Composite catalytic electrode for producing oxygen by electrolyzing water, and preparation method and application thereof

A catalytic electrode and oxygen recombination technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of restricting large-scale application, high cost and scarcity of precious metals, and achieve abundant raw materials, avoid loading process, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

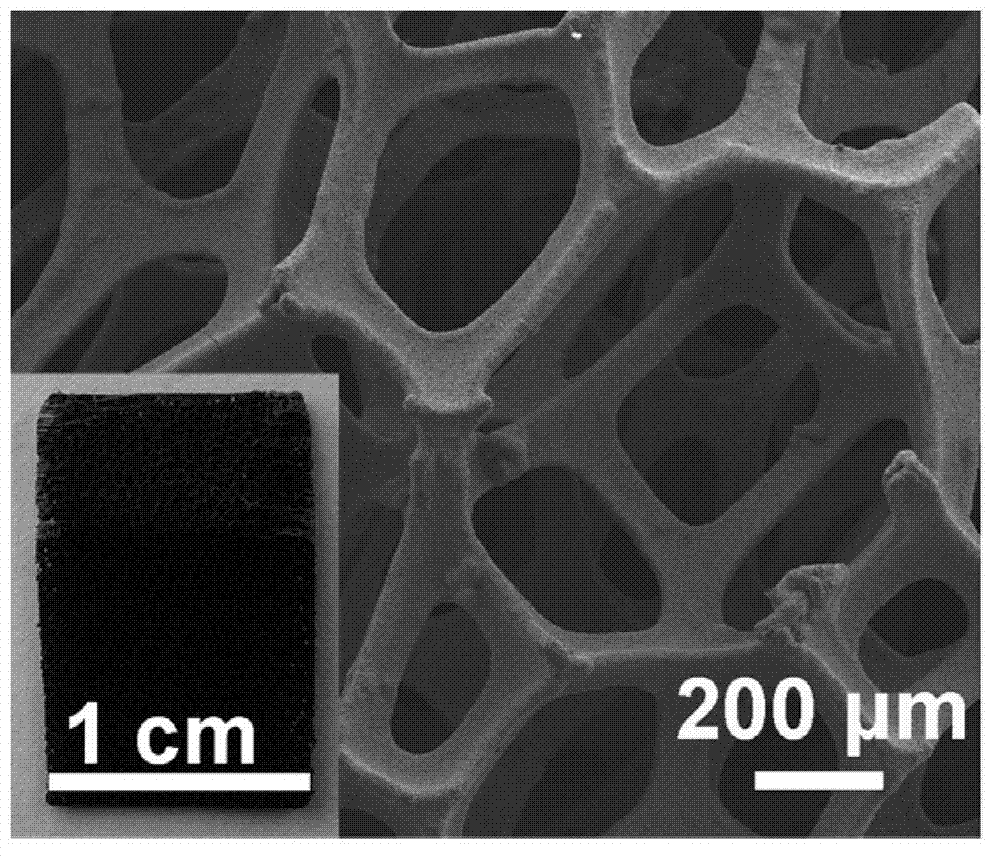

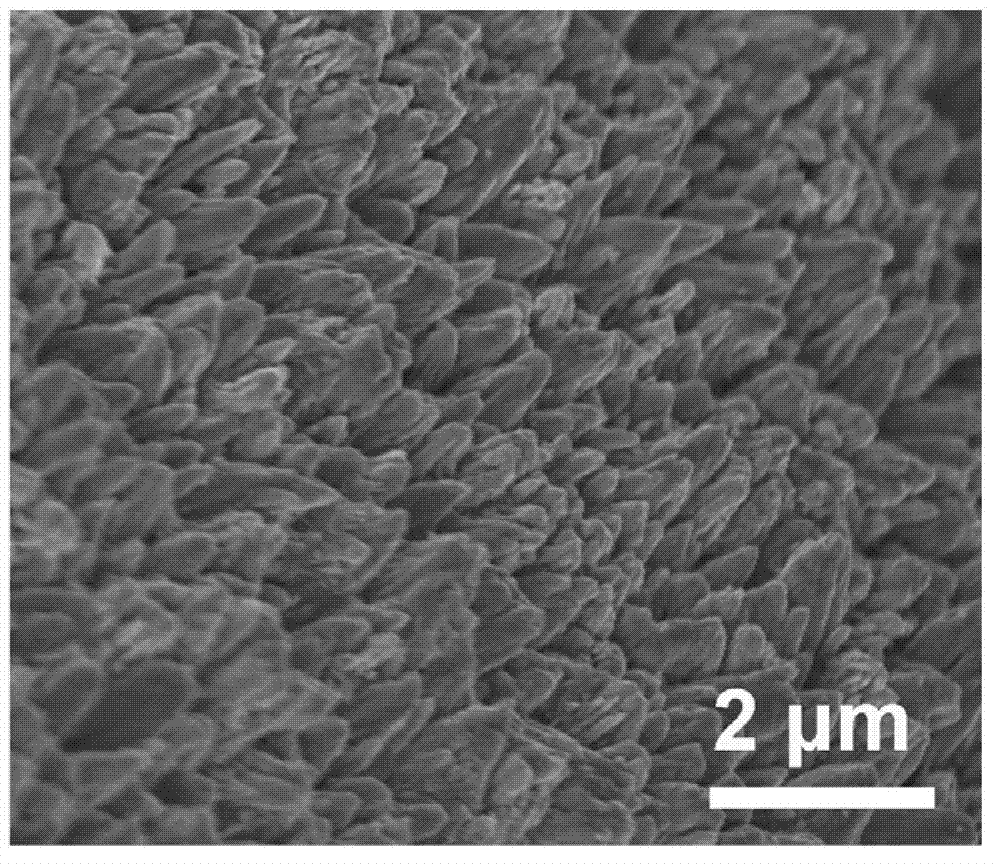

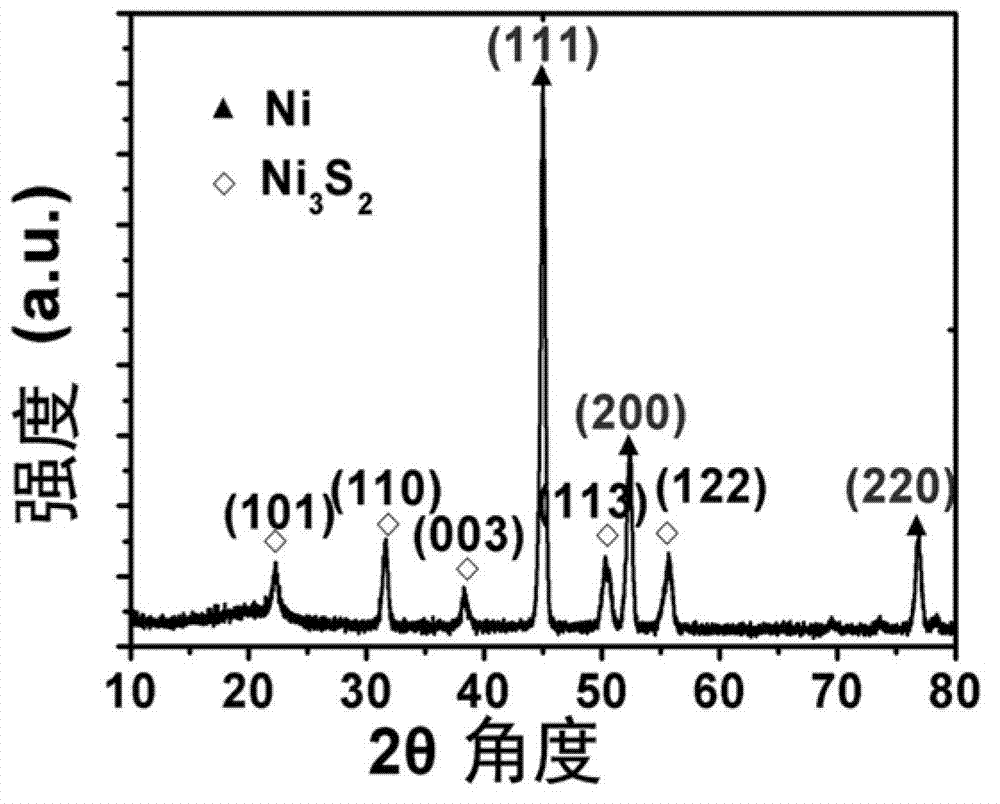

Embodiment 1

[0035] The nickel foam with a geometric area of 2 square centimeters was ultrasonically cleaned with deionized water, alcohol and acetone for 30 minutes in order to remove surface organic matter. Nickel foam was wrapped with tetrafluoroethylene tape, with an exposed area of 1 cm2, and immersed in 20 mL of an aqueous solution in which 320 mg of thioacetamide was dissolved. Then, the kettle was sealed and subjected to hydrothermal treatment at 180° C. for 4 hours to obtain nanorod nickel sulfide nanostructures with a length of 1 micron. After the hydrothermal kettle was cooled, the sample was rinsed with running water and dried at 60°C for 12 hours. The Ni(OH) 2 / Ni 3 S 2 / Ni's topography pictures are as follows Picture 1-1 and Figure 1-2 As shown, the crystal structure XRD result obtained by X-ray diffraction is as follows Figure 1-3 . Through the sulfidation reaction on the nickel surface, nickel sulfide (Ni 3 S 2 ) Nanorods grow vertically on nickel foam, with a ...

Embodiment 2

[0039] A flat nickel plate with a geometric area of 2 square centimeters was ultrasonically cleaned with deionized water, alcohol and acetone for 30 minutes in order to remove surface organic matter. Dip into 50 ml of an aqueous solution in which 500 mg of thioacetamide is dissolved. Then seal the pot, 180 ° C hydrothermal treatment for 4 hours to obtain Ni(OH) 2 / Ni 3 S 2 / Ni composite electrode. After the hydrothermal kettle was cooled, the sample was rinsed with flowing water and dried at 70°C for 12 hours to obtain Ni(OH) 2 / Ni 3 S 2 / Ni composite catalytic electrode. Nickel sulfide (Ni 3 S 2 ) Nanorods grow vertically on flat nickel, nickel hydroxide (Ni(OH) 2 ) thin layer covered with nickel sulfide (Ni 3 S 2 ) nanorod surface, the three constitute the Ni(OH) 2 / Ni 3 S 2 / Ni composite catalytic electrode. Nickel sulfide (Ni 3 S 2 ) Microscopic transmission electron microscope pictures of nanorods such as Figure 6 , Nickel sulfide rod-like morphology,...

Embodiment 3

[0042] A flat nickel plate with a geometric area of 2 square centimeters was ultrasonically cleaned with deionized water, alcohol and acetone for 30 minutes in order to remove surface organic matter. Nickel foam wrapped with tetrafluoroethylene tape, the exposed area is 1cm 2 , dipped into 20 ml of an aqueous solution in which 120 mg of thioacetamide was dissolved. Then seal the pot and heat treatment at 160°C for 2 hours to obtain Ni(OH) 2 / Ni 3 S 2 / Ni composite electrode. After the hydrothermal kettle was cooled, the samples were rinsed with running water and dried at 80°C for 16 hours. Obtained Ni(OH) 2 / Ni 3 S 2 / Ni composite electrode morphology as Figure 7 .

[0043] Electrochemical testing process is as described in embodiment 1, and test result is as follows: Ni(OH) 2 / Ni 3 S 2 / Ni composite electrode, at a current density of 10mA / cm 2 (0.1M KOH, 25°C), the overpotential is only 195mV, and the oxygen production efficiency is 1.4mmol / g h. After 1000 cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com