Method for producing large-section high-carbon-manganese-chromium steel continuous casting round billet

A high-carbon manganese-chromium steel and continuous casting round billet technology, which is applied in the production field of large-section high-carbon manganese-chromium steel continuous casting round billet, can solve billet center C segregation, inclusion MnS segregation, porosity, shrinkage cavity, internal Cracking metallurgical defects can not be eliminated and other problems, to achieve the effect of eliminating low-magnification white and bright bands, reducing central C segregation, and improving technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

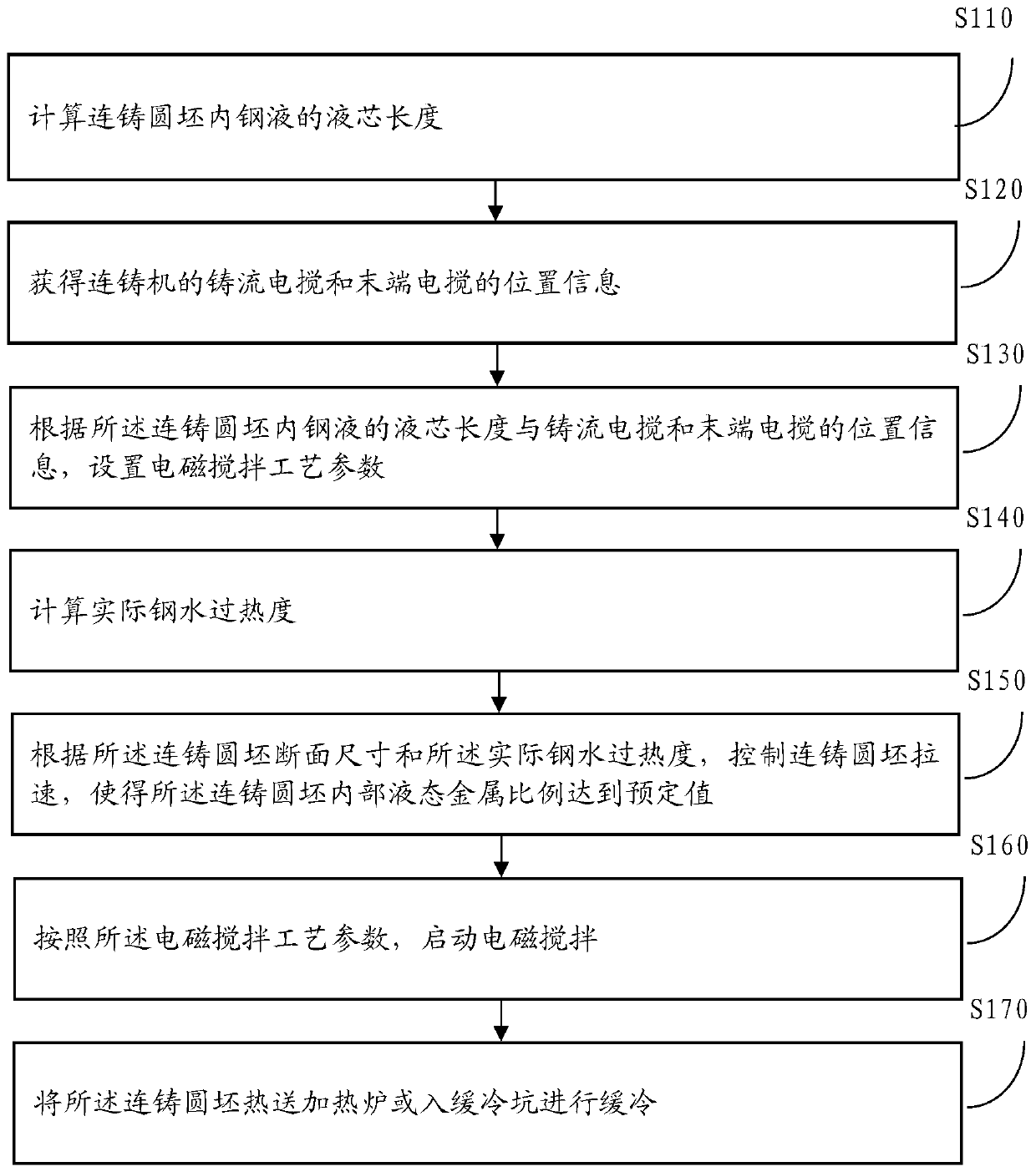

[0028] figure 1 It is a schematic flow chart of a production method of a large-section high-carbon manganese-chromium steel continuous casting round billet in an embodiment of the present invention, as figure 1 As shown, the method includes:

[0029] Step 110: Calculate the liquid core length of the molten steel in the continuous casting round billet;

[0030] Further, the calculation of the liquid core length of the molten steel in the continuous casting round billet includes: obtaining the composition of the steel type and the cross-sectional size of the continuous casting round billet; obtaining the preset cooling intensity, the preset degree of superheat of the molten steel and the preset casting speed; according to The composition of the steel type, the section size of the continuous casting round billet, the preset cooling intensity, the preset degree of superheat of molten steel and the preset casting speed are used to calculate the liquid core length of the molten ste...

Embodiment 2

[0049] A steel (GCr15SiMn) composition: [C]: 1.01%, [Si]: 0.60%, [Mn]: 1.15%, [Cr]: 1.52%, [Ni]: 0.04%, [Mo]: 0.02%, the rest Cu, Ca, Al, Ti, Fe and impurities P, S, As, Pb, Sn, etc.

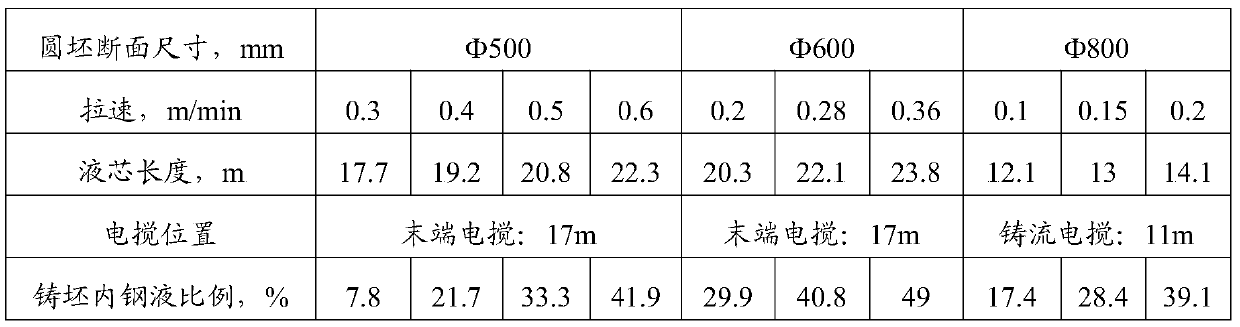

[0050] Table 1 Length of internal liquid core of GCr15SiMn steel slab (superheat degree: 25℃)

[0051]

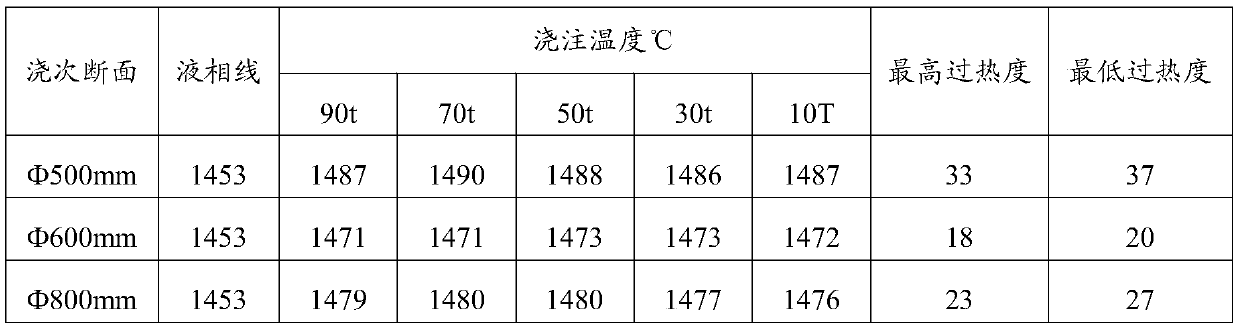

[0052] According to the progress of the project, the bearing steel GCr15SiMn smelting Ф500mm, Ф600mm, and Ф800mm will be poured once respectively.

[0053] Measure the temperature before the ladle is placed on the continuous casting rotary stand; the ladle is covered with a long nozzle and protected by argon gas, and the pouring is started; when the molten steel level of the tundish rises to 350mm, the pouring of each stream of the tundish is started step by step, and the pouring is started according to the regulations Start and start speed up; when the ladle is pouring 1 / 5, the tundish starts to measure the temperature, and the temperature measurement interval of the continuous pouring f...

Embodiment 3

[0064] B steel (special steel HF-1) composition: [C]: 1.04%, [Si]: 0.80%, [Mn]: 1.75%, [Cr]: 0.52%, [Ni]: 0.45%, [Mo]: 0.22%, the rest is Cu, Ca, Al, Ti, Fe and impurity P, S, H, O, N gas, etc.

[0065] Table 4 Length of internal liquid core of special steel HF-1 slab (superheat degree: 25°C)

[0066]

[0067] According to the progress of the project, the special steel HF-1 smelting will be carried out one time for Ф600mm and one time for Ф900mm respectively, and the casting speed of each time is tentatively set at 0.30m / min and 0.10m / min.

[0068] Measure the temperature before the ladle is placed on the continuous casting rotary stand; the ladle is covered with a long nozzle and protected by argon gas, and the pouring is started; when the molten steel level of the tundish rises to 350mm, the pouring of each stream of the tundish is started step by step, and the pouring is started according to the regulations Start and start speed up; when the ladle is poured 1 / 5, the tun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com