Method for producing liquid core microcapsule by electrostatic spraying

An electrostatic spray and microcapsule technology, applied in the field of microcapsule technology and polymer materials, can solve the problems of high price of reagent polylysine, poor biocompatibility, low capsule membrane strength, etc., and achieve low price and capsule formation. The effect of good performance and easy-to-obtain wall materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

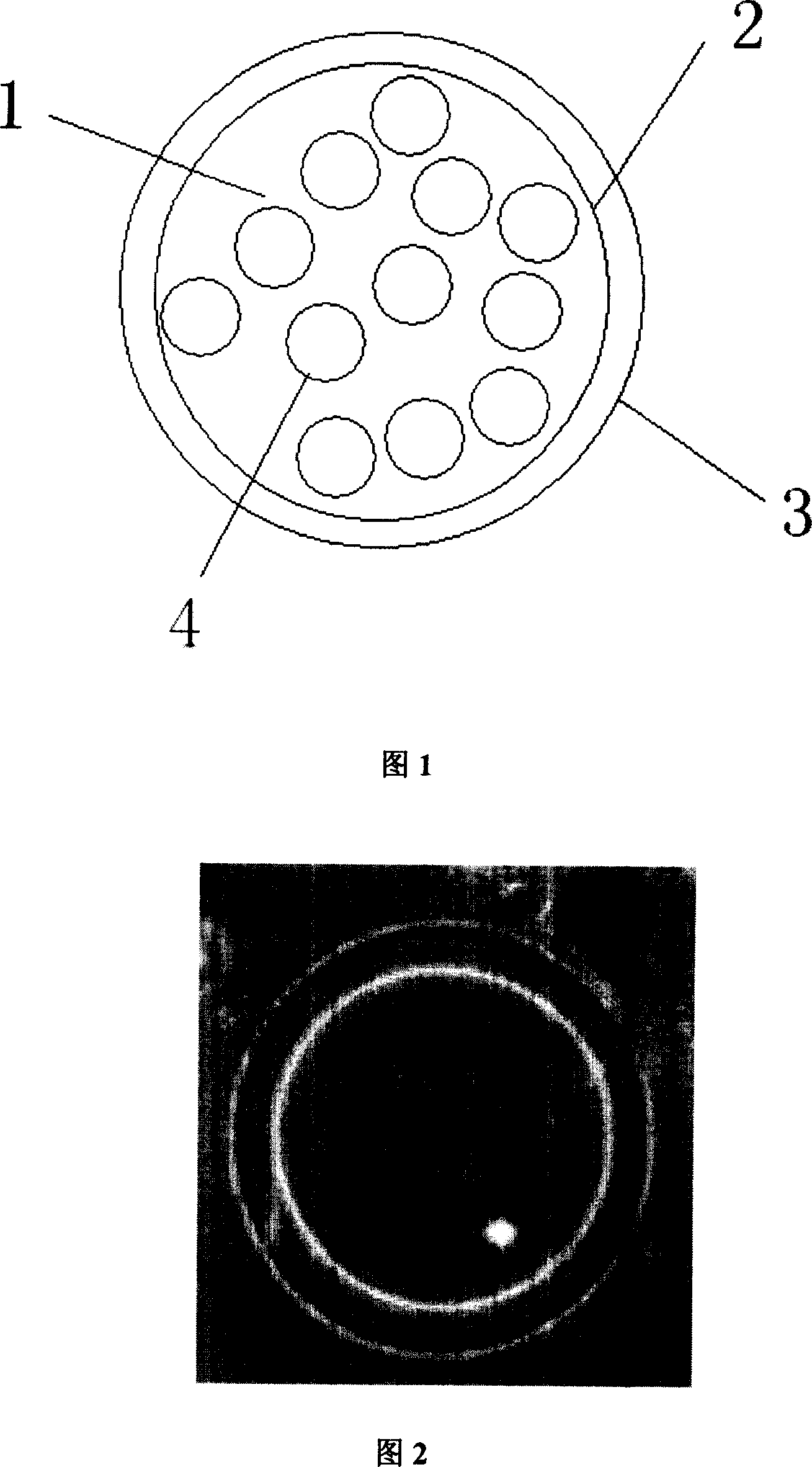

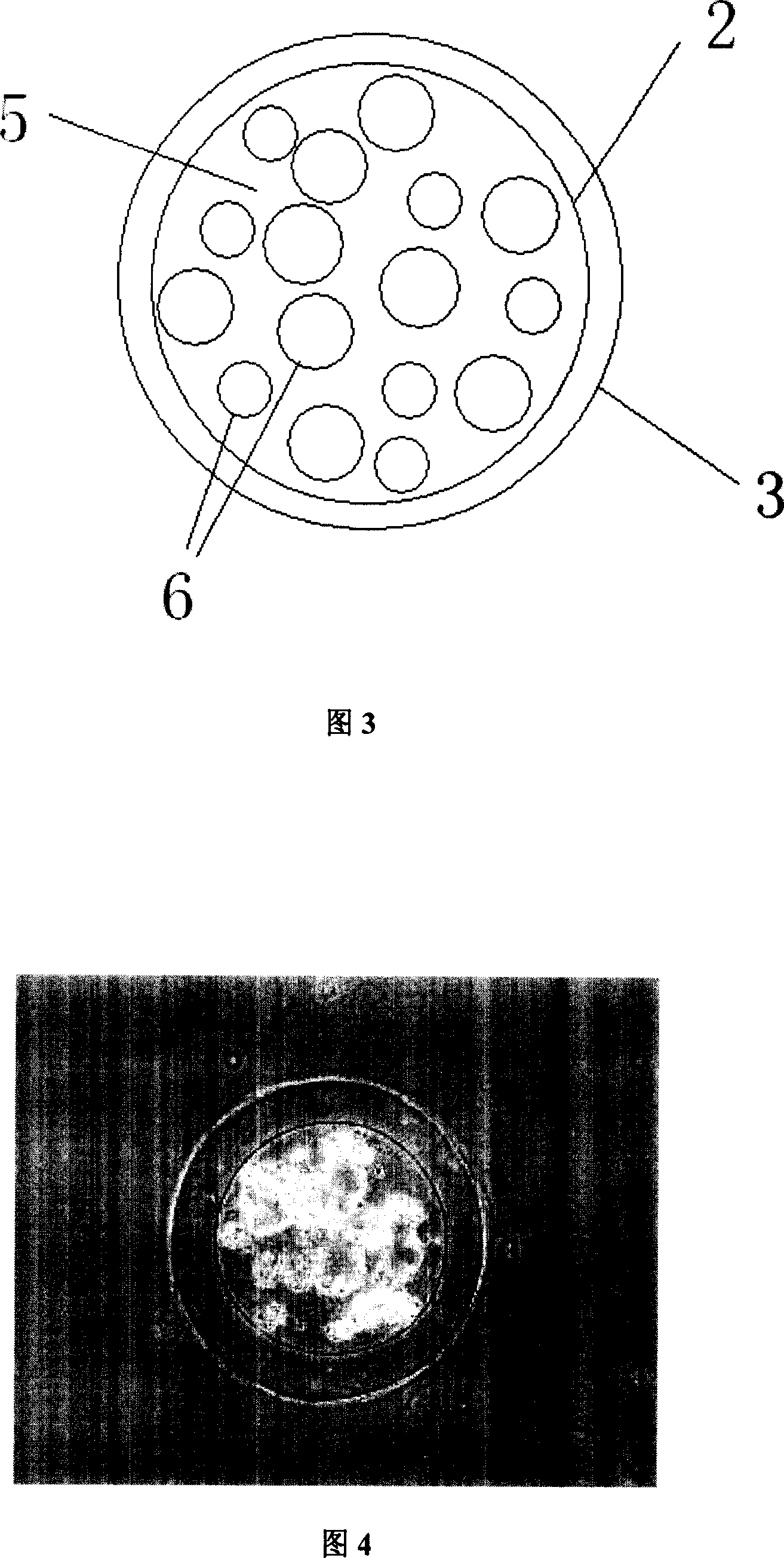

Embodiment 1

[0026] The tortoise shell powder is made into a water decoction in advance and filtered through a mesh screen; 2% calcium chloride solution is mixed with high-viscosity carboxymethyl cellulose sodium, and then mixed with the tortoise shell water decoction, and the sprayer uses a syringe and a flat needle without burrs , through a microcapsule forming device in a high-voltage electrostatic field, spray it into a sodium alginate solution with a concentration of 0.6% that is constantly stirred; the capsuled tortoise shell slow-release microcapsules are filtered and rinsed 2-3 times with distilled water, and placed in 1% Continue to solidify in the calcium chloride solution for 10 minutes, then filter out the microcapsules, and the tortoise shell water decoction is wrapped in a slow-release membrane. Rinse 2-3 times with distilled water before storing. The obtained tortoiseshell microcapsules have a particle size of about 0.12mm and a film thickness of about 0.14mm.

Embodiment 2

[0028] The tortoise shell powder is pre-made into a water decoction and filtered through a mesh screen; 2.5% calcium chloride solution is mixed with high-viscosity carboxymethyl cellulose sodium, and then mixed with the tortoise shell water decoction, and the sprayer uses a syringe and a flat needle without burrs , through a microcapsule forming device in a high-voltage electrostatic field, spray it into a sodium alginate solution with a concentration of 0.75% that is constantly stirred; the capsuled tortoise shell slow-release microcapsules are filtered and rinsed 2-3 times with distilled water, and placed in 1.2% The calcium chloride solution is solidified for 10 minutes, and then the microcapsules are filtered out, and the tortoise shell water decoction is wrapped in a slow-release membrane. Rinse 2-3 times with distilled water before storing. The obtained tortoiseshell microcapsules have a particle size of about 0.97mm and a film thickness of about 0.07mm.

Embodiment 3

[0030] The tortoise shell powder is pre-made into a water decoction and filtered through a mesh screen; 3% calcium chloride solution is mixed with high-viscosity carboxymethyl cellulose sodium, and then mixed with the tortoise shell water decoction, and the sprayer uses a syringe and a flat needle without burrs , through a microcapsule forming device in a high-voltage electrostatic field, spray it into a continuously stirred sodium alginate solution with a concentration of 1%. The calcium chloride solution is solidified for 10 minutes, and then the microcapsules are filtered out, and the tortoise shell water decoction is wrapped in a slow-release membrane. Rinse 2-3 times with distilled water before storing. The obtained tortoiseshell microcapsules have a particle size of about 0.85mm and a film thickness of about 0.09mm.

[0031] The prepared tortoise shell sustained-release preparation (microcapsule) has uniform particle size, good encapsulation performance, simple process,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com