A carbon dioxide coalbed methane vibration anti-reflection device

A carbon dioxide and liquid carbon dioxide technology, which is applied in wellbore/well components, production fluids, earthwork drilling, etc., can solve the problems of time-consuming and laborious gas drainage effect, inability to perform oscillation treatment, adverse effects of gas release, etc., and achieve easy filling. Connection port and conduit pipe, ensure anti-reflection effect, improve the effect of vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

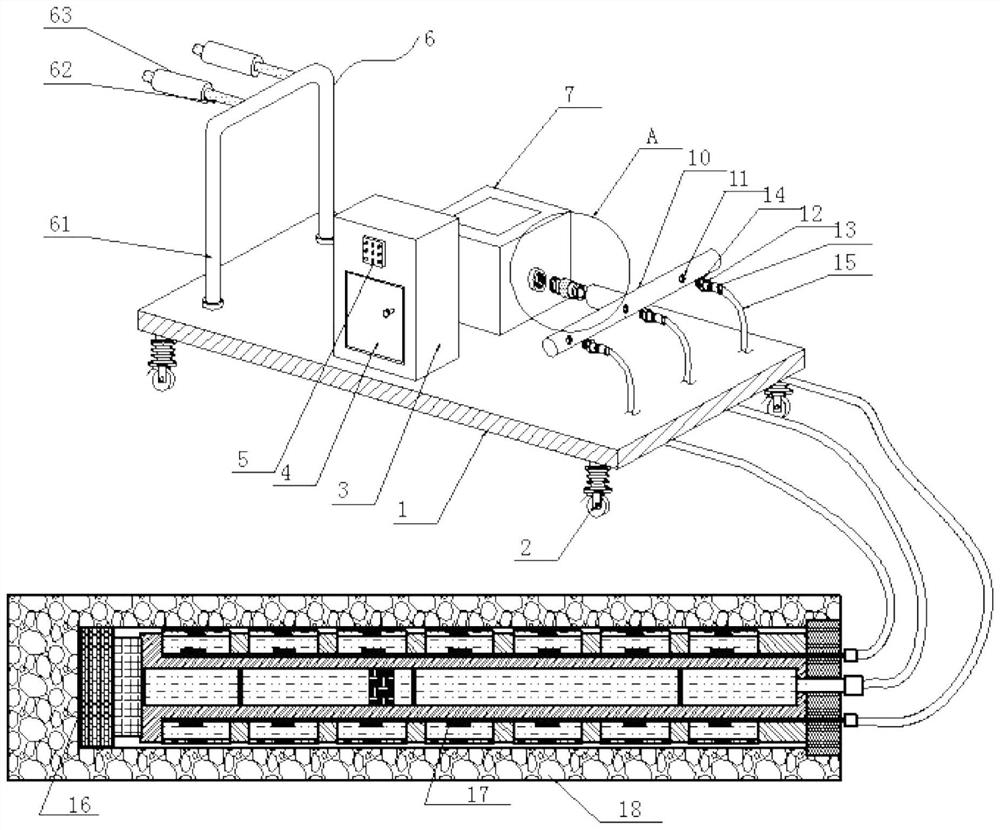

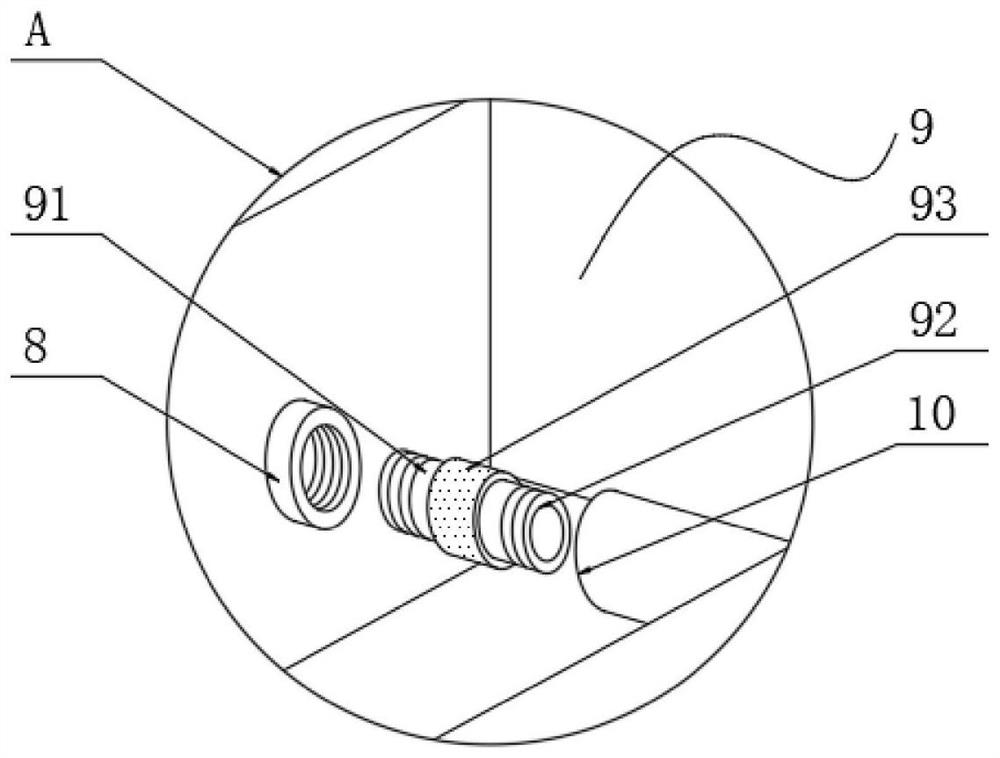

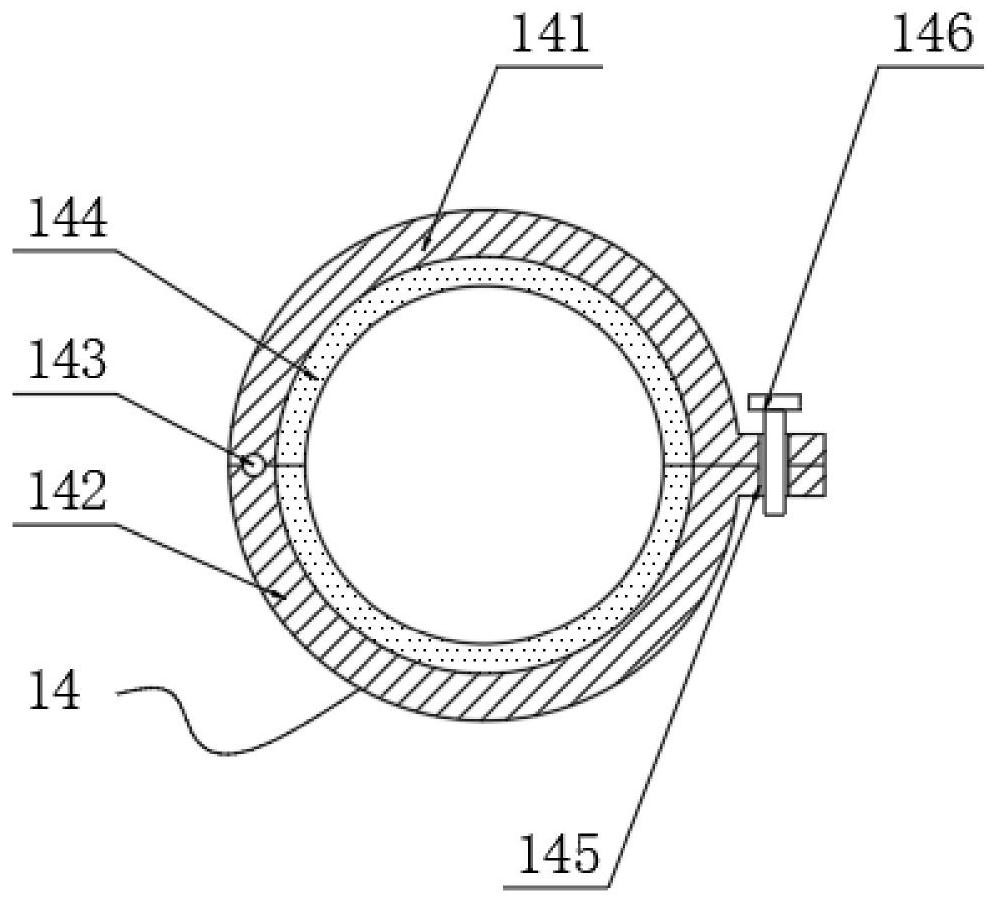

[0033] see Figures 1 to 7 In the embodiment of the present invention, a carbon dioxide coalbed methane vibration anti-reflection device includes a liquid carbon dioxide filling component, a vibrator 16 and a detonation and anti-reflection component 17, wherein the detonation and anti-reflection component 17 extends into the drill of the coal seam 18. inside the hole, and a hole sealer is used to seal the hole at the outer hole of the detonation and anti-reflection assembly 17;

[0034] The liquid carbon dioxide filling assembly is disposed on the moving assembly, and the output end of the liquid carbon dioxide filling assembly is connected to the detonation and anti-reflection assembly 17, so as to fill the detonation and anti-reflection assembly 17 with liquid carbon dioxide;

[0035]The vibrator 16 is placed at the innermost end of the borehole, and is positioned inside the detonation anti-reflection assembly 17; during the detonation anti-reflection assembly 17, the vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com