Wire clamp

A line card and card body technology, applied in the field of line cards, can solve problems such as rotational dislocation, and achieve the effects of avoiding rotational dislocation, easy operation and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

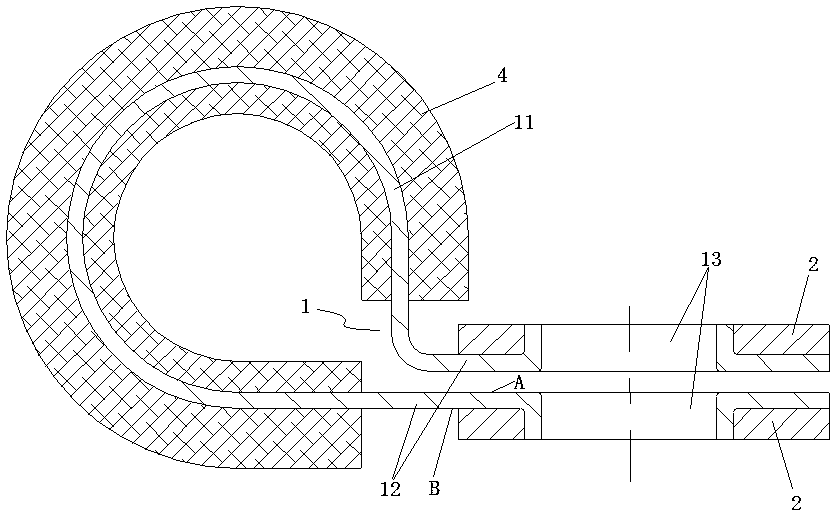

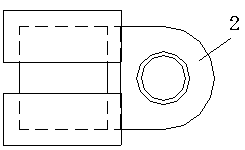

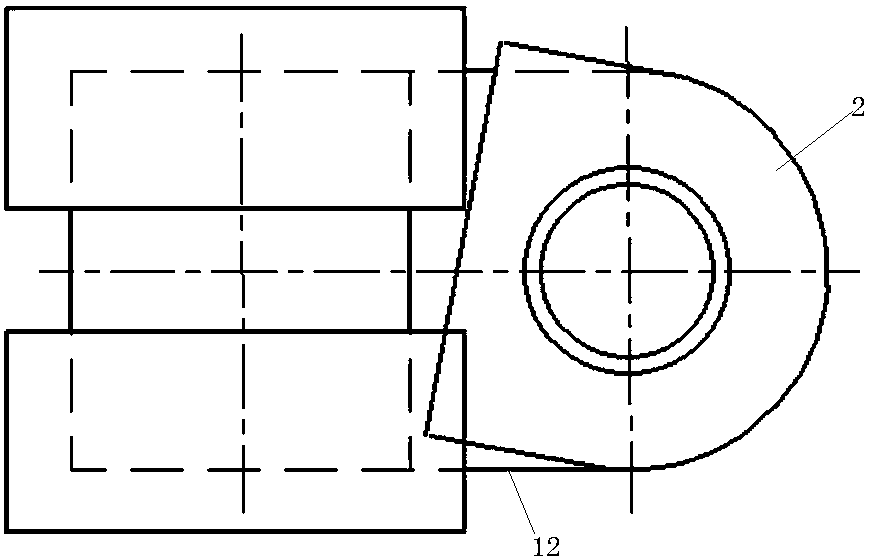

[0033] Such as Figure 4~6 As shown, a line card includes a card body 1 , and the card body 1 includes an annular clamping portion 11 . An opening is defined on the clamping portion 11 . Fastening platforms 12 are respectively connected to the two ends of the opening. The clamping portion 11 is integrally formed with the fastening platform 12 . The groove belt 4 is wrapped on the clamping part 11 . A tongue depressor 2 is stacked close to the outer surface of the fastening platform 12 .

[0034] The tongue depressor 2 is provided with a first through hole 21 . A semicircular concave notch 22 is formed on the inner wall of the first through hole 21 . The semi-arc radius of the concave notch 22 is preferably 0.5 mm. The longitudinal direction of the concave notch 22 is parallel to the axis of the first through hole 21 , and the concave notch 22 penetrates the inner wall of the first through hole 21 along its length direction. A second through hole 13 coaxial with the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com