Method for solving belt deviation of belt transmission system

A transmission system and belt technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as safety risks, reduce belt service life, increase belt investment, etc., so as to reduce manpower and material resources and speed up production progress. , the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

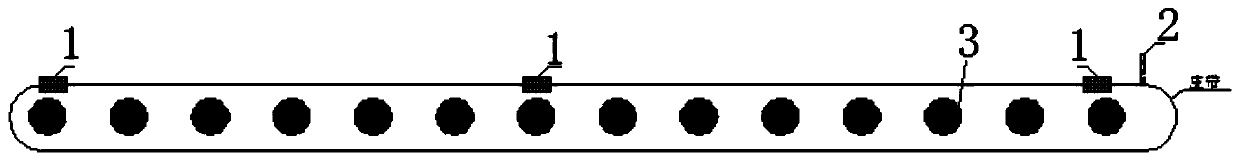

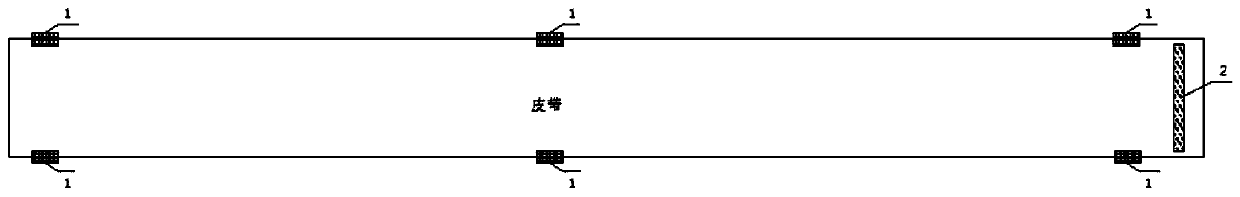

[0025] see Figure 1-3 A method for solving the belt deviation of the belt transmission system shown includes the following steps: making and installing an anti-belt deviation device, making and installing a roller cleaner, and dealing with roller slime;

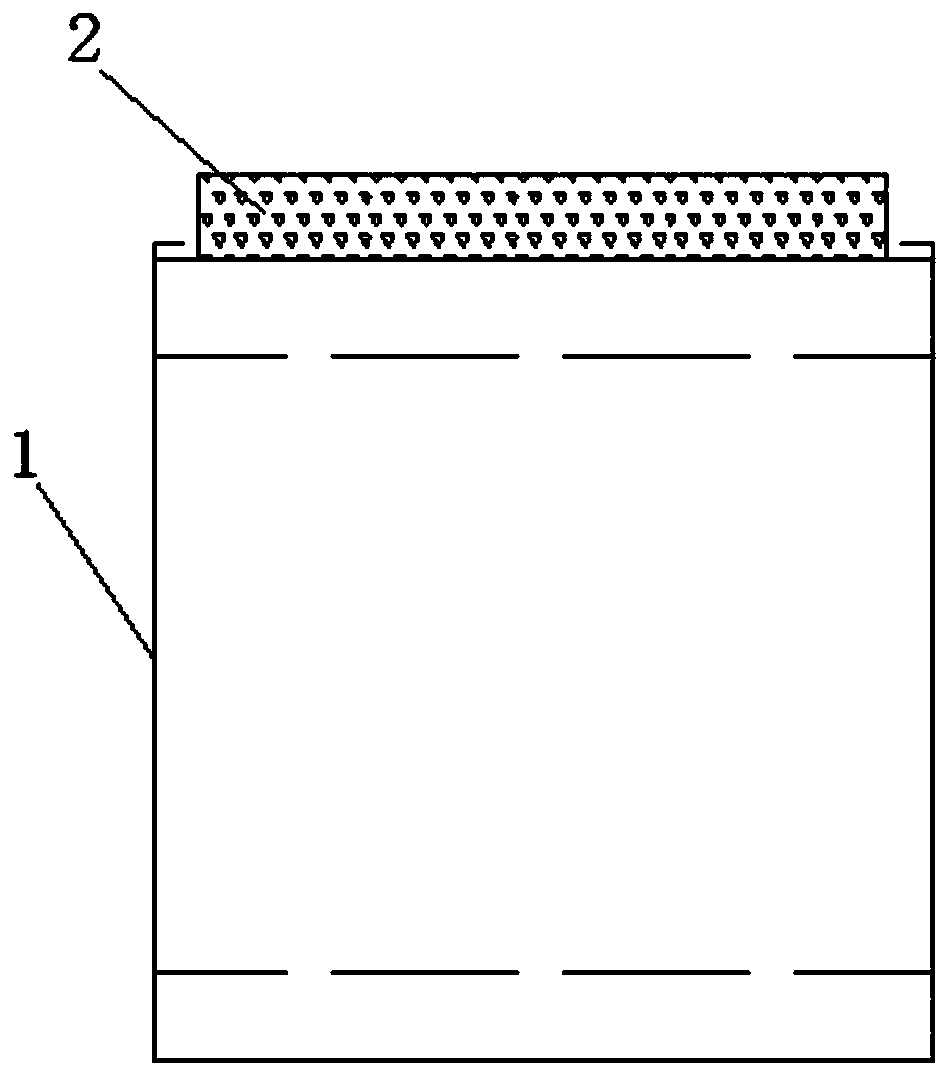

[0026] Make and install anti-belt deviation device 1:

[0027] 4) Select two 30×80 angle steels, cut a 2cm square hole on each angle steel, and prepare to insert the square holes into the left and right shaft ends of the 100×400 roller;

[0028] 5) After the above work is completed, fix the fabricated angle steel on the belt conveyor truss;

[0029] 6) Snap the left and right shaft ends of the 100×400 idler roller into the square holes that have been cut on the angle steel;

[0030] Make install roller cleaner 2:

[0031] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com