Ink jet image forming apparatus, and method for compensating defective nozzle thereof

一种成像装置、喷嘴的技术,应用在打印装置、矩阵打印机的视觉表示、印刷等方向,能够解决影响打印质量等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

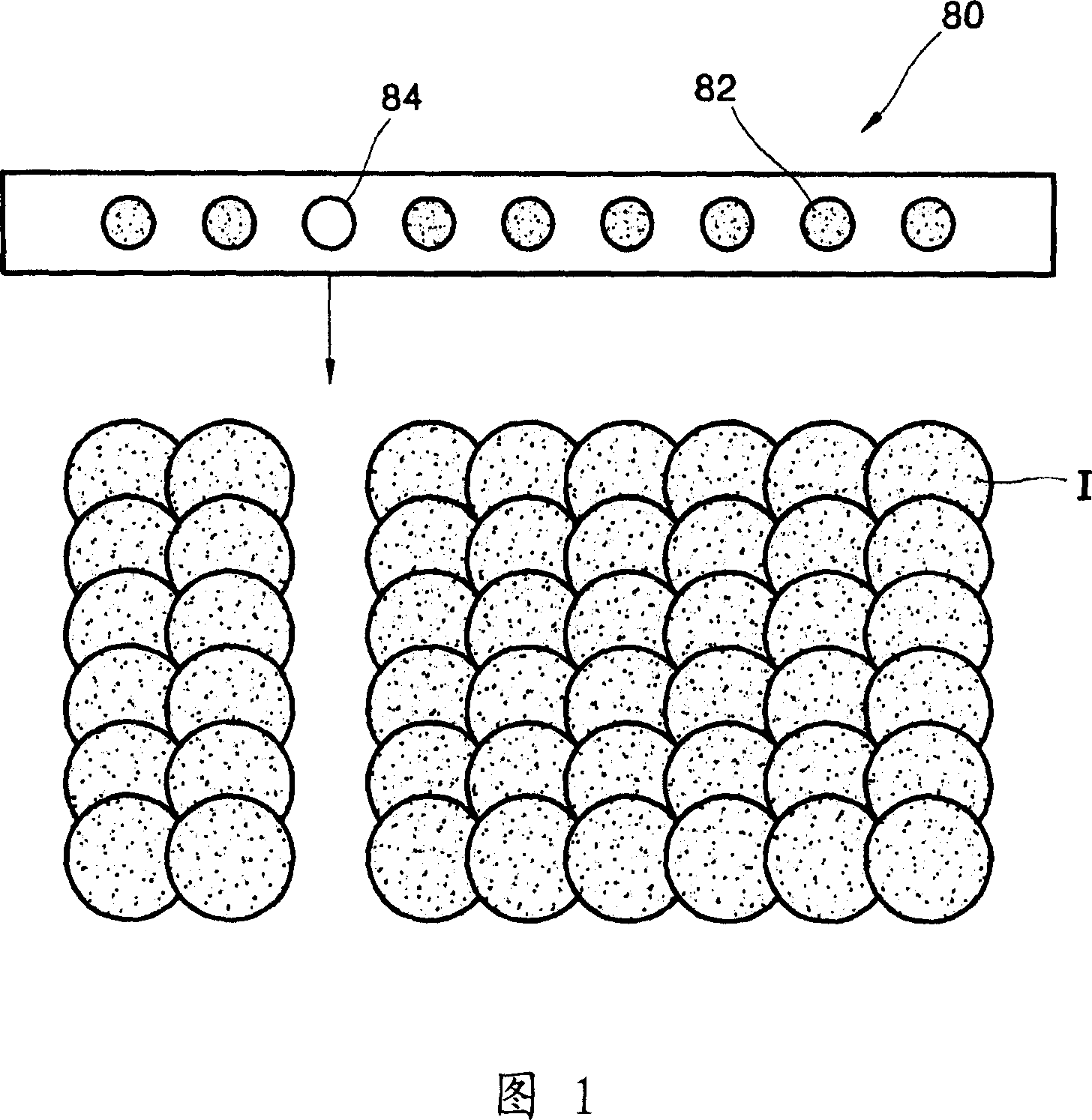

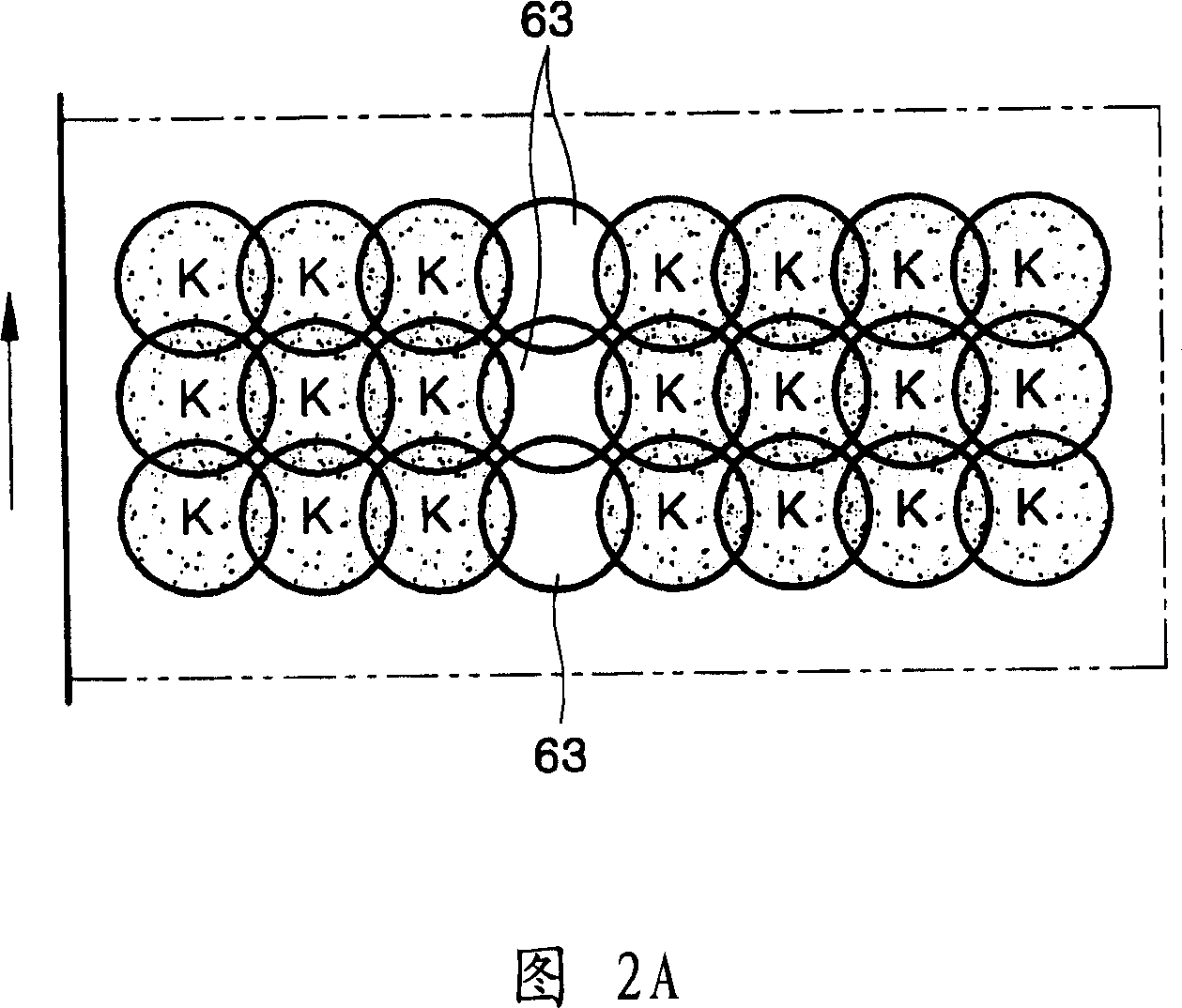

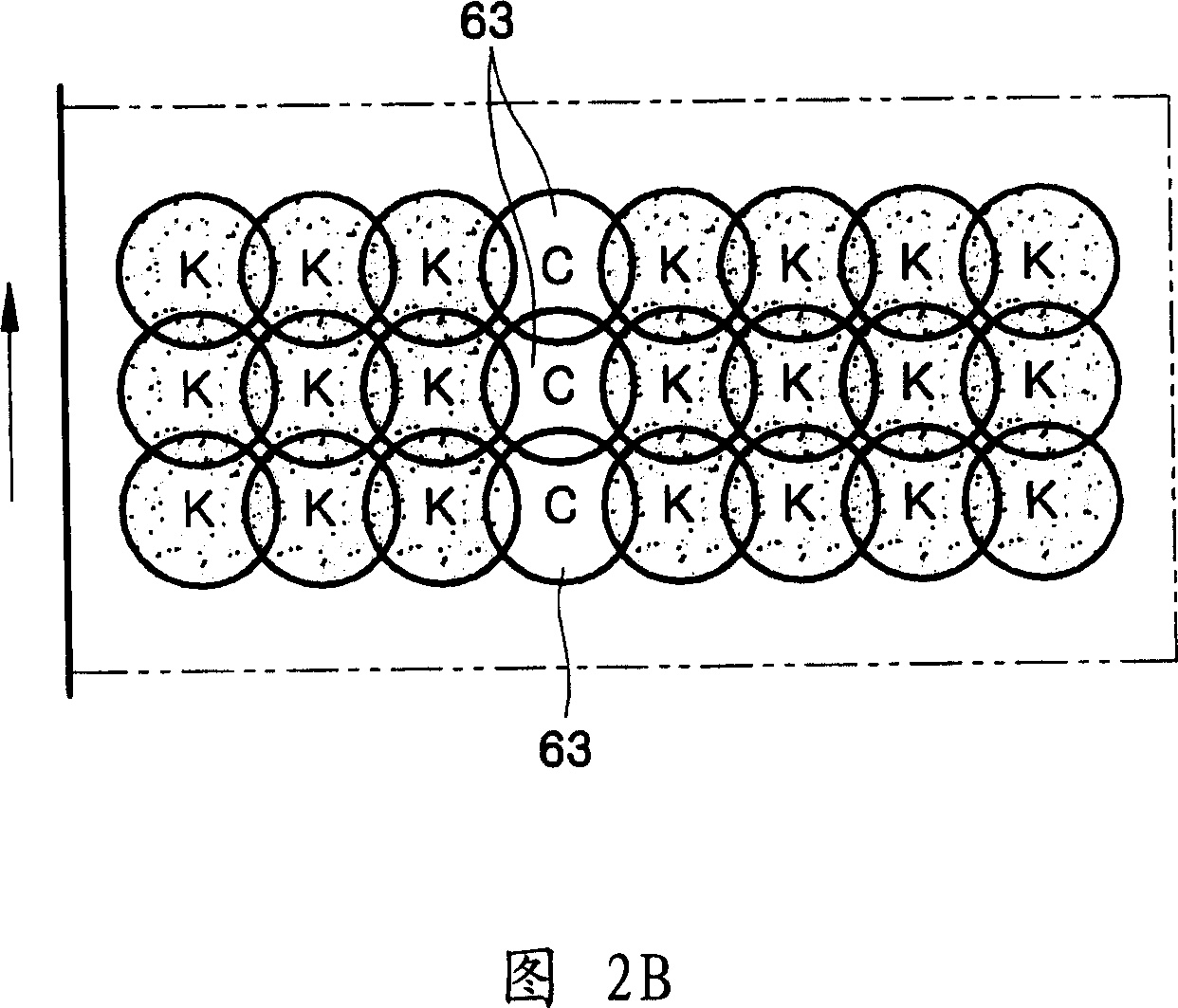

Image

Examples

Embodiment Construction

[0045] Reference will now be made in detail to embodiments of the present invention, which are shown in the accompanying drawings, wherein like numerals represent like elements throughout. The embodiments are described below in order to explain the present invention by referring to the figures.

[0046] FIG. 3 is a schematic view showing an inkjet image forming apparatus 125 according to an embodiment of the present invention, and FIG. 4 is a view showing a driving mechanism of a print head.

[0047] Referring to FIGS. 3 and 4 , the inkjet imaging device 125 includes a paper feed cassette 120, a print head unit 105, a supporting member 114 facing the print head unit 105, a faulty nozzle detection unit 132 that detects the presence and position of a faulty nozzle of the nozzle unit 112. , a printing medium conveying unit for conveying the printing medium P along the first direction (x direction), and a loading unit 140 for loading the printed printing medium P sent out. In add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com