Ultrathin silicon solar cell and preparation method thereof

A crystalline silicon solar cell, ultra-thin technology, applied in the field of solar cells, can solve the problems of narrow process window and poor matching, and achieve the effects of simple cell structure, reduced fragmentation rate, and reduced operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

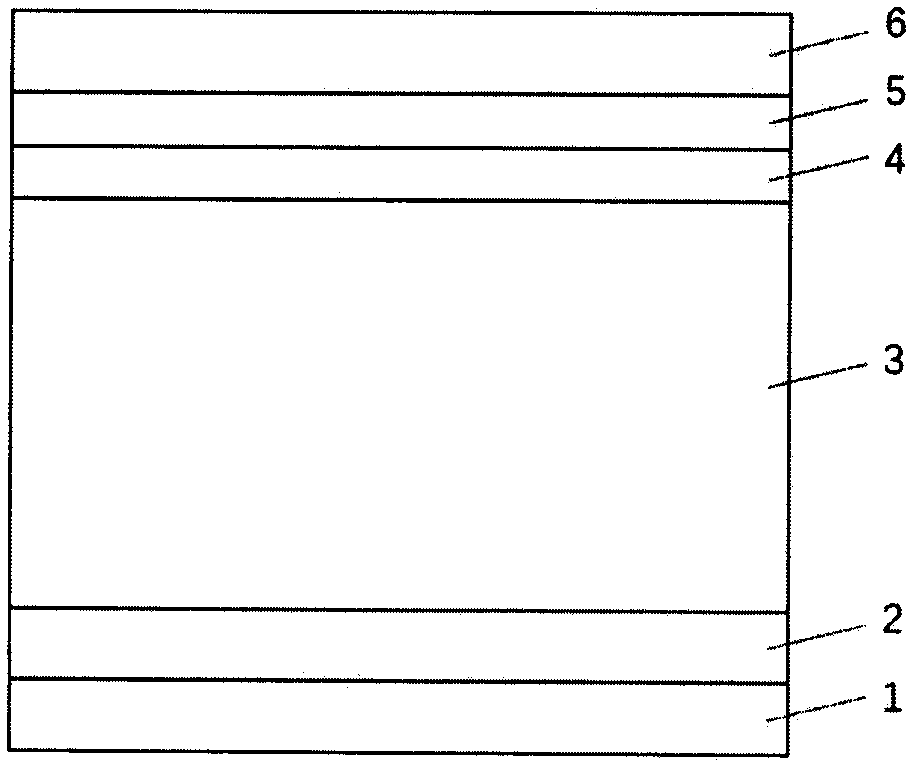

[0034] Ultra-thin crystalline silicon solar cells were constructed by modifying ITO with ultra-thin metallic aluminum with a work function of 4.28eV.

[0035] (1) Etching and thinning traditional hard monocrystalline silicon wafers at 90°C by using a sodium hydroxide solution with a concentration of 50 wt%, and thinning the silicon wafers with a thickness of 180 μm to 45 μm;

[0036] (2) Using deionized water to clean the surface of the silicon wafer;

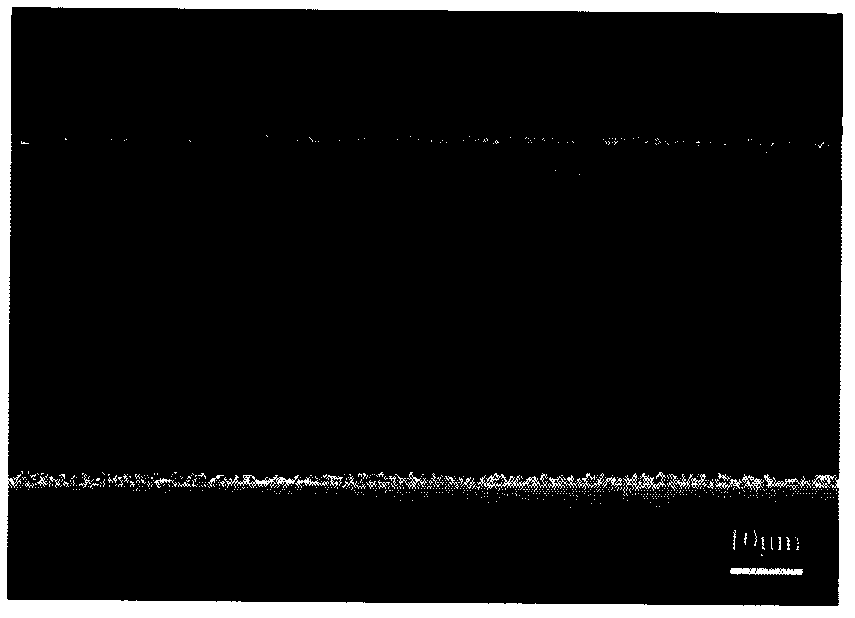

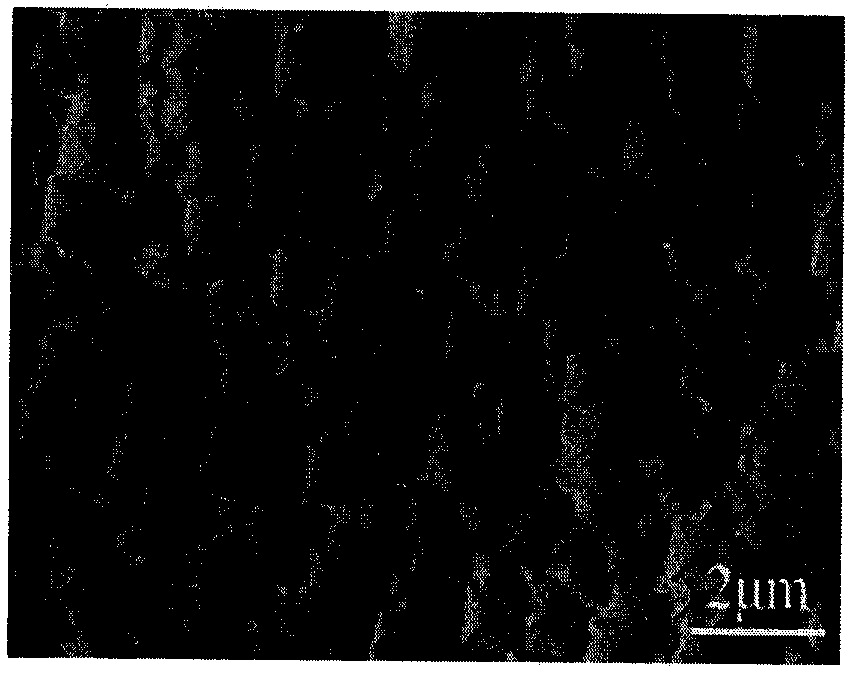

[0037] (3) MACE heavy silver solution (0.01mM AgNO3 +4M HF) to deposit silver on the surface of ultra-thin single crystal silicon wafers for 10-20s, and then put into the etching solution (7.36M HF+4.58M H 2 o 2 ) for 60s of catalytic corrosion to prepare a nanoporous structure;

[0038] (4) Immerse the prepared black silicon in the solution for etching to prepare an inverted pyramid black silicon structure: using the anisotropic corrosion effect of the nano-reconstruction solution on silicon, NaF:H 2 o 2 :H 2 O=1:2:4, the...

Embodiment 2

[0045] Ultra-thin crystalline silicon solar cells were constructed by modifying ITO with ultra-thin metal magnesium with a work function of 3.66eV.

[0046] (1) Etching and thinning traditional hard monocrystalline silicon wafers at 90°C by using a sodium hydroxide solution with a concentration of 50 wt%, and thinning the silicon wafers with a thickness of 180 μm to 45 μm;

[0047] (2) Using deionized water to clean the surface of the silicon wafer;

[0048] (3) MACE heavy silver solution (0.01mM AgNO 3 +4M HF) to deposit silver on the surface of ultra-thin single crystal silicon wafers for 10-20s, and then put into the etching solution (7.36M HF+4.58M H 2 o 2 ) for 60s of catalytic corrosion to prepare a nanoporous structure;

[0049] (4) Immerse the prepared black silicon in the solution for etching to prepare an inverted pyramid black silicon structure: using the anisotropic corrosion effect of the nano-reconstruction solution on silicon, NaF:H 2 o 2 :H 2 O=1:2:4, the...

Embodiment 3

[0056] Ultra-thin crystalline silicon solar cells were constructed by modifying ITO with ultra-thin metal magnesium with a work function of 3.66eV.

[0057] (1) Etching and thinning traditional hard monocrystalline silicon wafers at 90°C by using a sodium hydroxide solution with a concentration of 50 wt%, and thinning the silicon wafers with a thickness of 180 μm to 80 μm;

[0058] (2) Using deionized water to clean the surface of the silicon wafer;

[0059] (3) MACE heavy silver solution (0.01mM AgNO 3 +4M HF) to deposit silver on the surface of ultra-thin single crystal silicon wafers for 10-20s, and then put into the etching solution (7.36M HF+4.58M H 2 o 2 ) for 60s of catalytic corrosion to prepare a nanoporous structure;

[0060] (4) Immerse the prepared black silicon in the solution for etching to prepare an inverted pyramid black silicon structure: using the anisotropic corrosion effect of the nano-reconstruction solution on silicon, NaF:H 2 o 2 :H 2 O=1:2:4, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com