Patents

Literature

56results about How to "Small amount of thinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydro-mechanical deep drawing forming method capable of improving surface precision of large-scale thin-wall curved-surface part

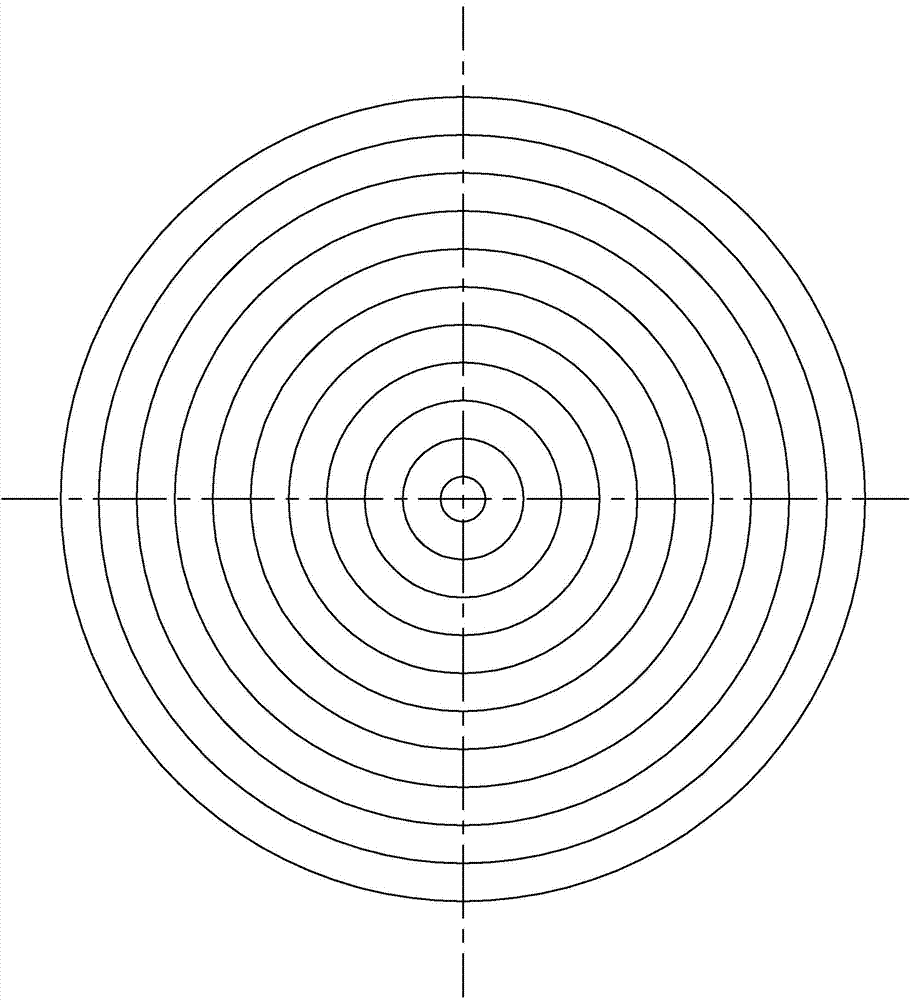

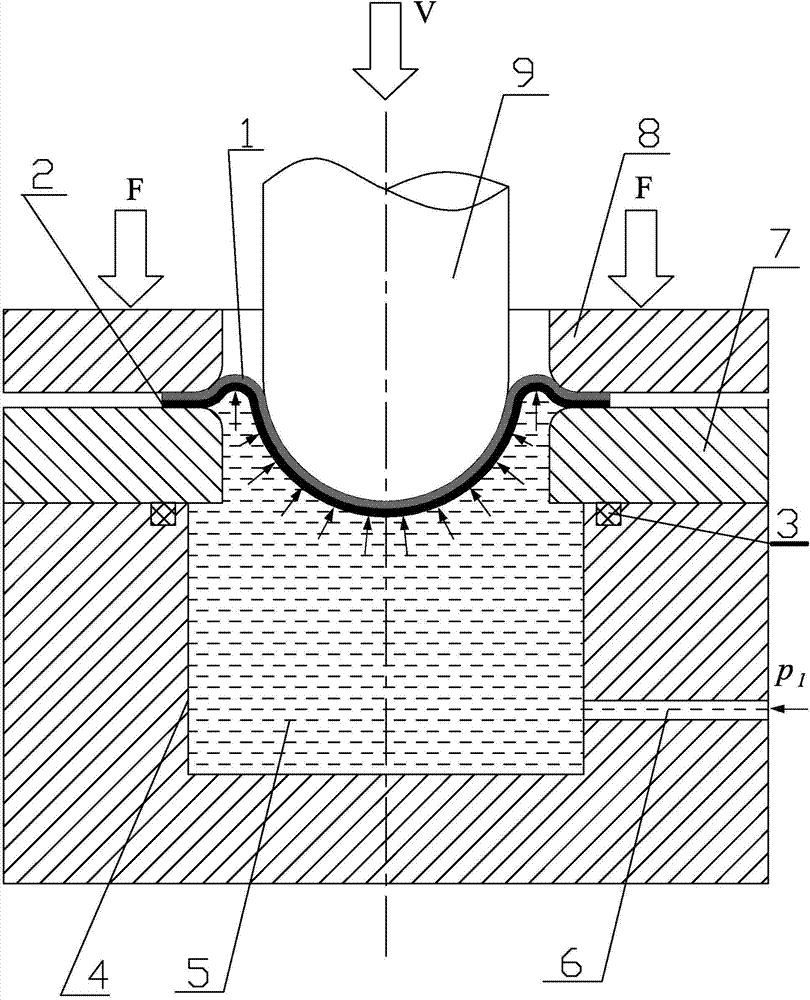

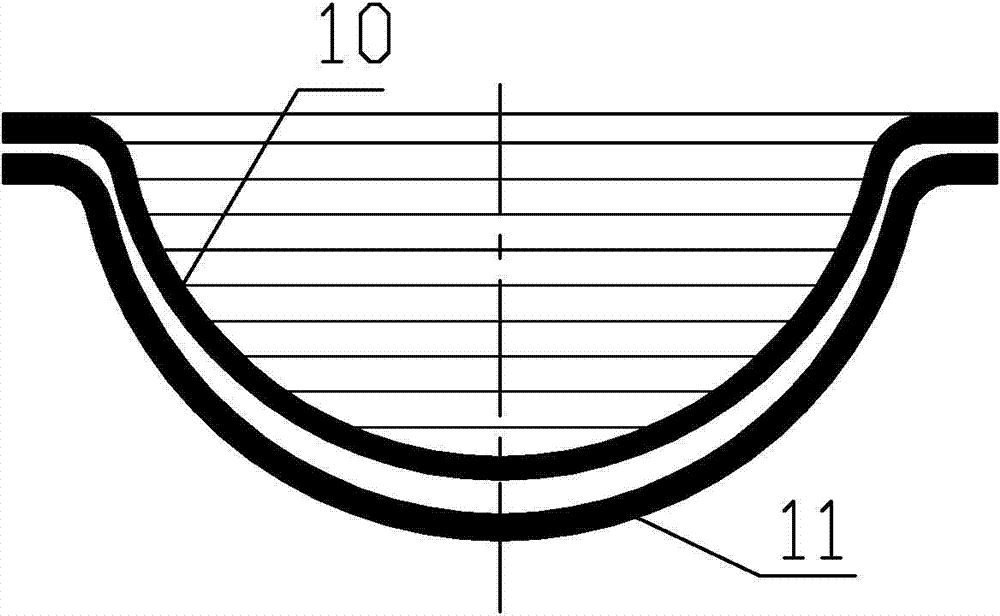

The invention discloses a hydro-mechanical deep drawing forming method capable of improving surface precision of a large-scale thin-wall curved-surface part, and relates to hydro-mechanical deep drawing forming methods. The problems that the curved-surface part is prone to be locally wrinkled and the surface precision is affected in the deep drawing process are solved. Concentric circles with certain distances are carved in the upper surface of an auxiliary forming sheet, the auxiliary forming sheet and a target forming sheet are stacked on a female die, and deep drawing forming is carried out on the auxiliary forming sheet and the target forming sheet. A gap generated by resilience of the auxiliary forming sheet and resilience of the target forming sheet is utilized for separating a deep drawing piece. The diameters and the thicknesses of the concentric circles of the deep drawing piece of the auxiliary forming sheet are measured. Normal inside offsetting is carried out on a molded surface generatrix of an initial deep drawing male die at the corresponding position. Fitting is carried out on an offset point, and the surface generatrix considering deformation and thinning of the auxiliary forming sheet can be obtained. According to the fitted surface generatrix, the initial deep drawing male die is finished, and an ideal deep drawing male die surface is obtained. Deep drawing forming and separation of the auxiliary forming sheet and the target forming sheet are carried out again, and the large-scale thin-wall curved-surface part with improved surface precision can be obtained.

Owner:抚顺三方机械制造有限公司

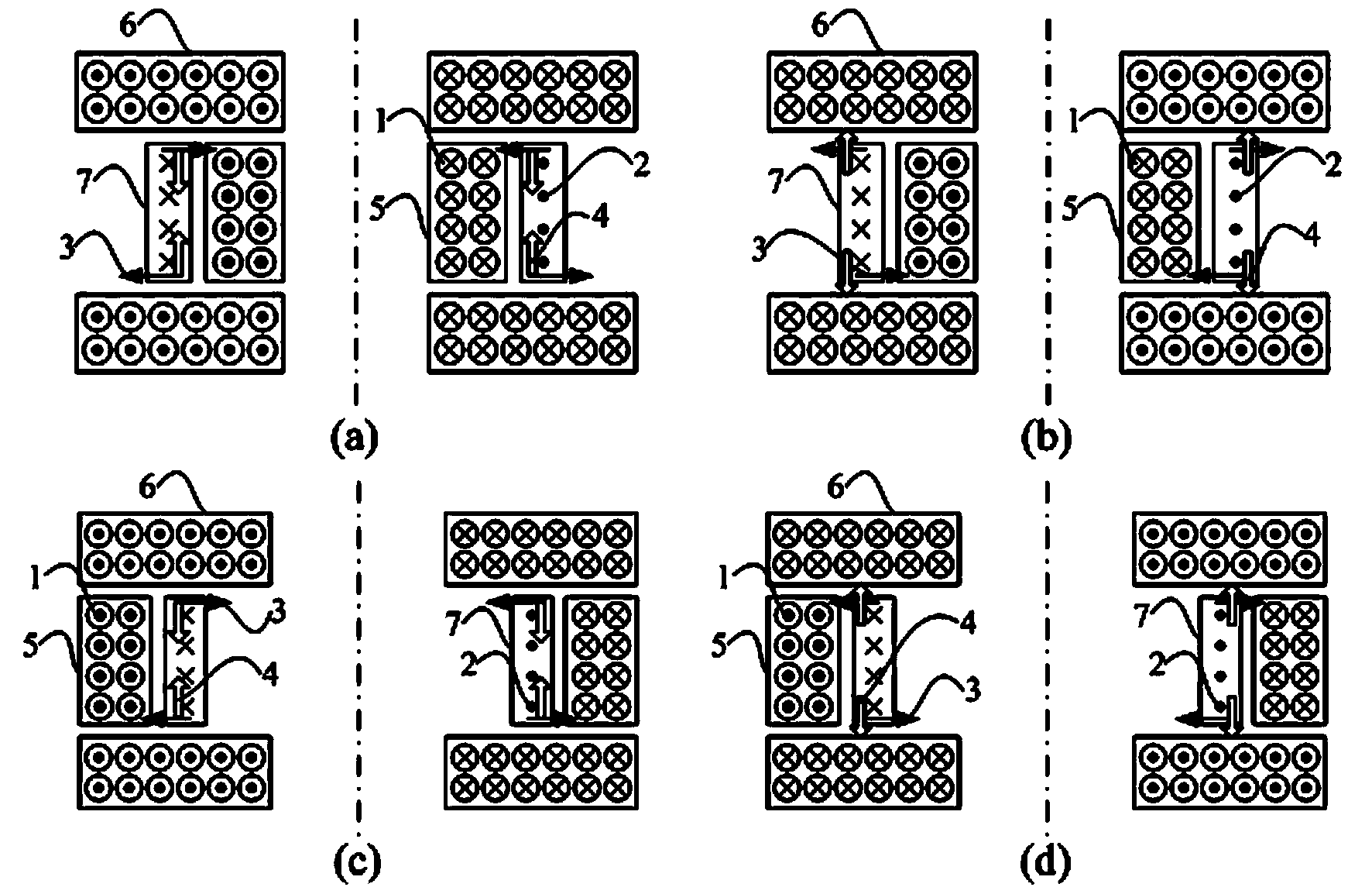

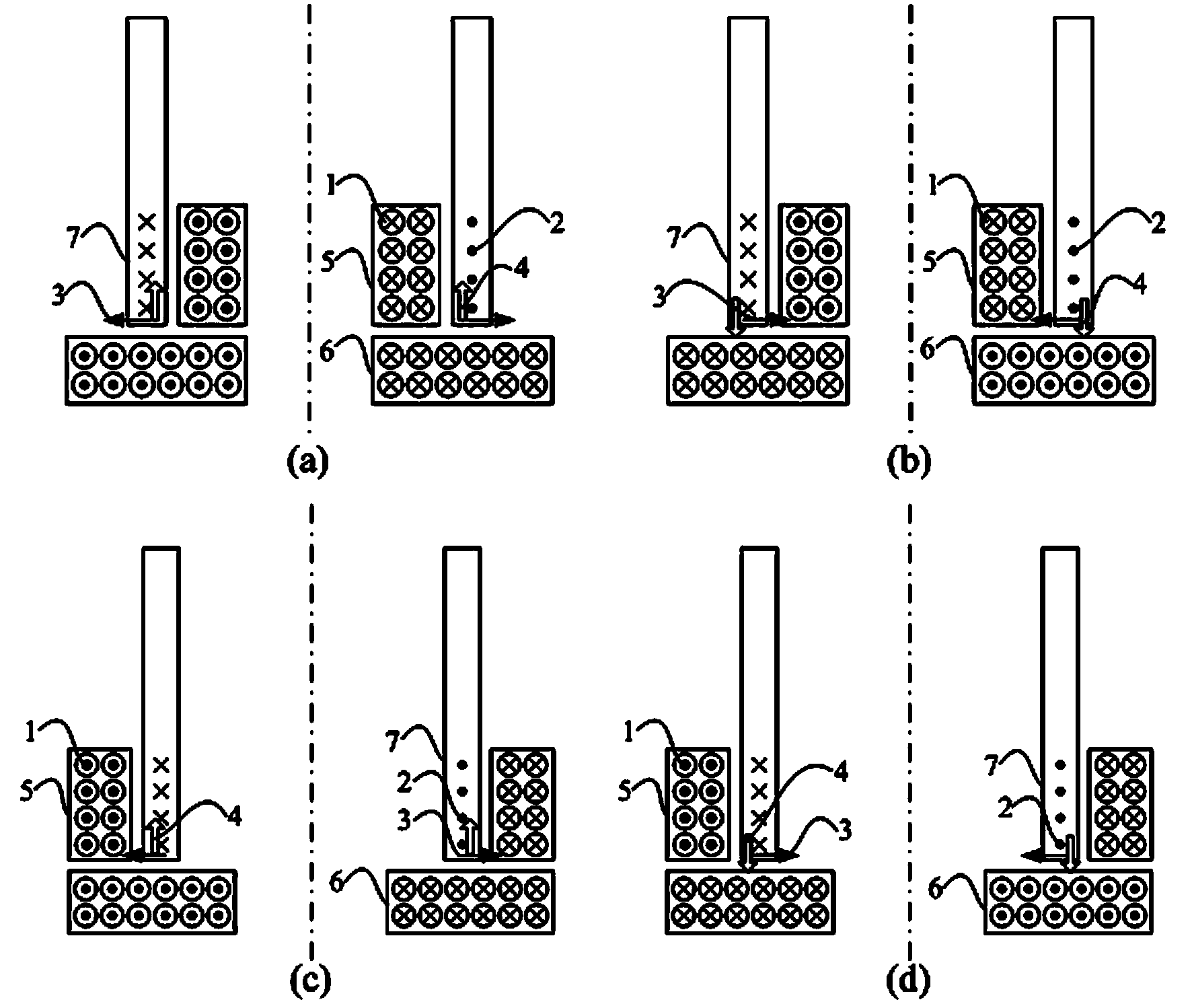

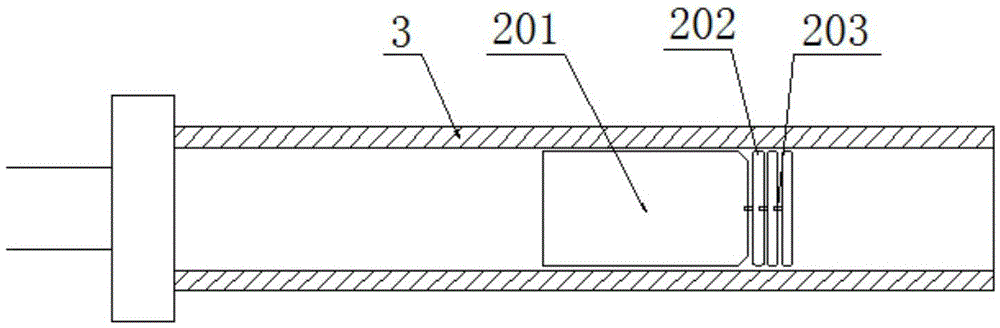

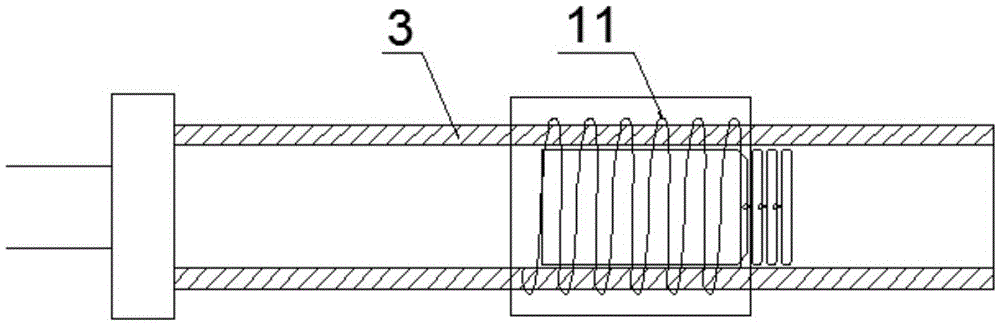

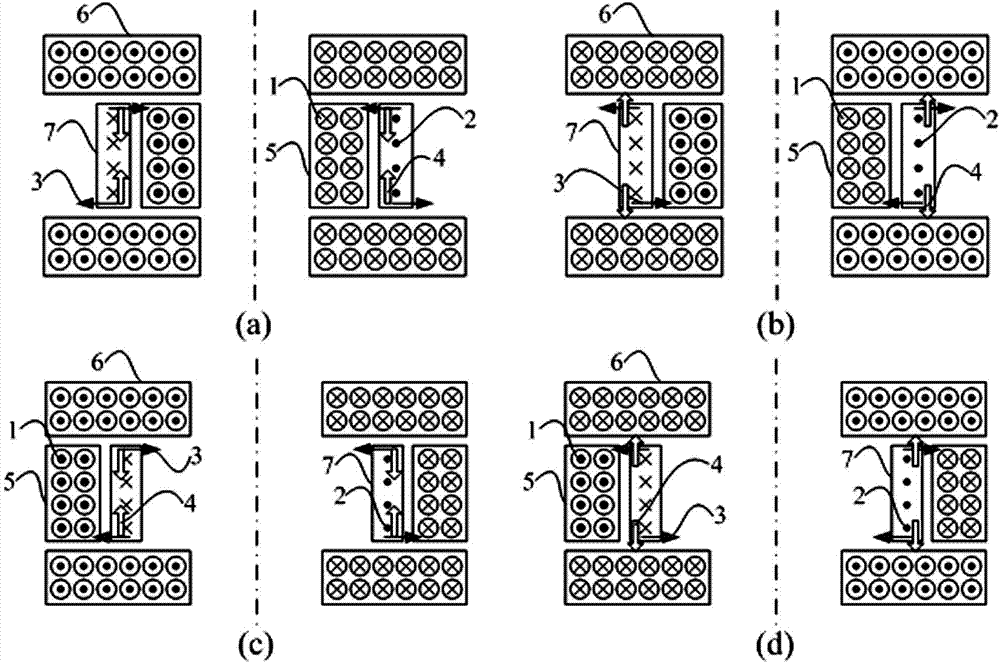

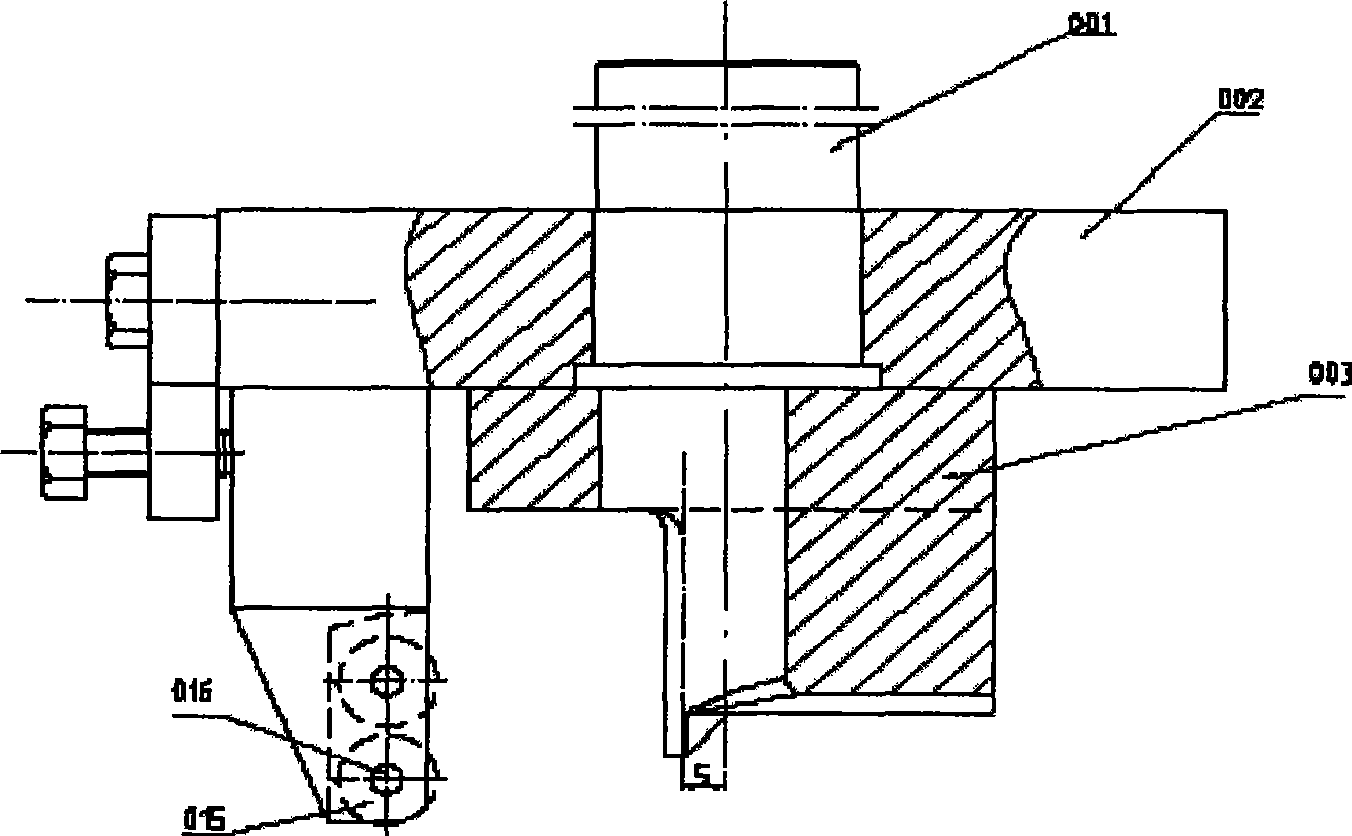

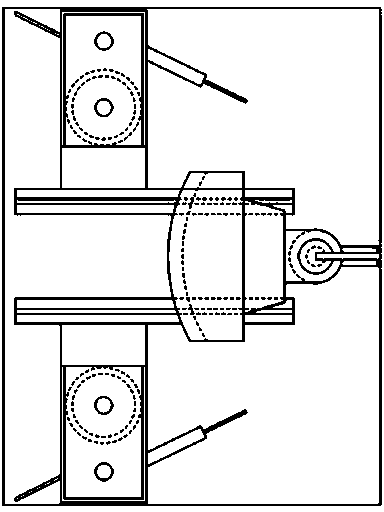

Method and device for electromagnetically forming metal pipe fitting in radial and axial loading mode

ActiveCN103406418ASolve the single load of electromagnetic forming factorSolve the problem caused byAxial compressionPipe fitting

The invention discloses a method and a device for electromagnetically forming a metal pipe fitting in a radial and axial loading mode. The device mainly comprises an eddy current coil, magnetic field coils and power systems. The eddy current coil generates induced eddy currents, the magnetic field coils generate radial magnetic fields, and the eddy current coil and the magnetic field coils are powered by the power systems. The method and the device have the advantages that electromagnetic force can be radially and axially loaded simultaneously in a procedure for electromagnetically forming the metal pipe fitting, an electromagnetic force loading mode can be adjusted, and accordingly machining requirements of different workpieces can be met; the axial compression type pipe fitting is electromagnetically expanded, so that the thickness reduction of a pipe wall in an expansion procedure can be effectively reduced, the forming limit of a formed workpiece is increased, and the forming performance of the formed workpiece is improved; high-speed deformation experiment conditions in different load forms can be provided for metal pipe fittings by the method for electromagnetically forming the metal pipe fitting in the radial and axial loading mode, and novel experiment measures are provided for research on high-speed deformation mechanisms of materials.

Owner:湖北继扬电力科技有限公司

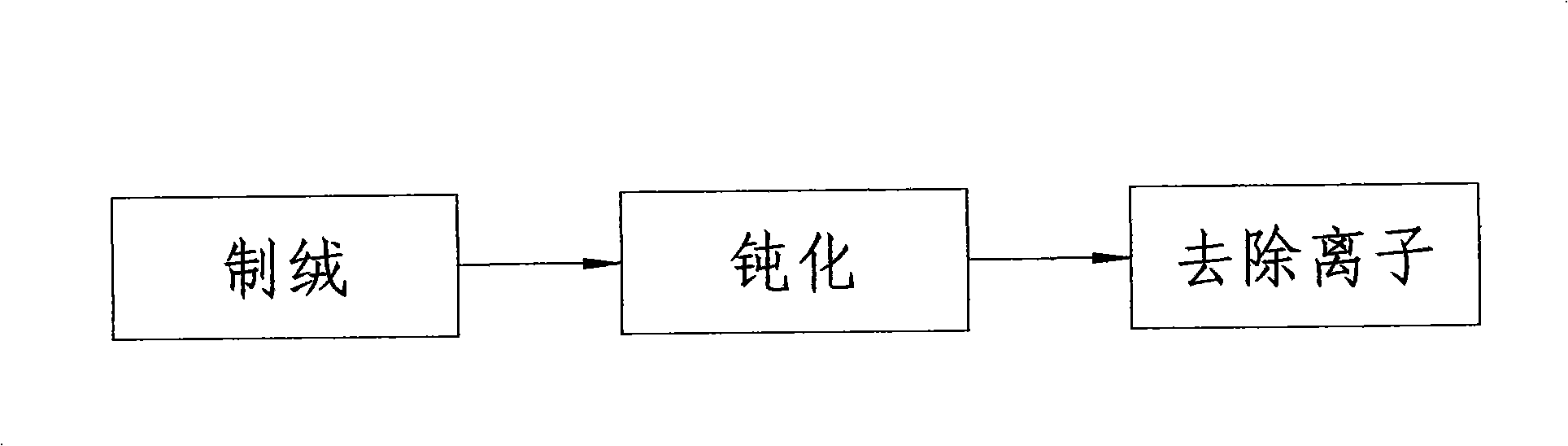

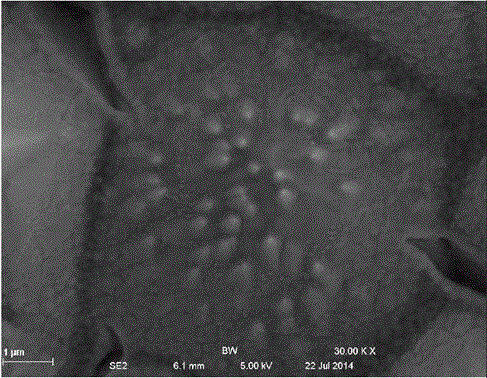

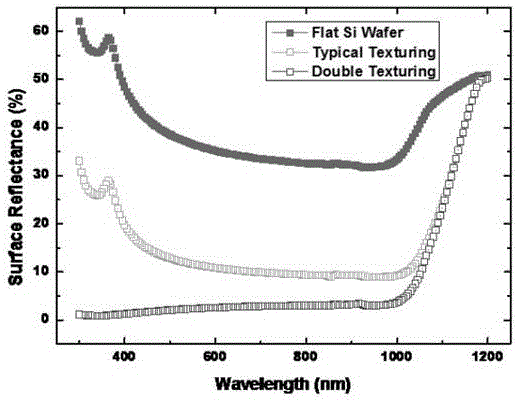

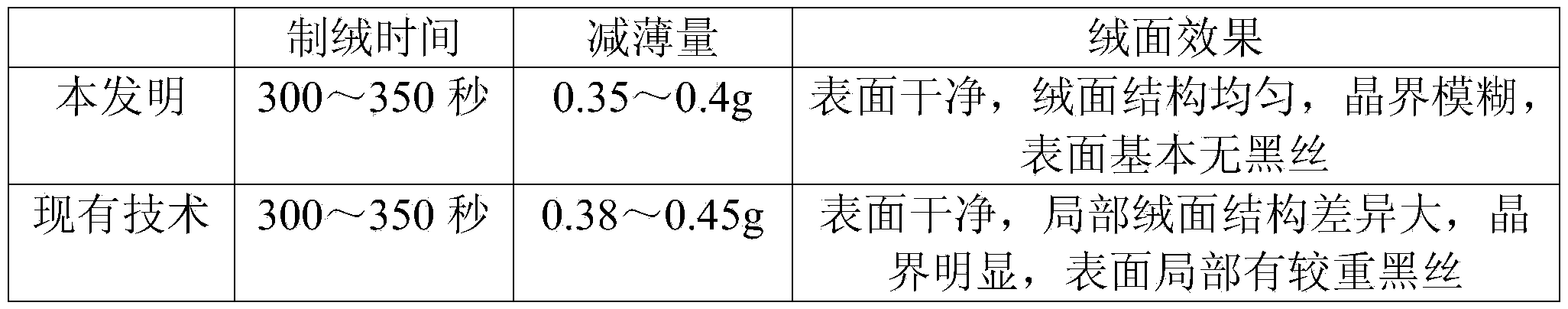

Method for fine-hair maring using monocrystalline silicon slice

InactiveCN101409312AUnbreakableUniform and fine suedeFinal product manufactureSemiconductor devicesHigh reflectivitySteady state

The invention discloses a method for texturing a monocrystalline silicon wafer. The method comprises the steps of texturing by corrosion, passivation and deionization. By the technical scheme of cancelling rough polishing, and changing a formula, reaction conditions and treatment flow, the method overcomes the problems and the disadvantages of the prior art that the texturing technological process is difficult to be controlled, the thickness reduction of the monocrystalline silicon wafer is greater, the silicon wafer is easily cracked during the treatment process, the textures formed on the silicon wafer is uneven, and bulky dimension of a cone structure leads to high reflectivity of the silicon wafer, lower short circuit current (Isc) and lower photoelectric conversion rate. The method provided for texturing the monocrystalline silicon wafer realizes that corrosive liquid is in a steady state which is easy to be controlled, the thickness reduction of the silicon wafer is reduced, the formed textures are even and the dimension of the cone structure is compact; the method reaches the purposes of reducing the reflectivity of the silicon wafer, increasing the short circuit current (Isc), and improving the photoelectric conversion rate, meanwhile, the method improves the quality and the qualification rate of the product on the whole, reduces the consumption of chemical reagents and lowers the cost.

Owner:SHANGHAI CHAORI (LUOYANG) SOLAR ENERGY CO LTD

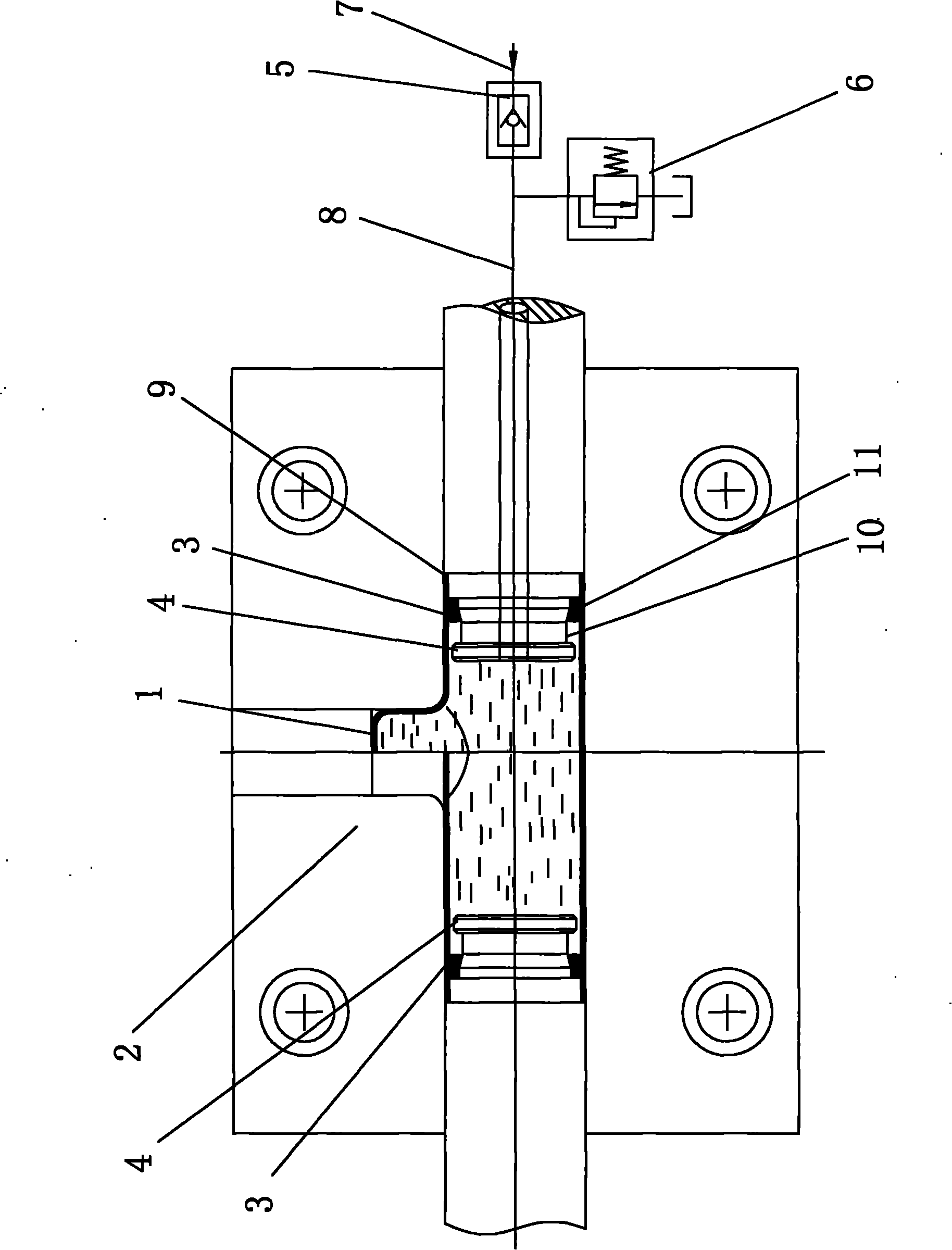

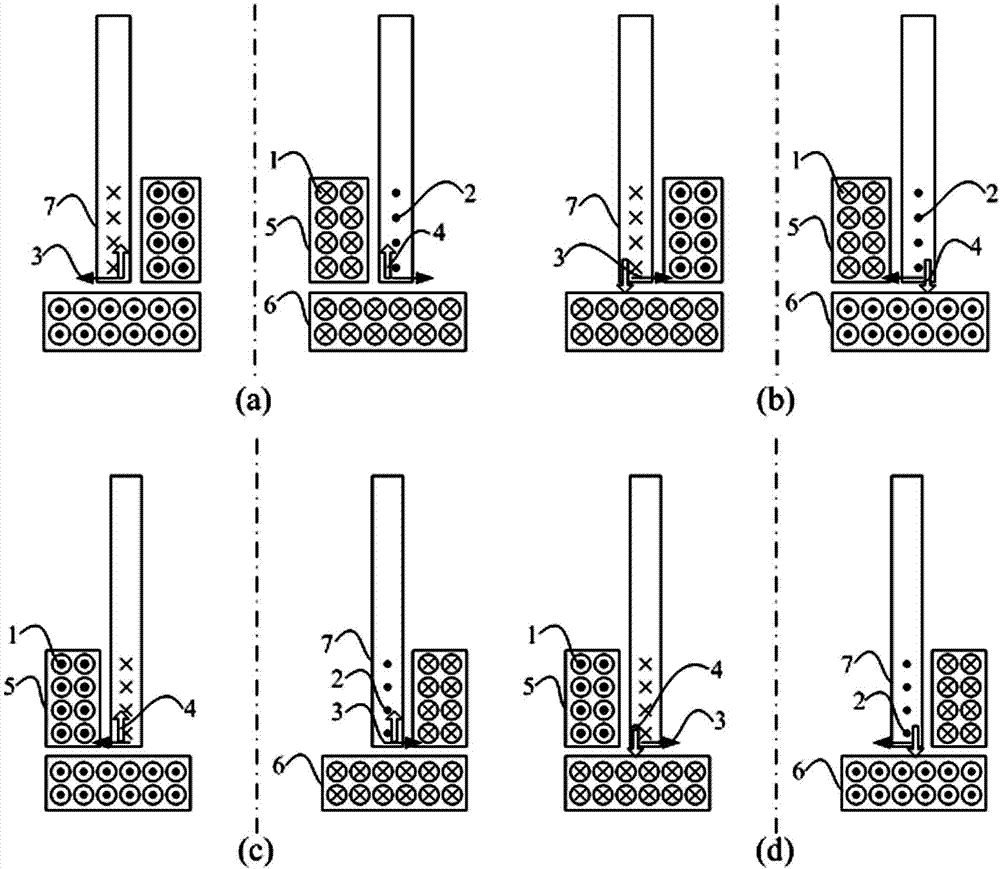

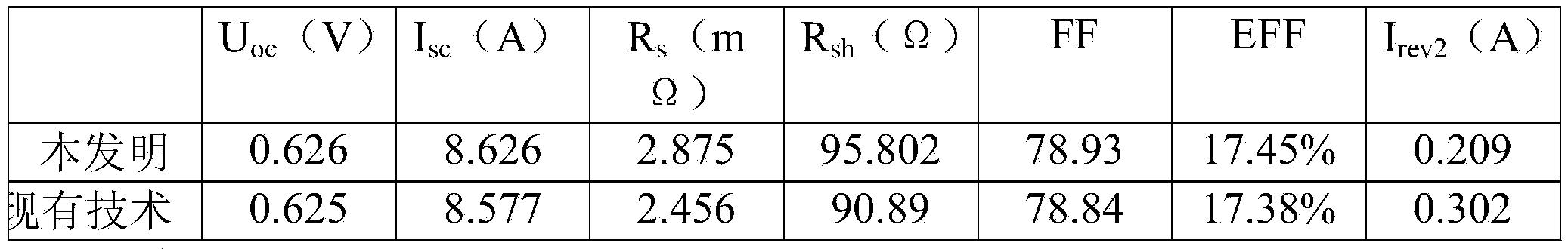

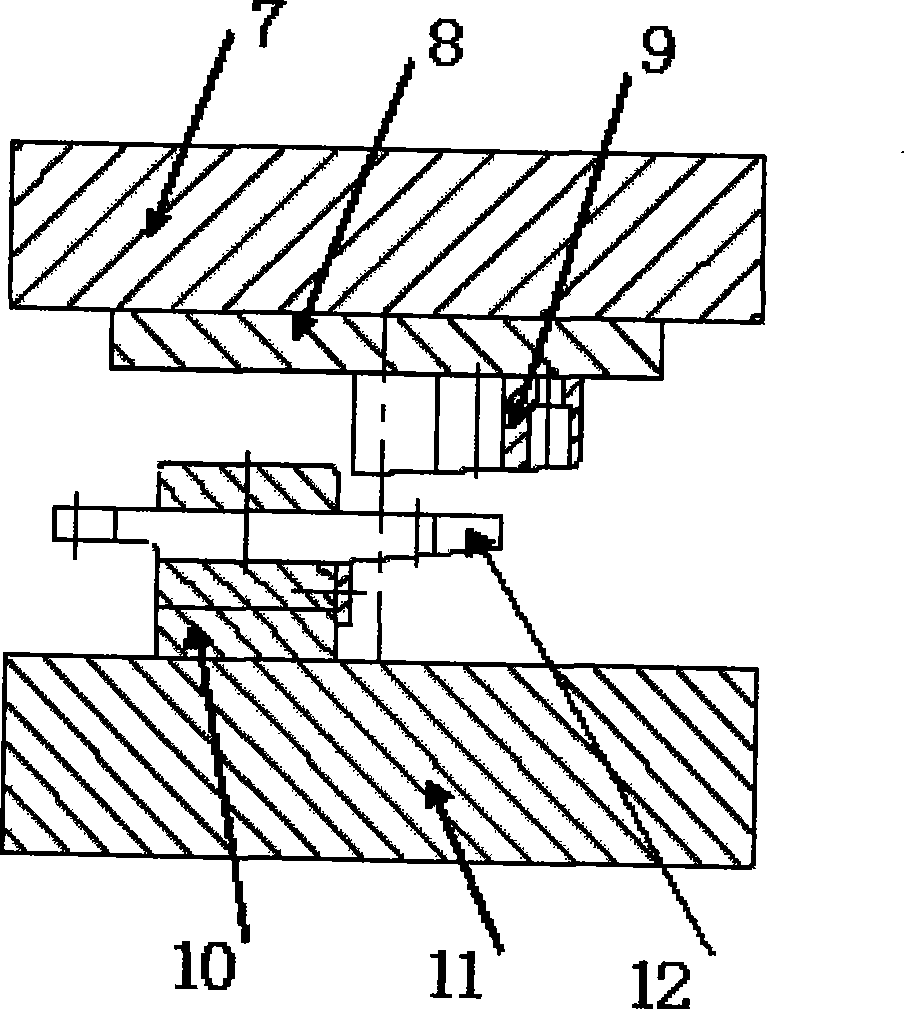

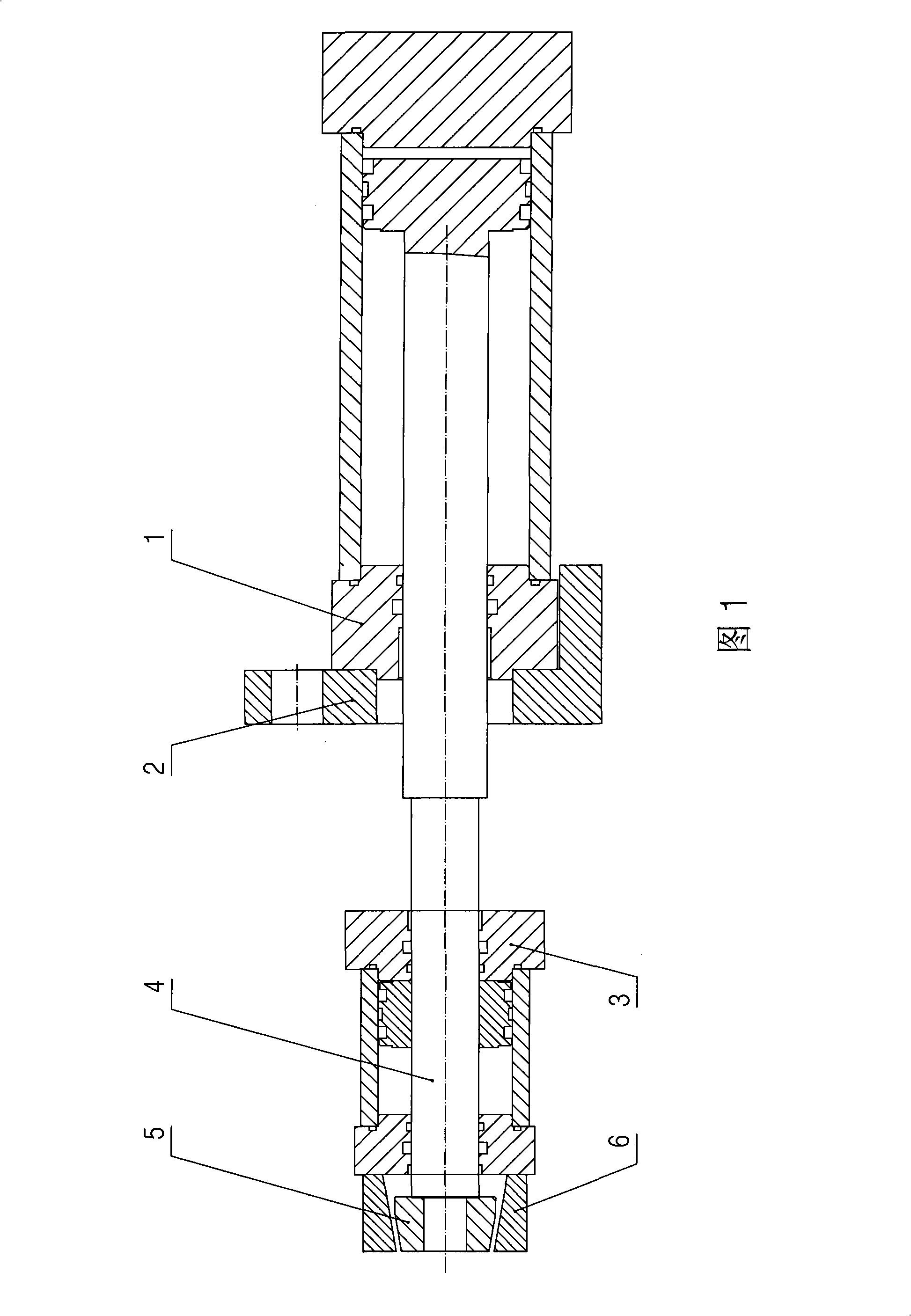

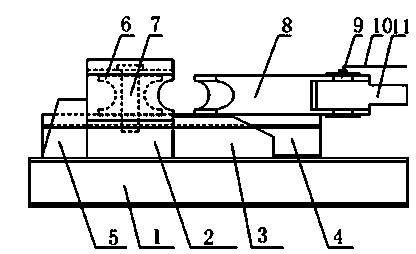

Inside high-pressure molding method and device of thin-wall stainless steel tube

InactiveCN102133596ASmall amount of thinningIncrease the pressure ratingInternal pressureUltra high pressure

The invention discloses an inside high-pressure molding method and device of a thin-wall stainless steel tube. The inside high-pressure molding method of the thin-wall stainless steel tube is characterized by comprising the following steps: placing a parison tube into the molding cavity of a mould, then injecting a low-pressure liquid to the inside of the parison tube and exhausting air in the parison tube while feeding to the parison tube by two extrusion heads; after the two extrusion heads are in contact with the end surface of the parison tube, stopping feeding the low-pressure liquid, sealing the liquid inside the parison tube to automatically establish superhigh molding pressure, and beginning expanding and molding when the parison tube yields; continuing to feed by virtue of the extrusion heads, continuing to increase the inside pressure and continuing to carrying out the molding process, and meanwhile, complementing two broken parison materials to an expanding and deforming part, and keeping the inside pressure of the parison tube constant by virtue of an overflow valve; and maintaining molding until finishing. The invention also discloses an inside high-pressure molding device which can automatically adapt to finish high-pressure molding by utilizing superhigh pressure inside parts without a special expensive superhigh-pressure generating mechanism and has the characteristics of high efficiency and low cost; and a molded part has the characteristics of small material thinning quantity and high strength, thereby increasing the pressure-bearing grade of a pipeline system.

Owner:宁波市华涛不锈钢管材有限公司

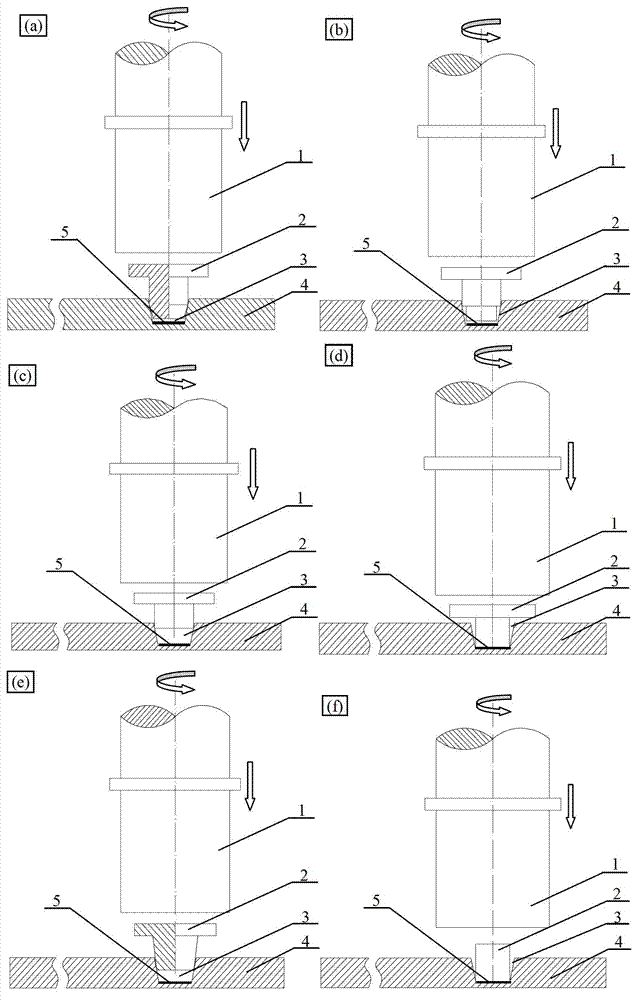

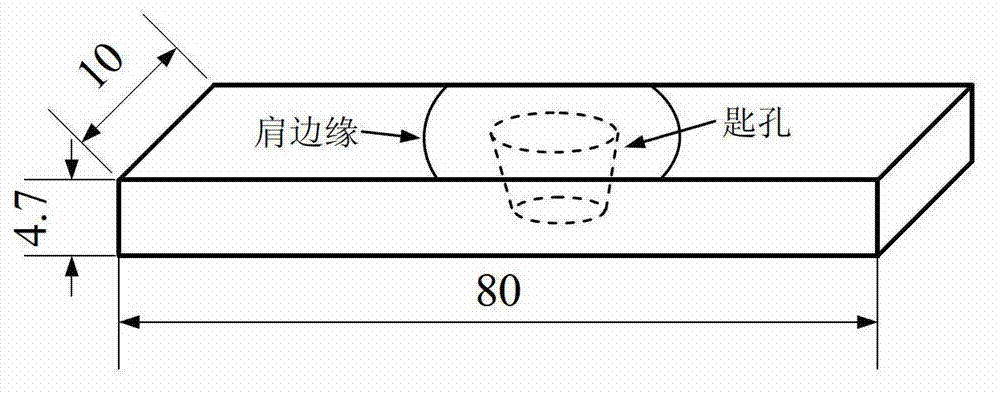

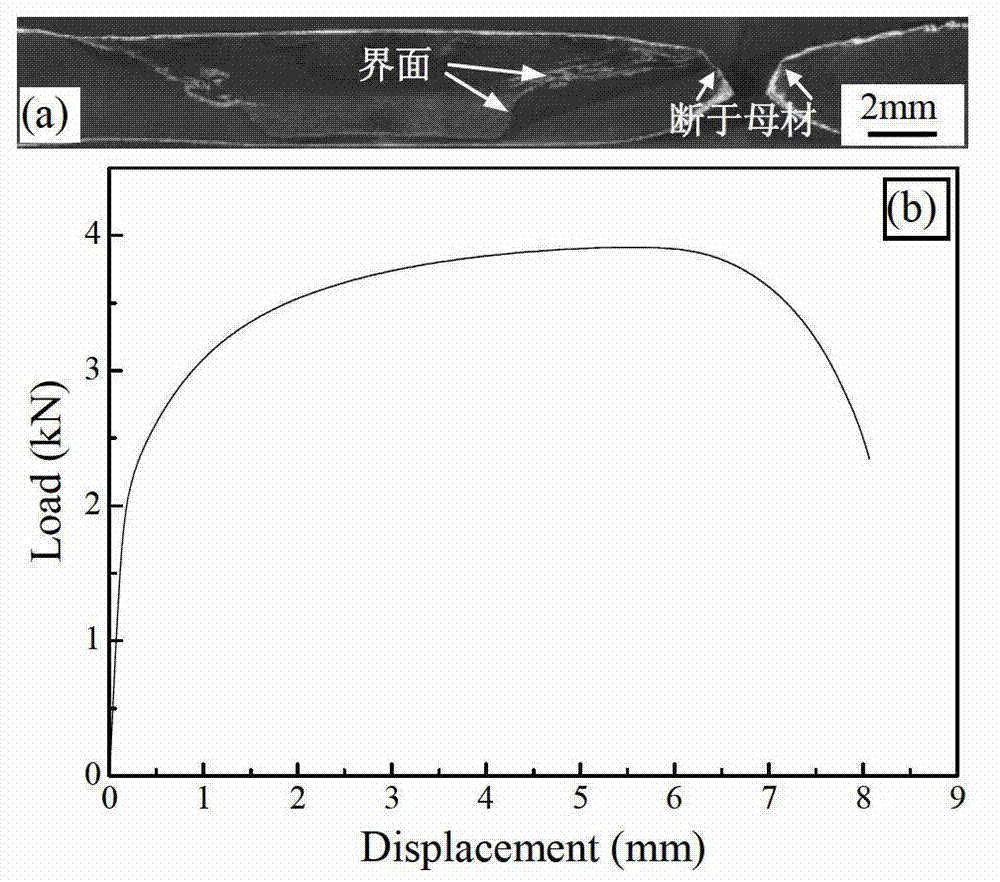

Method of brazing alloy extrusion and backflow stuffing for carrying out stirring and friction of welding keyhole

InactiveCN103071911AAvoid smallImprove liquidityNon-electric welding apparatusFilling materialsBraze alloy

The invention discloses a method of brazing alloy extrusion and backflow stuffing for carrying out stirring and friction of a welding keyhole. The method comprises the following steps that brazing alloy is preset in a keyhole, then a stuffing block is added in the keyhole, a T-typed stuffing block is subjected to rotation and friction through a needleless stirring head and is compressed down, the brazing alloy is heated to be softened, liquid brazing alloy is extruded and stirred by the stuffing block in an enclosed environment formed by the keyhole and the stuffing block, the liquid brazing alloy is stuffed in a driving and flowing way, and the liquid brazing alloy is enabled to be filled into a gap on the bottom of the keyhole; and due to the property of non-compression of the liquid brazing alloy, the liquid brazing alloy back flows along a side wall interface upward to stuff the remaining gap of the side wall, the side wall interface is dissolved, and compact alloying of the side wall and the bottom interface is realized. When the welding keyhole is repaired in batches, the replacement of tools is not needed, reduction of a welded keyhole does not exist or is extremely small, stuffing materials are saved, preset operation of the brazing alloy and the stuffing block is convenient, and the shaping of a surface of a stirring area is smooth.

Owner:XI AN JIAOTONG UNIV

Monocrystalline silicon wafer precleaning liquid and cleaning method thereof

ActiveCN103087850AReduce concentrationReduce Fragmentation RateInorganic non-surface-active detergent compositionsCleaning using liquidsHydrogenWater rinsing

The invention relates to monocrystalline silicon wafer precleaning liquid and a cleaning method thereof. The invention is characterized in that the precleaning liquid comprises the following compositions: hydrogen peroxide, sodium hydroxide or potassium hydroxide, and water. The cleaning method of the monocrystalline silicon wafer precleaning liquid as in claim 1 is characterized in that the method comprises the following steps: putting a silicon wafer inserted into a flower basket into a uniformly mixed monocrystalline silicon wafer precleaning liquid at a temperature of 55-80 DEG C, performing ultrasonic cleaning for 60-600 seconds, after ultrasonic cleaning, rinsing with deionized water at 60 DEG C for 1 min, after deionized water rinsing, taking the silicon wafer out, and drying. The advantages of the invention are that with the hydrogen peroxide process, the alkali concentration is reduced; the hydrogen generation amount is low; no bubble trace is generated on the silicon wafer surface; no basket rinsing is caused; no obvious boundary is generated. Since the alkali concentration is reduced, the thickness reduction amount is effectively decreased, which facilitates the reduction of the fragment rate of battery pieces in subsequent procedures.

Owner:徐州鑫宇光伏科技有限公司 +1

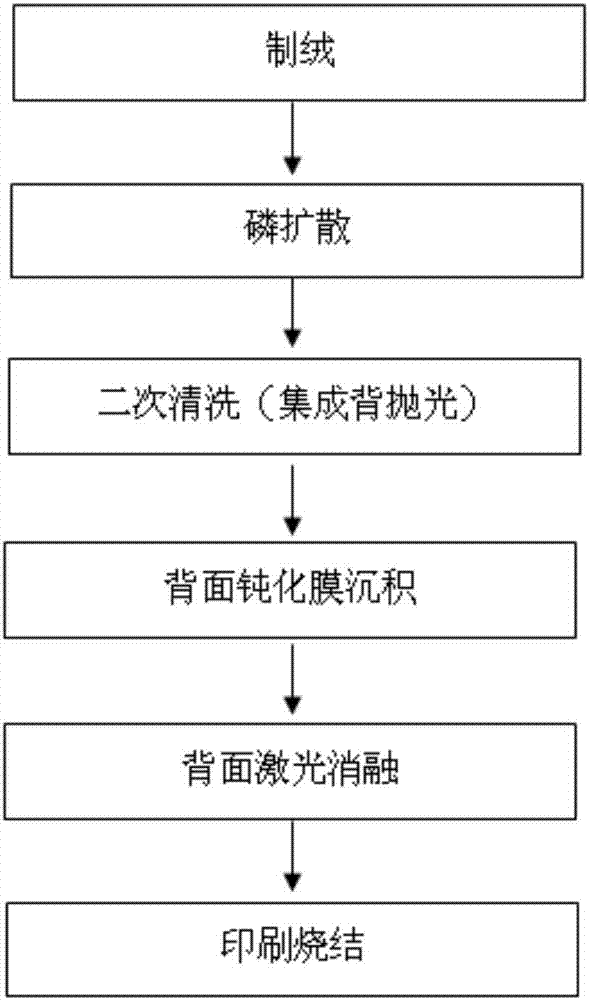

Single-side polishing process of solar monocrystalline silicon battery

ActiveCN102969392ALow wafer thinningNo etching process requiredAfter-treatment detailsFinal product manufactureSilicon chipIon

The invention discloses a single-side polishing process of a solar monocrystalline silicon battery and aims at solving problems that silicon chips are too thin due to the fact that thickness reduction of monocrystalline silicon chips is over-large by means of double-side polishing, reaction of chained single-side alkaline polishing solutions is difficult to control, chained acid polishing is severe in pollution, and wastewater treatment is difficult. The single-side polishing process comprises three main steps of a former process, a back-side polishing and silk-screen printing and sintering, and the single-side polishing process has the advantages that the polishing solutions are free from metal ion pollution, thickness reduction of the silicon chips is low, an etching process is not required, the polishing solutions are convenient to adjust, and costs of devices are low.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

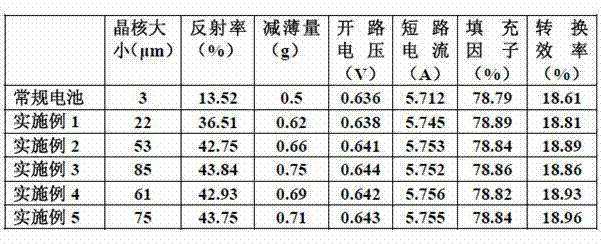

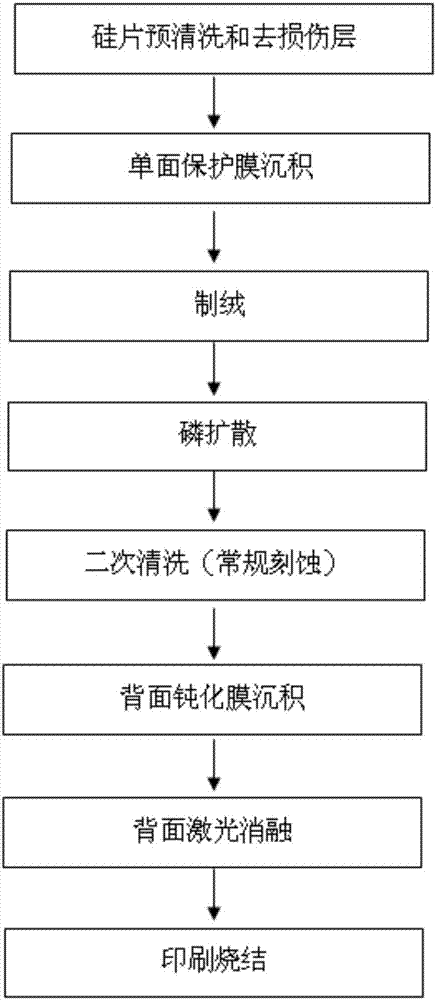

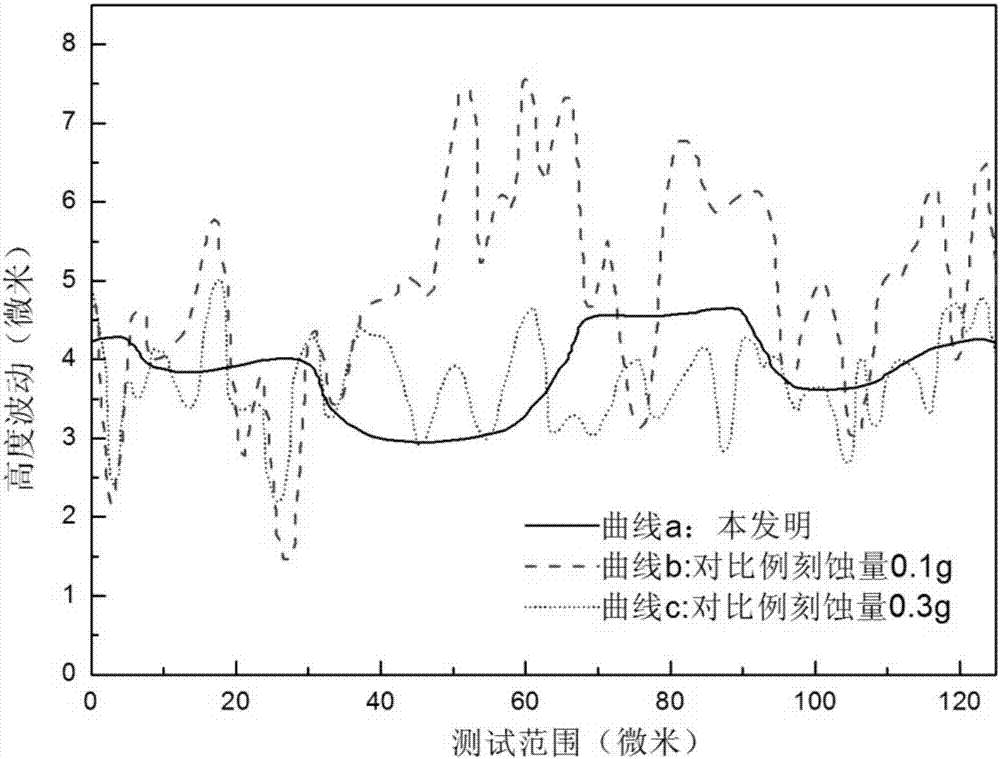

Method for preparing backside-polished PERC battery

InactiveCN107123702ASmall amount of thinningAchieve flatnessFinal product manufacturePhotovoltaic energy generationMicro nanoScreen printing

The invention discloses a method for preparing a backside-polished PERC battery. The method comprises: (1), depositing a single-sided protective film on the backside of a silicon wafer; (2) carrying out texturing on the silicon wafer plated with the single-sided protective film and removing the single-sided protective film of the silicon wafer during a pickling process after texturing; (3), carrying out diffusion on the single-sided-textured silicon wafer; (4), carrying out conventional secondary cleaning; and (5), depositing aluminium oxide / silicon nitride laminated passivation film at the back side, carrying out laser grooving, screen printing and sintering, thereby obtaining a backside-polished PERC battery. According to the method disclosed by the invention, the volume production threshold is low; the operation cost is low; micro-nano flatness is realized; and the photoelectric conversion of the battery is improved.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

Solid solution-bending-aging forming device and method for vehicle body aluminum alloy pipe

The invention discloses a solid solution-bending-aging forming device and method for a vehicle body aluminum alloy pipe. The device comprises a heating mechanism and a bending mechanism. The heating mechanism comprises an induction coil and a high-frequency power source. The induction coil is arranged on the periphery of a bent part of the pipe in a sleeving mode and connected with the high-frequency power source. The bending mechanism comprises a bending die, a fixed clamp block, a crease-resistant block, movable clamp blocks and a rigid / flexible core die. The bent part of the pipe is placed on the bending die. One end of the pipe is clamped on the bending die through the fixed clamp block and the crease-resistant block, and the other end of the pipe is clamped by the movable clamp blocks. The rigid / flexible core die is arranged in the pipe. The fixed clamp block, the crease-resistant block and the movable clamp block are designed in a split mode, and the bending die is designed in an insert mode, so that water channels are processed conveniently and replacement after abrasion is convenient. The bending die, the fixed clamp block, the crease-resistant block and the movable clamp blocks are all internally provided with serpentine channels used for introducing cooling water. The solid solution-bending-aging forming device and method for the vehicle body aluminum alloy pipe can significantly improve the strength, the hardness and the forming precision of aluminum alloy pipes, and the springback problem of the pipes after bending and quenching is effectively solved.

Owner:WUHAN UNIV OF TECH

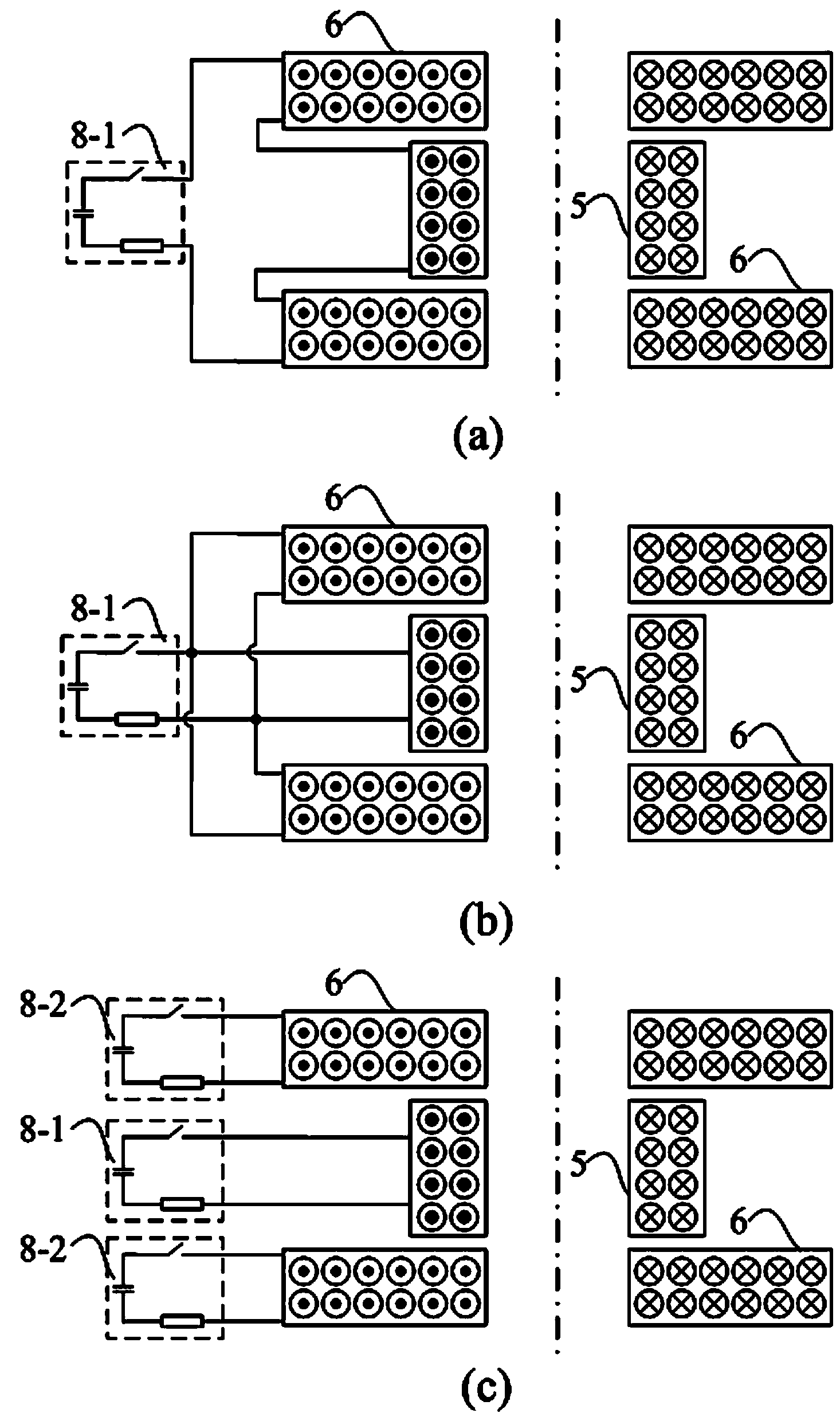

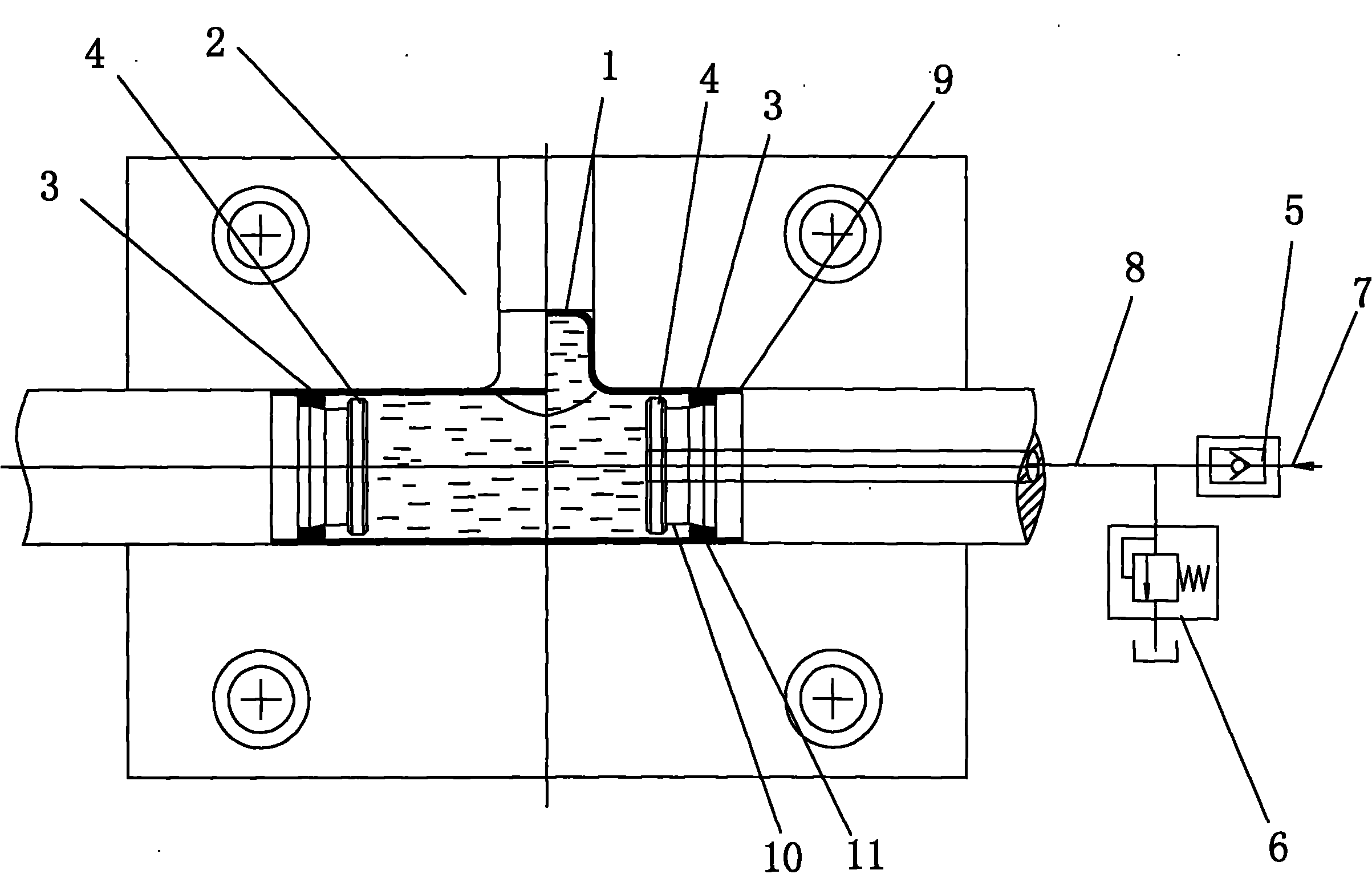

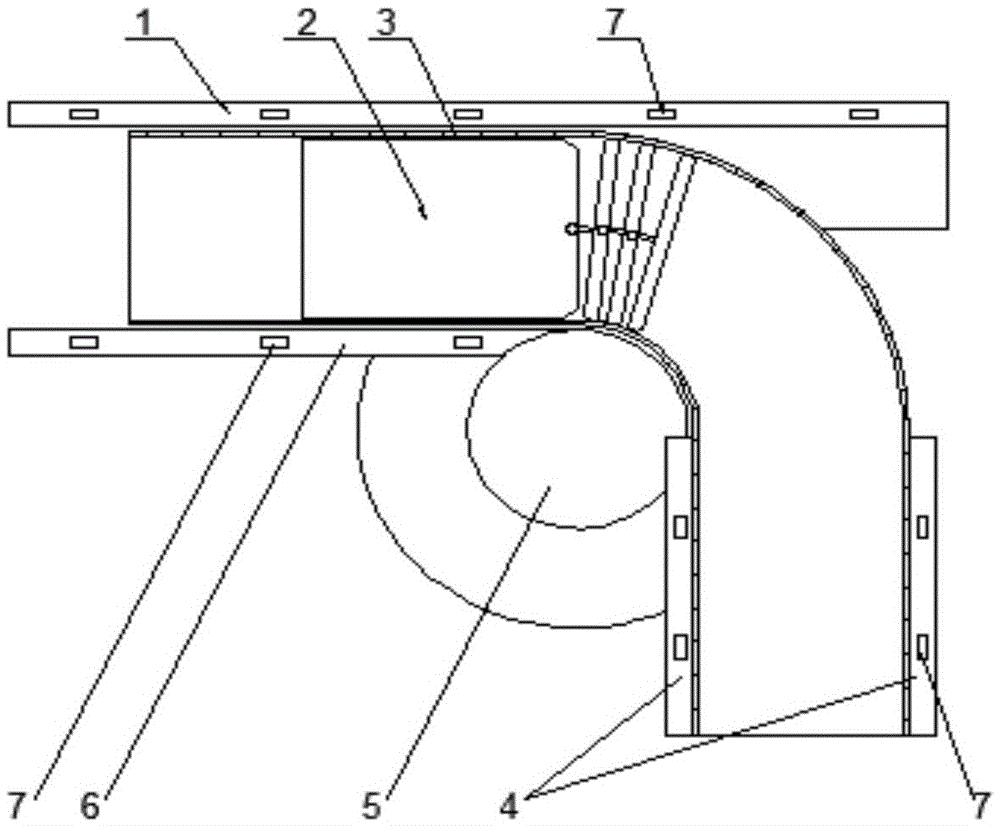

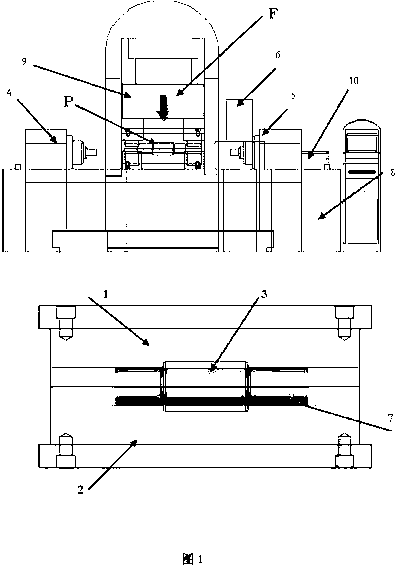

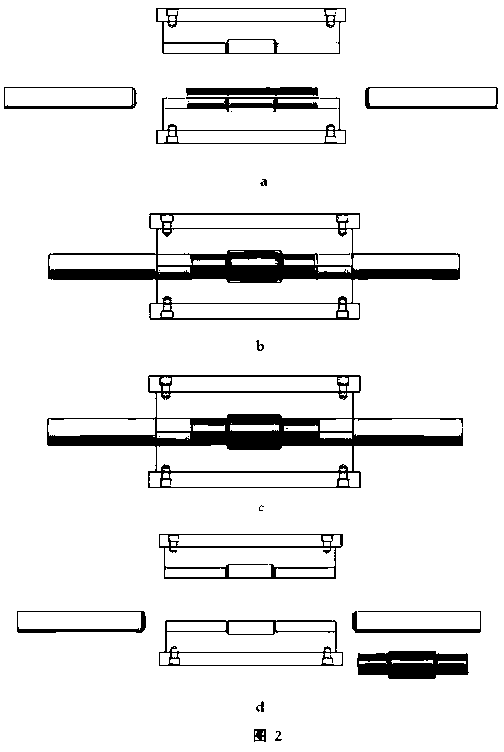

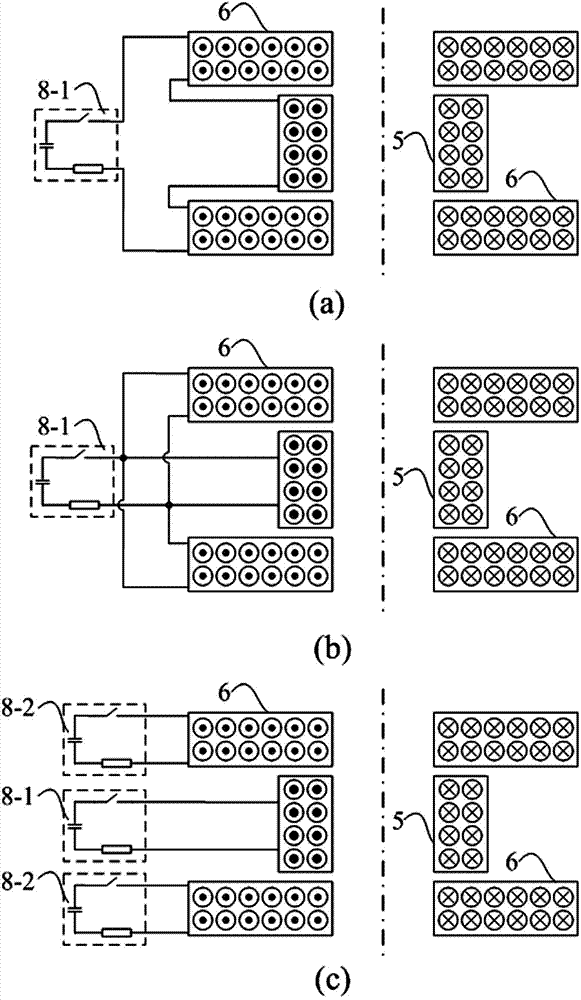

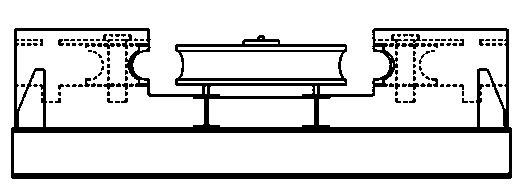

Variable-mold-clamping-force pipe internal high-pressure forming device and method

ActiveCN103212619AReduced pressure holding performance requirementsSmall tonnageEngineeringAxial force

The invention relates to a variable-mold-clamping-force pipe internal high-pressure forming method, which comprises the steps that after an upper mold and a lower mold are clamped, forming media with certain pressure is filled into a mold cavity, pushing heads on a left side and a right side simultaneously push pipe blanks into the mold cavity from the left side and the right side, the pipe blanks are pressed into the mold cavity to be formed through internal pressurization and axial force application and material compensation under the joint effect of the pressure of the forming media and the material compensation of the pushing heads, and finally the pipe blanks are in fit with the mold cavity to realize part formation. Since different mold clamping forces are adopted at different stages, the defects that the pressure required by the traditional constant-mold-clamping-force tube internal high-pressure forming method is high, the requirements on machine performance, mold performance, sealing performance and mold lubricating performance are high, the machine cost is high, the situation of mold lifting is apt to occur, the part forming pressure is high, large-deformation complex parts cannot be formed, the working efficiency is low and the like are overcome.

Owner:NINGBO POWER PRECISION HYDRAULIC MACHINERY

Method and device for electromagnetically forming metal pipe fitting in radial and axial loading mode

ActiveCN103406418BAdjustable loading methodMeet the process requirementsPipe fittingAxial compression

The invention discloses a method and a device for electromagnetically forming a metal pipe fitting in a radial and axial loading mode. The device mainly comprises an eddy current coil, magnetic field coils and power systems. The eddy current coil generates induced eddy currents, the magnetic field coils generate radial magnetic fields, and the eddy current coil and the magnetic field coils are powered by the power systems. The method and the device have the advantages that electromagnetic force can be radially and axially loaded simultaneously in a procedure for electromagnetically forming the metal pipe fitting, an electromagnetic force loading mode can be adjusted, and accordingly machining requirements of different workpieces can be met; the axial compression type pipe fitting is electromagnetically expanded, so that the thickness reduction of a pipe wall in an expansion procedure can be effectively reduced, the forming limit of a formed workpiece is increased, and the forming performance of the formed workpiece is improved; high-speed deformation experiment conditions in different load forms can be provided for metal pipe fittings by the method for electromagnetically forming the metal pipe fitting in the radial and axial loading mode, and novel experiment measures are provided for research on high-speed deformation mechanisms of materials.

Owner:湖北继扬电力科技有限公司

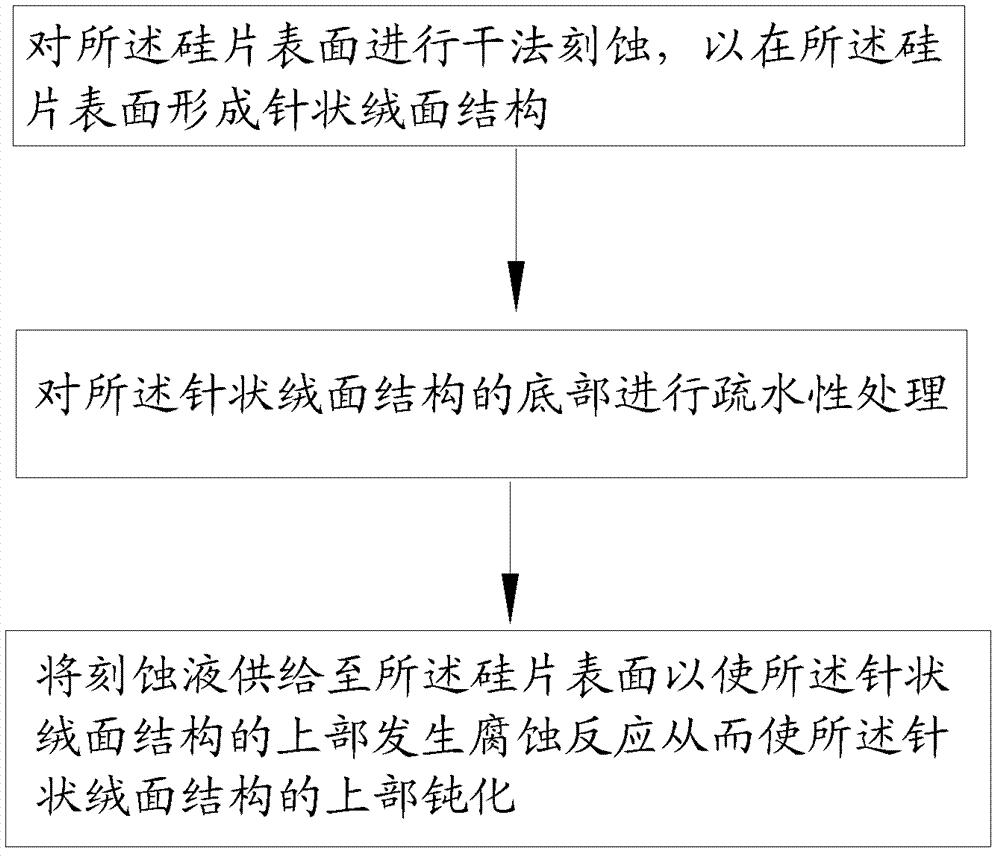

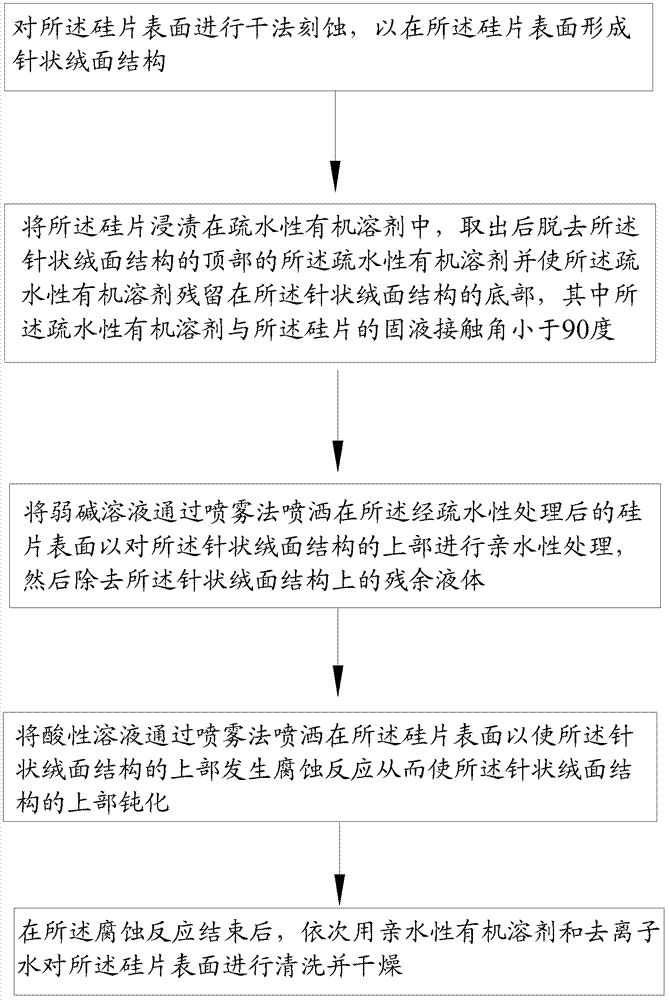

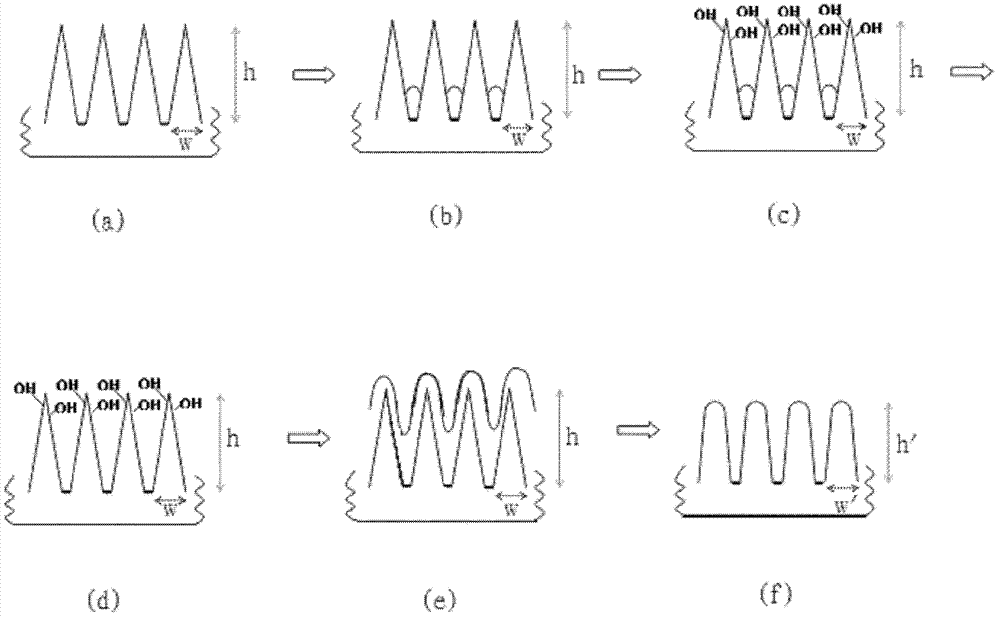

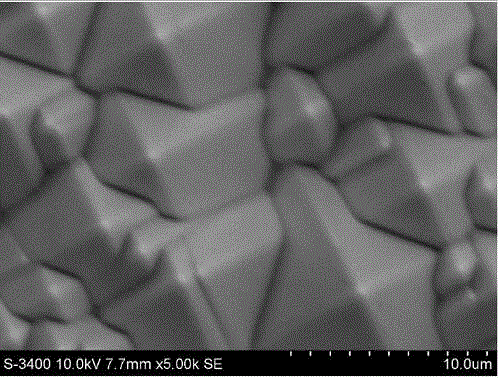

Texture surface making treatment method for silicon wafer

ActiveCN102820370AGuaranteed anti-reflection effectPrevent leakageFinal product manufactureSemiconductor devicesCorrosion reactionScreen printing

The invention discloses a texture surface making treatment method for a silicon wafer. The texture surface making treatment method includes steps of 1), performing dry etching for the surface of the silicon wafer so as to form a needle-shaped texture surface structure on the surface of the silicon wafer; 2), performing hydrophobic treatment for the bottom of the needle-shaped texture surface structure; and 3), supplying etching liquid to the surface of the silicon wafer so that the upper portion of the needle-shaped texture surface structure is subjected to corrosion reaction and is passivated. The texture surface making treatment method for the silicon wafer in an embodiment of the invention has the advantages that the top of the needle-shaped texture surface structure can be passivated on the premise that the size and the angle of the needle-shaped texture surface structure are maintained, so that an anti-reflection effect of the texture surface structure can be guaranteed, the needle-shaped texture surface structure can also be prevented from being broken in a follow-up screen printing process for an electrode, and electric leakage can be avoided.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

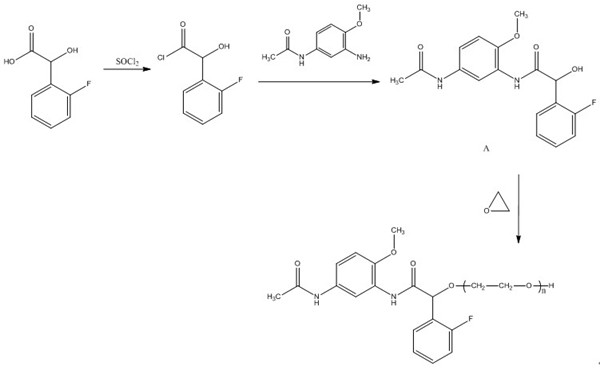

Preparation method of novel all back electrode crystalline silicon solar cell

ActiveCN105161553ASmall amount of thinningIncrease the number ofPhotovoltaic energy generationSemiconductor devicesNano structuringCrystalline silicon

The invention relates to a preparation method of a novel all back electrode crystalline silicon solar cell. The method comprises the following steps: pre-cleaning, injury removal, mask protection, preparation of a pyramid texture, second preparation of the texture, texture aftertreatment, post cleaning, all back electrode fabrication and the like. The crystalline silicon pyramid texture with a nano structure shape prepared by the method has a nano short column which covers the overall pyramid surface; the pyramid top is still clear; through a test, the surface reflectivity of the texture is reduced to 3.7% from 12.5% of a conventional process.

Owner:TRINA SOLAR CO LTD

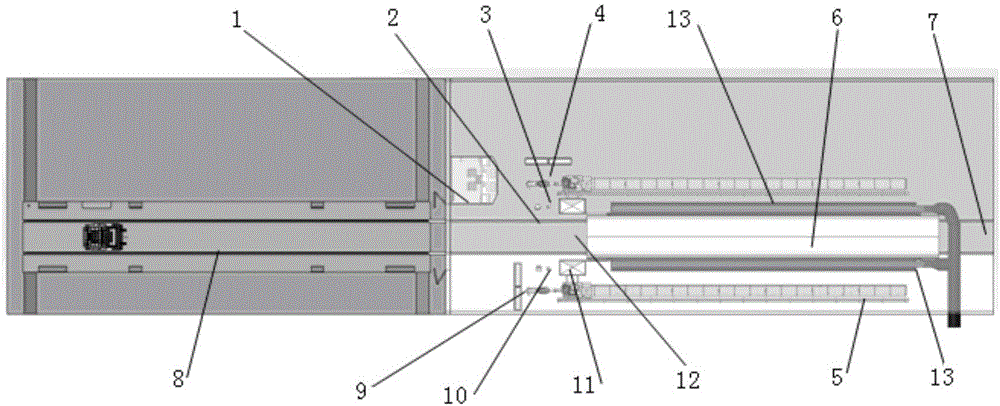

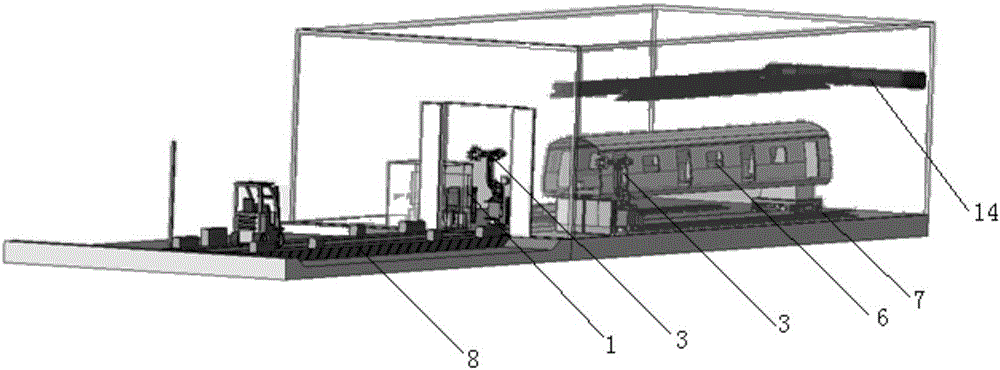

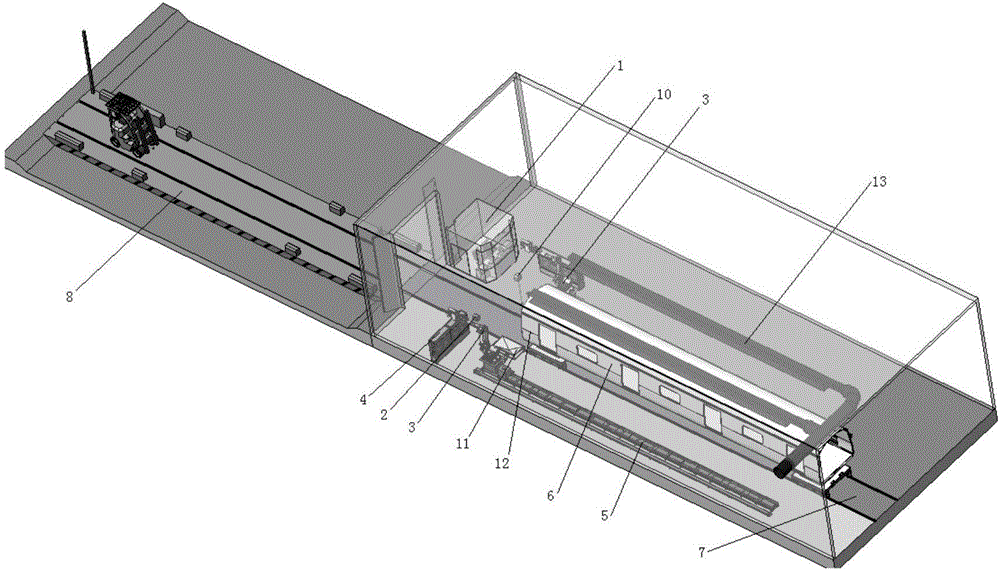

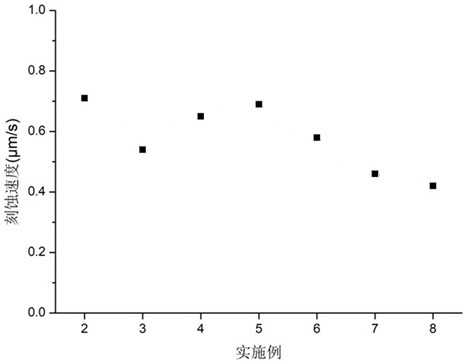

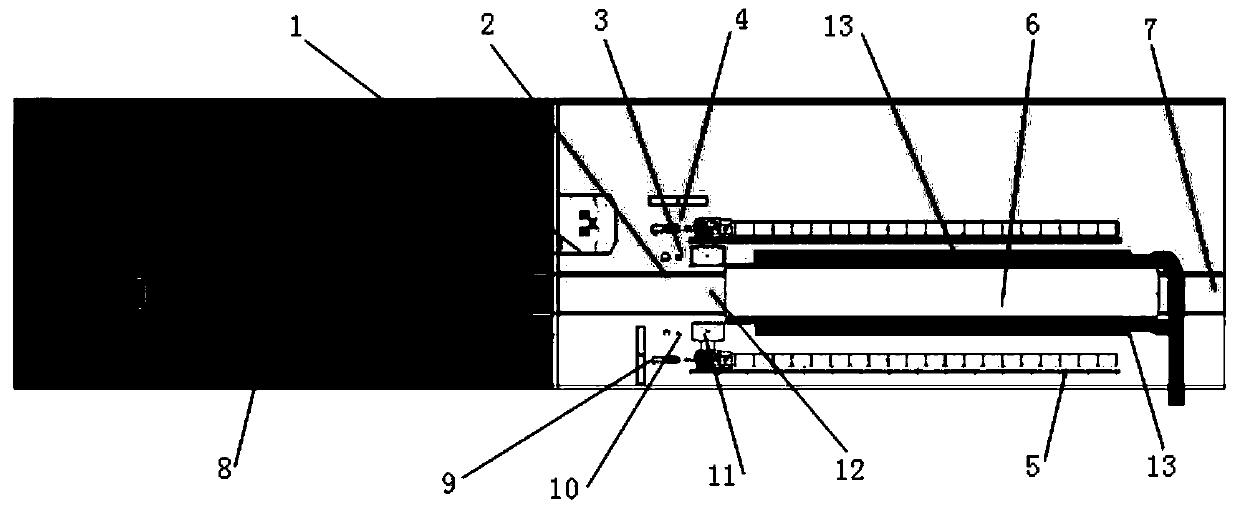

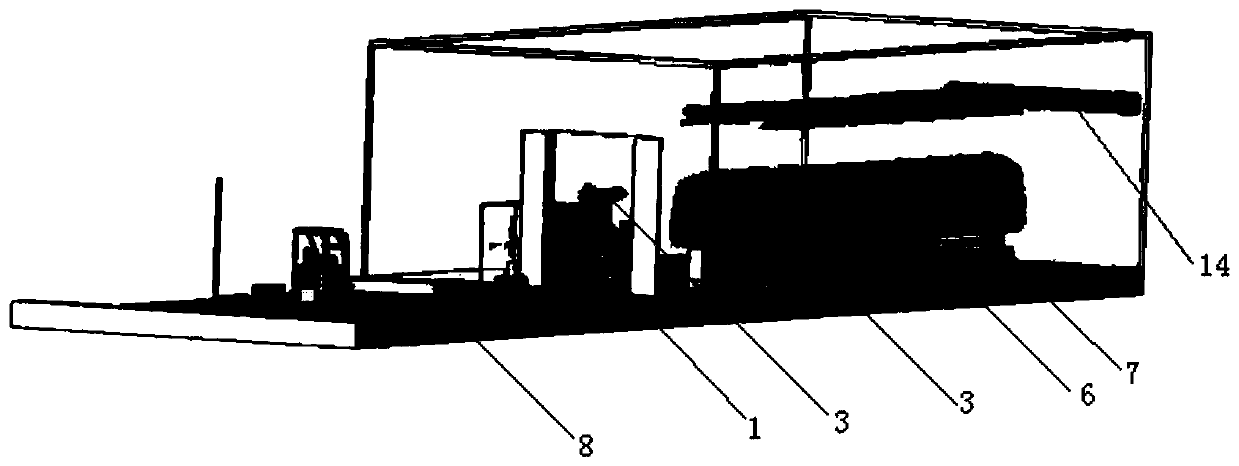

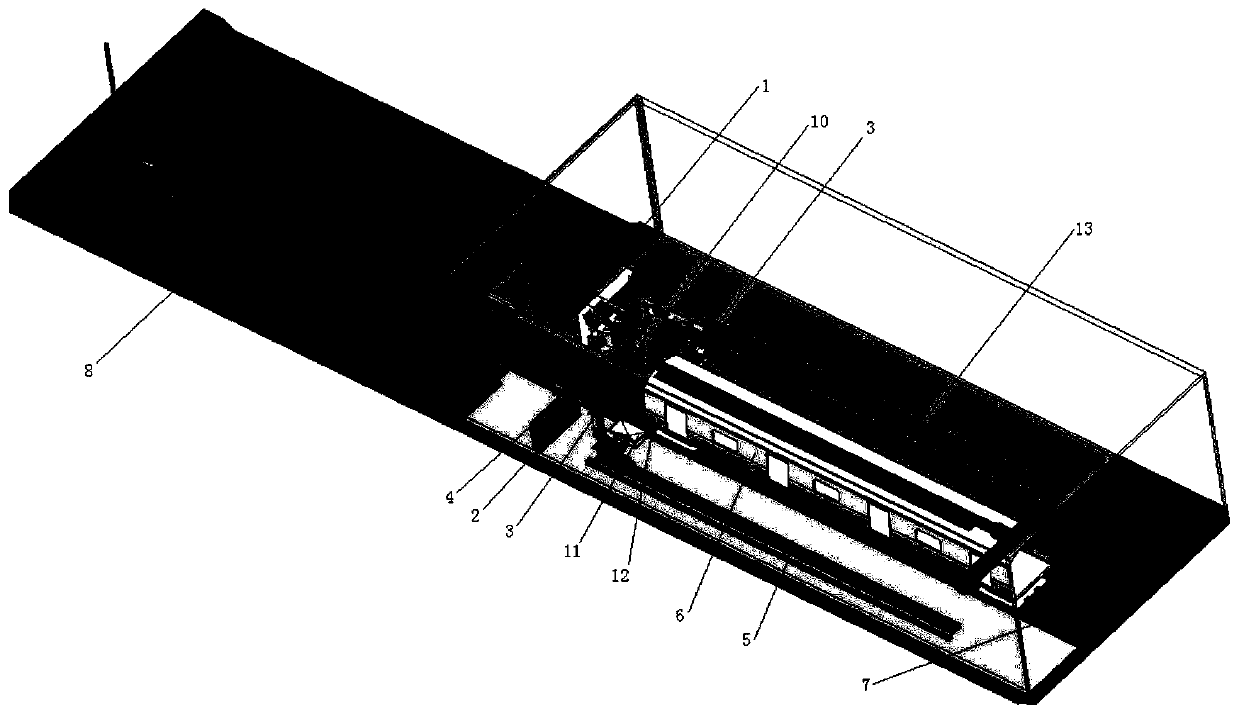

Automatic wire drawing system for side wall of rail vehicle and wire drawing process

ActiveCN106181593AHigh flexibility and intelligenceRealize wire drawingGripping headsBelt grinding machinesControl systemElectronic control system

The invention provides an automatic wire drawing system for the side wall of a rail vehicle. The system comprises a central control system, a robot, a wire drawing device, a rail, a laser measurement system, off-line programming software and an electronic control system. The wire drawing operation of the side wall of a vehicle body is automatically completed. The invention further provides a process method through which wire drawing operation can be conducted by means of the system. By means of the automatic wire drawing system for the side wall of the rail vehicle and the wire drawing process, automatic flexible intelligent wire drawing operation can be achieved, the automatic wire drawing system and the wire drawing process automatically adapt to changes, within a certain range, of the shapes of surfaces of workpieces, the constant normal wire drawing force is kept all the time, and the optimal wire drawing effect is achieved.

Owner:CRRC QINGDAO SIFANG CO LTD

Polycrystalline silicon battery chip corrosion solution and preparation process thereof

InactiveCN104131356AControl reaction rateSmall amount of thinningAfter-treatment detailsHydrofluoric acidNitrogen

The invention relates to a polycrystalline silicon battery chip corrosion solution and a preparation process thereof. The polycrystalline silicon battery chip corrosion solution comprises the following components in parts by weight: 10-12 parts of hydrofluoric acid, 80-82 parts of nitric acid, 1-3 parts of texturing aid and 66 parts of water, wherein the mass percentage concentration of the hydrofluoric acid is 49+ / -1%, and the mass percentage concentration of the nitric acid is 78+ / -1%. The preparation process for the polycrystalline silicon battery chip corrosion solution is characterized by comprising the steps of injecting 66 parts by weight of water into a texturing tank, cooling the water to 12-15 DEG C, and adding 10-12 parts by weight of hydrofluoric acid, 80-82 parts by weight of nitric acid and 1-3 parts by weight of texturing aid; introducing nitrogen for bubbling, meanwhile, circularly cooling with chilled water to keep the temperature at 5-8 DEG C to obtain the corrosion solution; wherein the flow rate of the nitrogen is 5-15L / min, and the temperature of the circular chilled water is 0-4 DEG C. By adopting the corrosion solution disclosed by the invention, the speed of reaction between a silicon chip and the acidic corrosion solution is easy to control, and a uniform surface morphology structure can be formed.

Owner:无锡尚品太阳能电力科技有限公司

Processing method of thin-wall copper tube end cold forming seal

The invention relates to a processing method of a thin-wall copper tube end cold forming seal, which is characterized in that the method comprises the following techniques: firstly, a tube stock is cut into a certain length of oblique stocks on a stock feeding and cutting machine; secondly, cutting and flanging are sequentially carried out on the well-put thin-wall copper tube on a punching machine under the action of a feed mechanism; thirdly, stretching, contracting and kneading are carried out on the flanged stock on a two-station tube reducing machine after the flanged stock gets soft by a re-crystallization annealing technique. The method has the advantages that the production cost is reduced greatly, the utilization of the copper product is increased greatly, and the environment is not polluted. However, the processing performance of the material is very poor and the cold processing forming technology is still difficult for breakthrough.

Owner:九江财兴卫浴实业有限公司

Monocrystalline silicon solar cell piece surface texture liquid containing soybean oligosaccharide, and preparation method therefor

InactiveCN106129139AGood product quality and stabilityReduce excessive corrosionSemiconductor/solid-state device manufacturingPhotovoltaic energy generationSalicylic acidThinning

The invention discloses a monocrystalline silicon solar cell piece surface texture liquid containing soybean oligosaccharide. The monocrystalline silicon solar cell piece surface texture liquid is prepared from the following raw materials in parts by weight: 0.1-0.2 parts of soybean oligosaccharide, 1.5-2.5 parts of styrene, 1-2 parts of 5-10% of ammonium persulfate solution, 0.1-0.2 parts of lauryl sodium sulfate, 0.1-0.15 parts of dodecafluoroheptyl-propyl-trimethoxysilane, 0.1-0.15% of nonylphenol polyoxyethylene ether, 3-5 parts of sodium hydroxide, 0.3-0.5 parts of citric acid, 0.05-0.1 parts of emulsified silicone oil, 0.1-0.15 parts of salicylic acid and 100-120 parts of water. The silicon wafer texture liquid provided by the invention has relatively high reaction speed, moderate corrosion, low thinning amount and high repeating utilization factor; the prepared textured pyramid has a uniform size and relatively small granules; in addition, the product quality is high in stability; the product is high in uniformities among different batches; and the rate of finished products is high.

Owner:CHINALAND SOLAR ENERGY

Method for determining fillet radiuses of spinning rollers during spinning of tubular part by three spinning rollers

ActiveCN112756463AImprove appearance qualityReduced apparent qualityComplex mathematical operationsSpinningMetallic materials

The invention relates to a method for determining the fillet radiuses of spinning rollers during spinning of a tubular part by three spinning rollers. By comprehensively considering the influence rules of the diameter D of the tubular part, the initial wall thickness t0 of a spinning blank, the pass reduction amount delta t, the type and strength of metal materials, the rigidity of a spinning machine, the number of spinning rollers, spinning core mold parameters, a cooling mode and the flow of cooling liquid on the spinning forming precision of the three spinning rollers of the tubular part, the calculation method determines the fillet radiuses of the spinning rollers during three-spinning-roller spinning of the tubular part, and provides a basis for calculation and selection of the fillet radiuses of the spinning rollers of the high-precision thin-wall tubular part during three-spinning-roller spinning. The method is used for guiding the actual production and machining process, conveniently and rapidly setting the fillet radius parameters of the spinning rollers and stably forming a high-precision tubular spinning structural part, and has high machining precision and stability.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

Rare earth-itaconic acid monocrystalline silicon solar cell surface texture liquid and preparation method thereof

InactiveCN105977345AGood quality and stabilityReduce excessive corrosionAfter-treatment detailsFinal product manufactureCerium nitrateRare earth

The invention discloses a rare earth-itaconic acid monocrystalline silicon solar cell surface texture liquid. The texture liquid is prepared from the following raw materials in parts by weight: 0.1-0.2 of itaconic acid, 0.05-0.1 of cerium nitrate, 1.5-2.5 of styrene, 1-2 of 5-10% ammonium persulfate solution, 10 0.1-0.15 of emulsifier OP, 0.1-0.2 of sodium dodecyl sulfate, 0.1-0.15 of dodecafluoroheptyl-propyl-trimethoxysilane, 3-5 of sodium hydroxide, 0.3-0.5 of citric acid, 0.05-0.1 of hydroxyl propyl methylcellulose, and 100-120 of water. According to the invention, the silicon chip texture liquid has moderate corrosion, small thinning amount, stable properties, high repetition utilization rate, has even sized suede pyramids, small granular, rapid reaction speed, excellent quality stability, and excellent product uniformity.

Owner:CHINALAND SOLAR ENERGY

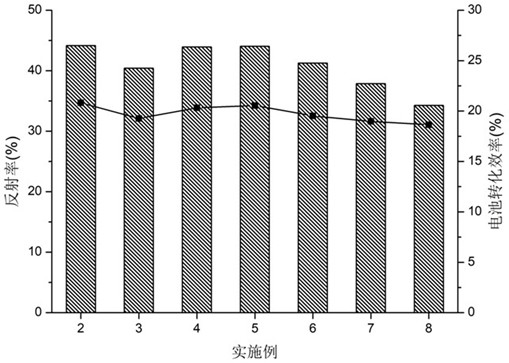

Alkali etching and polishing method for monocrystalline silicon wafer

ActiveCN113980580ASmall amount of thinningPromote absorptionOrganic compound preparationTransportation and packagingActive agentGlycerol

The invention provides an alkali etching and polishing method for a monocrystalline silicon wafer and belongs to the technical field of silicon wafer etching. According to the method, an alkaline polishing solution containing grinding particles, glycerol, an organic amine compound, sodium tartrate, a fluorine-containing nonionic surfactant and sodium tartrate is utilized to perform etching and polishing on monocrystalline silicon through the steps of surface pretreatment, surface etching and polishing, alkali cleaning, acid cleaning, water washing and the like, etching and polishing at the low temperature are achieved, energy consumption is reduced, the etching and polishing effect is good, the silicon wafer thinning amount is low, and the silicon wafer surface reflectivity and the battery conversion efficiency are effectively improved.

Owner:绍兴拓邦新能源股份有限公司

A rail vehicle side wall automatic wire drawing system and wire drawing process

ActiveCN106181593BHigh flexibility and intelligenceRealize wire drawingGripping headsBelt grinding machinesElectronic systemsControl system

The invention provides an automatic wire drawing system for the side wall of a rail vehicle. The system includes a central control system, a robot, a wire drawing device, a track, a laser measurement system, off-line programming software and an electric control system, and automatically completes the wire drawing operation of the side wall of the car body. ; The present invention also provides a process method that can use the system to carry out wire drawing operations. The invention provides an automatic wire drawing system and a wire drawing process for the side wall of a rail vehicle, which can realize automatic, flexible and intelligent wire drawing operations, automatically adapt to changes in the surface shape of the workpiece within a certain range, and always maintain a constant normal wire drawing force to achieve the best Brushed effect.

Owner:CRRC QINGDAO SIFANG CO LTD

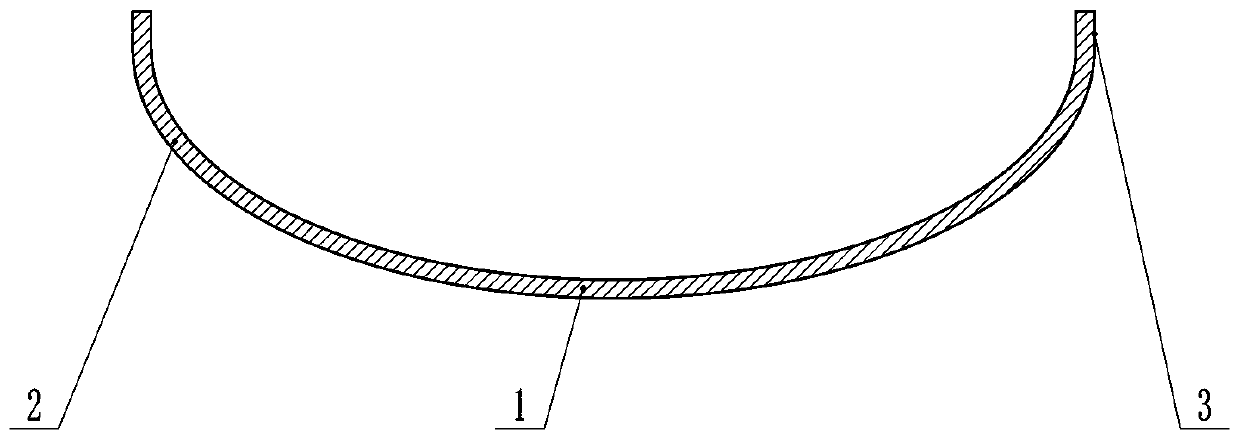

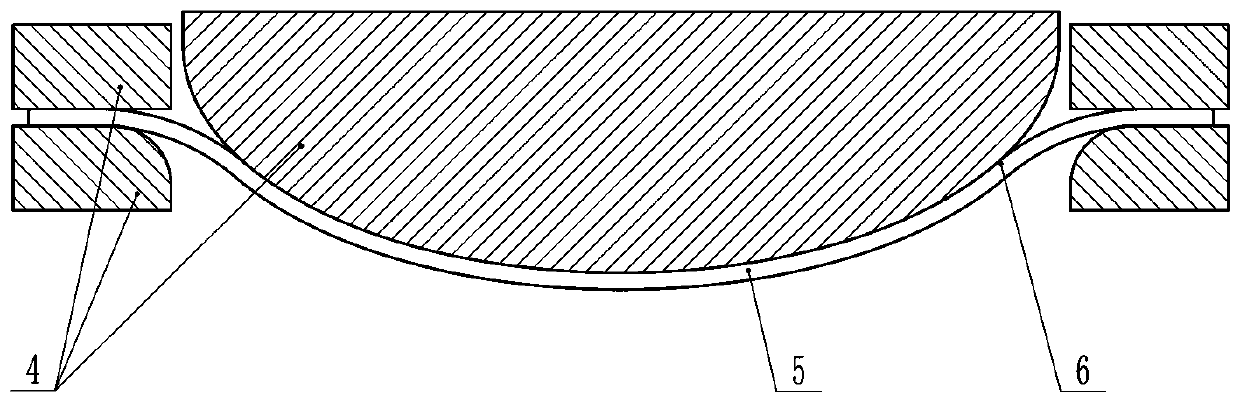

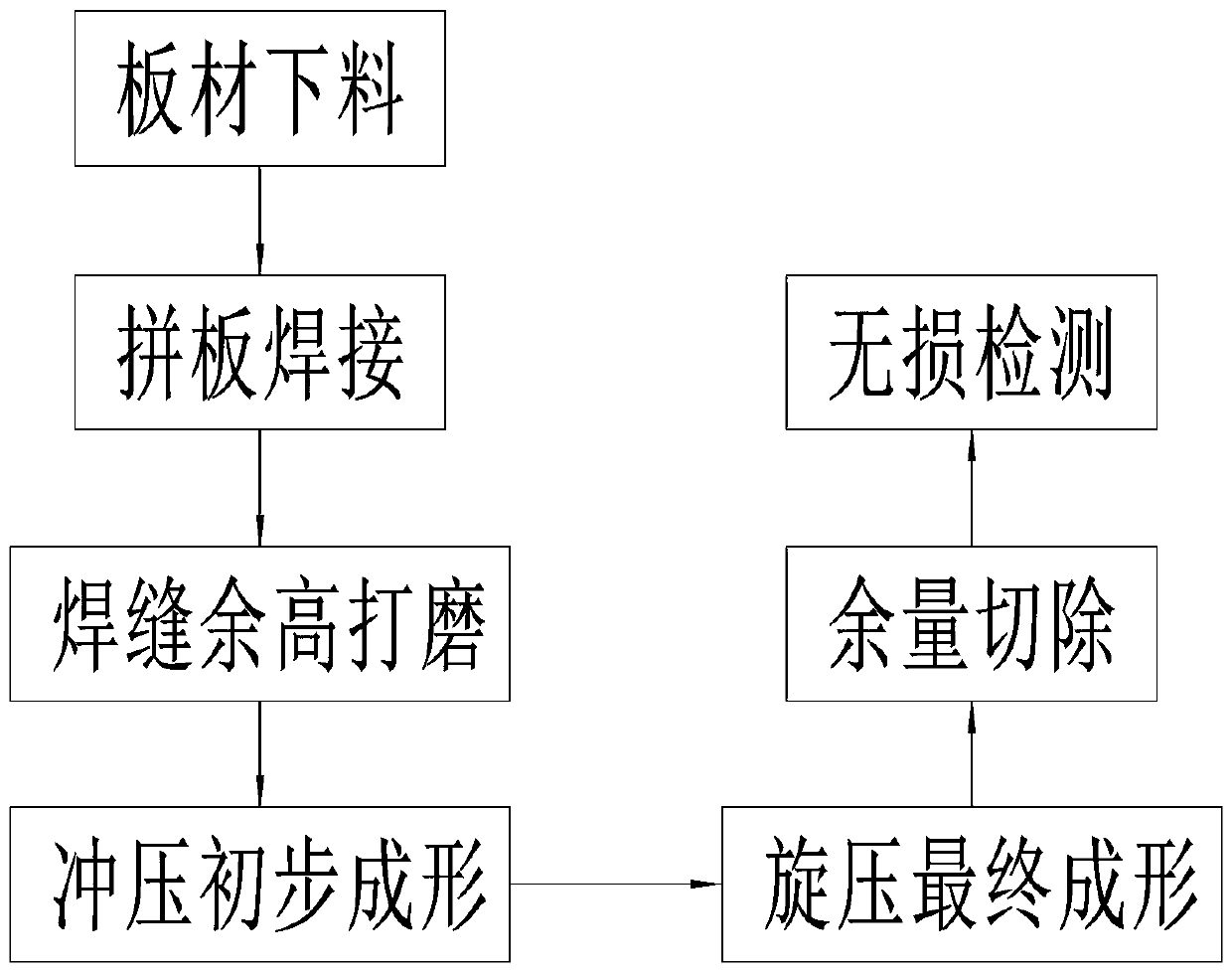

Production process of elliptical head or dish-shaped head

The invention provides a production process of an elliptical head or a dish-shaped head. The production process comprises the following steps: (a) preparing a planar plate to be processed according tothe size of the head to be formed; (b) selecting a stamping die with the radius close to that of a gentle arc section at the bottom of the elliptical head or the dish-shaped head, placing the planarplate on the stamping die, and stamping to form a primarily formed plate after the centers are aligned; (c) selecting a spinning die matched with the radius of a sharp turn arc section in the middle of the elliptical head or the dish-shaped head, aligning the center of the forming position of the primarily formed plate with the center of a working turntable of an edge folding machine, starting theedge folding machine, and forming the part above the forming position of the primarily formed plate to form a primarily formed head; and (d) cutting off the part, higher than a product net material,of the top of the primarily formed head to obtain the finished head. The production process of the elliptical head or the dish-shaped head has the advantages of no need of special dies, high operability, high production efficiency, reduction of hardening of the head and low thinning amount.

Owner:HENAN SHENZHOU PRECISION MFG CO LTD

Behenyl alcohol - sodium lignin sulfonate surface texture liquid of monocrystalline silicon solar cell and preparation method thereof

InactiveCN106087069AGood response controllabilityReduce excessive corrosionAfter-treatment detailsPhotovoltaic energy generationSilicon solar cellControllability

The invention discloses a behenyl alcohol - sodium lignin sulfonate surface texture liquid of a monocrystalline silicon solar cell. The behenyl alcohol - sodium lignin sulfonate surface texture liquid is prepared from the following raw materials in parts by weight: 0.1 to 0.15 part of behenyl alcohol, 0.1 to 0.15 part of sodium lignin sulfonate, 1.5 to 2.5 parts of styrene, 1 to 2 parts of 5-10% ammonium persulfate solution, 0.1 to 0.2 part of lauryl sodium sulfate, 0.1 to 0.15 part of dodecafluoroheptyl-propyl-trimethoxysilane, 0.1 to 0.2 part of triethanolamine, 3 to 5 parts of sodium hydroxide, 0.3 to 0.5 part of citric acid, 0.05 to 0.1 part of phosphoricacidethylhexylester, and 100 to 120 parts of water. The behenyl alcohol - sodium lignin sulfonate surface texture liquid has the advantages that the reaction speed is higher, the corrosion is moderate, the thinning amount is little, the repeated utilization rate is high, the prepared suede pyramid has uniform size, the particle size is small, the reaction controllability is good, and the surface quality of a silicon chip is high.

Owner:CHINALAND SOLAR ENERGY

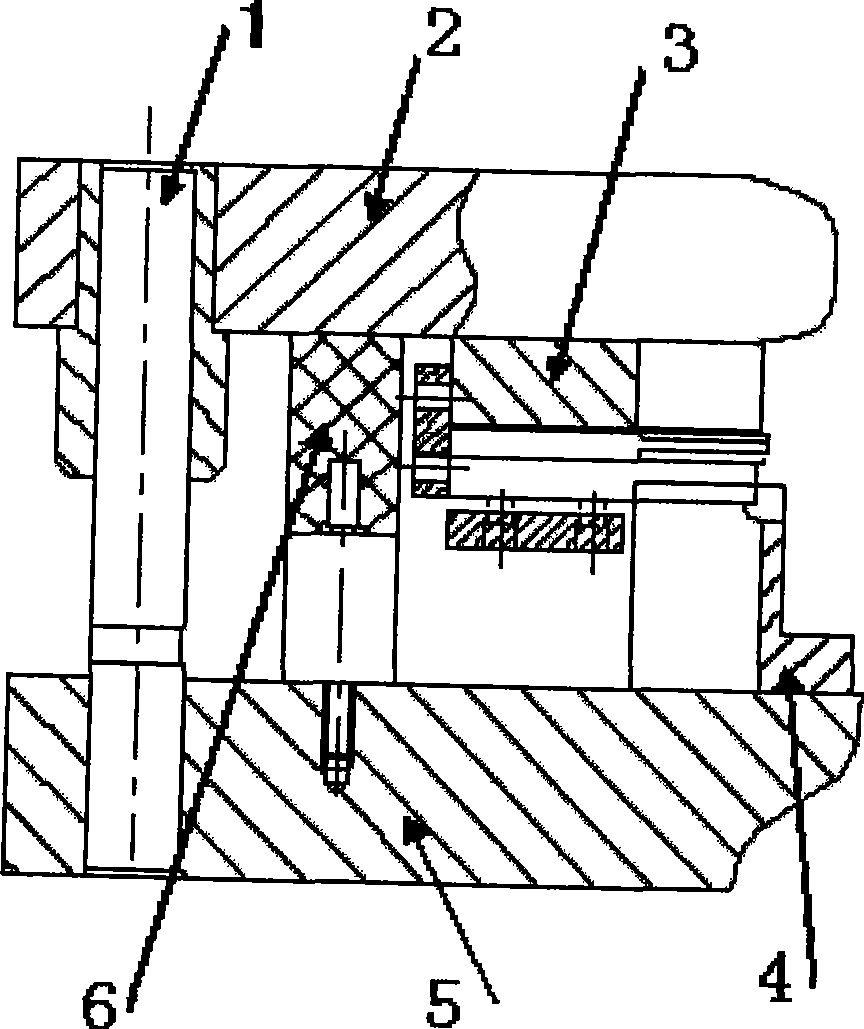

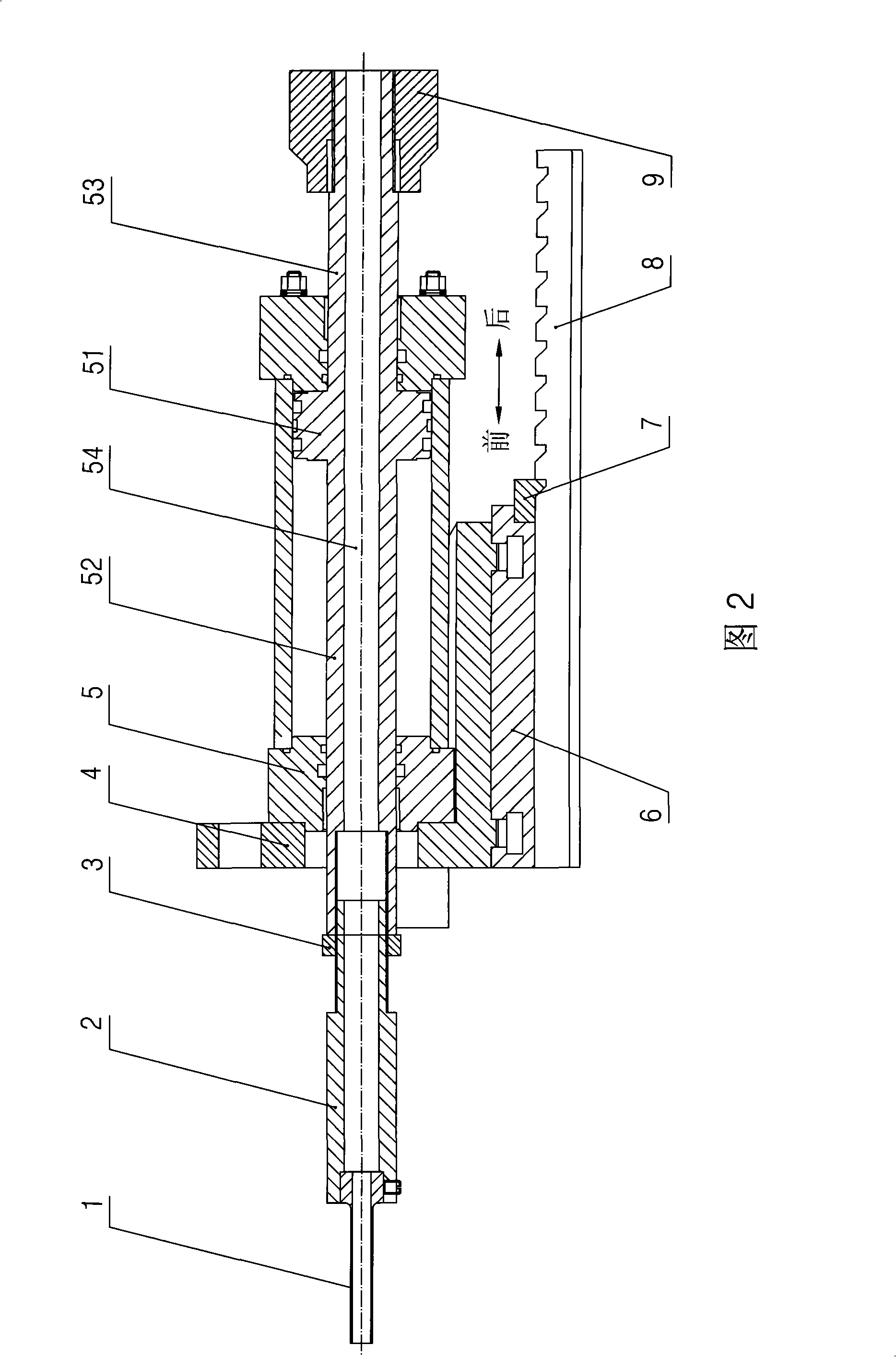

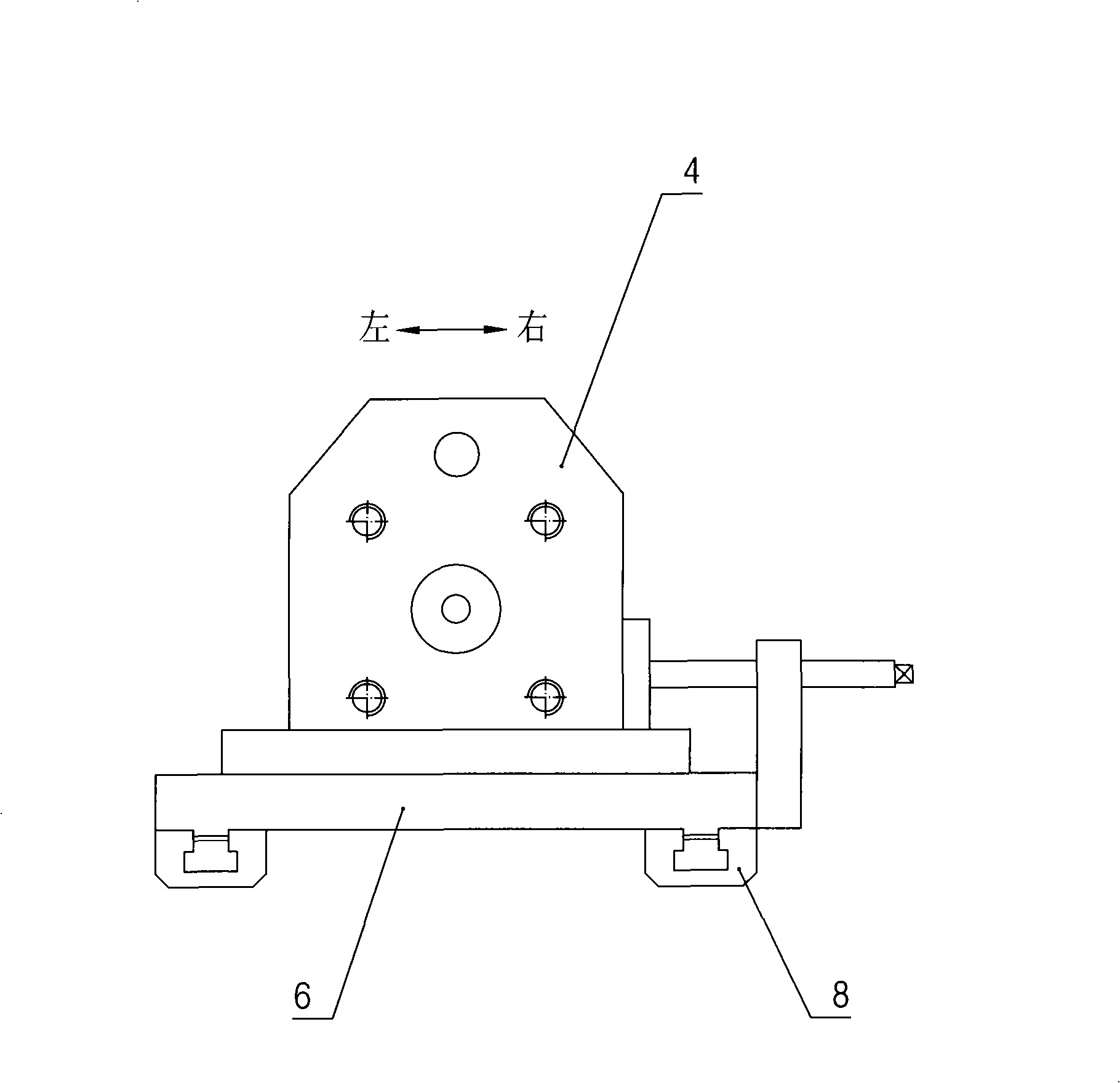

Top pulling device in pipe bender

The invention discloses a pushing device in a pipe bending machine, which can cause the pipe bending machine to bend short pipes; the pushing device comprises a pushing pipe, an oil cylinder base and a dual-outlet type pushing oil cylinder which is arranged on the oil cylinder base; a piston of the pushing oil cylinder and piston rods which are arranged at the left side and the right side of the piston are provided with perforated operation holes; the end part of the piston rod at the left side is provided with the pushing pipe; the internal hole of the pushing pipe is communicated with the operation hole; the end part of the piston rod at the right side is provided with a position limit nut by a thread; the oil cylinder base is movably arranged on a sliding plate which is movably arranged on a rack; the rack is provided with a positioning tooth; the side part of one side of the positioning tooth is embedded in the positioning concave trough of the sliding plate. A pushing connecting pipe with a hollow structure is also arranged between the pushing pipe and the piston rod. The pipe bending machine installed with the pushing device of the invention can be used for processing the short pipes, especially for the short pipes with the bending radius which is equal to or less than 1.5 times of the external diameter of the pipe.

Owner:JIANGSU HEFENG MECHANICAL MAKING

Preparation method of heterojunction battery

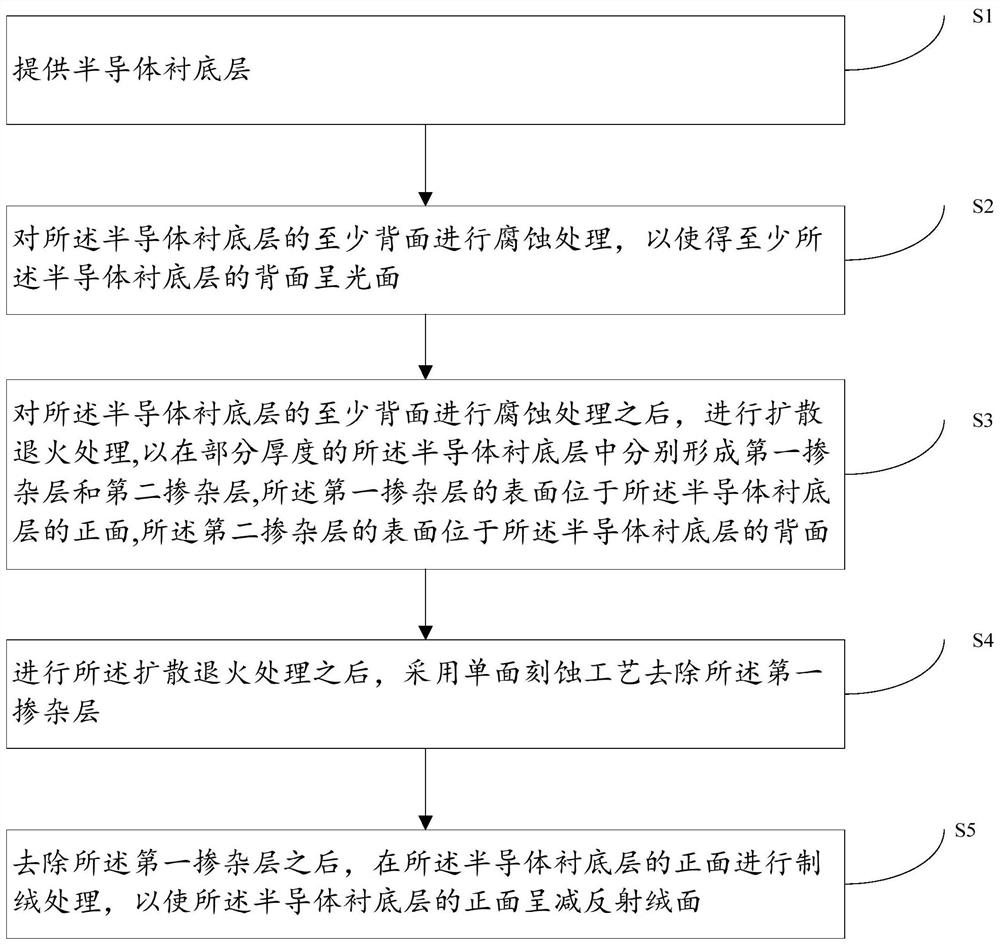

PendingCN113675300AReduce the amount of reflectionIncrease the optical pathFinal product manufacturePhotovoltaic energy generationHeterojunctionEtching

A preparation method of a heterojunction battery comprises the following steps of providing a semiconductor substrate layer, carrying out corrosion treatment on at least the back surface of the semiconductor substrate layer so as to enable at least the back surface of the semiconductor substrate layer to be a smooth surface, after at least the back surface of the semiconductor substrate layer is subjected to corrosion treatment, conducting diffusion annealing treatment, so that a first doping layer and a second doping layer are respectively formed in the semiconductor substrate layer with partial thickness, the surface of the first doping layer is located on the front surface of the semiconductor substrate layer, and the surface of the second doping layer is positioned on the back surface of the semiconductor substrate layer, after the diffusion annealing treatment is carried out, adopting a single-side etching process to remove the first doping layer, and after the first doping layer is removed, conducting texturing processing on the front surface of the semiconductor substrate layer, so that the front surface of the semiconductor substrate layer is an antireflection textured surface. According to the method, the distribution trailing of the photoelectric conversion efficiency of the heterojunction cell is avoided, and the cost is reduced.

Owner:宣城睿晖宣晟企业管理中心合伙企业(有限合伙)

A kind of single crystal silicon chip pre-cleaning liquid and cleaning method thereof

ActiveCN103087850BReduce concentrationReduce Fragmentation RateInorganic non-surface-active detergent compositionsCleaning using liquidsPotassium hydroxideSingle crystal

Owner:徐州鑫宇光伏科技有限公司 +1

Pushing-type predeformation hydraulic cold roll forming mill

InactiveCN104368651AGuaranteed levelnessSolve the problem that the horizontal concentricity is difficult to control accuratelyMetal-working feeding devicesMetal working apparatusRoll formingEngineering

The invention discloses a pushing-type predeformation hydraulic cold roll forming mill comprising a workbench, a predeformation jacking machine head and two positioning rollers. The predeformation jacking machine head capable of moving front and back is arranged on the central axis of the workbench, the two positioning rollers are arranged on two sides of the central axis symmetrically, and the positions of the positioning rollers on the workbench are located on two sides of the front of the predeformation jacking machine head. A hydraulic pushing rod is hinged to the rear end of the predeformation jacking machine head through a connecting shaft, and the hydraulic pushing rod is connected with a hydraulic driving device. A graduated scale is fixed to the top of the connecting shaft. The predeformation jacking machine head moves on the workbench forwards and backwards through sliding rails arranged at the bottom. Each positioning roller fixing platform is provided with a horizontal positioning bracket on one side in the direction of the predeformation jacking machine head. The pushing-type predeformation hydraulic cold roll forming mill is simple to operate, high in efficiency, accurate in horizontal concentricity positioning, effective in deformation control and adaptable to production requirements of small-bore cold bends in engineering construction.

Owner:中石化胜利油建工程有限公司

Ultrathin silicon solar cell and preparation method thereof

ActiveCN110444616AReduce lossSmall amount of thinningFinal product manufactureNanotechnologyInverted pyramidSilicon solar cell

The invention relates to an ultrathin silicon solar cell and a preparation method thereof. The ultrathin silicon solar cell employs a random nanometer inverted pyramid as a surface anti-reflection structure, a titanium oxide thin film deposited by an atomic layer and a TCO thin film modified by low-work function ultrathin metal are respectively used as an electron transmission layer and an upper electrode, and a back field with small thermal stress and an back electrode is built through depositing a metal aluminum thin film by magnetron sputtering and combining subsequent low-temperature annealing. The ultrathin silicon solar cell has the advantages that the cell structure is simple, and no warping phenomenon is generated; and compared with a traditional high-temperature thermal diffusionprocess, the low-temperature process has the advantages that the operation difficulty of cell preparation can be greatly reduced, the debris rate of the cell is reduced, and the low-temperature process is an ultrathin crystal silicon battery preparation technology having potential application.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Single crystalline silicon solar cell piece surface texture solution containing pomegranate bark extract and preparation method thereof

InactiveCN106012029AGood processing qualityGood process quality and stabilityAfter-treatment detailsFinal product manufacturePolyphenolSodium hydroxide

The invention discloses a single crystalline silicon solar cell piece surface texture solution containing a pomegranate bark extract. The single crystalline silicon solar cell piece surface texture solution is prepared from, by weight, 0.1-0.2 part of xylitol, 1.5-2.5 parts of styrene, 1-2 parts of a 5-10% ammonium persulfate solution, 3-5 parts of pomegranate bark powder, 0.1-0.15 part of cocoanut fatty acid diethanolamide, 0.1-0.2 part of sodium lauryl sulfate, 0.1-0.15 part of dodecafluoroheptyl-propyl-trimethoxysilane, 3-5 parts of sodium hydroxide, 0.3-0.5 part of citric acid, 0.05-0.1 part of tea polyphenol and 100-120 parts of water. The silicon slice texture solution is high in reaction speed, moderate in corrosion, small in thickness reduction and high in repeated utilization factor, the obtained texture pyramid is uniform in size, granules are small, the repeatability is good, and the single crystalline silicon solar cell piece surface texture solution is good in technological processing quality stability, high repeatability, low in cost and environmentally friendly.

Owner:CHINALAND SOLAR ENERGY

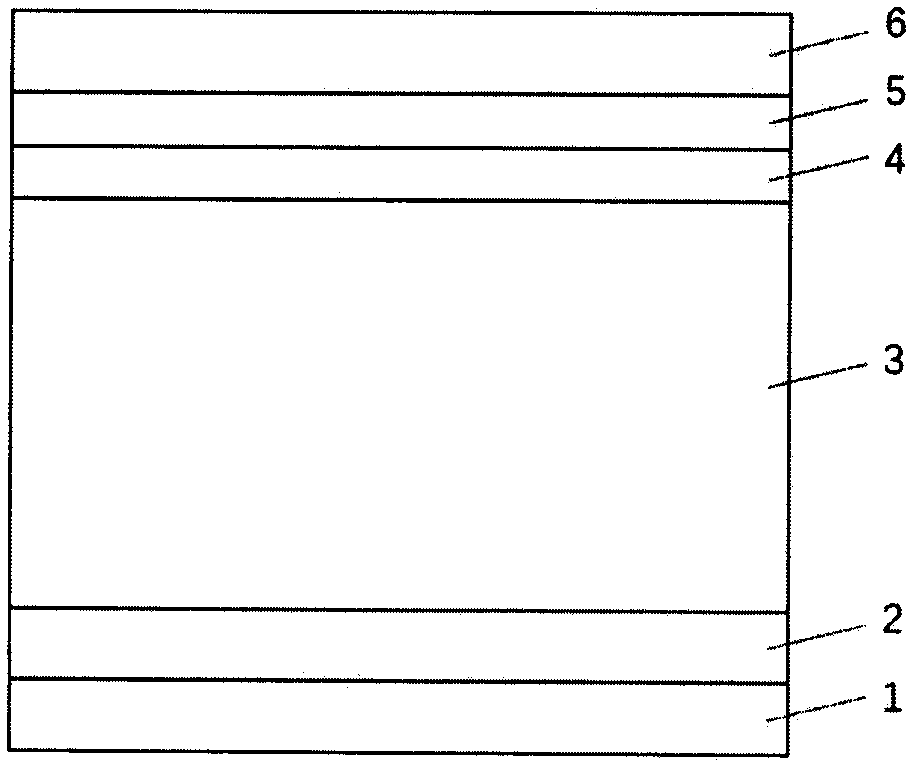

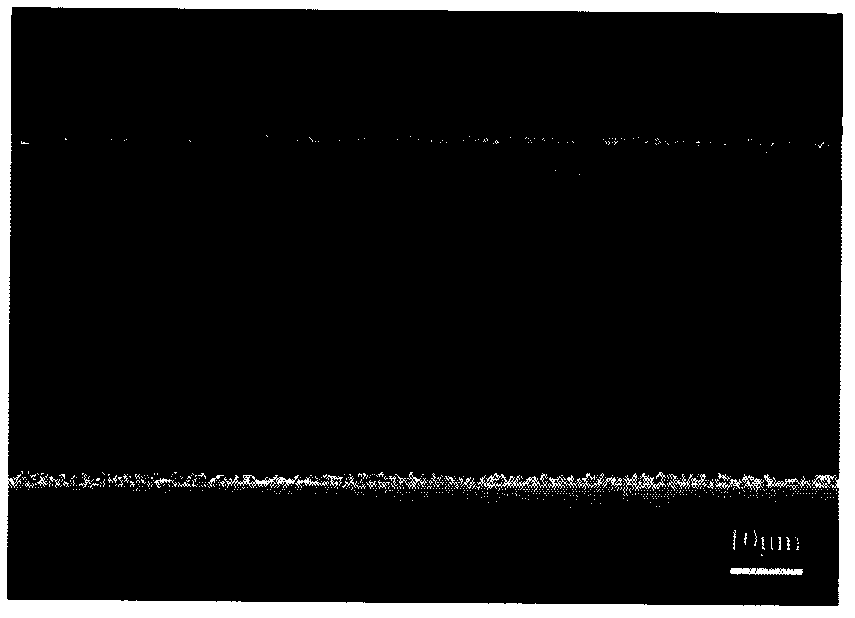

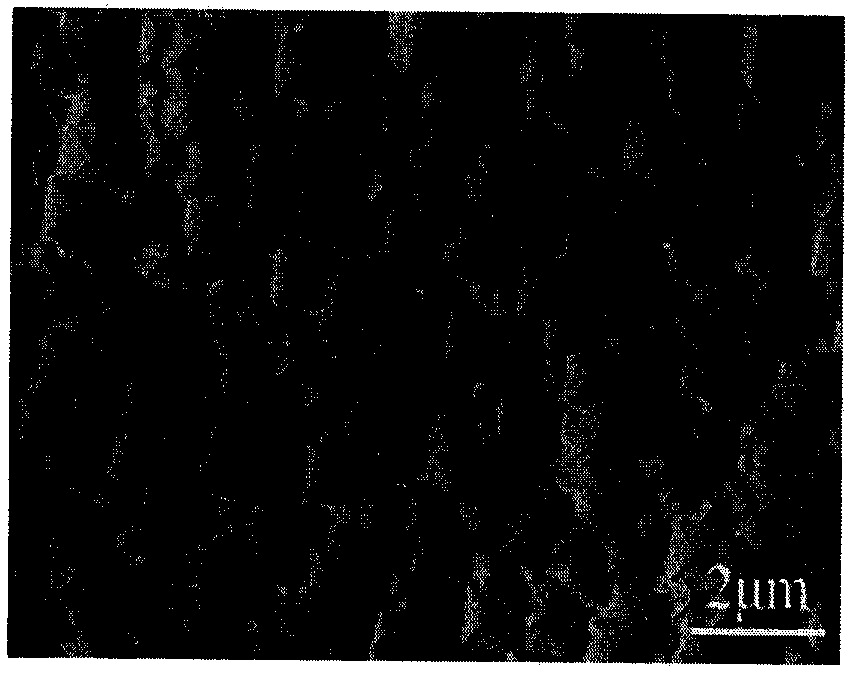

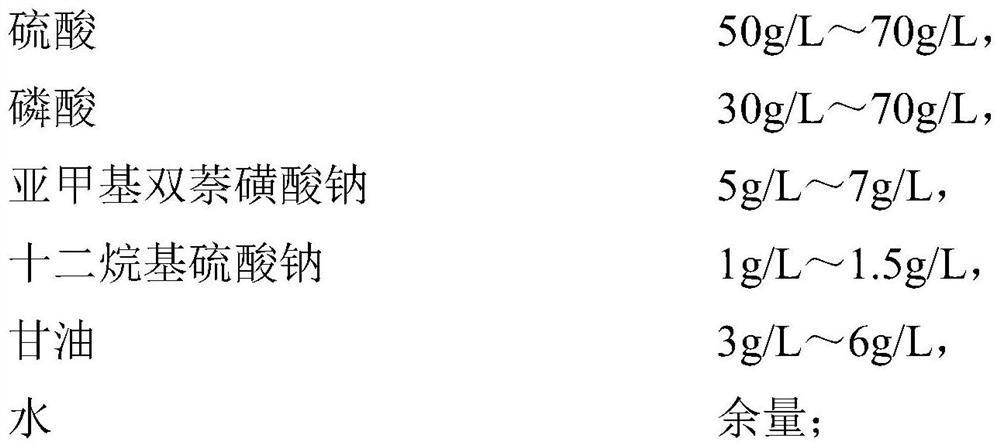

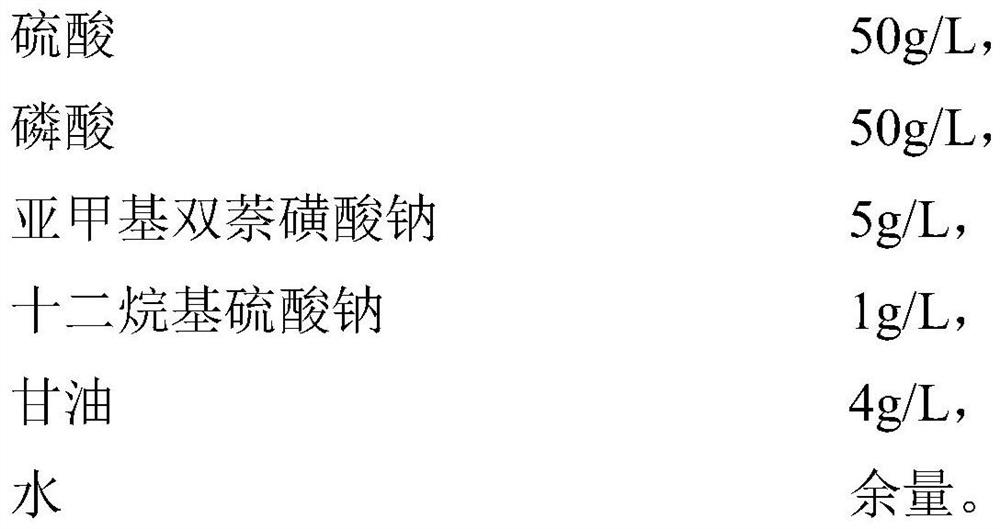

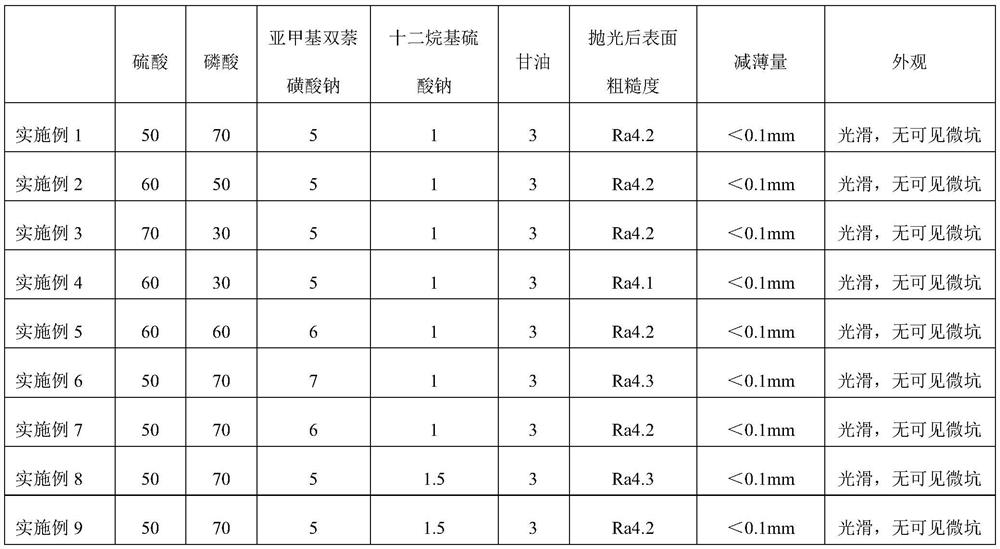

A kind of superalloy chemical polishing agent and preparation method thereof

The invention relates to a high-temperature alloy chemical polishing agent and a preparation method thereof, and belongs to the technical field of high-temperature alloy treatment. The polishing agentcomprises the components of 50 g / L to 70 g / L of sulfuric acid, 30 g / L to 70 g / L of phosphoric acid, 5 g / L to 7 g / L of sodium methylene bis-naphthalene sulfonate, 1 g / L to 1.5 g / L of sodium dodecyl sulfate, 3 g / L to 6 g / L of glycerinum, and the balance being water. The preparation method comprises the steps that phosphoric acid and sulfuric acid are mixed and are fully stirred, the temperature isdecreased to the room temperature, and a component A is obtained; sodium methylene bis-naphthalene sulfonate, sodium dodecyl sulfate and glycerinum are added into water, and a component is obtained after stirring; the component A is added into the component B, the components are fully stirred, and the polishing agent is obtained. According to the high-temperature alloy chemical polishing agent andthe preparation method thereof, the polishing agent does not contain nitric acid and hydrochloric acid, less volatile harmful gases are generated during operation, stability is good, environmental pollution is low, and surface quality of a polished high-temperature alloy is high; and in the method, the situations that during mixing, the temperature of the polishing agent is increased as sulfuricacid releases heat, and harmful gases are generated due to decomposition of nitric acid are avoided.

Owner:BEIJING POWER MACHINERY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com