A high-efficiency anti-permeability coal method using liquid nitrogen-hot gas cooling and heating cycles

A technology of cold and heat circulation and liquid nitrogen, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve problems such as poor stability, low effective pressure and flow rate, and increasing the time required for coal seam penetration enhancement. , to achieve the effect of wide cracking area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below.

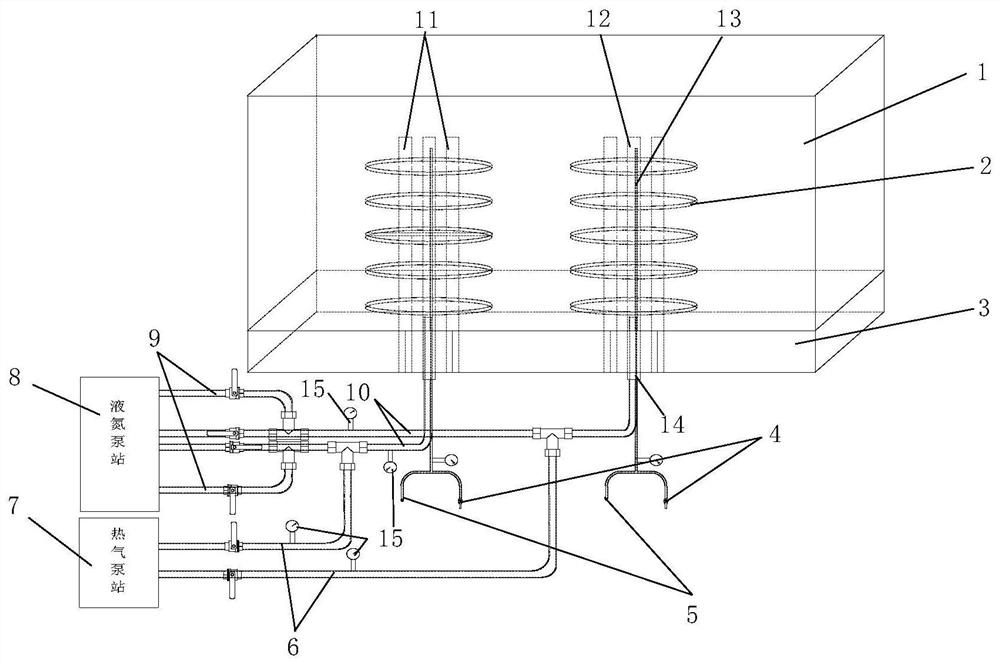

[0020] Such as figure 1 Shown, concrete steps of the present invention are:

[0021] A, set at least one layer-penetrating borehole 12 in the roadway, and the borehole passes through the rock formation 3 and extends into the coal seam 1;

[0022] B. Use hydraulic slotting equipment to extend into the seam 12 to reach the coal seam 1, and cut out a plurality of disks at equal intervals in the coal seam 1 with the seam 12 as the center along the direction perpendicular to the seam 12 crack 2;

[0023] C. Extend one end of the liquid nitrogen and hot gas delivery pipe 13 and one end of the exhaust pipe 14 into the layer-penetrating borehole 12 to reach the coal seam 1, and then connect the liquid nitrogen and hot gas delivery pipe 13 and the exhaust pipe 14 with the layer-penetration drilling 12 rock formation The other end of the exhaust pipe 14 is respectively connected to two gas pipelines through a three-way j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com