Preparation method of novel all back electrode crystalline silicon solar cell

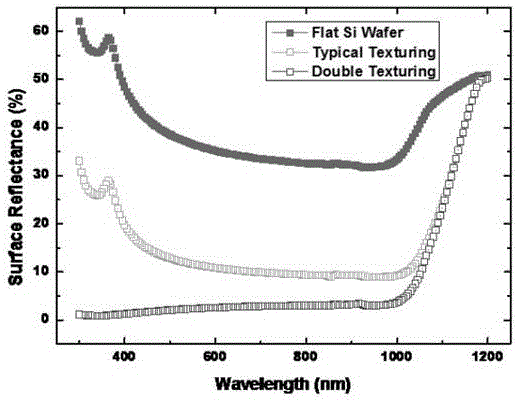

A full-back electrode and solar cell technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increased micro-defect density, large thinning of silicon wafers, and high fragmentation rate, and achieves reduced surface defect state density, surface Uniform cleanliness and reduced surface reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the solution of the present invention, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0031] The preparation method of the novel all-back-electrode crystalline silicon solar cell of the present invention comprises the following steps:

[0032] S1 pre-cleaning: place the prepared solar-grade Czochralski monocrystalline silicon wafer in a pre-cleaning solution composed of alkali solution and oxidizing agent for pre-treatment to eliminate small molecule organic and inorganic pollutants on the surface of the substrate; among them, all The pre-cleaning solution is a mixed solution of NaClO and NaOH with a volume ratio of 1:3-1:6, the reaction temperature is controlled at 65-80°C, and the time is controlled at 3-10min;

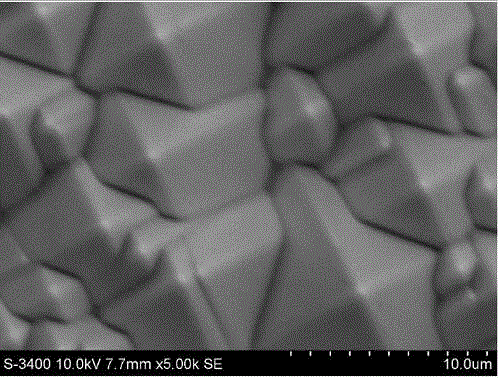

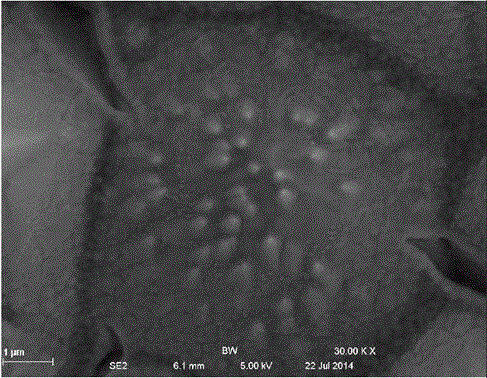

[0033] S2: De-damage: Use a de-damage solution to partially remove the mechanical damage layer on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com