Single-side polishing process of solar monocrystalline silicon battery

A single-crystal silicon cell, single-side polishing technology, applied in polishing compositions, circuits, crystal growth and other directions, can solve the problems of too thin silicon wafers, difficult to control, large pollution in chain acid polishing, etc., without etching process. , The effect of low silicon wafer thinning and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

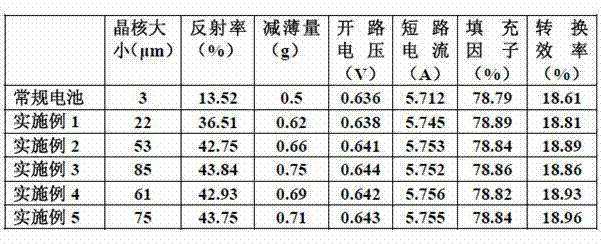

Examples

Embodiment 1

[0020] (1) Pre-process: Firstly, the monocrystalline silicon wafer is pre-cleaned in a NaOH solution with a temperature of 80°C and a mass concentration of 14% for 30 seconds to remove the damaged layer on the surface of the silicon wafer, and then wash it with pure water. Then carry out texturing in the texturing liquid to form a pyramid textured structure on the front and back of the monocrystalline silicon wafer, and wash and dry with pure water; the composition and mass percentage of each component of the texturing liquid are: 1.2% NaOH, 0.2% Na 2 SiO 3 , 3% isopropanol, the balance of water; the temperature of the texture is controlled at 80 ℃, and the time is 15min. Phosphorus is then diffused on the front of the single crystal silicon wafer to form an n-type emitter with a diffusion resistance range of 70R □ ; Clean the phosphosilicate glass on the surface of the single crystal silicon wafer with HF solution with a volume concentration of 10%, and dry it; finally, dep...

Embodiment 2

[0024] This embodiment is the same as Embodiment 1, except that the back polishing time is 10 minutes.

Embodiment 3

[0026] This embodiment is the same as Embodiment 1, except that the back polishing time is 15 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com