Continuous casting billet secondary cooling dynamic control system

A secondary cooling and dynamic control technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of determination dependence of process parameters, lack of in-depth involvement of complexity, poor scalability and portability, etc., to achieve The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

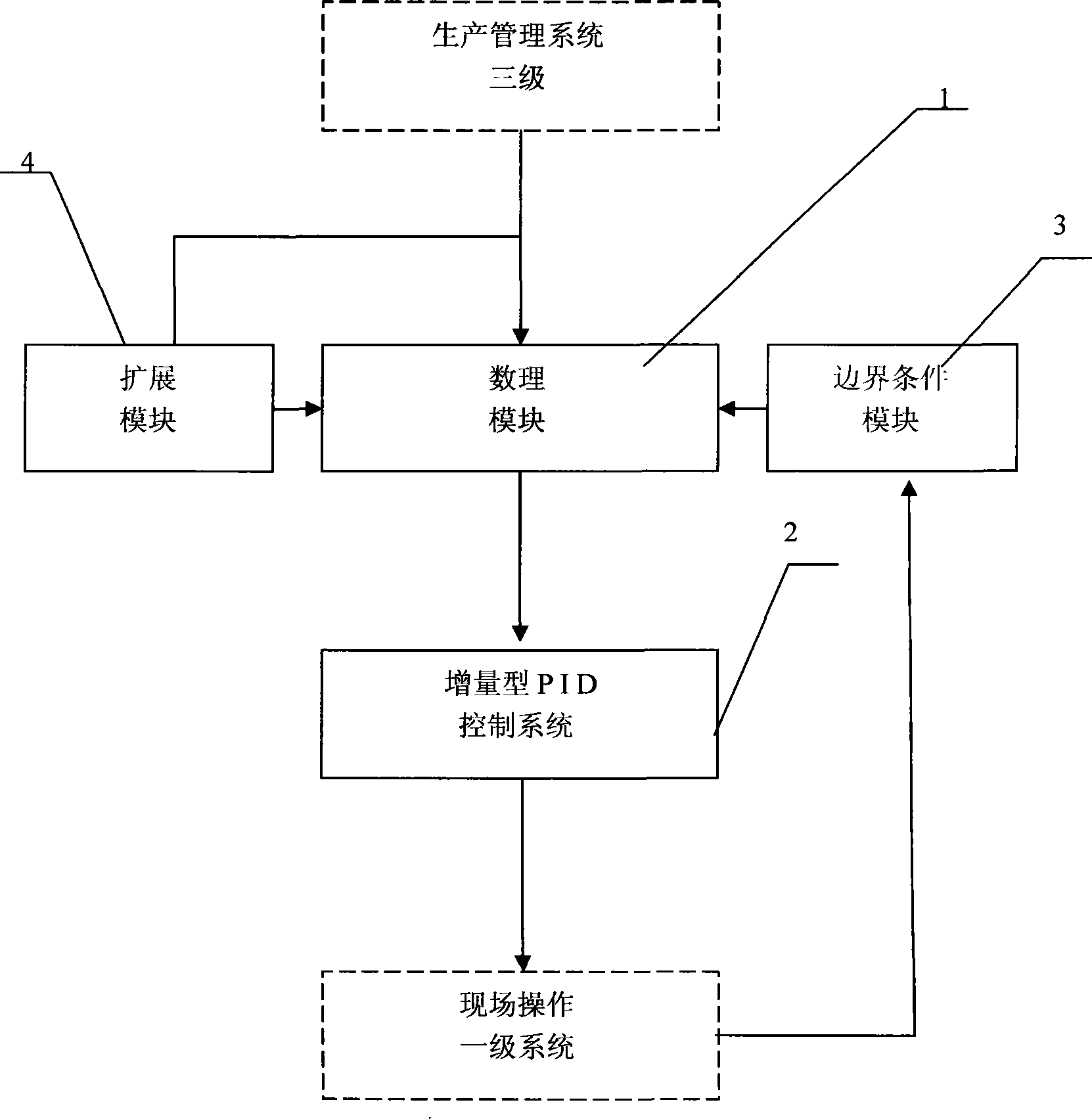

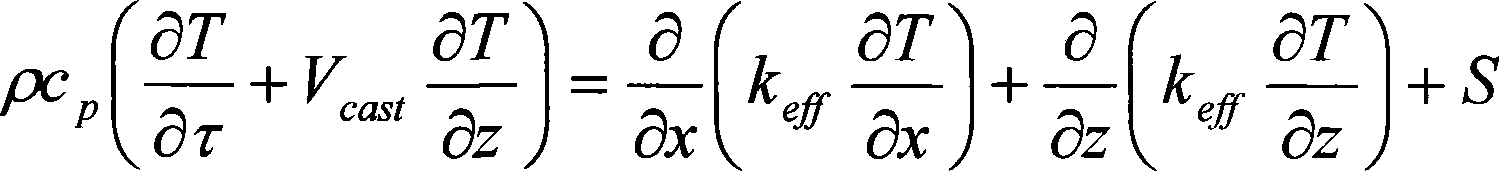

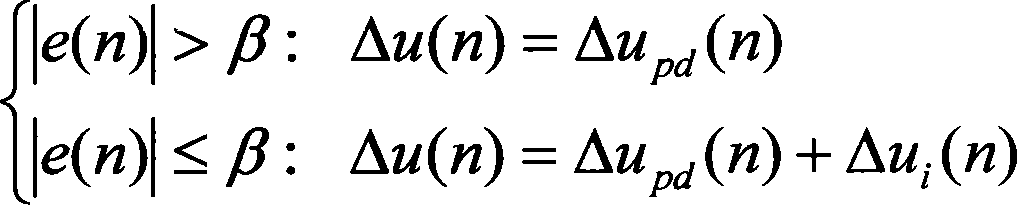

[0022] As shown in the figure, the present invention is connected between the first-level system and the third-level system, which is called the second-level system. The first-level system is based on on-site operation, and the third-level system is based on production management. Plan is main content, and the present invention promptly described secondary system mainly comprises: mathematical module 1, increment type PID control system 2, boundary condition module 3 and expansion module 4, described mathematical module 1, its input end is connected with respectively The three-level system, the boundary condition module 3 is connected to the output of the expansion module 4, and its output is connected to the input of the incremental PID control system 2, and the output of the incremental PID control system 2 is connected to the on-site operation The first-level system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com