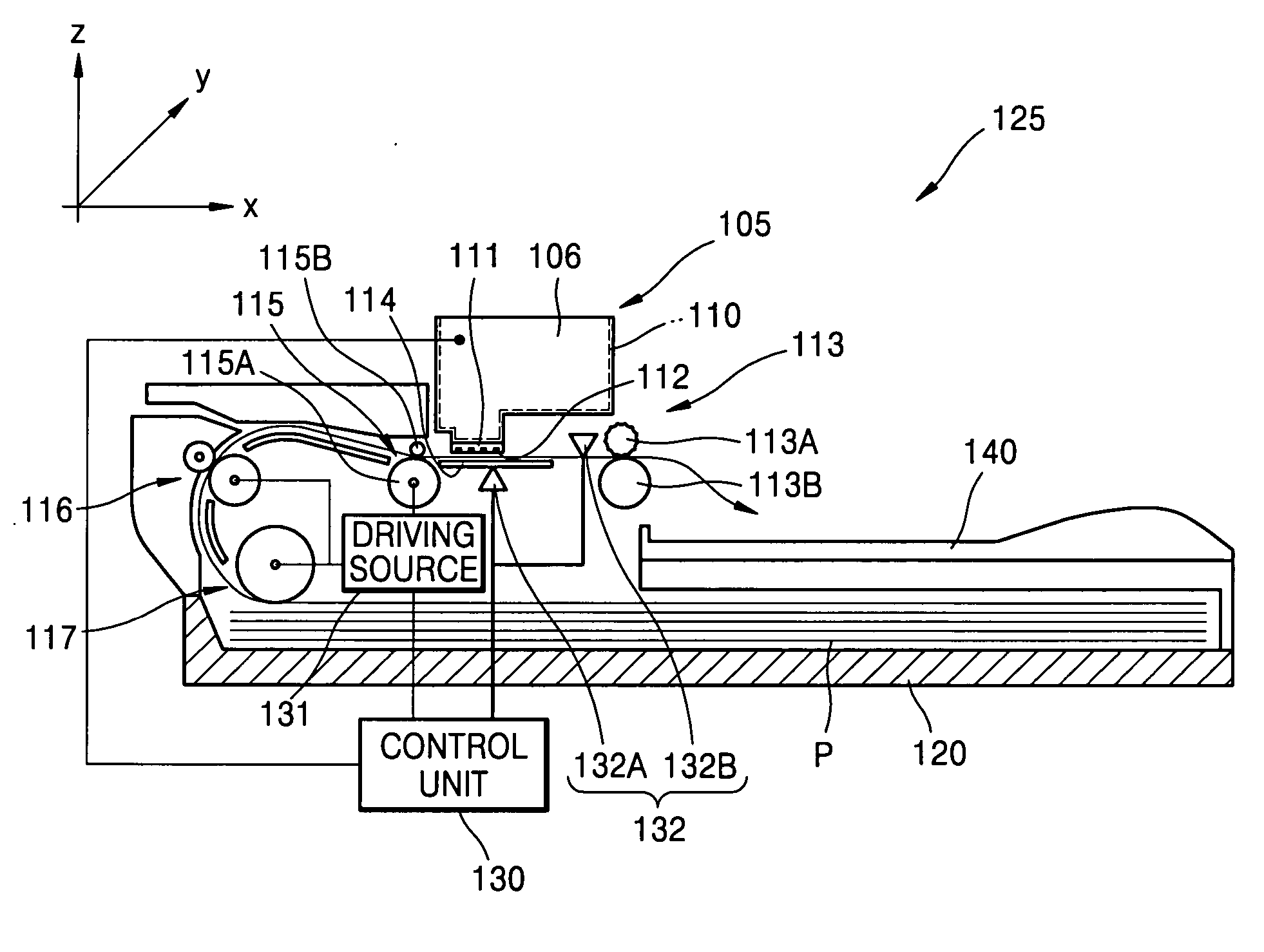

Inkjet image forming apparatus and method of compensating for defective nozzle

InactiveUS20070070100A1Improve image qualityMinimize impactOther printing apparatusCompensation effectImaging quality

An inkjet image forming apparatus and method of compensating for a defective nozzle in an inkjet image forming apparatus are provided. By analyzing firing states of nozzles firing ink at a compensated position, which is a position printed with the defective nozzle, and at positions adjacent to the compensated position, and by firing ink having a color different from that of the defective nozzle at the compensated position according to the firing states of the nozzles to diffuse the ink fired at the adjacent positions into the compensated position, the defective nozzle is compensated. Accordingly, the missing dot of the defective nozzle is compensated for, so that it is possible to prevent deterioration in image quality such as a white band which can be easily perceived by a user. In addition, by adjusting a firing amount or chroma of the ink fired at the compensated position or the adjacent positions, it is possible to improve a compensation effect.

Owner:S PRINTING SOLUTION CO LTD

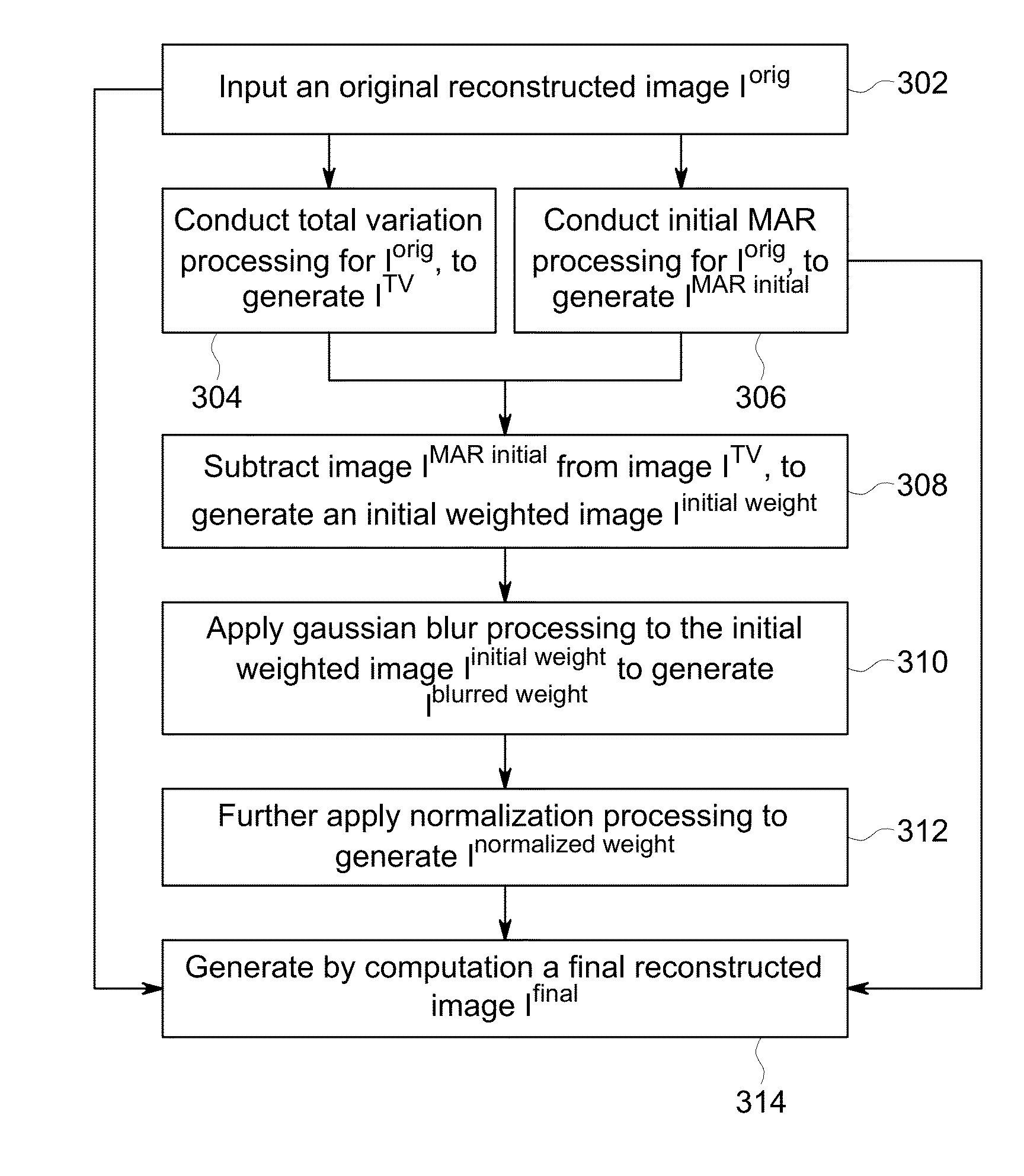

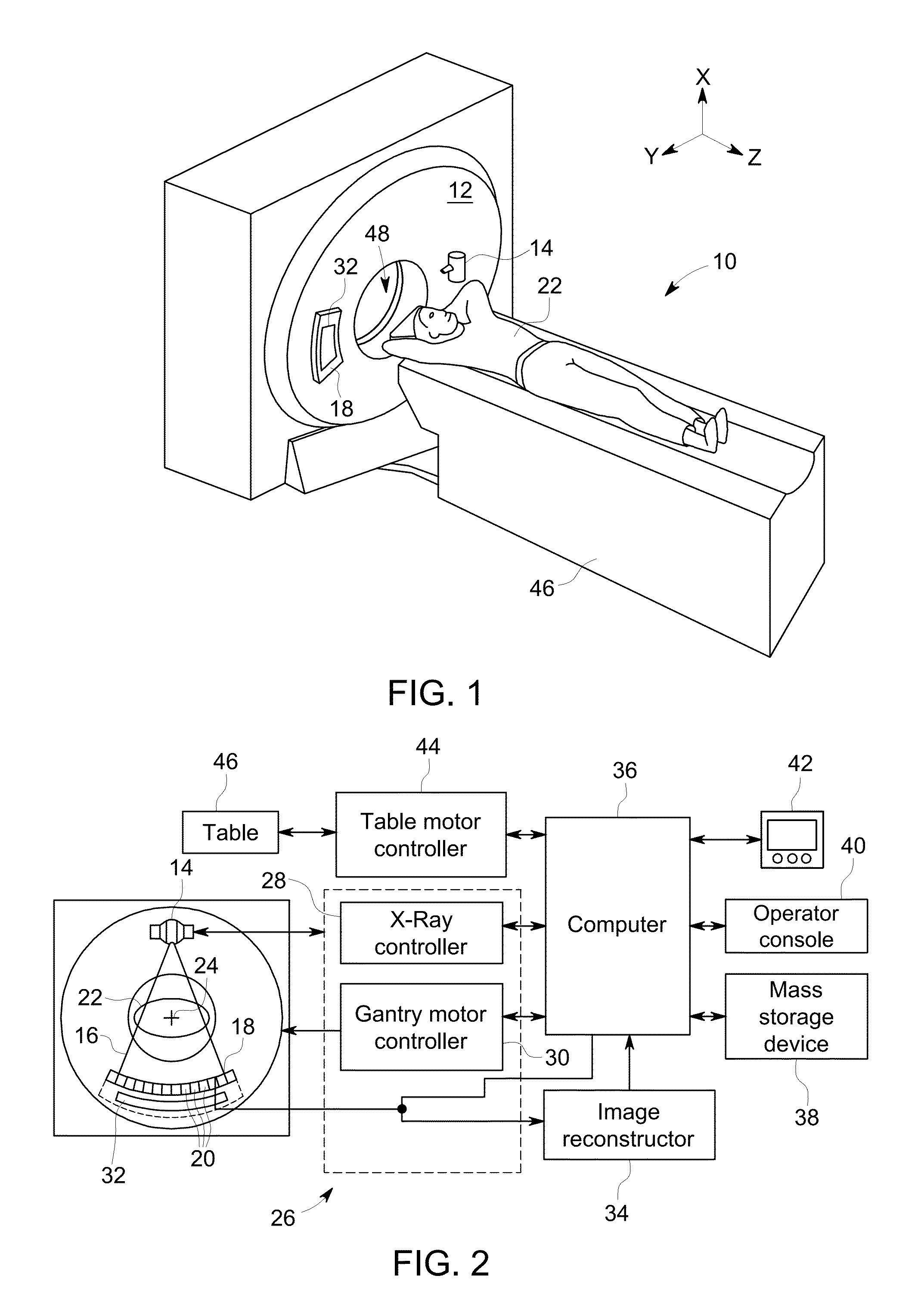

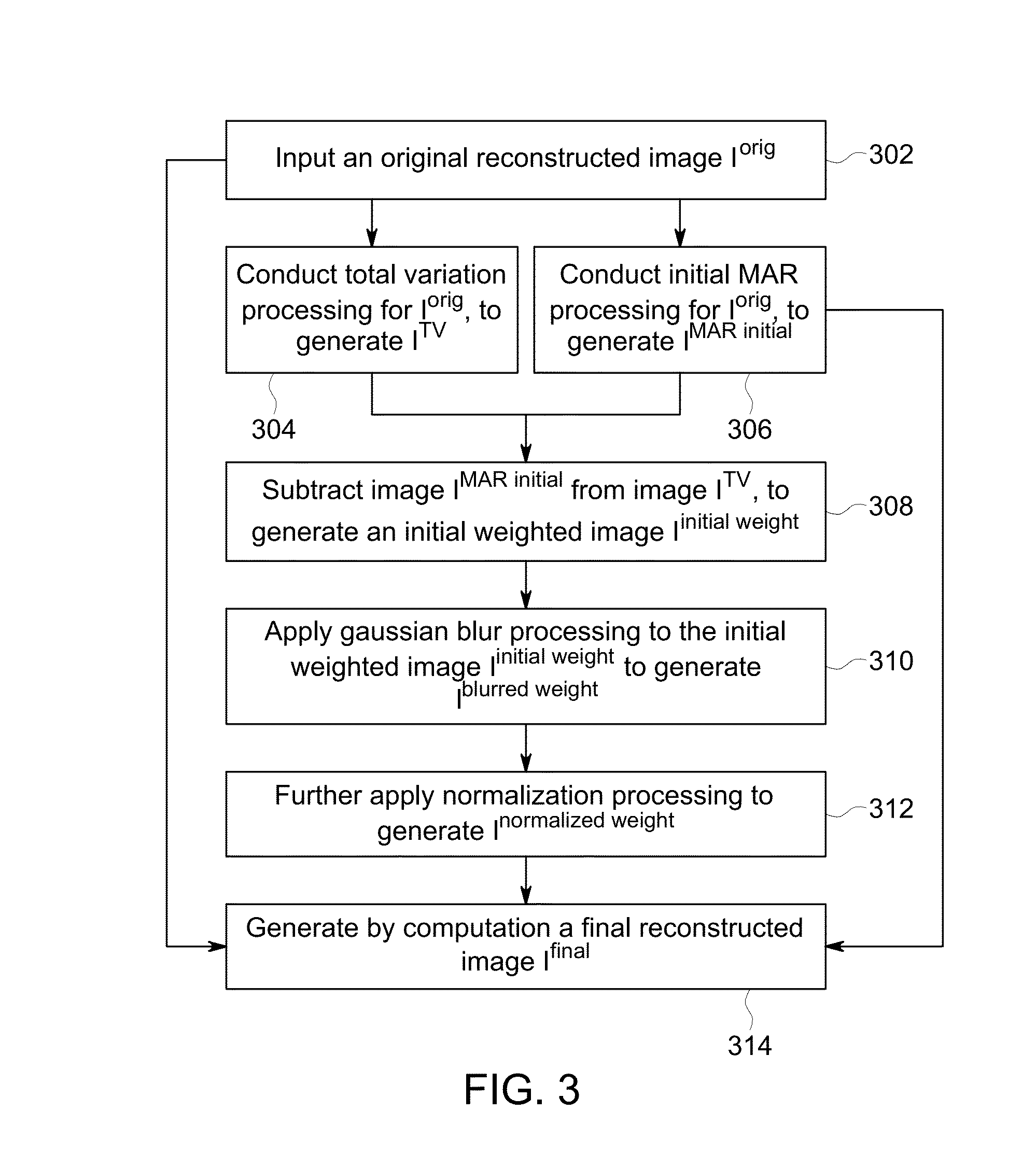

Method and apparatus for reducing artifacts in computed tomography (CT) image reconstruction

The present invention provides a method and apparatus for reducing artifacts in Computed Tomography (CT) image reconstruction. The method comprises acquiring an original reconstructed image, then conducting total variation processing for the original reconstructed image generating a total variation reconstructed image, conducting an initial metal artifact reduction processing for the original reconstructed image generating an initial metal artifact reduction reconstructed image, generating a weighted image based on the total variation reconstructed image and the initial metal artifact reduction reconstructed image, wherein the weighted image reflects that the original reconstructed image contains white-band artifactsd combining a portion of the original reconstructed image and a portion of the initial metal artifact reduction reconstructed image through the weighted image to generate a final image, wherein the final image does not contain white-band artifact.

Owner:GENERAL ELECTRIC CO

Sensing aiding method and system for cognitive radio

ActiveUS9094972B2Reduce the likelihood of failureReduce overheadWireless commuication servicesNetwork planningFrequency spectrumCognitive radio

The disclosure discloses a sensing aiding method for cognitive radio. The method includes the following steps. a high level node transmits configuration information to a base station; the base station combines with a subordinate node of the base station to perform frequency spectrum sensing measurement, in which the subordinate node has sensing capability, and feeds back a result of the sensing measurement to the high level node; and the high level node formulates a corresponding WS allocation policy according to the received result of the sensing measurement. The disclosure also discloses a system. By the method and the system of the disclosure, the high level node transmits the configuration information to the base station; the base station performs the spectrum sensing measurement in combination with the subordinate node having the sensing capability of the base station in a designated frequency band and feeds the result of the sensing measurement back to the high level node; and the high level node formulates the corresponding WS allocation policy according to the result of the sensing measurement. Available white band resources are acquired; the probability of base station configuration failure is reduced, and the overhead caused by configuration failures is reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com