Straight pushing and pressing structure of wire drawing rollers

A technology of drawing roller and driving structure, which is applied to the parts of grinding machine tools, machine tools suitable for grinding workpiece planes, grinding machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

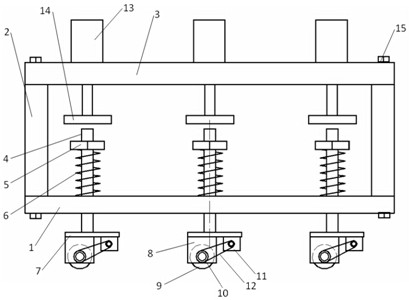

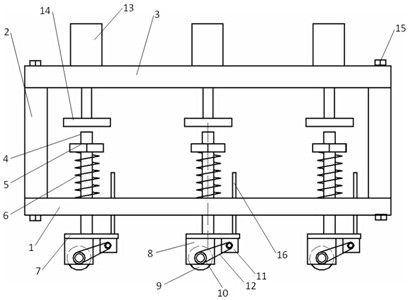

[0027] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

[0028] Such as Figure 1~2 As shown, a direct push-down structure of a wire drawing roller includes a bottom plate 1, two parallel vertical plates 2 are arranged on the bottom plate 1, a top plate 3 is arranged on the upper end of the vertical plate 2, and a top plate 3 is arranged on the bottom plate 1. There are a plurality of lifting rods 4 that can be lifted vertically, and the lower end of the lifting rods 4 is provided with an assembly plate 7, and the lower end of the assembly plate 7 is provided with two parallel side mounting plates 8, and the side mounting plates 8 are arranged between There is a wire drawing roller 9 for wire drawing operation.

[0029] The installation section of the drawing roller 9 protrudes from the side installation plate 8, the driven wheel 10 is arranged on the installation section, the motor 11 is arranged on the assembly plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com