Texture surface making treatment method for silicon wafer

A processing method and technology of silicon wafers, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of reducing production efficiency and achieve the effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

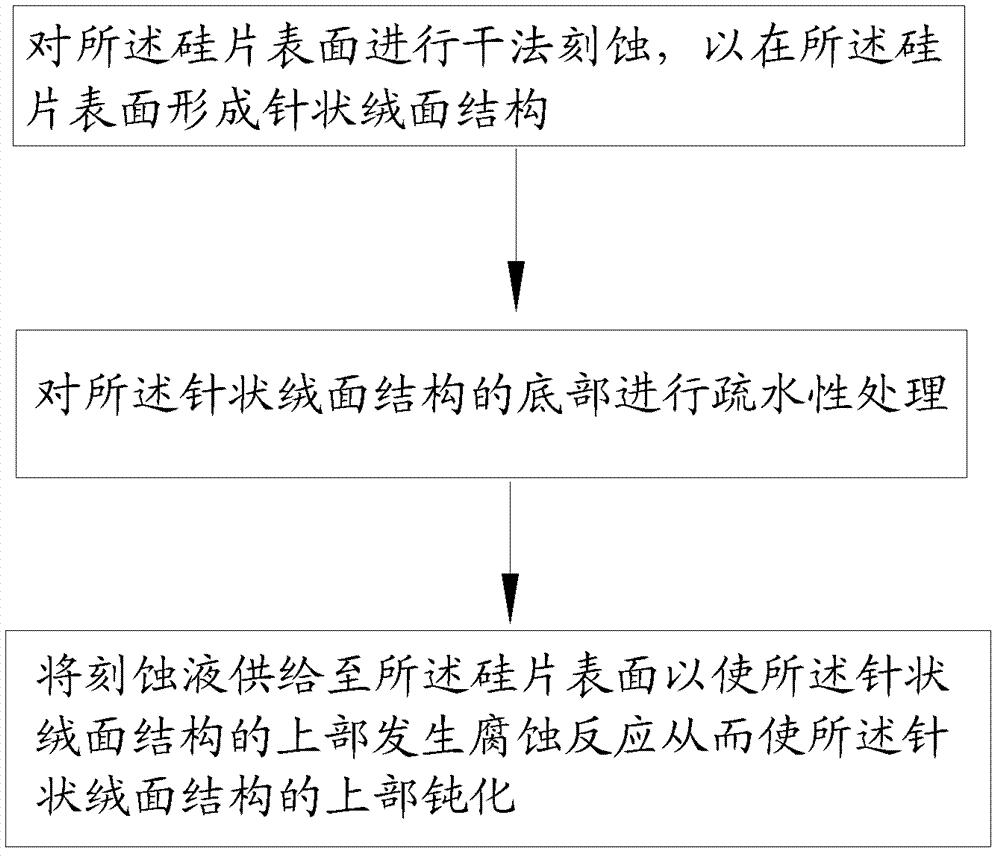

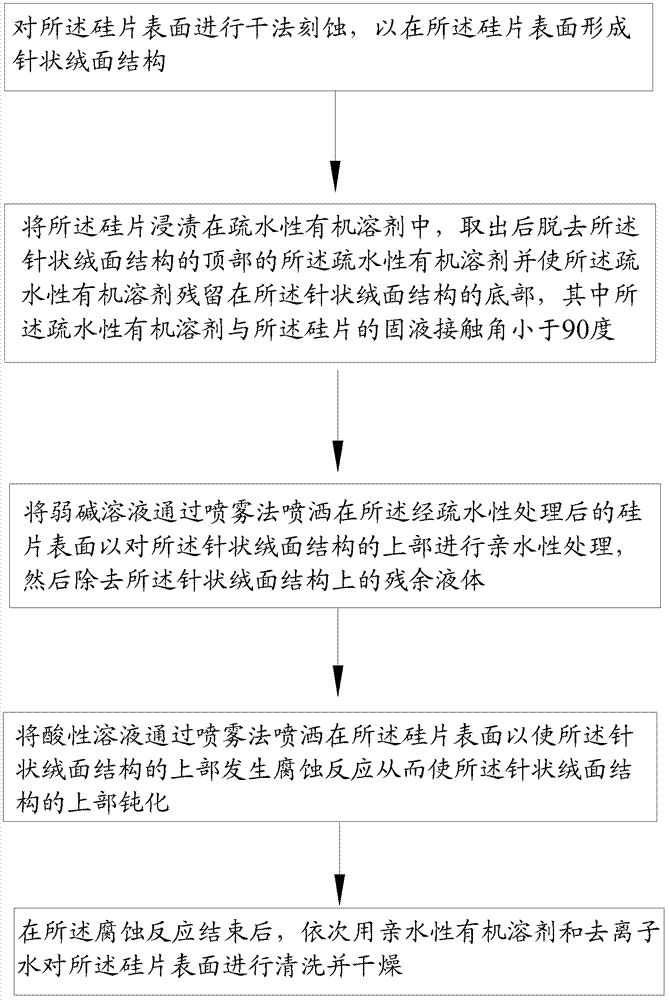

Method used

Image

Examples

example 1

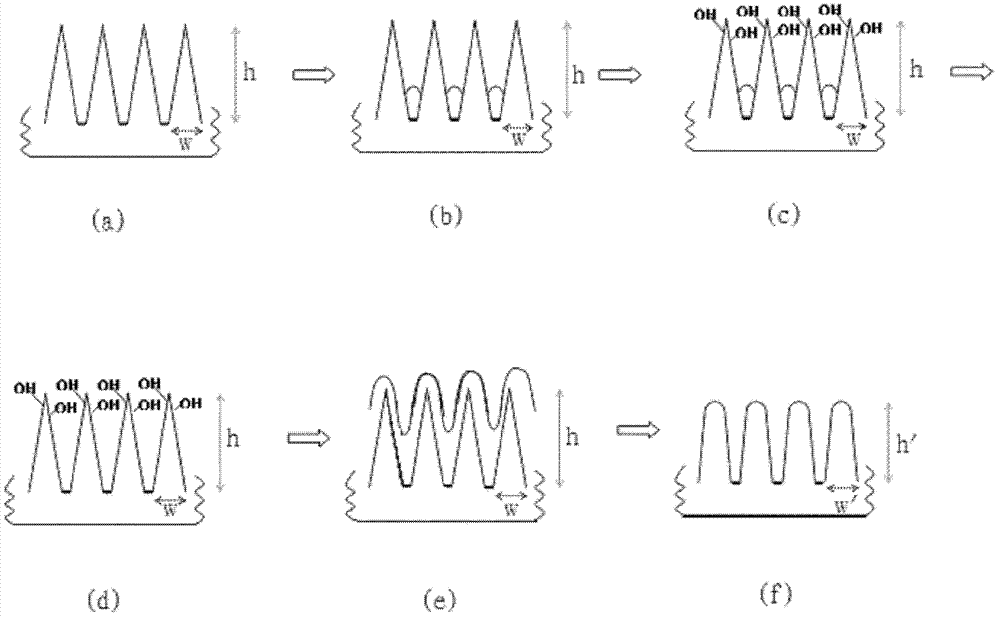

[0074] 1) Use Cl 2 , SF 6 , O 2 , Ar and other gases to etch the surface of the silicon wafer. At the same time, the ratio of various gases can be controlled, such as image 3 As shown in (a), an acicular suede structure with a depth h of 1 μm and a width w of 0.3 μm is formed, and the apex of the acicular suede is sharp.

[0075] 2) Hydrophobic treatment is performed on the bottom of the needle-like suede structure.

[0076] Next, the silicon wafer is immersed in hexane, and after taking it out, it is centrifugally dried at a speed below 1500RPM, such as image 3 As shown in (b), hexane remains at the bottom of the needle-like suede structure.

[0077] 3) supplying an etchant to the surface of the silicon wafer to cause a corrosion reaction on the upper portion of the needle-shaped textured structure to passivate the upper portion of the needle-shaped textured structure.

[0078] Firstly, the mixed solution of ammonia water and hydrogen peroxide is sprayed on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com