Light-emitting element

A light-emitting element and cladding layer technology, which is applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve the problems of lateral diffusion, the inability to increase the total luminous energy, and cumbersome procedures, etc., and achieve the effect of increasing the total luminous energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

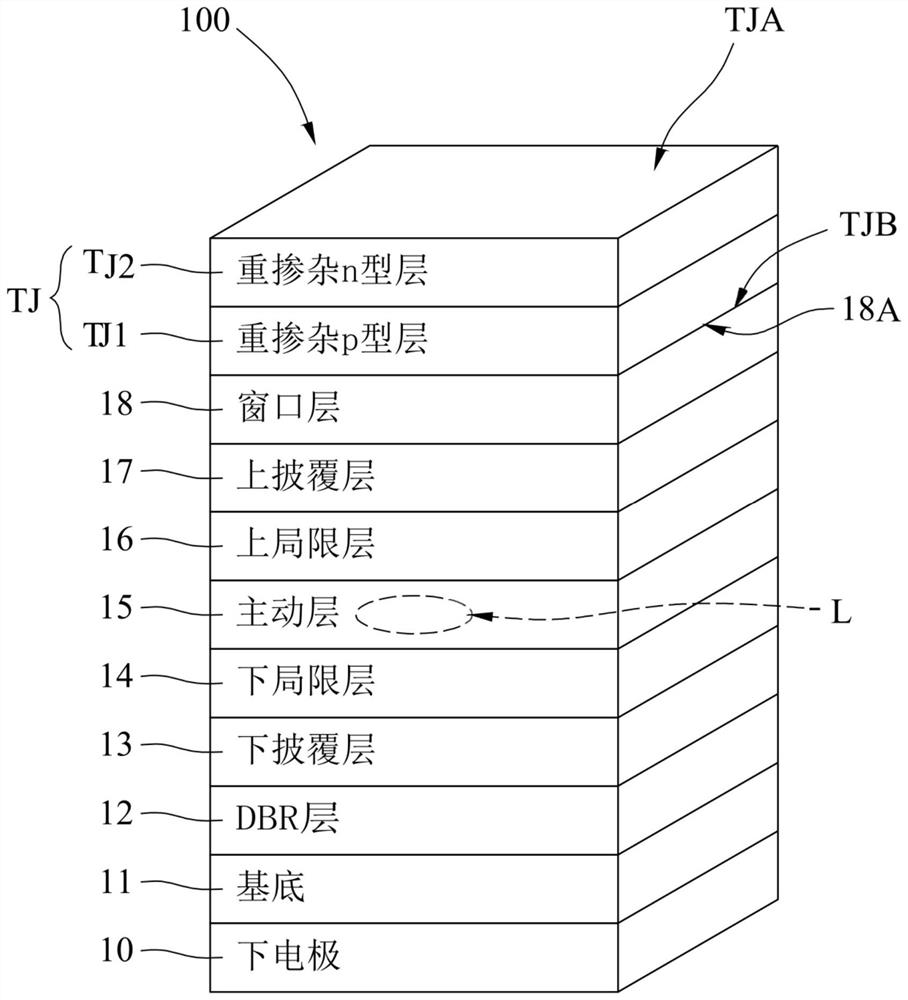

[0032]

[0033] *: The area of the upper surface TJA and the area of the lower surface TJB of the tunnel junction layer TJ are respectively equal to the area of the window layer upper surface 18A of the window layer 18 .

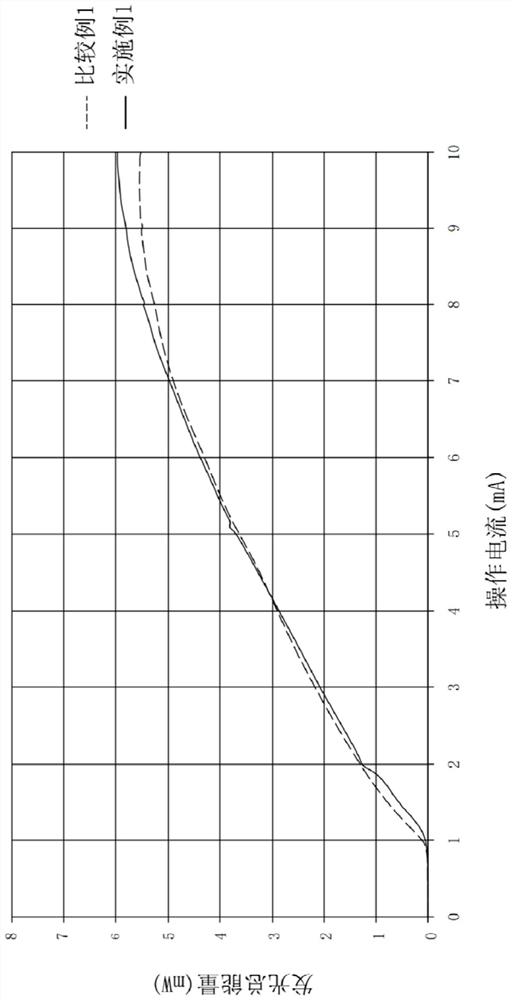

[0034] Table 3 below lists the total luminous energy of Example 1 and Comparative Example 1 of the light-emitting element 100 of the present invention under high current (greater than or equal to 8mA) operating conditions. Also see image 3 .

[0035] Table three

[0036]

[0037] Table 4 below lists the temperatures of the active layer 15 of Example 1 of the light-emitting element 100 of the present invention and the active layer of Comparative Example 1 under the operating condition of an operating current of 10 mA.

[0038] Table four

[0039] Operating current 10mA Active layer (E) of Comparative Example 1 485℃ Active layer 15(F) of embodiment 1 390℃ (F)-(E) -95℃

[0040] It can be seen from the above Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com