Nitrogen-doped carbon material and preparation method thereof

A nitrogen-doped carbon and electrode material technology, applied in the field of materials, can solve the problems of low capacitance performance, high equipment requirements, complicated processes, etc., and achieve the effects of low cost, simple preparation method and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

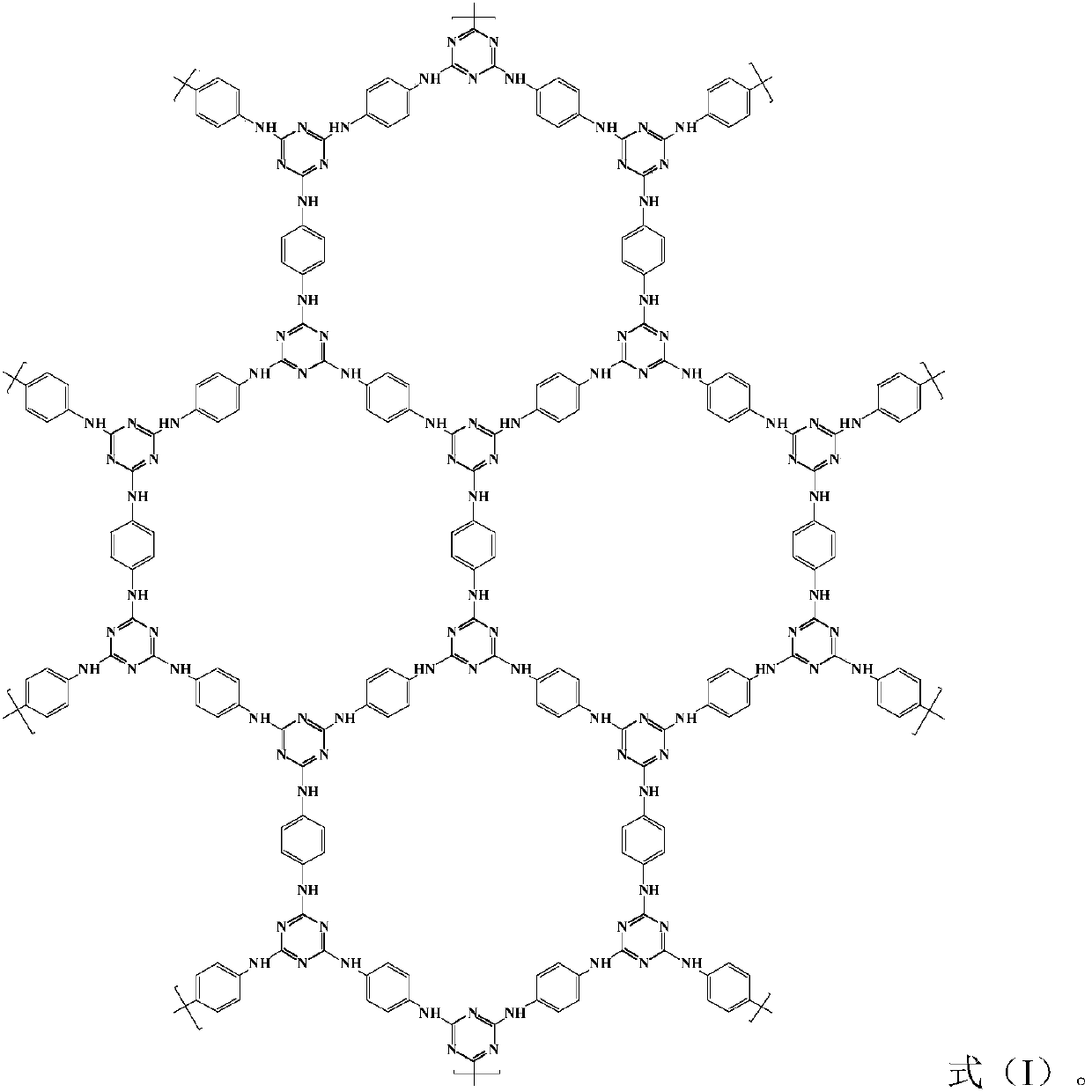

[0043] (1) Weigh 5.19g of p-phenylenediamine and 9.71g of triethylamine in a 250ml conical flask, then measure 150ml of tetrahydrofuran as a solvent, and stir ultrasonically to completely dissolve p-phenylenediamine; Add 8.85g of cyanuric chloride and 50ml of tetrahydrofuran to the solution; after p-phenylenediamine and cyanuric chloride are completely dissolved, pre-ice bath for 1h for later use.

[0044] (2) Add cyanuric chloride solution while stirring (1000rpm) in the p-phenylenediamine solution in a complete ice bath, and place it in an ice bath environment at 0°C to react for 1 hour; after the ice bath reaction, continue to react at room temperature for 24 hours; Finally, the reaction was condensed and refluxed at 60°C for 24 hours; after the synthesis, the polymer was centrifuged and washed three times with ethanol, ultrapure water and concentrated hydrochloric acid, and dried in a vacuum oven at 60°C for 24 hours.

[0045] (3) After the product is completely dried, mea...

Embodiment 2

[0050] (1) Weigh 5.19g of p-phenylenediamine and 9.71g of triethylamine in a 250ml conical flask, then measure 150ml of tetrahydrofuran as a solvent, and stir ultrasonically to completely dissolve p-phenylenediamine; Add 8.85g of cyanuric chloride and 50ml of tetrahydrofuran to the solution; after p-phenylenediamine and cyanuric chloride are completely dissolved, pre-ice bath for 1h for later use.

[0051](2) Add cyanuric chloride solution while stirring (1000rpm) in the p-phenylenediamine solution in a complete ice bath, and place it in an ice bath environment at 0°C to react for 1 hour; after the ice bath reaction, continue to react at room temperature for 24 hours; Finally, the reaction was condensed and refluxed at 60°C for 24h; after the synthesis, the polymer was centrifuged and washed three times with ethanol and ultrapure water respectively, and dried in a vacuum oven at 60°C for 24h.

[0052] (3) Weigh 0.5g of dried product in a boat-shaped crucible, 2 Calcination an...

Embodiment 3

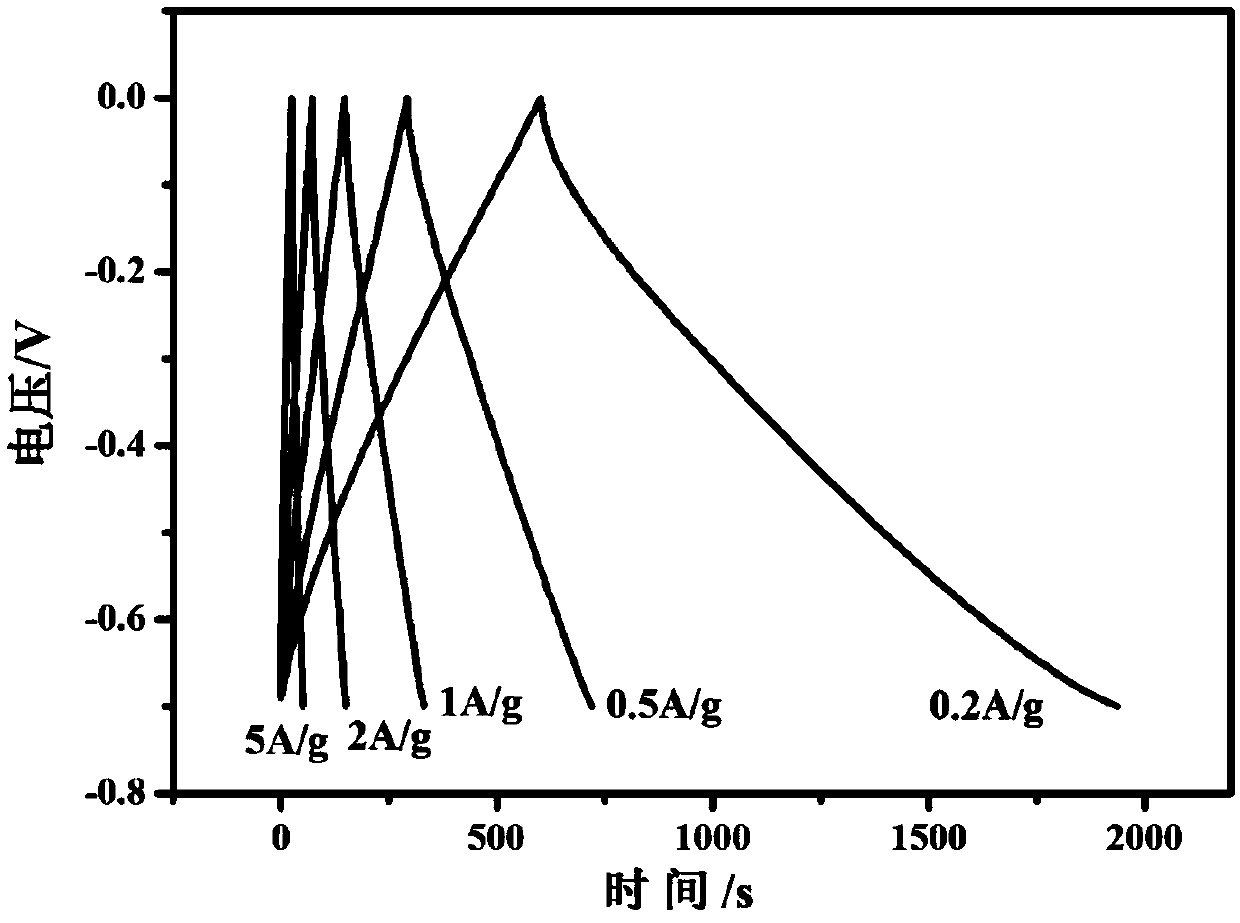

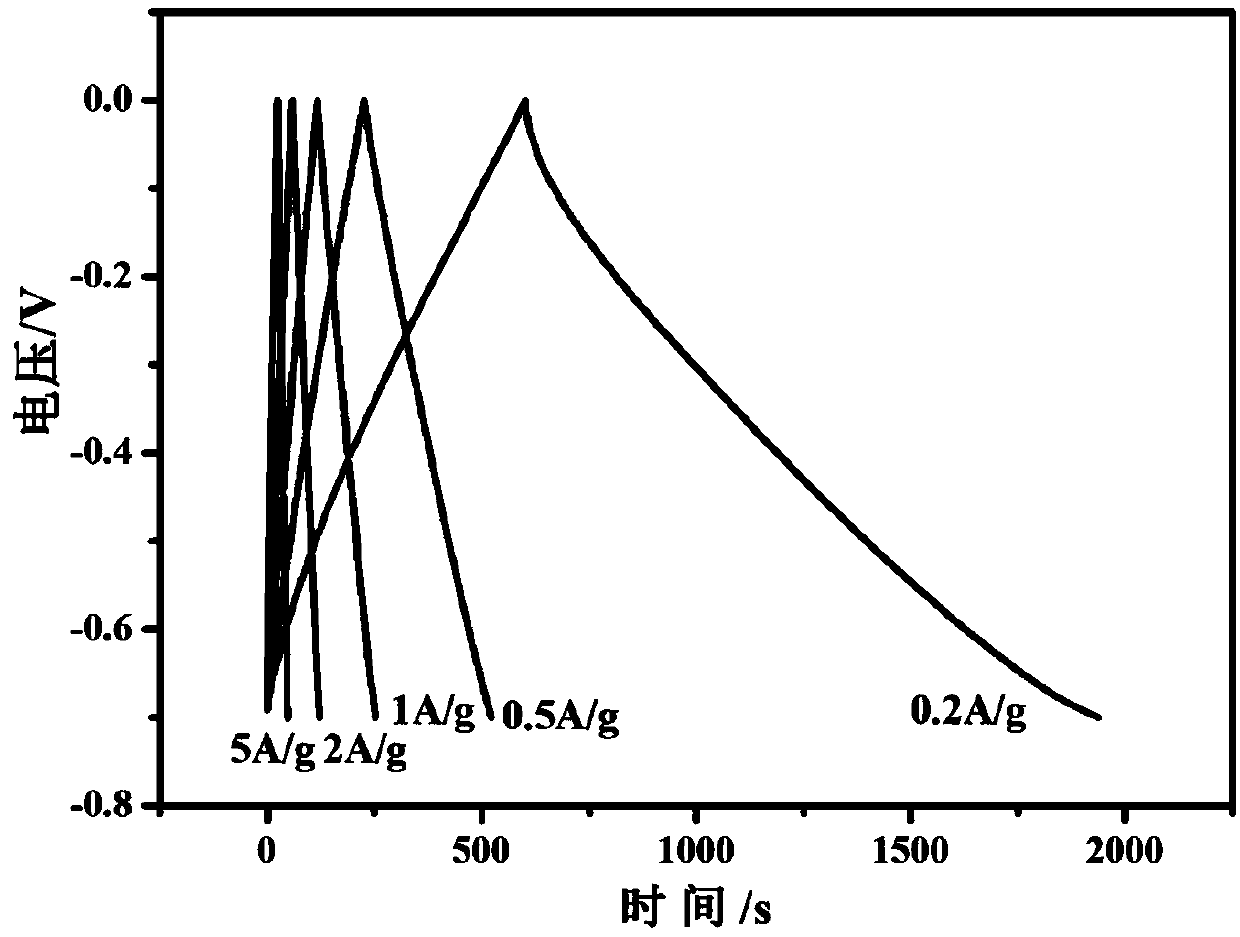

[0056] Nitrogen-doped carbon materials were prepared at different calcination temperatures. Referring to Example 1, the calcination temperatures in step (4) were replaced with the temperature values in Table 1, and other conditions remained unchanged, and nitrogen-doped carbon materials were obtained. The capacitance results of the obtained materials at a current density of 1A / g are shown in Table 1.

[0057] Table 1 Capacitance of nitrogen-doped carbon materials prepared at different calcination temperatures

[0058] Calcination temperature °C

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com