Electrolyzing apparatus

A kind of electrolysis equipment and equipment technology, applied in the direction of electrolysis components, electrolysis process, electrolysis coating, etc., can solve the problems of leucorrhea with different densities, and achieve the effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

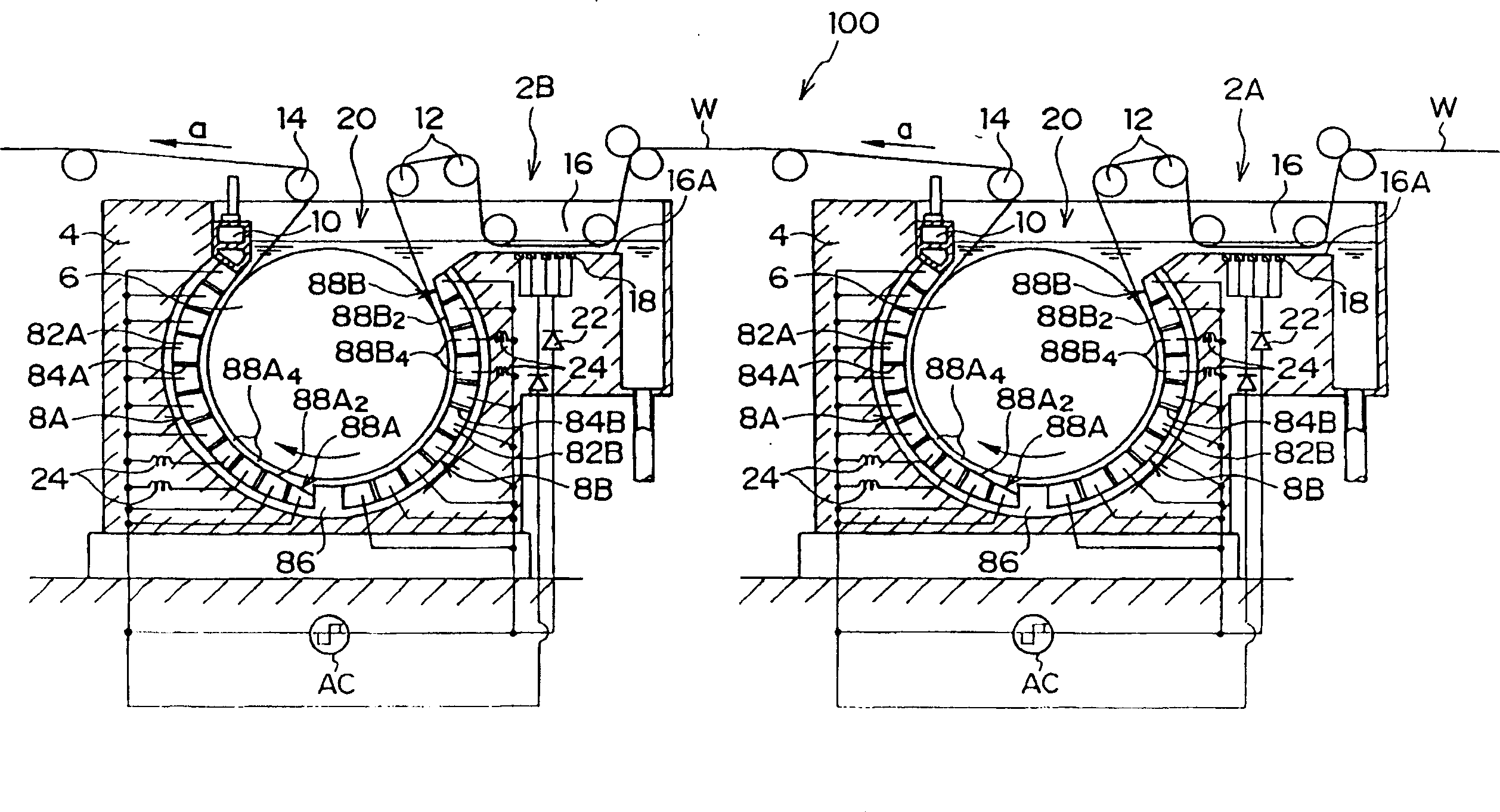

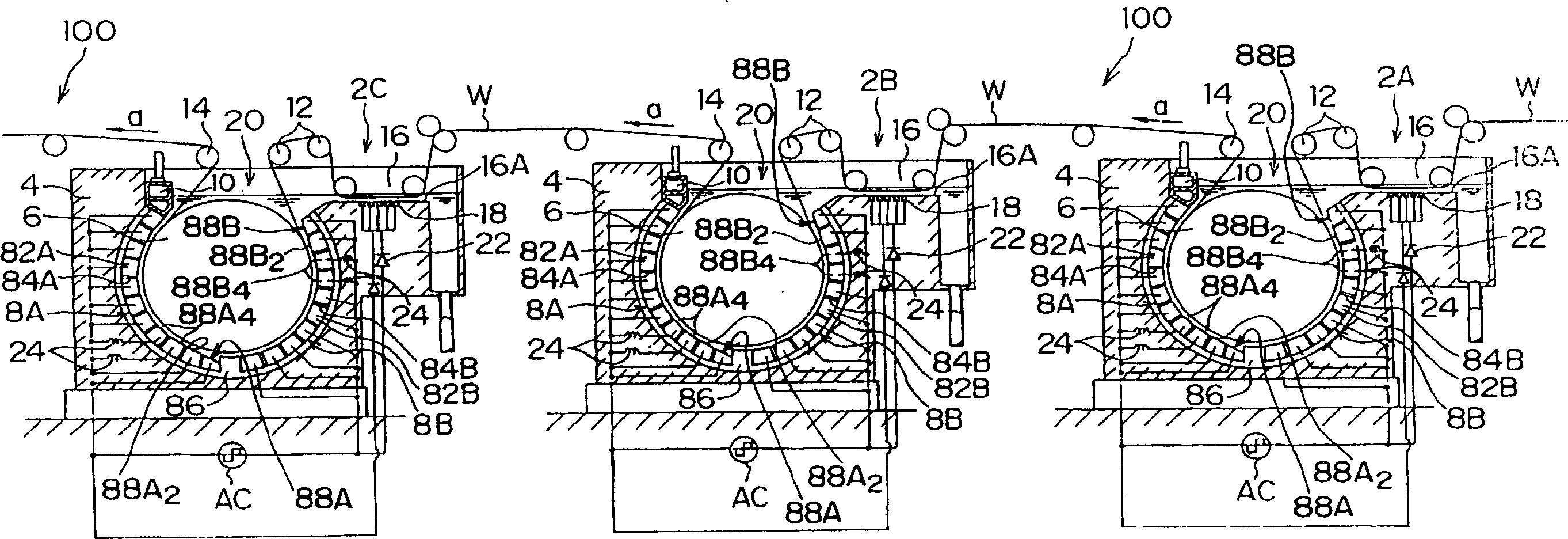

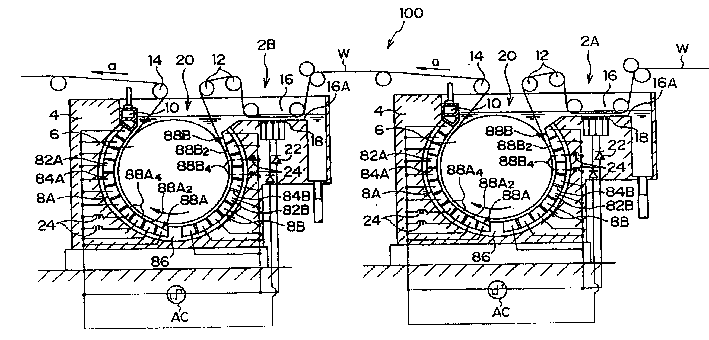

[0059] An apparatus 100 for performing electrolytic roughening treatment according to a first embodiment of the present invention, which has two electrolytic cells, will now be described.

[0060] figure 1 The structure of an apparatus 100 for electrolytic roughening is shown.

[0061] Such as figure 1 As shown in , the apparatus 100 for electrolytic roughening treatment has an electrolytic cell 2A at an upstream position with respect to the conveying direction of the aluminum strip W and an electrolytic cell 2B at a downstream position with respect to the conveying direction.

[0062] Each of the electrolytic tanks 2A and 2B has a main electrolytic tank 4 filled with an acidic electrolytic solution, and a conveying roller 6 provided horizontally in the main electrolytic tank 4 and rotating clockwise around its axis to convey the aluminum strip W.

[0063] Each main electrolytic tank 4 has a substantially cylindrical inner wall, and electrodes 8A and 8B having a semi-cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com