Metal sheet high-speed tensile test device driven by electromagnetic force

A technology of high-speed stretching and metal sheeting, which is applied in measuring devices, using stable tension/pressure testing materials, instruments, etc., can solve problems such as difficulty in implementation and expensive equipment, and achieve low experimental cost, accurate establishment, and stress. - Strain curve accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to enable those skilled in the art to better understand the technical solutions of the present application, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

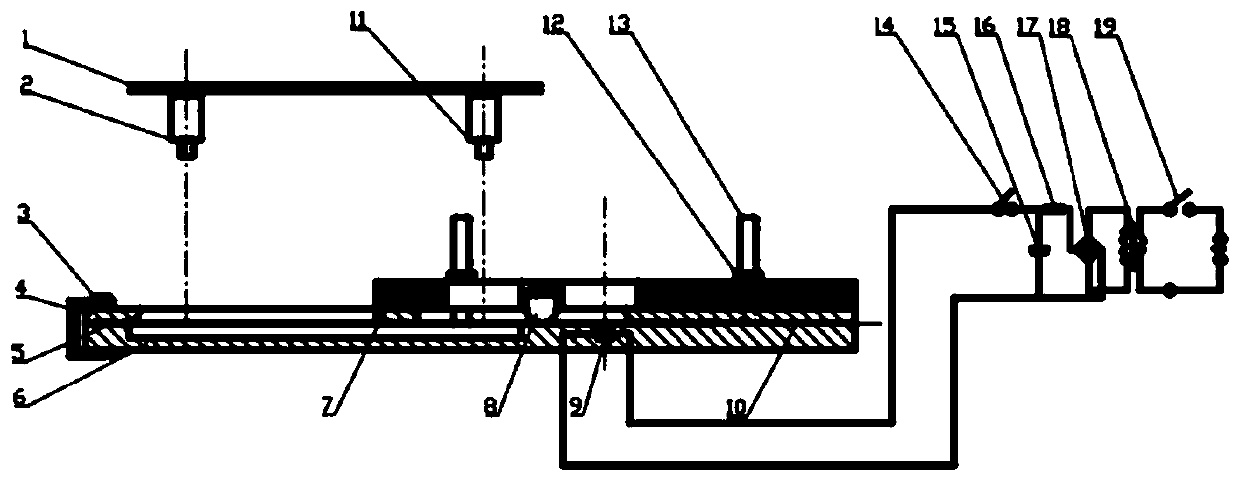

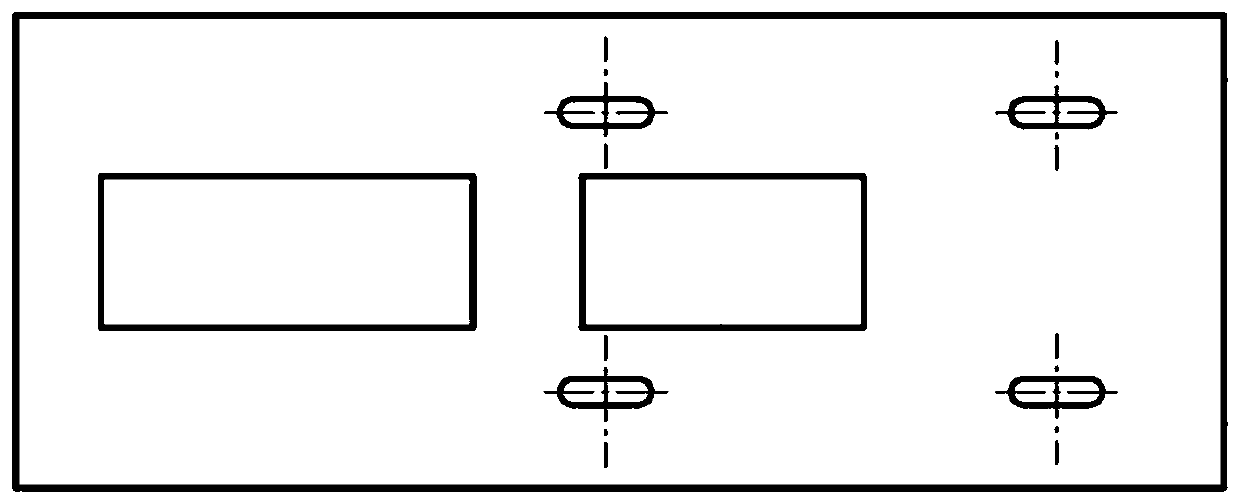

[0048] This embodiment describes a metal sheet high-speed tensile test device driven by electromagnetic force, such as figure 1 As shown, the tensile test device includes: a lifting bracket 1, a stress shooting camera 2, a C-shaped clamp 3, an insulating rigid plate 4, a tensile sample 5, an experimental platform 6, a steel plate pressing block 7, an insulating insert 8, Insulation gasket 10, strain shooting camera 11, fastening nut 12, support stud 13 and power supply unit.

[0049] The stress photographing camera 2 and the strain photographing camera 11 are respectively fixed at preset positions on the elevating support 1, and the elevating support 1 can carry the stress photographing camera 2 and the strain photographing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com