Production process of elliptical head or dish-shaped head

A disc-shaped head and elliptical head technology, which is applied in the field of head production technology, can solve the problems of increasing the number of molds, large operable space, and small operable space, and achieves reduced hardening, high operability, and thinner low volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

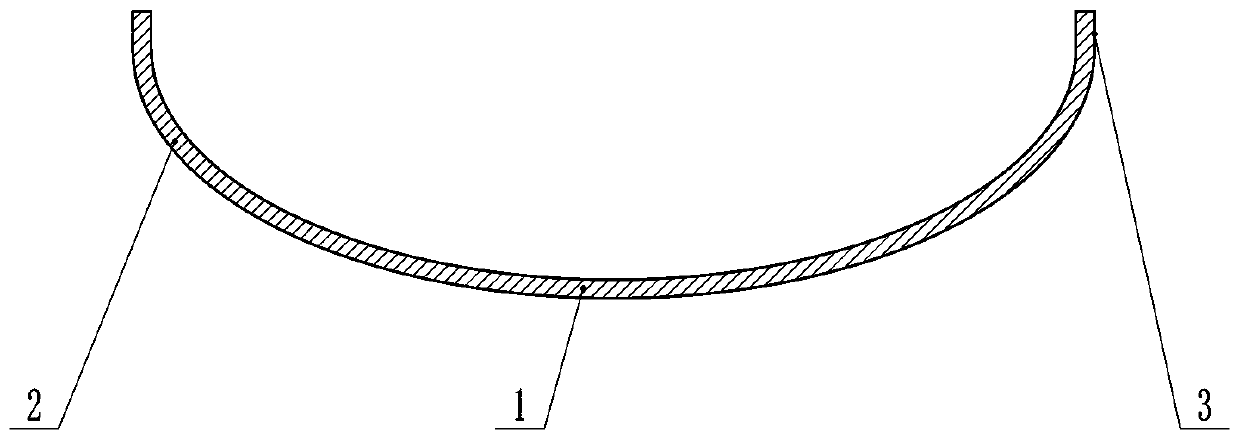

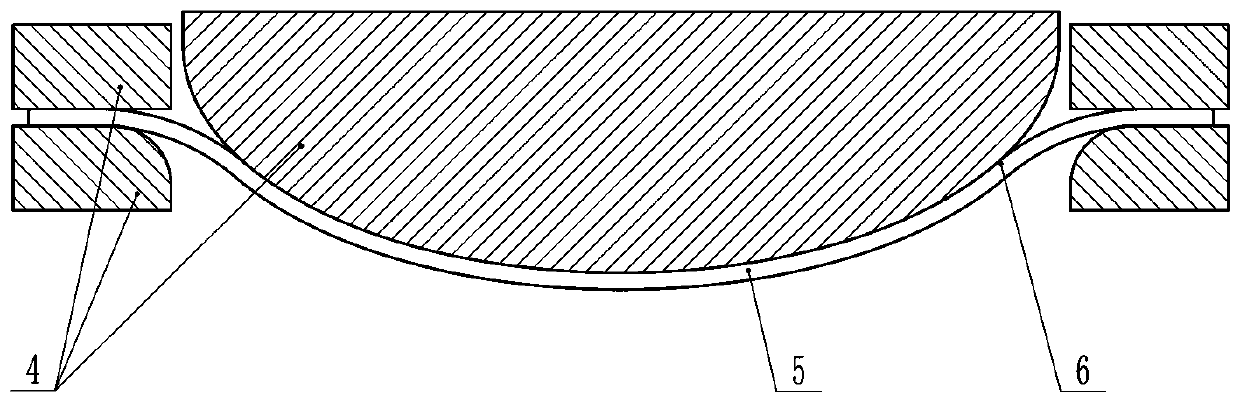

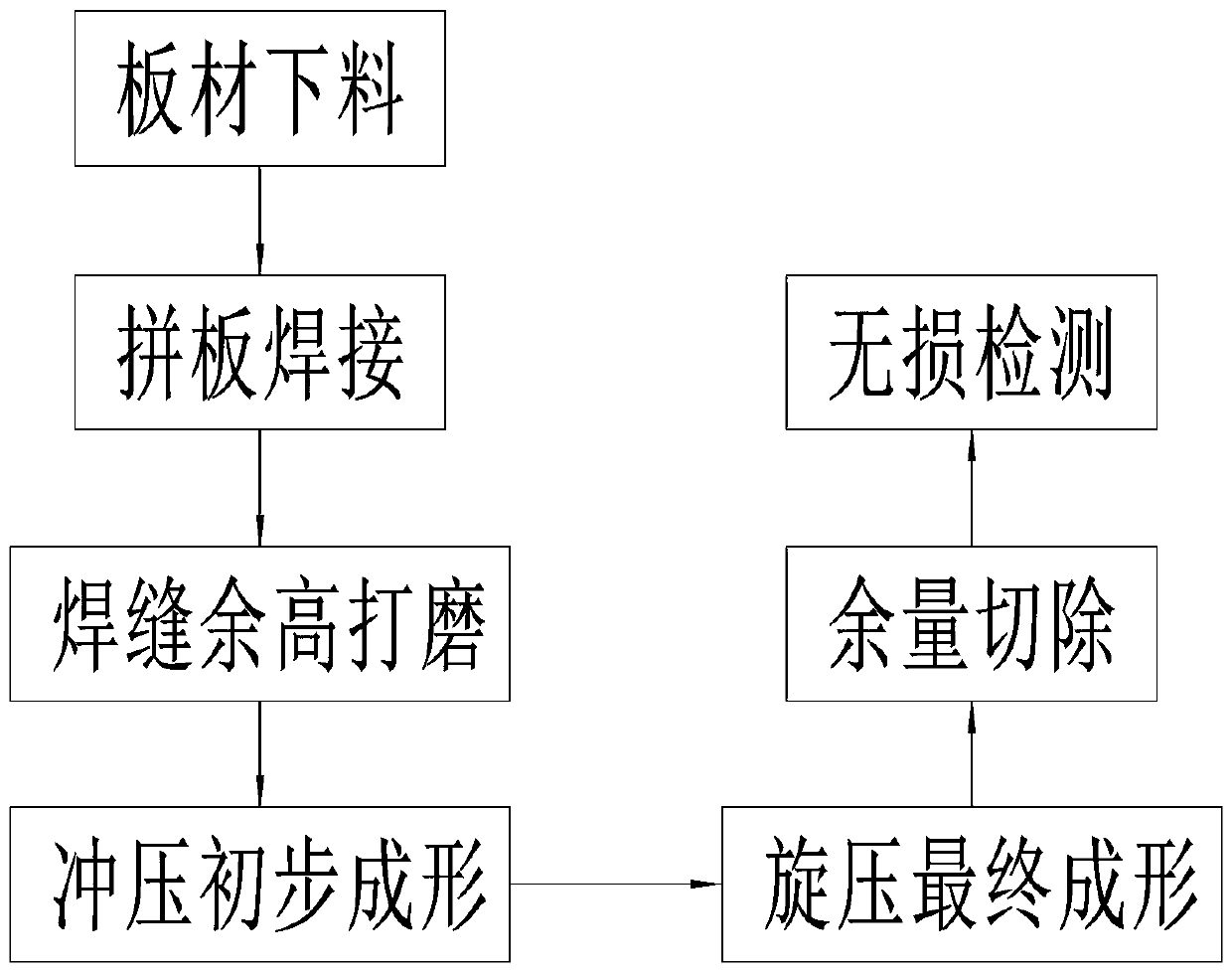

[0019] Such as Figure 1-3 As shown, a production process of an elliptical head and a dished head comprises the following steps:

[0020] (1) Plate cutting: according to the size of the head to be formed, determine the shape and size of the planar plates to be prepared, and cut out a number of plates to be spliced for splicing the planar plates from the raw plates;

[0021] (2) Panel welding: select the corresponding welding process according to the different materials and thickness of the product, and weld multiple panels to be spliced together;

[0022] (3) Grinding of weld reinforcement: Grinding and polishing the weld to obtain the flat plate for use. When grinding, first use a grinding wheel to quickly grind the weld so that the weld reinforcement is between 0-0.5mm, and then use polishing With careful polishing, the welding se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com