Method and device for electromagnetically forming metal pipe fitting in radial and axial loading mode

A technology of metal pipe fittings and electromagnetic forming, which is applied in the field of metal forming manufacturing, can solve the problem of single loading, achieve the effect of reducing the amount of thinning, improving the forming limit and forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

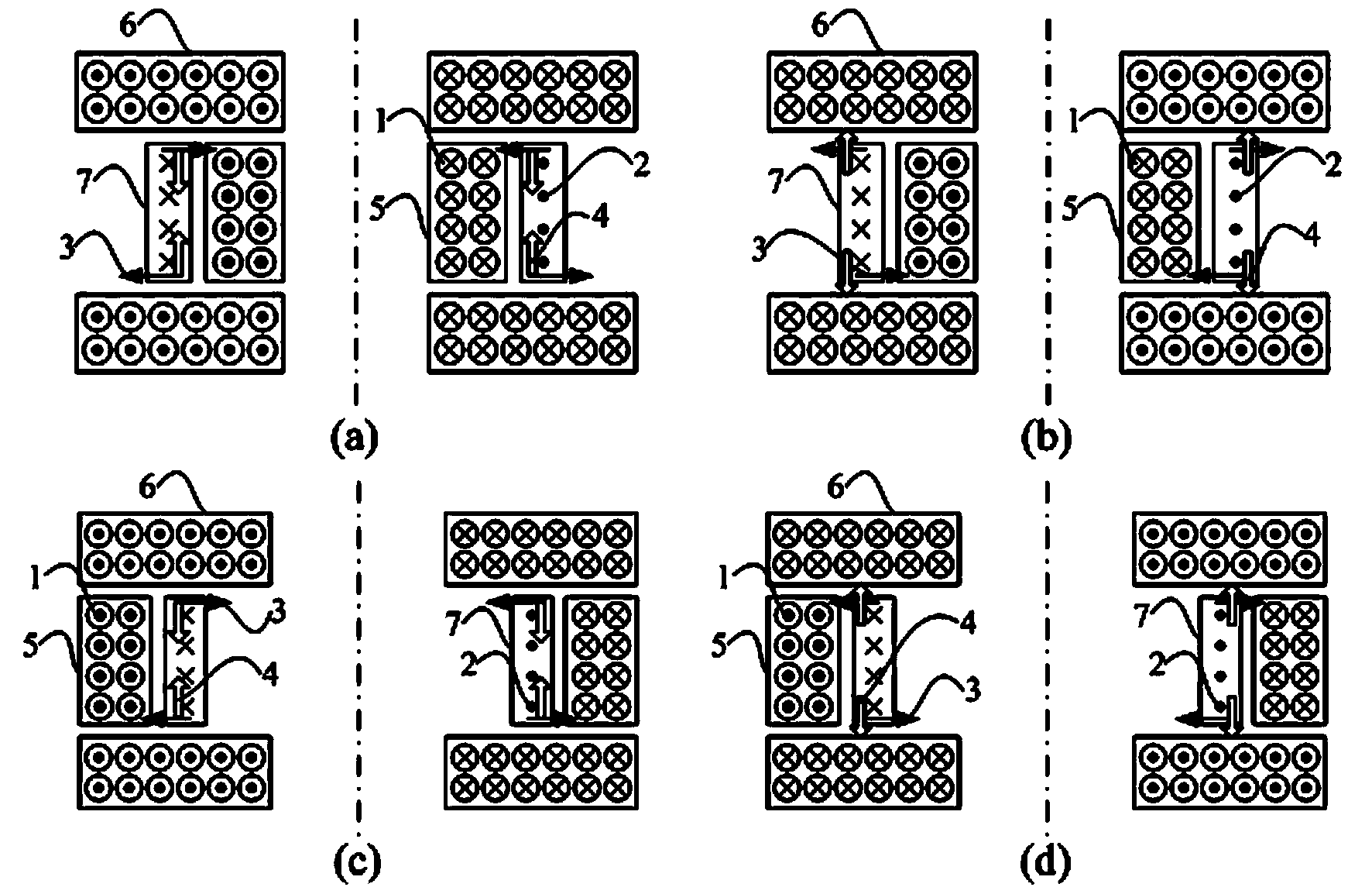

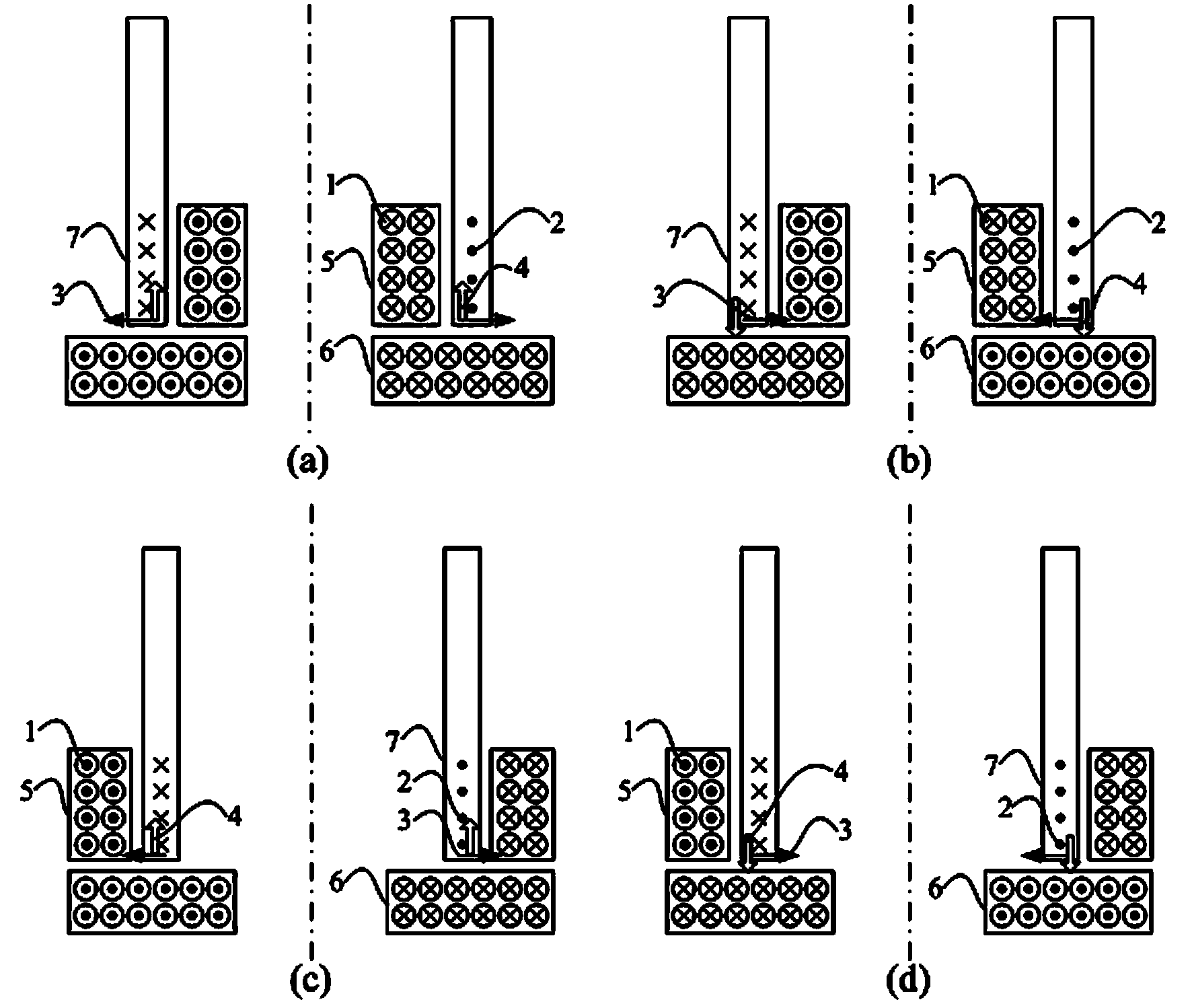

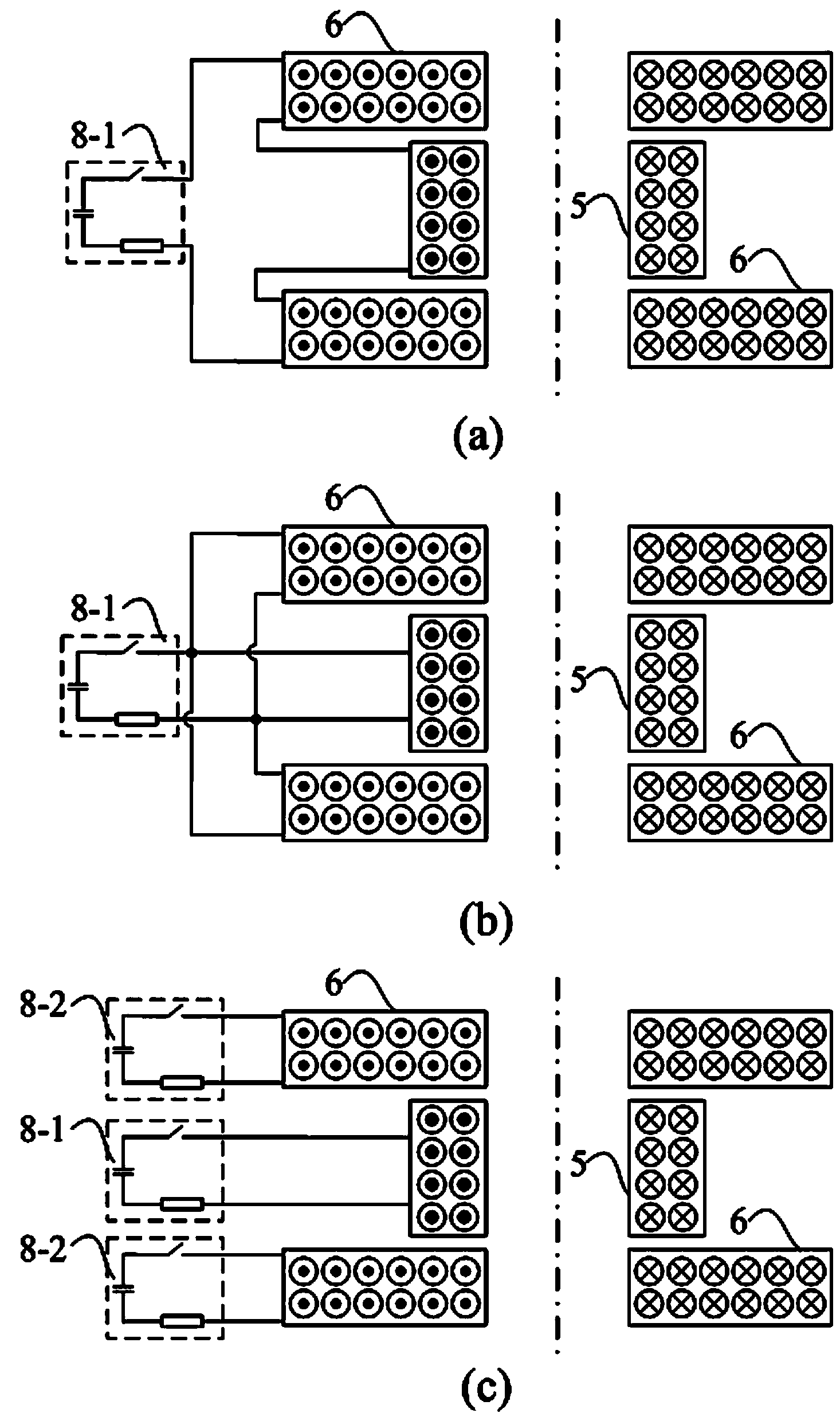

Embodiment 1

[0051] An electromagnetic processing device for metal pipe fittings, including a power supply system, a fixedly installed eddy current coil 5 and two magnetic field coils 6, the eddy current coil 5 and the two magnetic field coils 6 are connected to the power supply system, and the eddy current coil 5 is located between the two magnetic field coils 6 In the middle position, the metal pipe 7 is located outside the eddy current coil 5 and fixed, and the two magnetic field coils 6 are respectively located at the two ends of the metal pipe 7. Turn on the power supply system, the eddy current coil 5 and the magnetic field coil 6 generate a source current 1, the source current 1 generates an induced eddy current 2 in the metal pipe 7, and the metal pipe 7 area generates a radial magnetic field 3 and an axial magnetic field, and the induced eddy current 2 and the The radial magnetic field 3 interacts with the axial magnetic field to generate axial electromagnetic force 4 and radial el...

Embodiment 2

[0054] An electromagnetic processing device for metal pipe fittings, including a power supply system, a combined coil 9, the combined coil 9 is connected to the power supply system, the metal pipe 7 is located outside the combined coil 9 and fixed, the power supply system is turned on, and the combined coil 9 generates a source current 1, a source current 1 The induced eddy current 2 is generated in the metal pipe 7, and the area of the metal pipe 7 generates a radial magnetic field 3 and an axial magnetic field, and the induced eddy current 2 interacts with the radial magnetic field 3 and the axial magnetic field to generate an axial electromagnetic force 4 and a radial electromagnetic force , drive the metal workpiece 7 to deform in the manner of axial compression and radial expansion, and complete the processing of the metal pipe 7 .

Embodiment 3

[0056] When the metal workpiece 7 needs overall bulging processing, it can be used figure 1 (a) Both ends of the workpiece shown in (a) are simultaneously loaded with an axially compressed pipe fitting electromagnetic bulging device or figure 1 (b) The two ends shown in (b) are simultaneously loaded with an axially stretched metal pipe fitting electromagnetic bulging device, and the two ends of the metal workpiece 7 are simultaneously loaded with an axial electromagnetic force to process the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com