Slag system for ingot stripping and electroslag remelting of nickel-based alloy plate blank

A nickel-based alloy and electroslag remelting technology, which is applied in the field of special alloy refining, can solve the problems of steel leakage, slag leakage, and difficulty in obtaining surface quality, so as to reduce energy consumption, reduce production costs, and save forging and blanking. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The production of nickel-based alloy UNS N06625 electroslag slab by adopting the slag system of the present invention comprises the following steps.

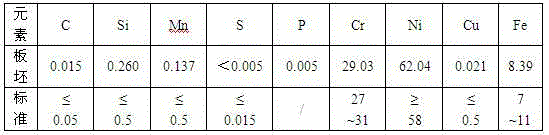

[0027] The first step is to use intermediate frequency furnace + AOD furnace to smelt consumable electrodes. The thickness, width and length of the electrodes are 270 mm, 1320 mm and 2800 mm respectively. The chemical composition of the electrodes meets the standard requirements, as shown in Table 1;

[0028] Table 1 Electrode chemical composition (wt%)

[0029]

[0030] The second step is to polish the surface of the consumable electrode;

[0031] The third step is to prepare slag. The slag system adopts CaF 2 、Al 2 o 3 , CaO, SiO 2 Quaternary slag system, the weight percentage of each component is 63%, 15%, 13%, 9% respectively, and the slag amount is 300kg. Put the slag into the electric furnace separately, control the temperature at 800°C, and bake for 7 hours;

[0032] The fourth step, the baked slag system...

Embodiment 2

[0041] The production of nickel-based alloy UNS N06600 electroslag slab by adopting the slag system of the present invention includes the following steps.

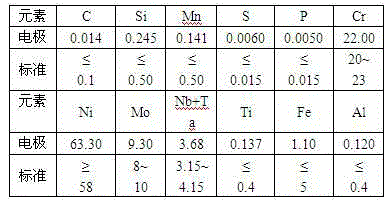

[0042] The first step is to use intermediate frequency furnace + AOD furnace to smelt consumable electrodes. The thickness, width and length of the electrodes are 270 mm, 1320 mm and 2800 mm respectively. The chemical composition of the electrodes meets the standard requirements, as shown in Table 3;

[0043] Table 3 Electrode Chemical Composition (wt%)

[0044]

[0045] The second step is to polish the surface of the consumable electrode;

[0046] The third step is to prepare slag. The slag system adopts CaF 2 、Al 2 o 3 , CaO, SiO 2 Quaternary slag system, the weight percentage of each component is 64%, 16%, 14%, 6% respectively, and the slag amount is 300kg. Put the slag into the electric furnace separately, control the temperature at 800°C, and bake for 7 hours;

[0047] The fourth step, the baked slag system ...

Embodiment 3

[0056] The slag system of the present invention is used to produce nickel-based alloy UNS N06690 electroslag slabs, comprising the following steps.

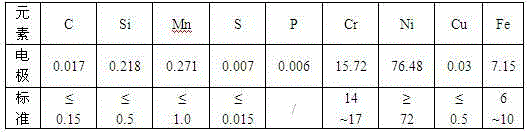

[0057] The first step is to use intermediate frequency furnace + AOD furnace to smelt consumable electrodes. The thickness, width and length of the electrodes are 270 mm, 1320 mm and 2800 mm respectively. The chemical composition and weight percentage of the electrodes meet the requirements of Table 5:

[0058] Table 5 Electrode Chemical Composition (wt%)

[0059]

[0060] The second step is to polish the surface of the consumable electrode;

[0061] The third step is to prepare slag. The slag system adopts CaF 2 、Al 2 o 3 , CaO, SiO 2 Quaternary slag system, the weight percentage of each component is 65%, 15%, 13%, 7% respectively, the amount of slag is 300kg, the slag is placed separately in the electric furnace, the temperature is controlled at 800°C, and baked for 7 hours;

[0062] The fourth step, the baked slag sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com