A rail vehicle side wall automatic wire drawing system and wire drawing process

A rail vehicle side wall and wire drawing technology, which is applied to vehicle exterior cleaning devices, grinding automatic control devices, manufacturing tools, etc. Human-computer interaction friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

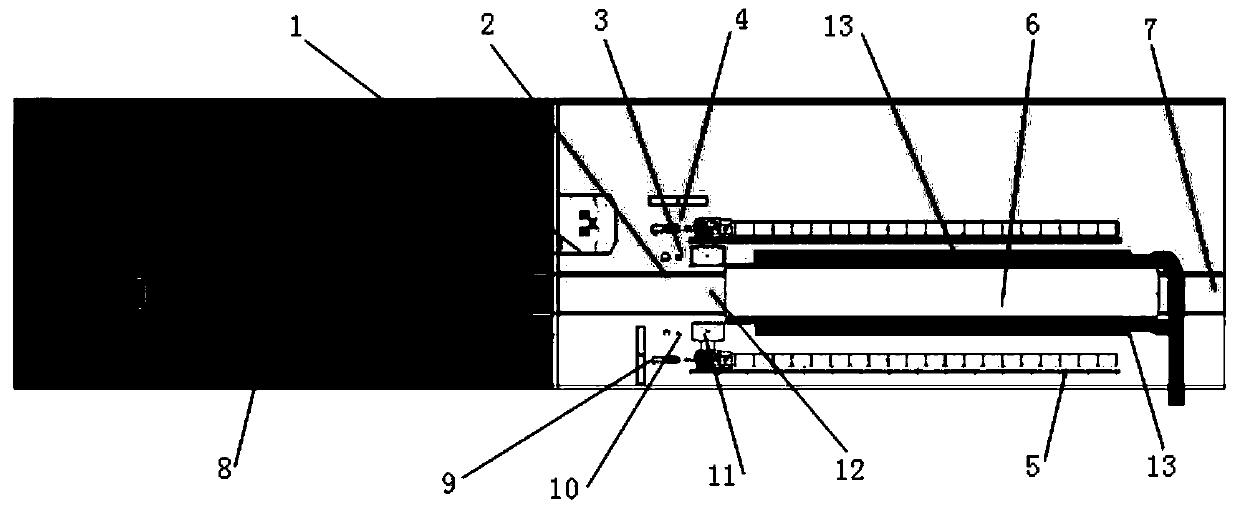

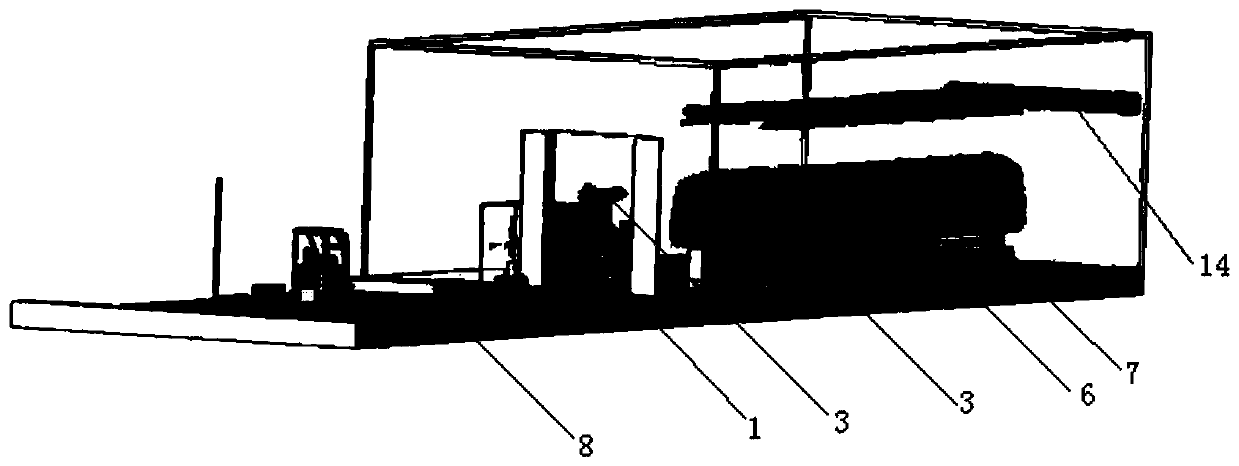

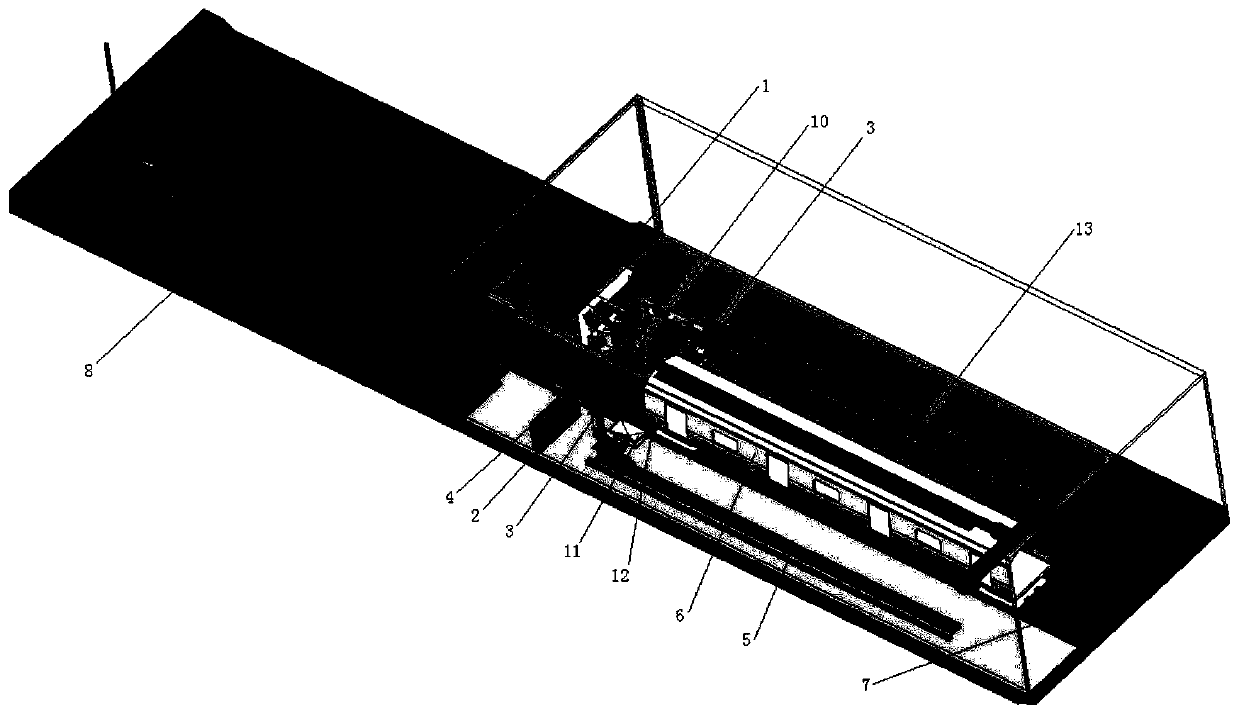

[0037] Such as Figure 1 to Figure 3 As shown, a rail vehicle side wall automatic wire drawing system provided by the present invention includes a central control system, a robot 3, a wire drawing device 9, a track 7, a laser measurement system, off-line programming software and an electric control system,

[0038] The laser measurement system can be calibrated online, scan the outline of the car body, determine the exact position of the car body, doors and windows, and upload the measured pose data to the central control system;

[0039] The central control system is equipped with off-line programming software to calculate the measured pose data. According to the built-in control algorithm, the wire drawing process parameters and paths are planned online to generate accurate wire drawing paths to ensure the best wire drawing for diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com