Patents

Literature

51results about How to "Easy core pulling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

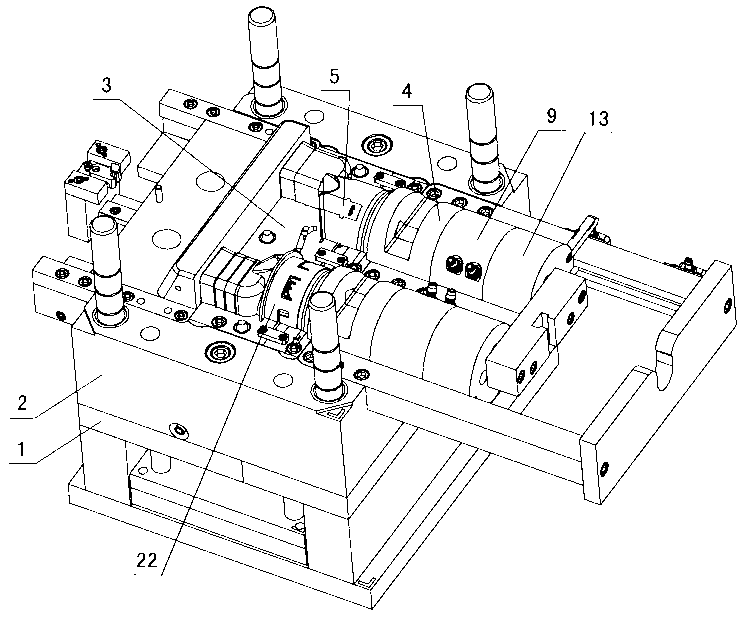

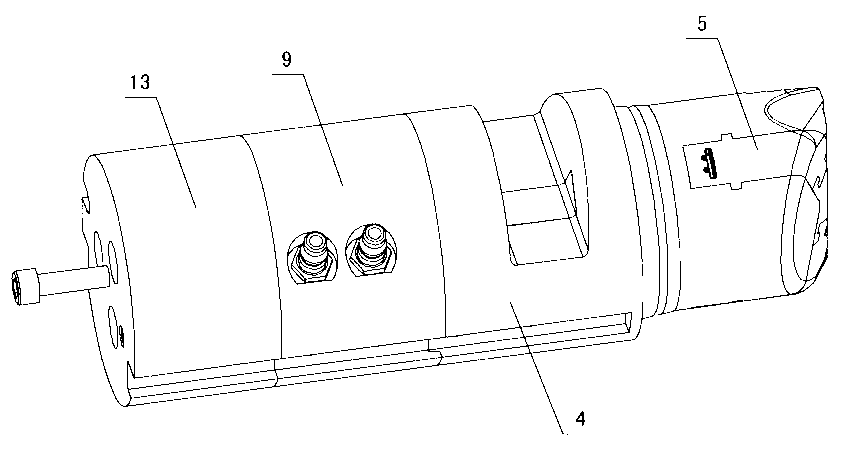

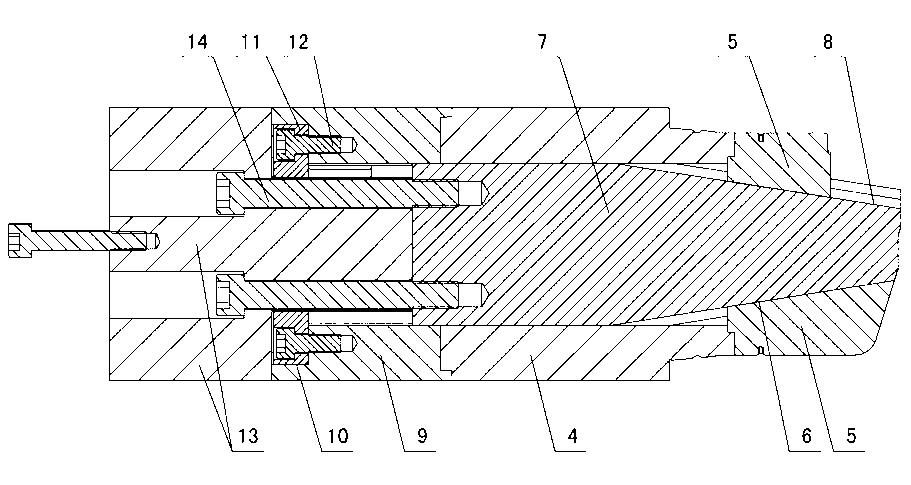

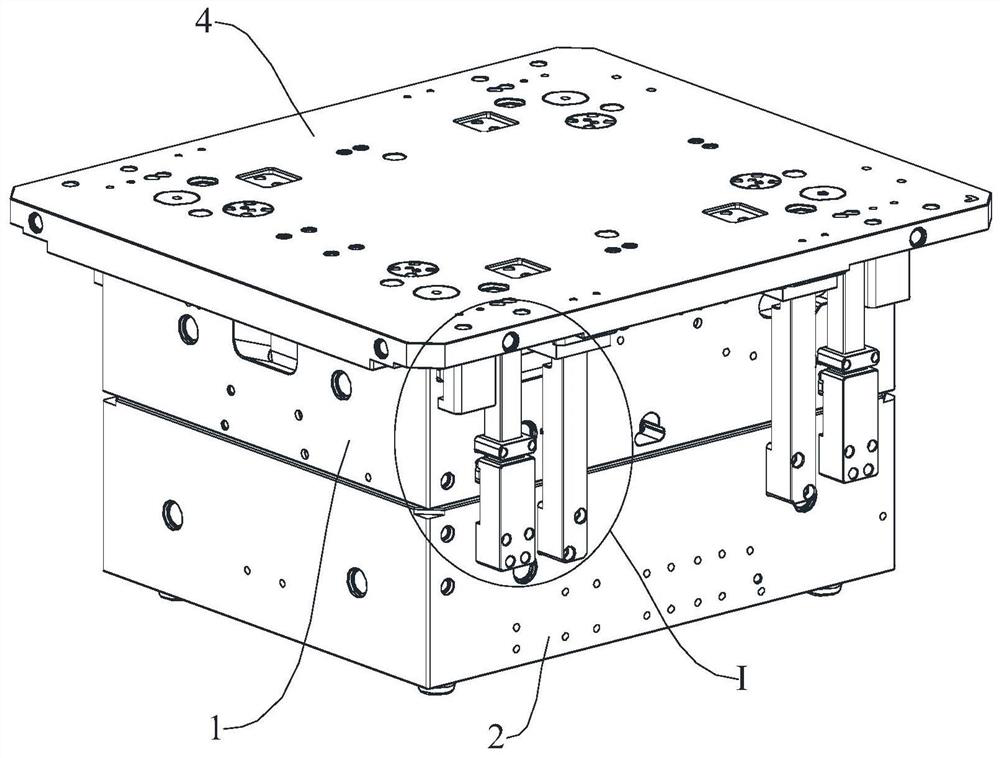

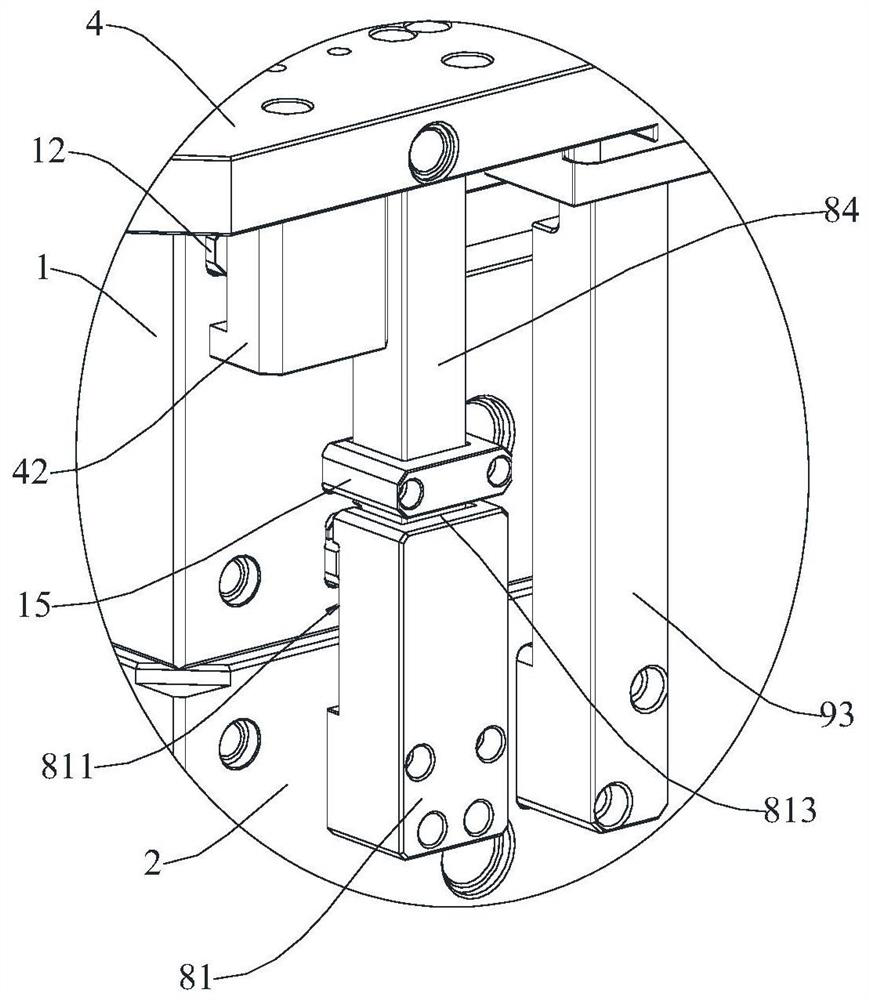

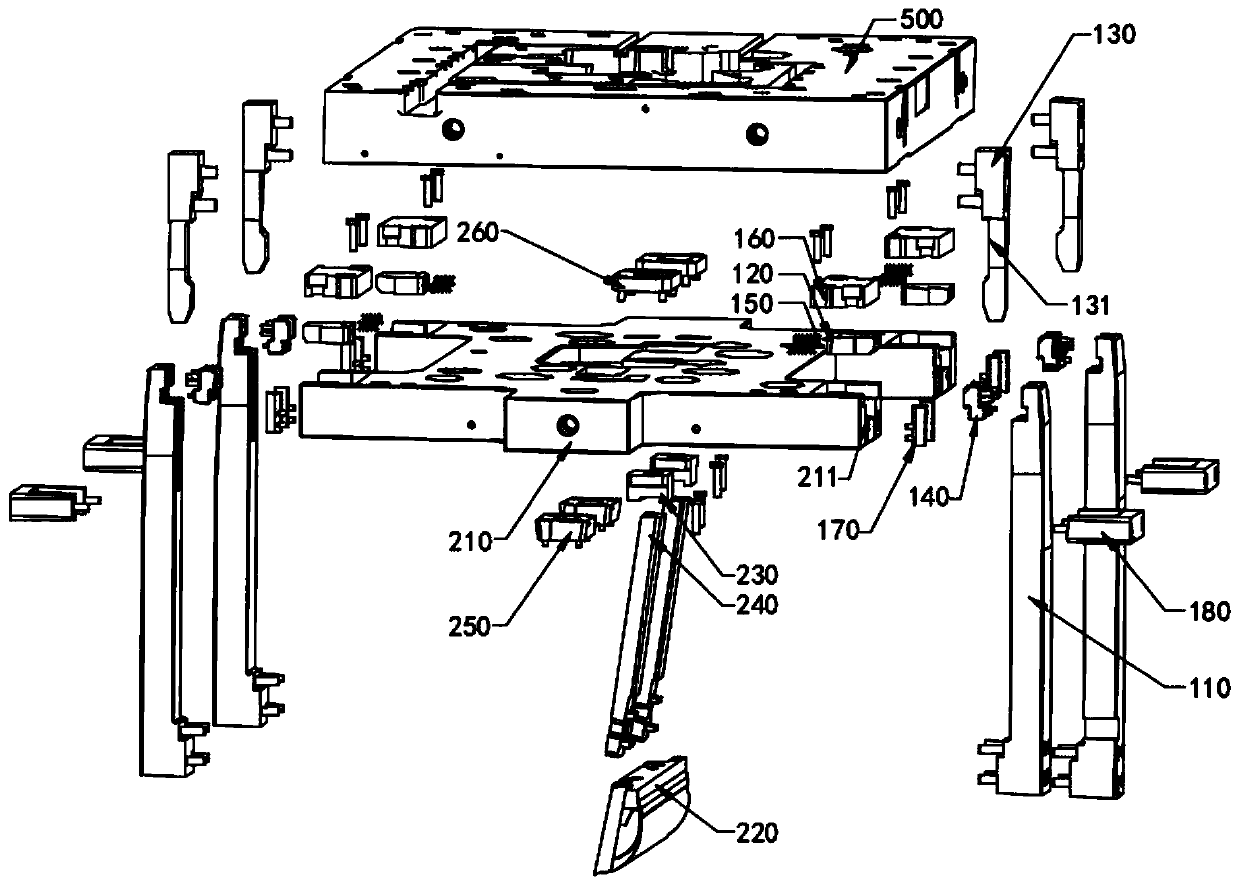

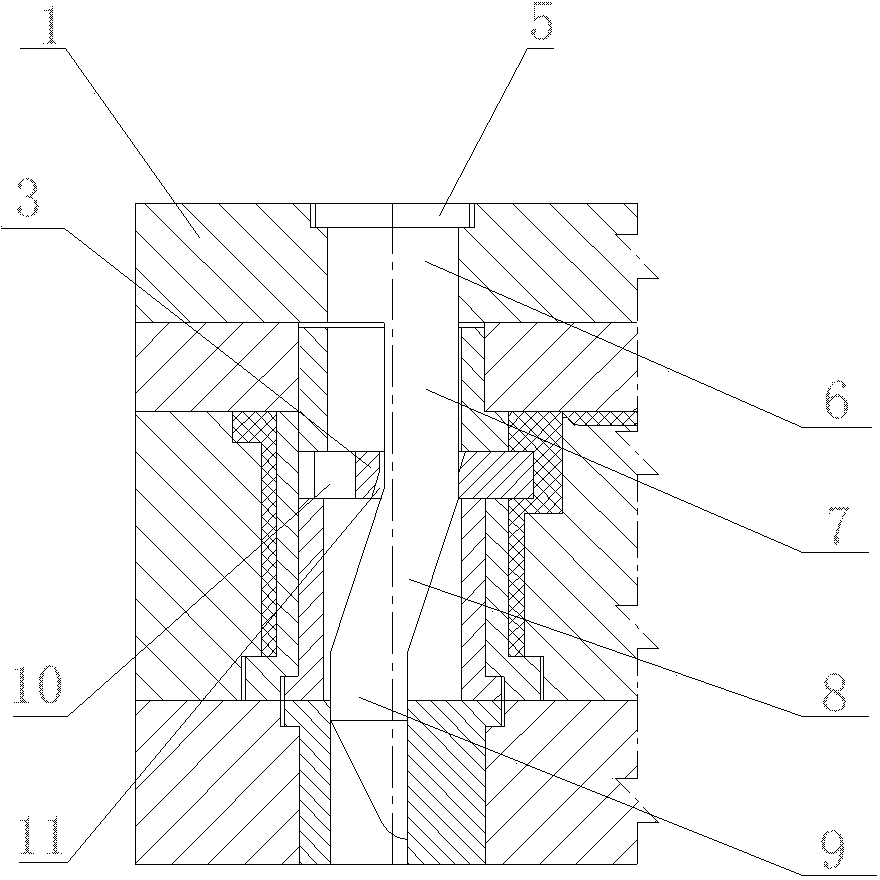

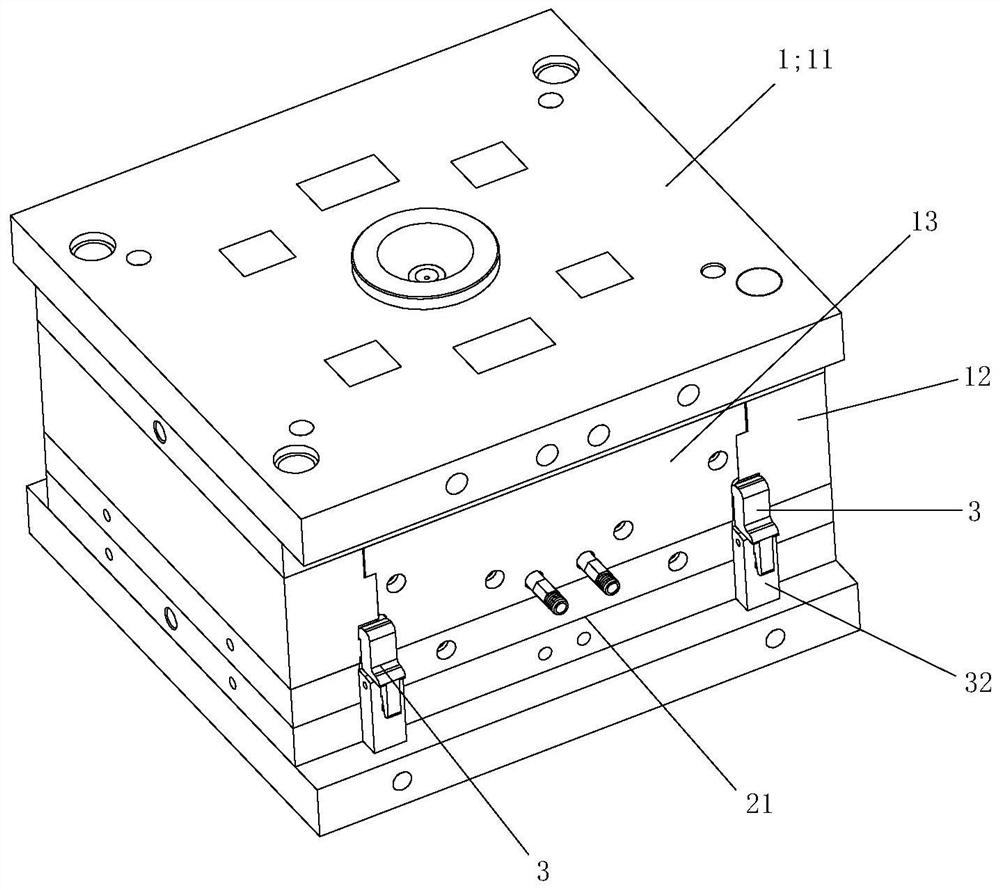

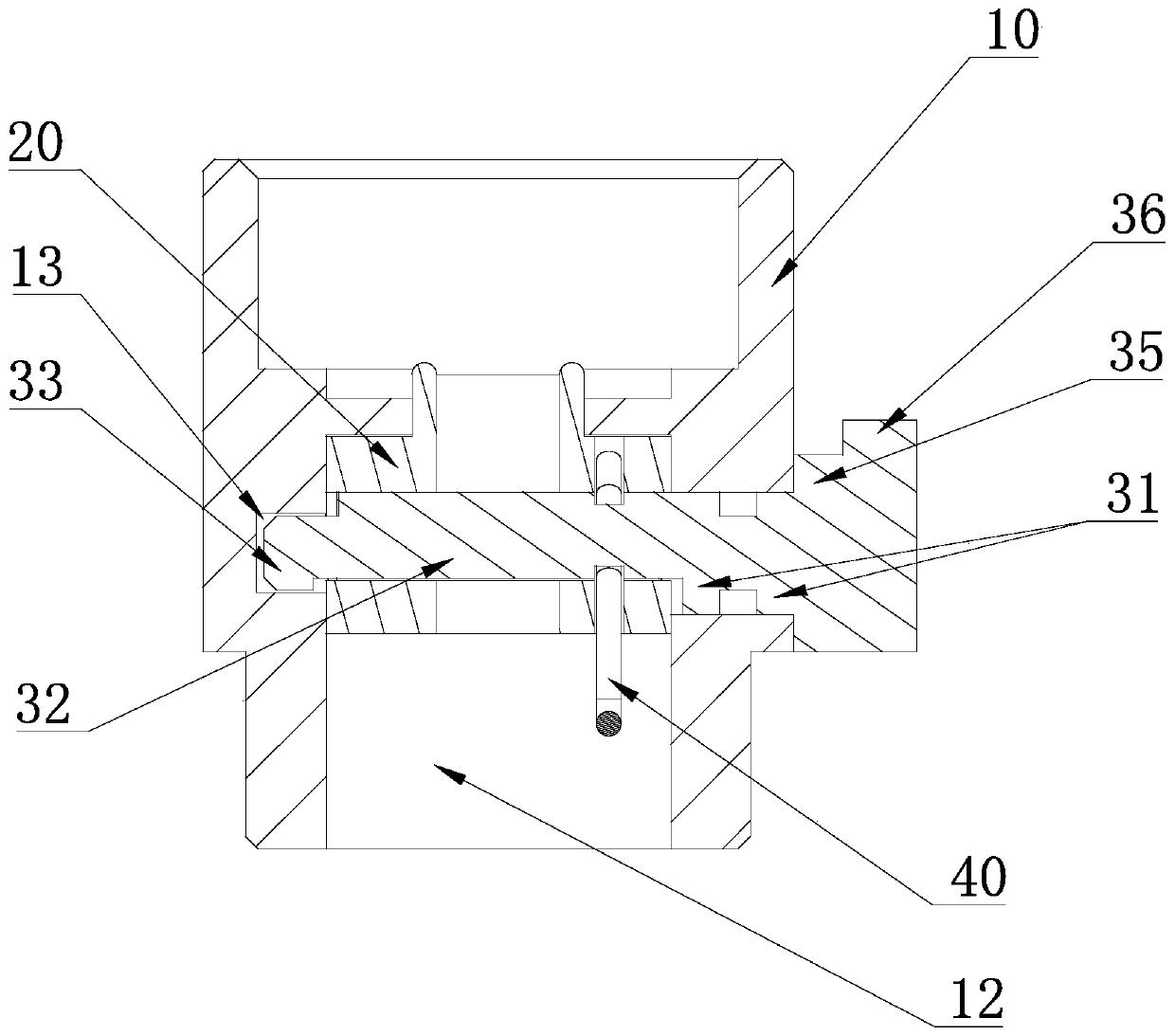

Reducing coupling injection mold core-pulling mechanism

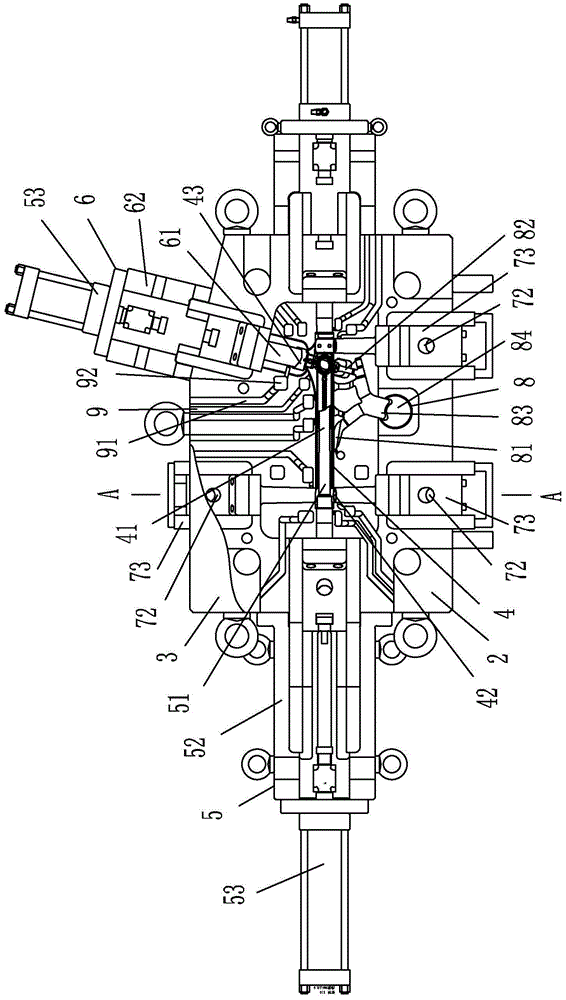

The invention discloses a reducing coupling injection mold core-pulling mechanism which comprises a movable mold base plate and a movable template, wherein a movable mold insert is arranged on the movable template; a secondary internal core-pulling mechanism is arranged on the movable template; floating core-pulling mechanisms are arranged on the movable mold base plate, the movable template and the movable mold insert; according to the secondary internal core-pulling mechanism, an inner inclined sliding surface is formed in a core-pulling small slide block connected in front of a main mold core; an outer inclined sliding surface formed on a sliding rod arranged in the main mold core is matched with the inner inclined sliding surface; a fixing plate is arranged in a mounting groove formed in the rear end of a connecting seat behind the main mold core and is fixed together with the connecting seat through a screw; the sliding seat and the sliding rod are fixed through a bolt; according to the floating core-pulling mechanism, one end of a spring arranged in the movable template is contacted with the movable template, and the other end of the spring is contacted with the movable mold base plate; a core-pulling slide block arranged in the movable mold insert is matched with an external fastener; the core-pulling slide block is provided with a T-shaped clamping block; inclined guide slots formed in an I-shaped locking module are formed in the movable template and the movable mold insert; the upper part of the I-shaped locking module is matched with the T-shaped clamping block through the inclined guide slots; and the lower part of the I-shaped locking module and the movable mold base plate are fixed together.

Owner:TAIZHOU HUANGYAN WEIDA PLASTIC MACHINERY

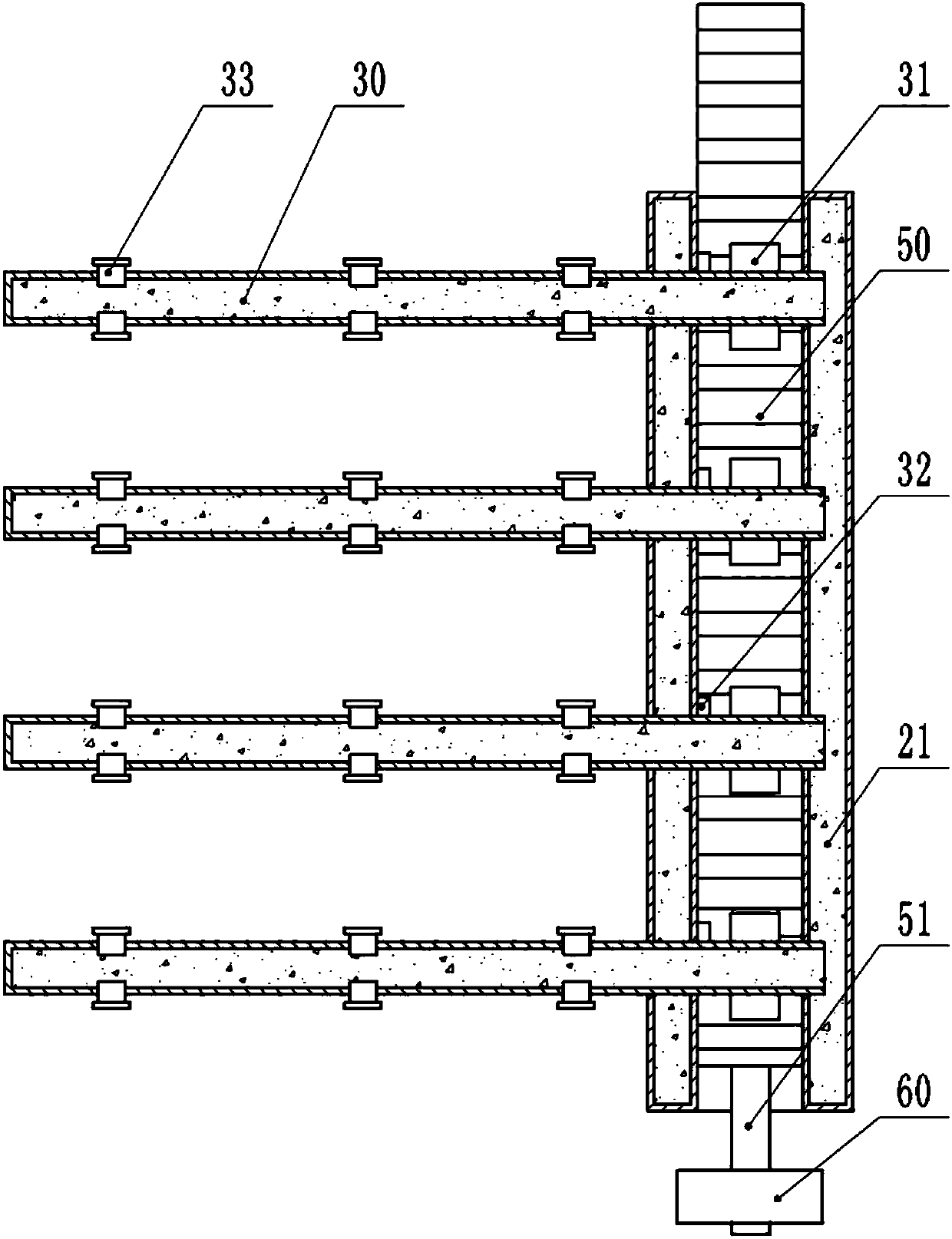

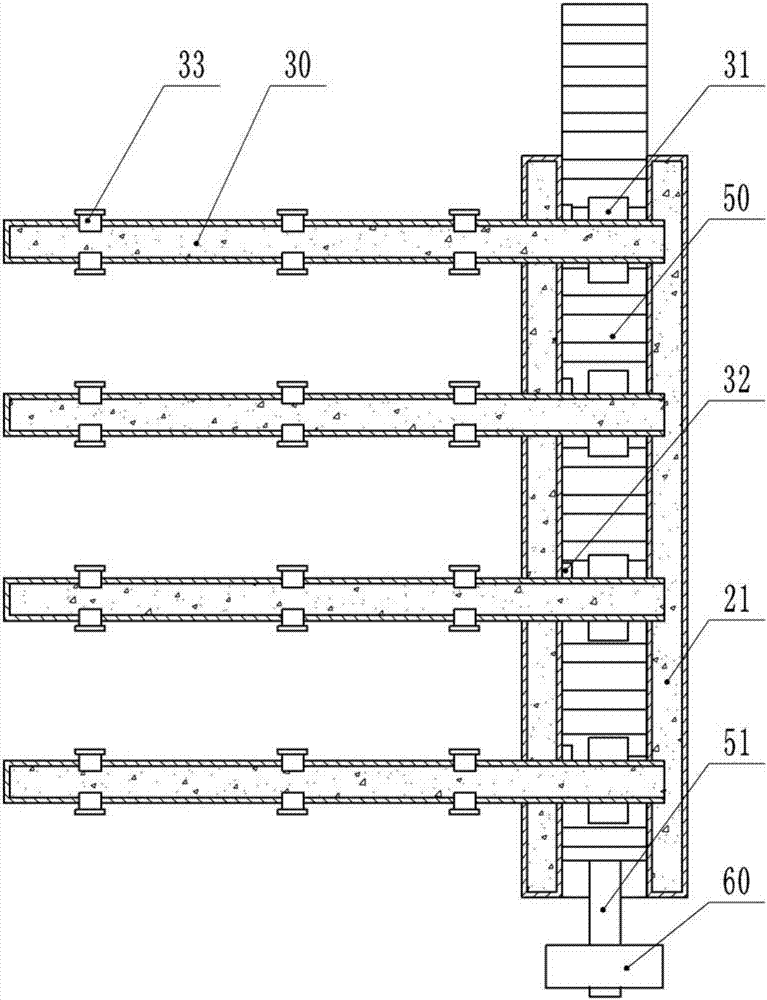

Core pulling process for light weight wallboard

ActiveCN107791370AEasy to drawAvoid stickingCeramic shaping mandrelsCeramic shaping coresElectric machineryEngineering

The invention belongs to the technical field of light weight wallboard production and particularly discloses a core pulling process for a light weight wallboard. Core pulling of the light weight wallboard is carried out by means of a core pulling device. The process comprises the following steps: (1) threading a steel tube through a supporting pipe and placing the steel tube on the supporting pipe; (2) pushing a plunger, and stopping pushing the plunger when a supporting block is tightly attached to the inner wall of the steel tube; (3) starting a motor to drive a drawing and pulling trolley to move towards a mold, and adding raw materials for producing the light weight wallboard into the mold after the steel tube is inserted into the mold; (4) when the light weight wallboard is solidifiedand formed initially, driving the motor to move towards the opposite direction to drive the drawing and pulling trolley to be far from the mold; (5) examining whether the light weight wallboard aftercore pulling meets the quality standard or not; and (6) repeating the steps (3)-(5) when next batch of light weight wallboards is produced. By adopting the process to pull cores of the light weight wallboards, the steel tube can move linearly while rotates, and the core pulling operation is simple and convenient.

Owner:重庆成维轻质墙板有限公司

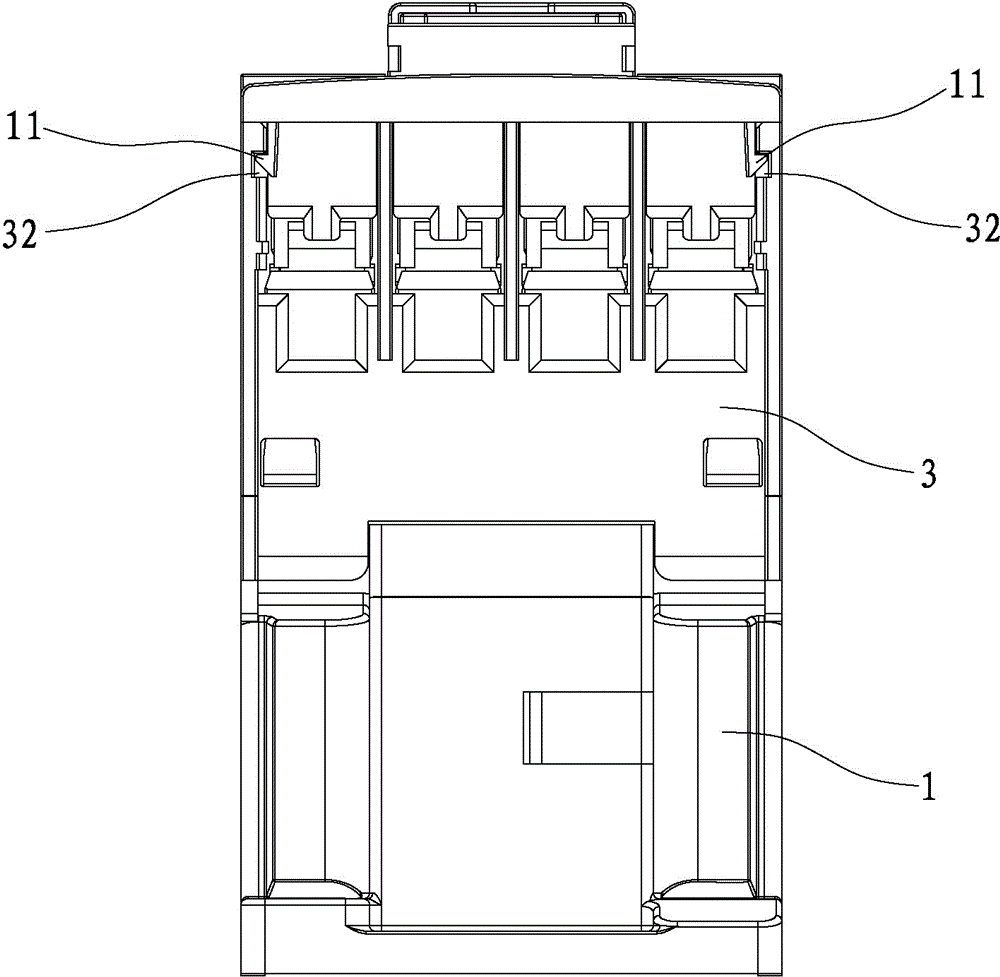

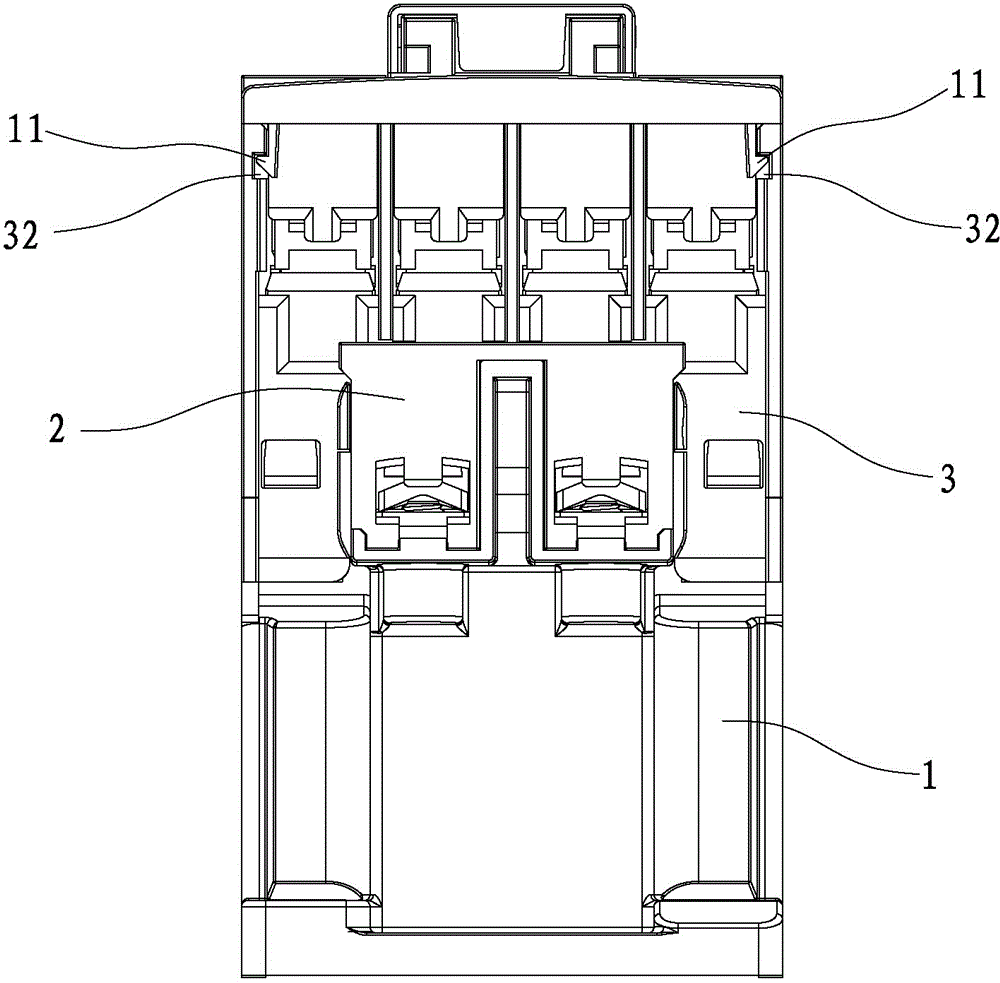

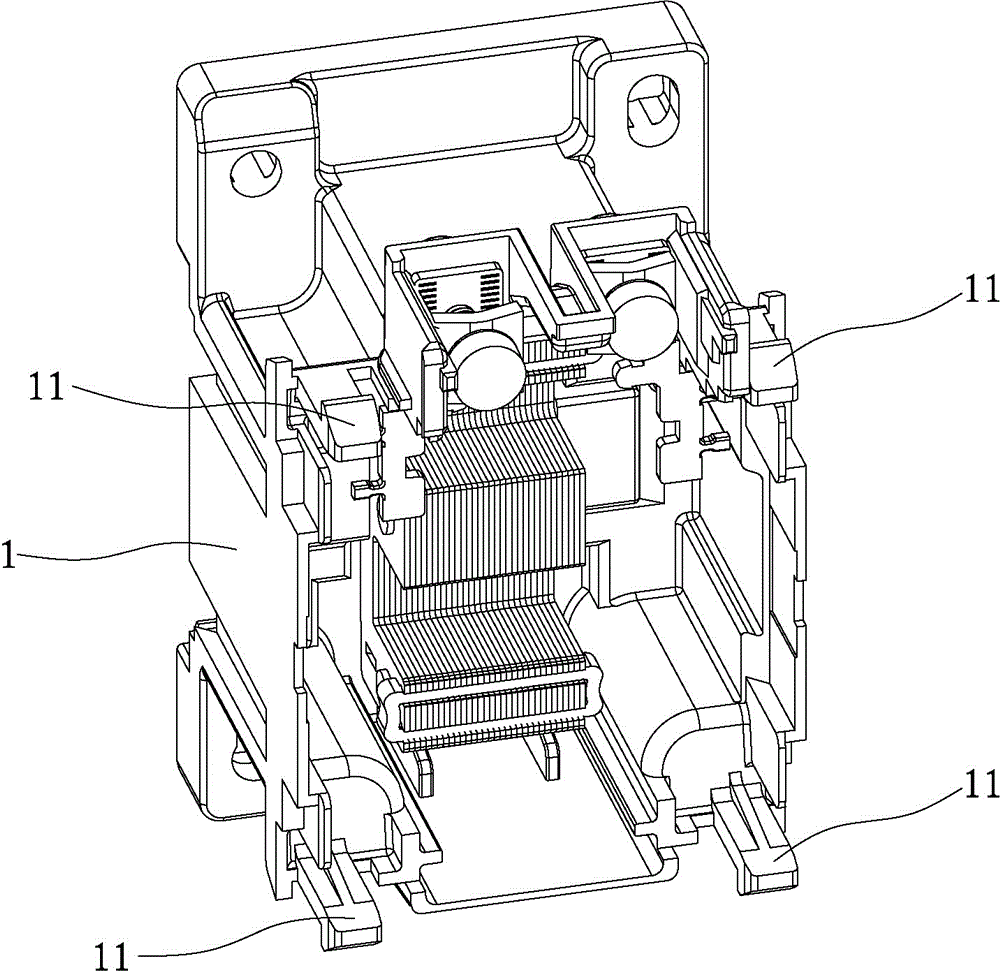

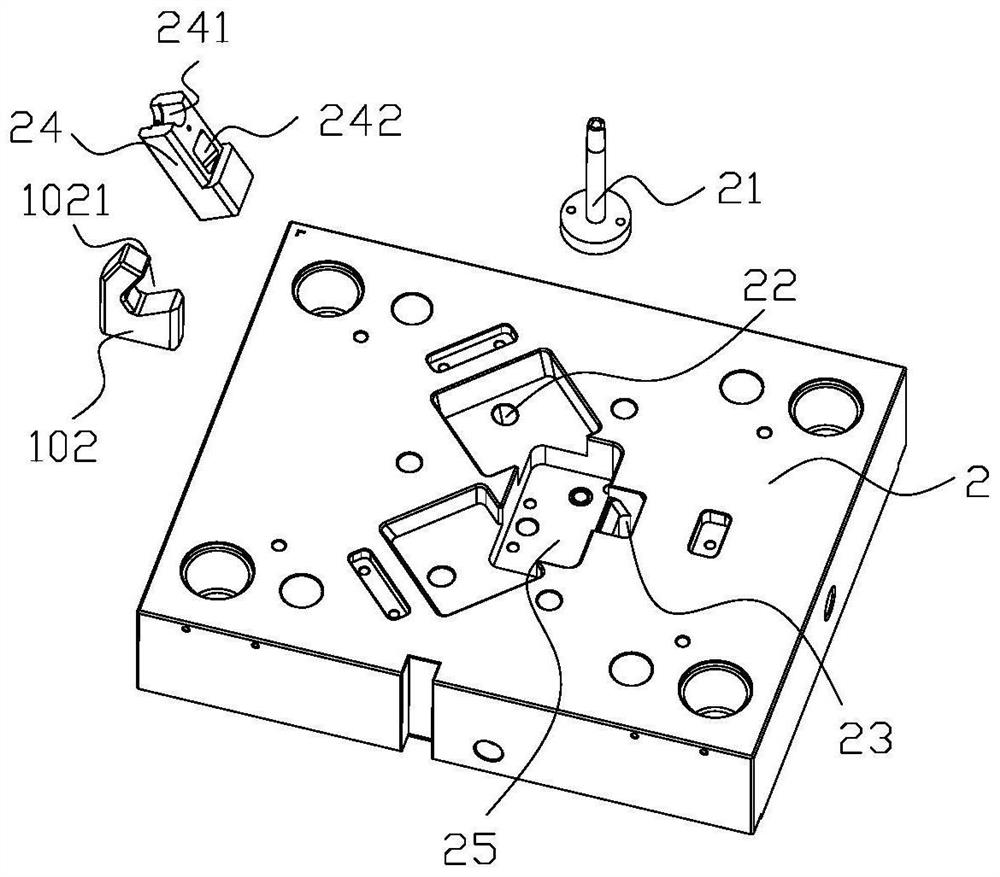

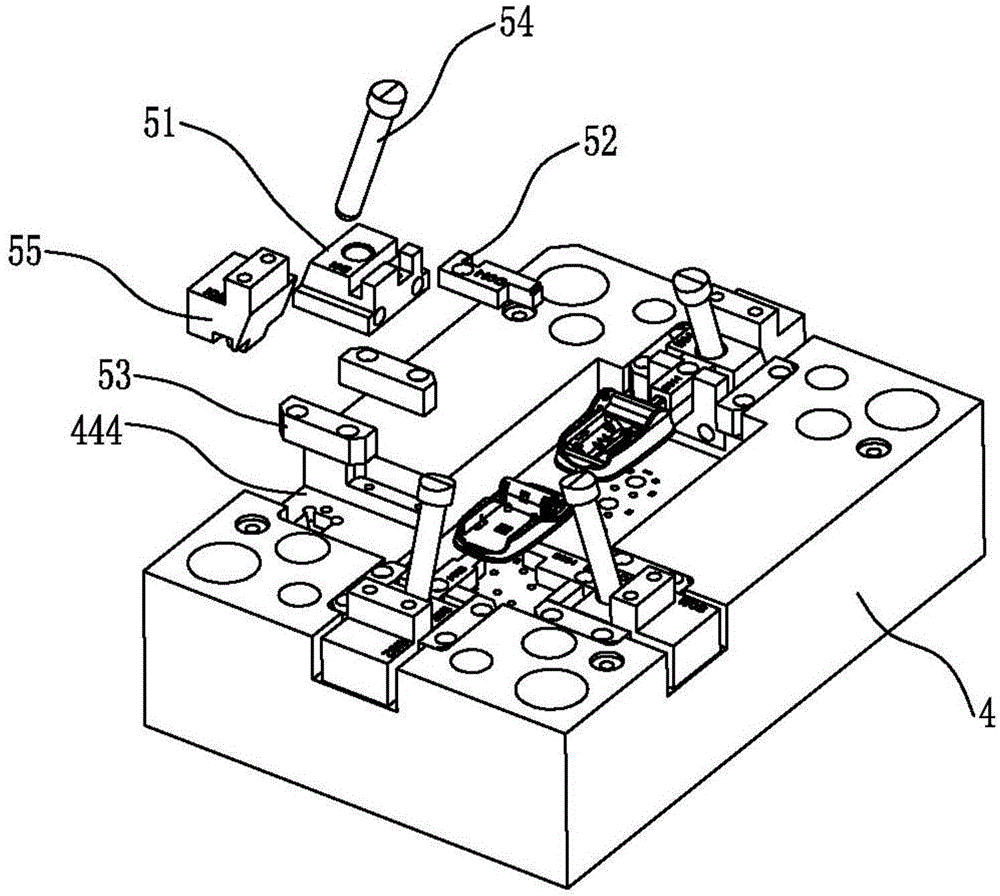

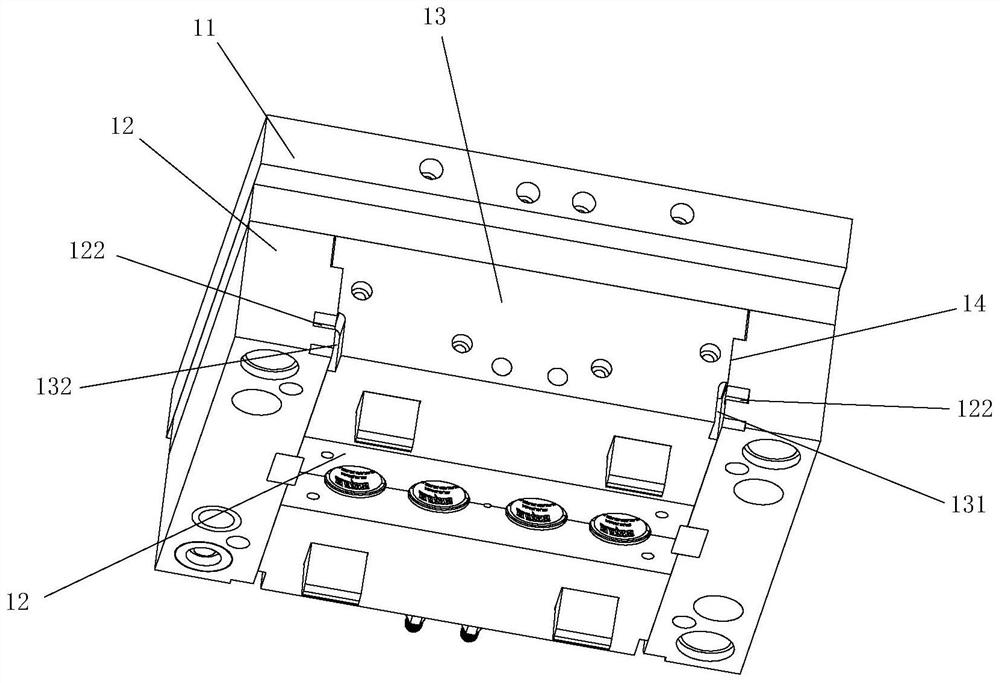

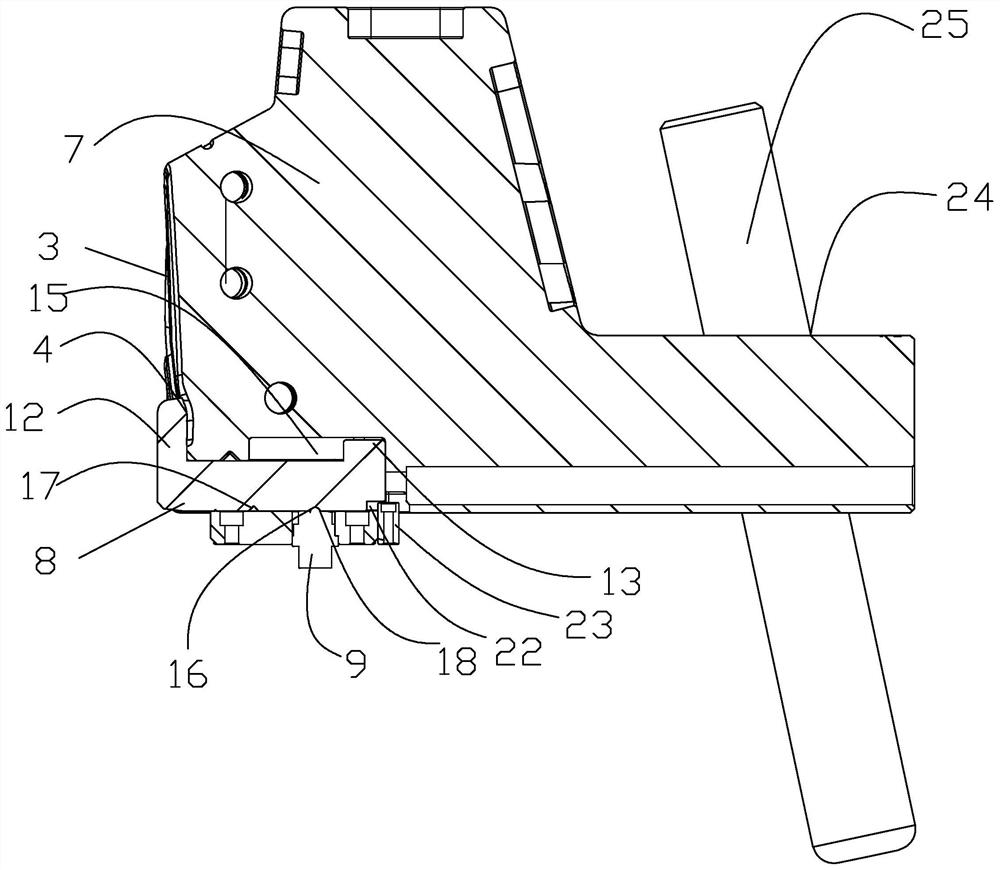

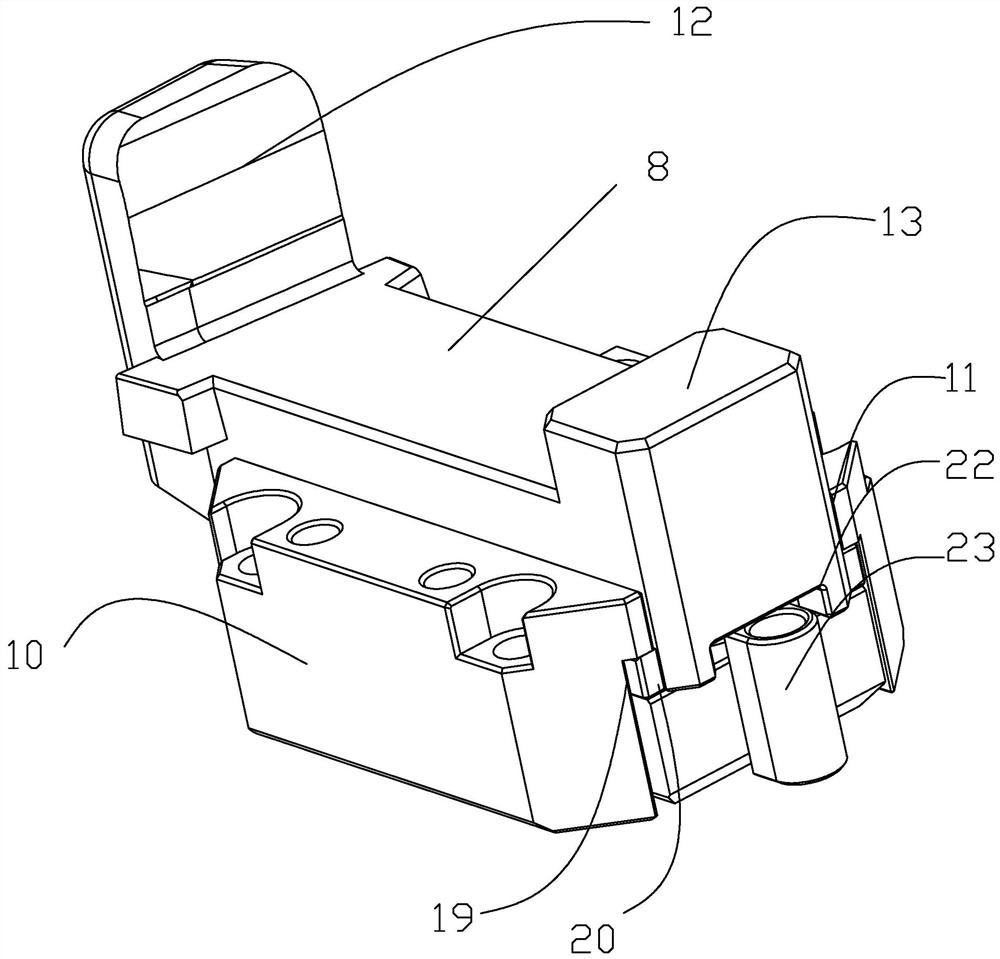

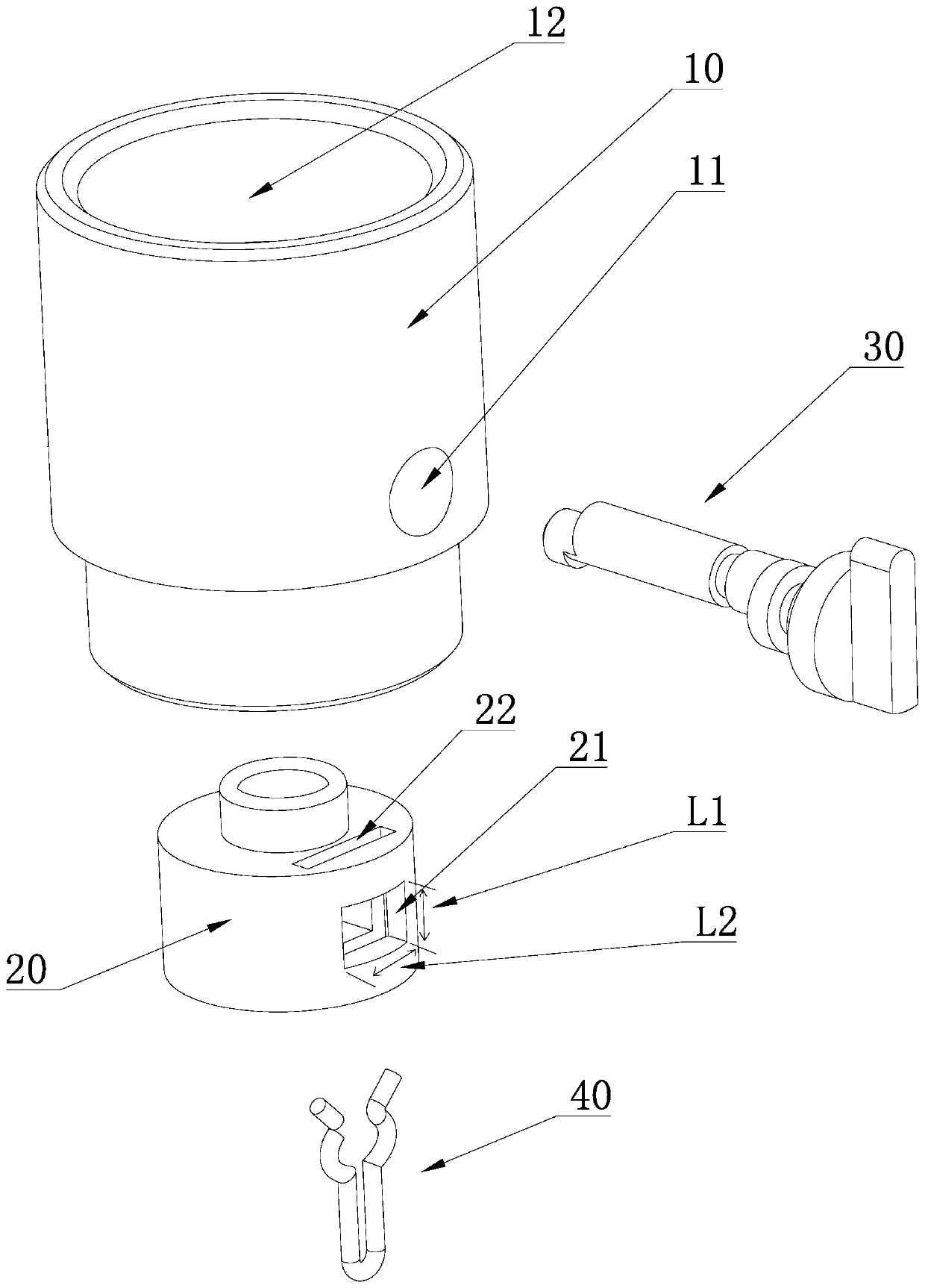

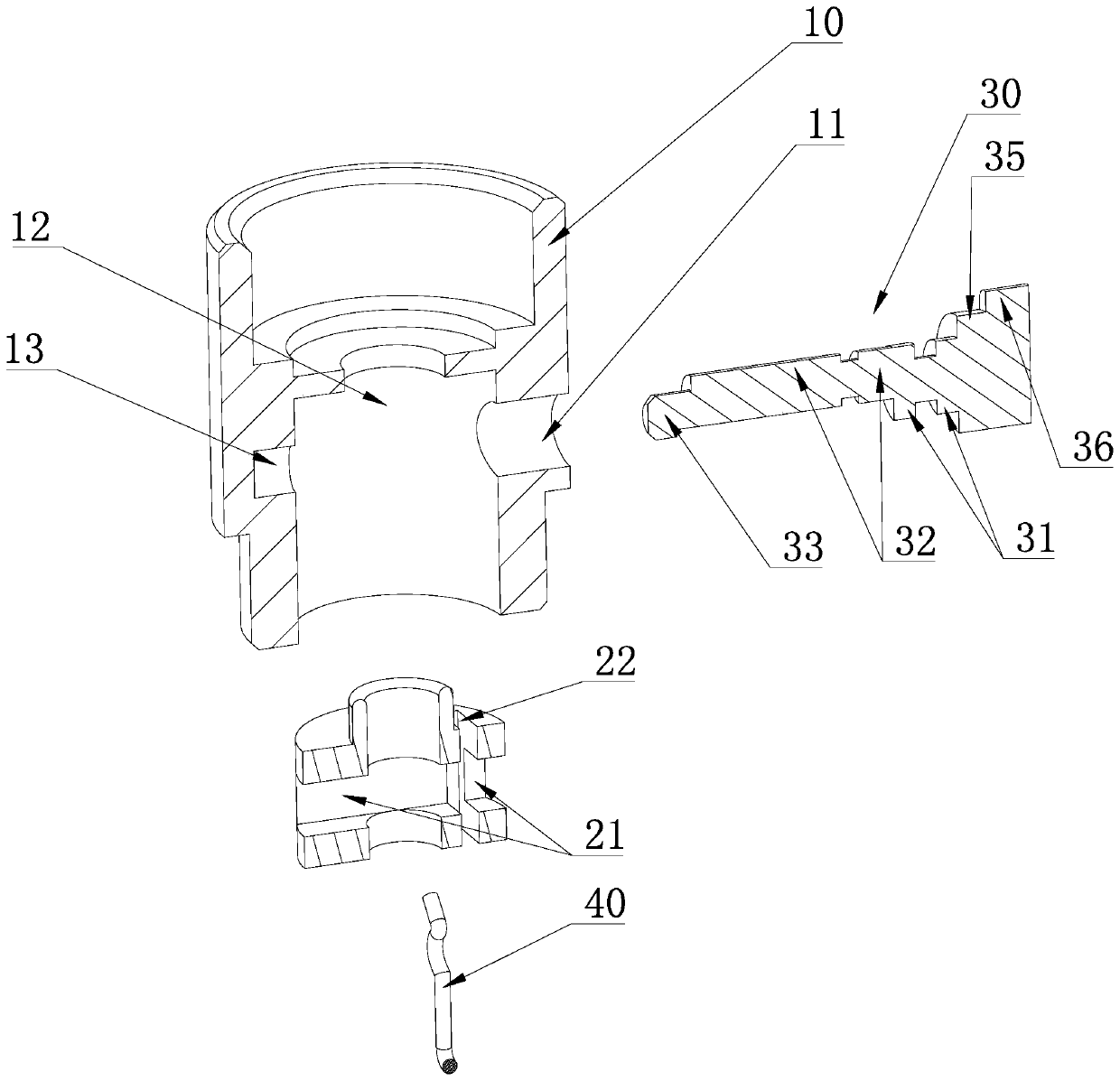

Buckle type connection structure of contactor

ActiveCN104064405ASimple structural designEasy core pullingElectromagnetic relay detailsEngineeringContactor

The invention discloses a buckle type connection structure of a contactor. The buckle type connection structure comprises a shell and a coil frame. Containing cavities used for mounting contacts are formed in the shell and are separated by side plates. The buckle type connection structure is characterized in that the coil frame and the shell are connected through a first buckle, the first buckle protrudes and extends on the center side plate of the shell to be a buckle, the center side plate is on the axial center line of the shell, correspondingly, a limiting groove which is matched with the center side plate is formed on the coil frame, the coil frame is inserted into the shell, the center side plate passes through the limiting groove, the center side plate buckle is hooked on the coil frame at one side of the limiting groove, and the coil frame and the shell are connected. According to the buckle type connection structure, the contactor is suitable for automatic assembly, and the production cost is reduced.

Owner:XIAMEN HONGFA ELECTRICAL SAFETY & CONTROLS CO LTD

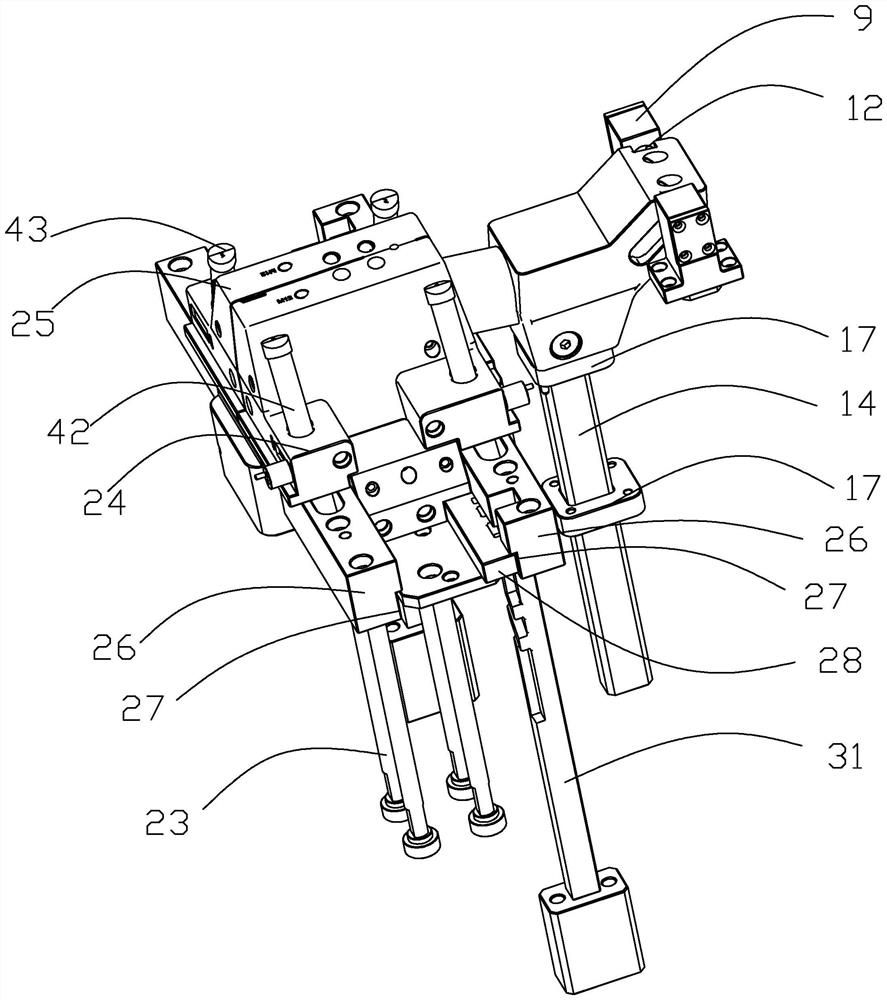

Core pulling mechanism of automobile rear door handle

The invention discloses a core pulling mechanism of an automobile rear door handle. The core pulling mechanism comprises a product, a lower die plate, a first mold core, a second mold core, a large sliding block and an air cylinder, wherein a rectangular post is arranged on the inner side wall of the product, a groove is formed in the rectangular post in the axis direction of the rectangular post,a buckle is arranged on the top of a groove, the first mold core is used for forming the upper part of the groove, the second mold core is used for forming the lower part of the groove, a bulged block which is used for forming the buckle and protrudes from the upper surface of the first mold core is arranged on the upper surface of the first mold core, a first open groove is formed in the lower die plate, the large sliding block can be matched with the interior of the first open groove in a forward and backward sliding mode, the large sliding block is driven by the air cylinder, a first sliding block is arranged on one end, which is away from the product, of the first mold core, a second sliding block is arranged on one end, which is away from the product, of the second mold core, and oneend, which is away from the product, of the second sliding block is arranged on the large sliding block. The core pulling mechanism of the automobile rear door handle has the advantages of low cost and high efficiency.

Owner:NINGBO FANGZHENG TOOL

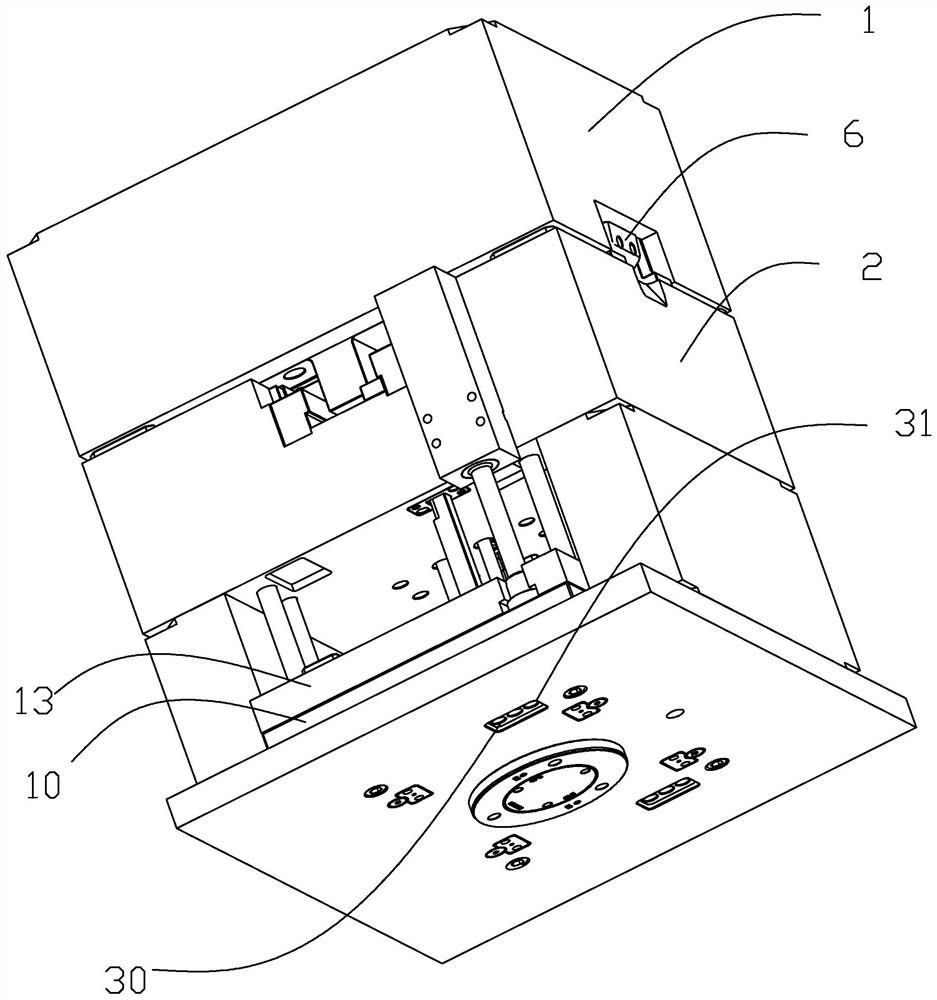

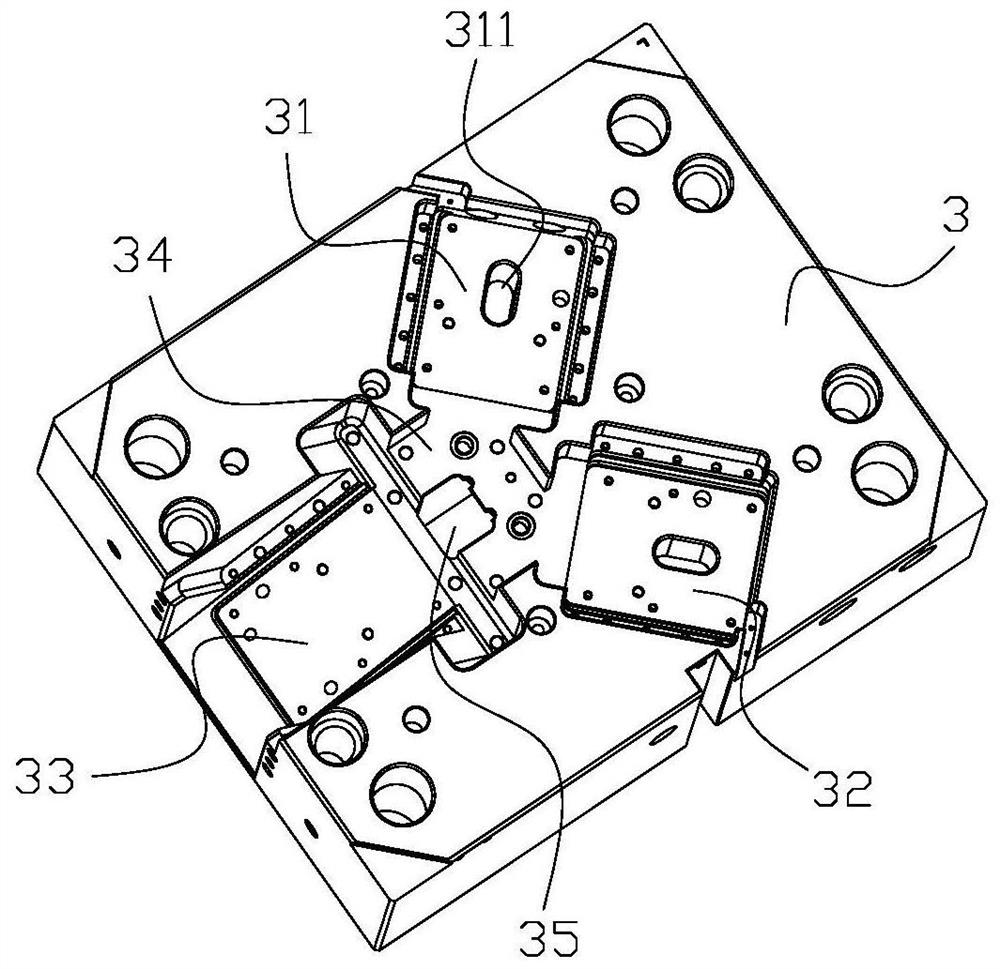

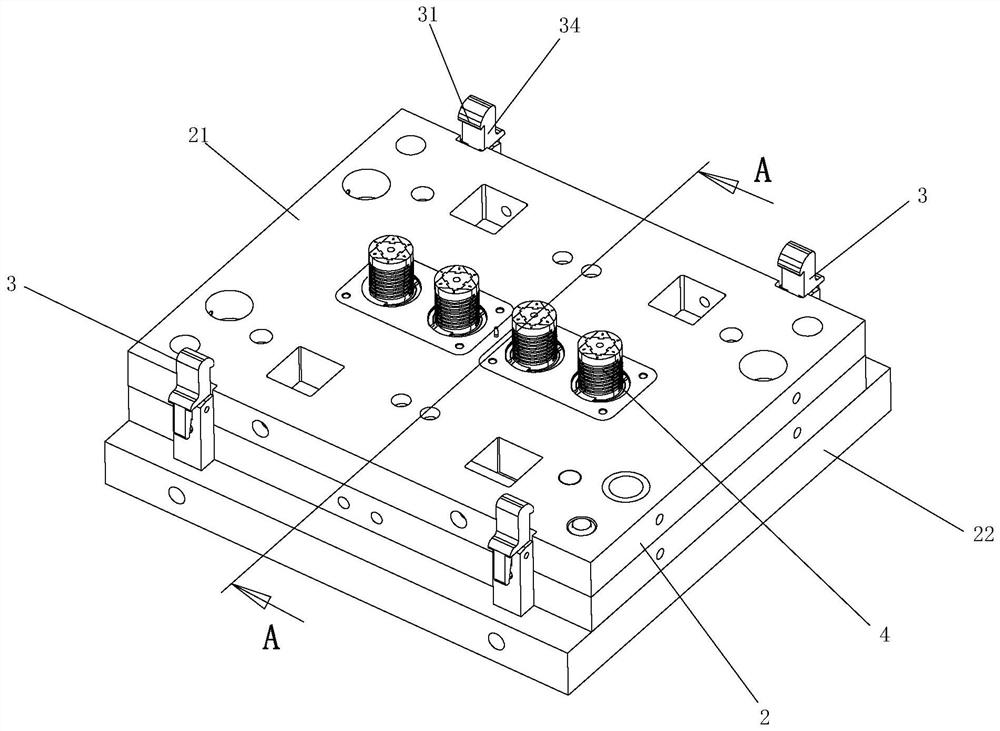

Bicolor mold

ActiveCN104772855AHigh dimensional accuracy requirementsLow machining accuracy requirementsMaterials science

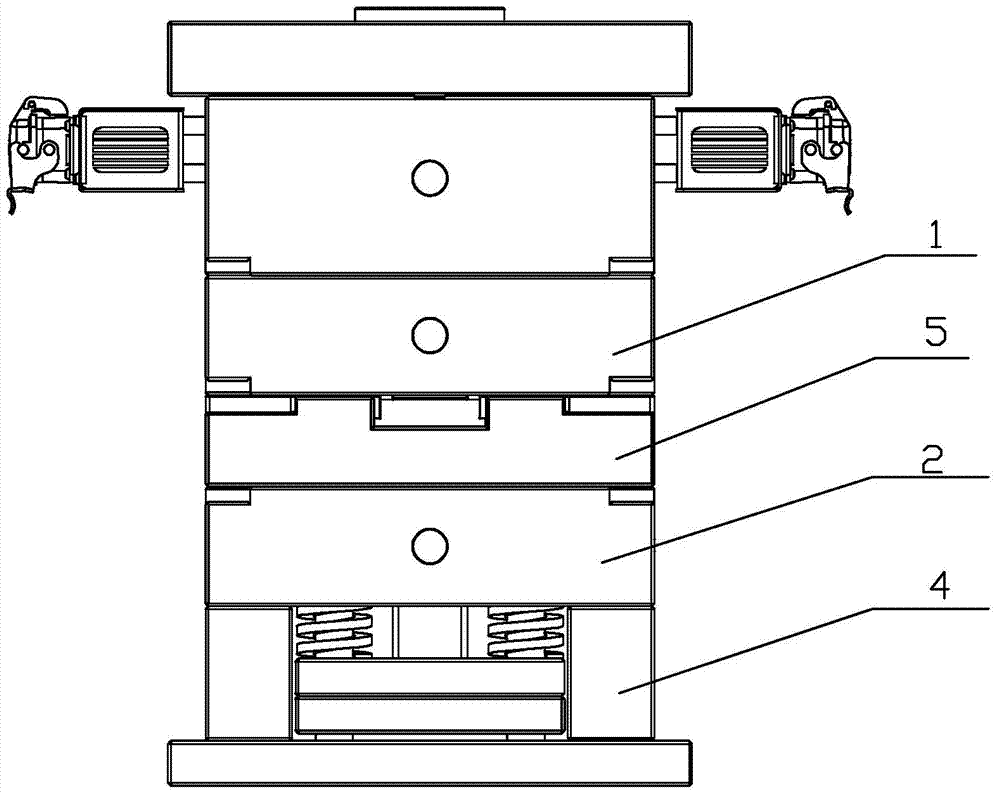

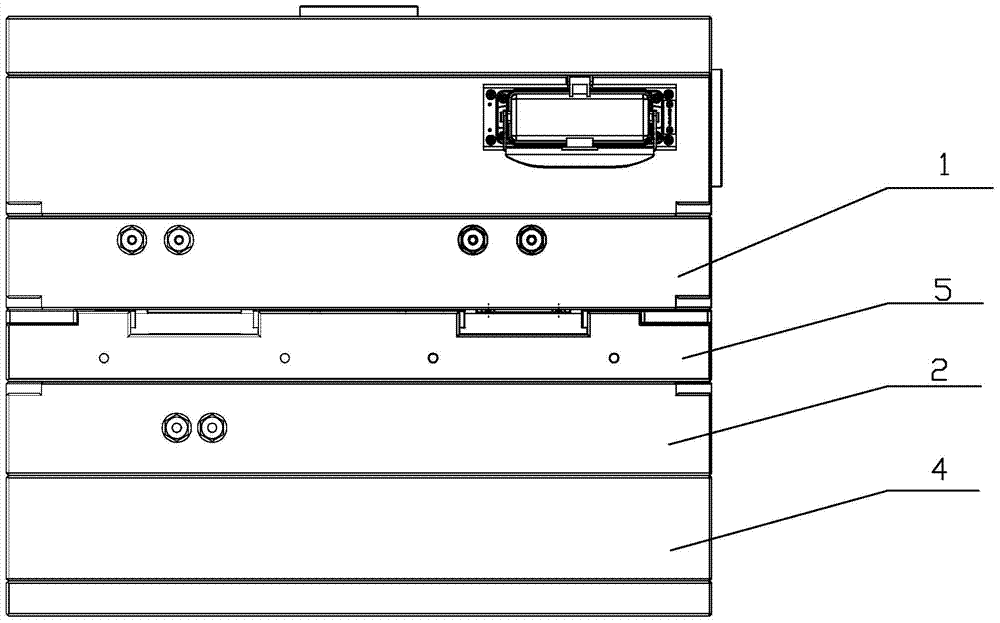

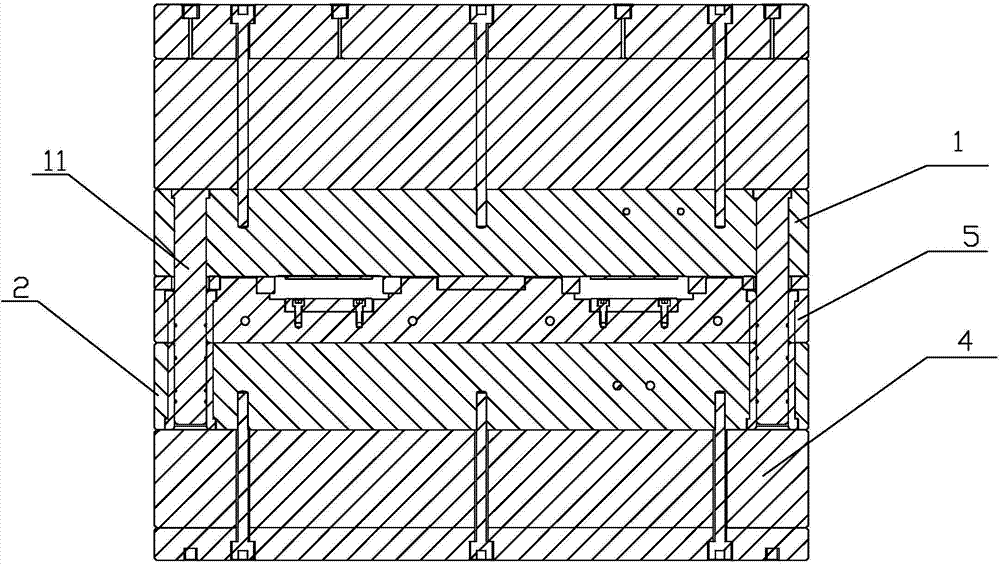

The invention discloses a bicolor mold, which comprises an upper mold plate (1), a lower mold plate (2), a sliding block (3) and a mold mount (4), wherein the lower mold plate (2) is fixed on the mold mount (4); the upper mold plate (1) is arranged above the lower mold plate (2); a front mold push plate (5) is arranged between the upper mold plate (1) and the lower mold plate (2); the sliding block (3) is arranged on the front mold push plate (5); during demolding, the front mold push plate (5) and the upper mold plate (1) together are disconnected together with the lower mold plate (2) and the front mold push plate (5) is separated with the upper mold plate (2); a turntable is fixed on the lower surface of the mold mount (4); a guide column hole (6) is formed in the sliding block (3); a guide column (7) in sliding match with the guide column hole (6) is arranged on the upper mold plate (1). According to the bicolor mold, the cost is greatly reduced as the precision requirement of mold processing is low.

Owner:宁波永成蓝鲸模具有限公司

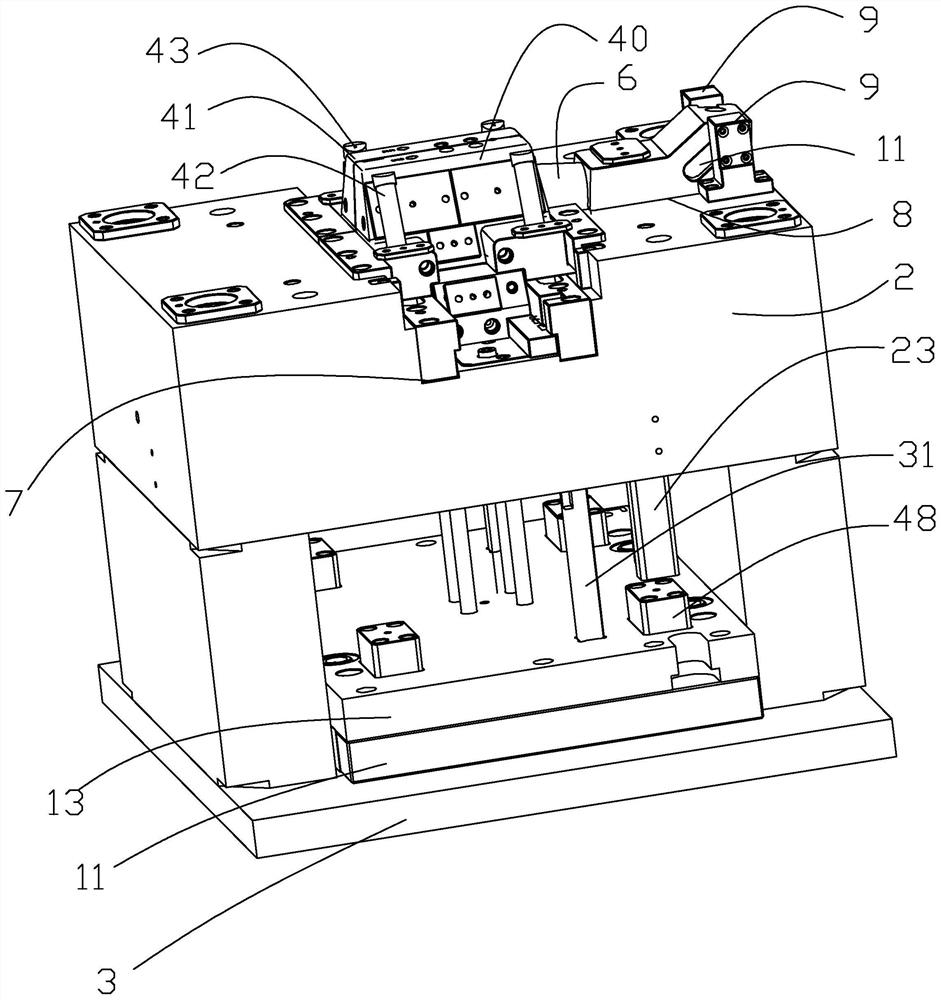

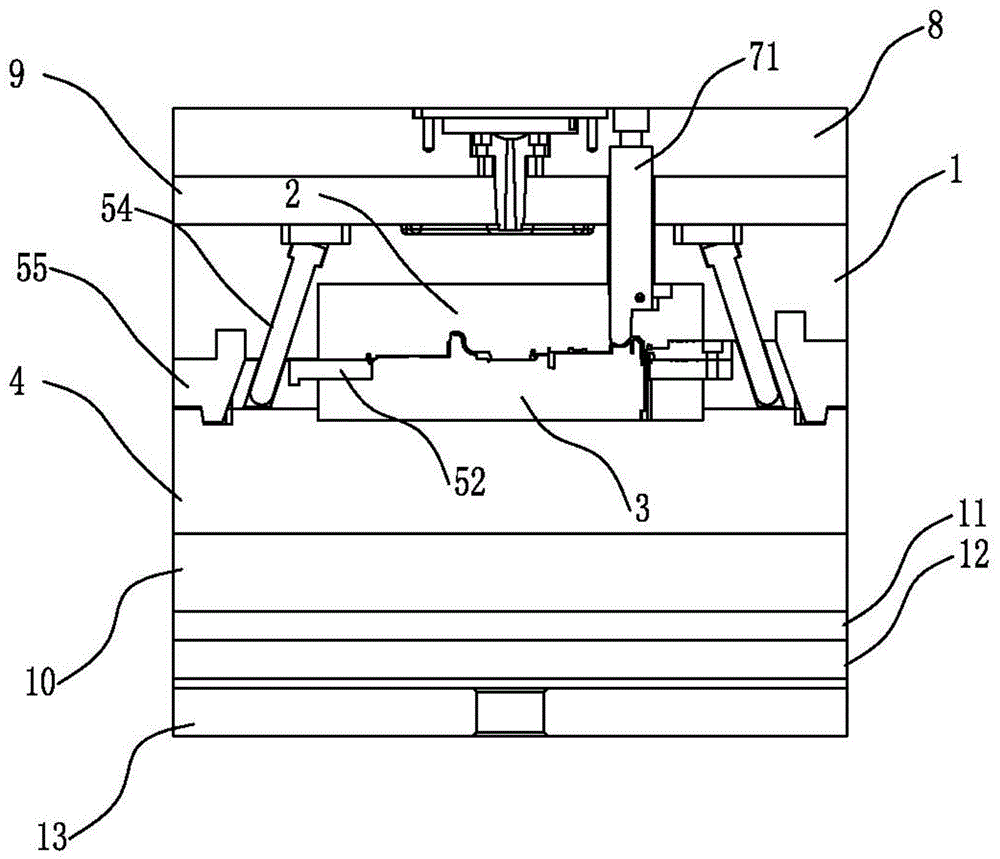

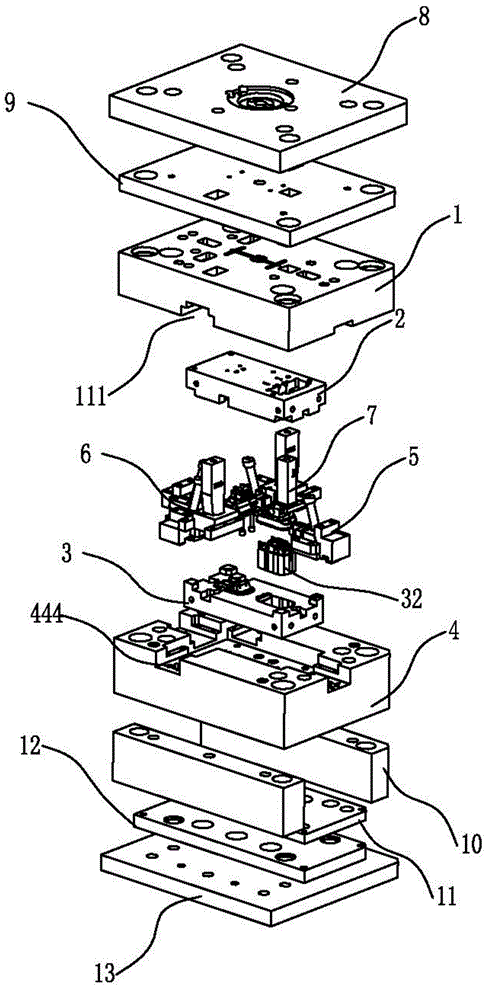

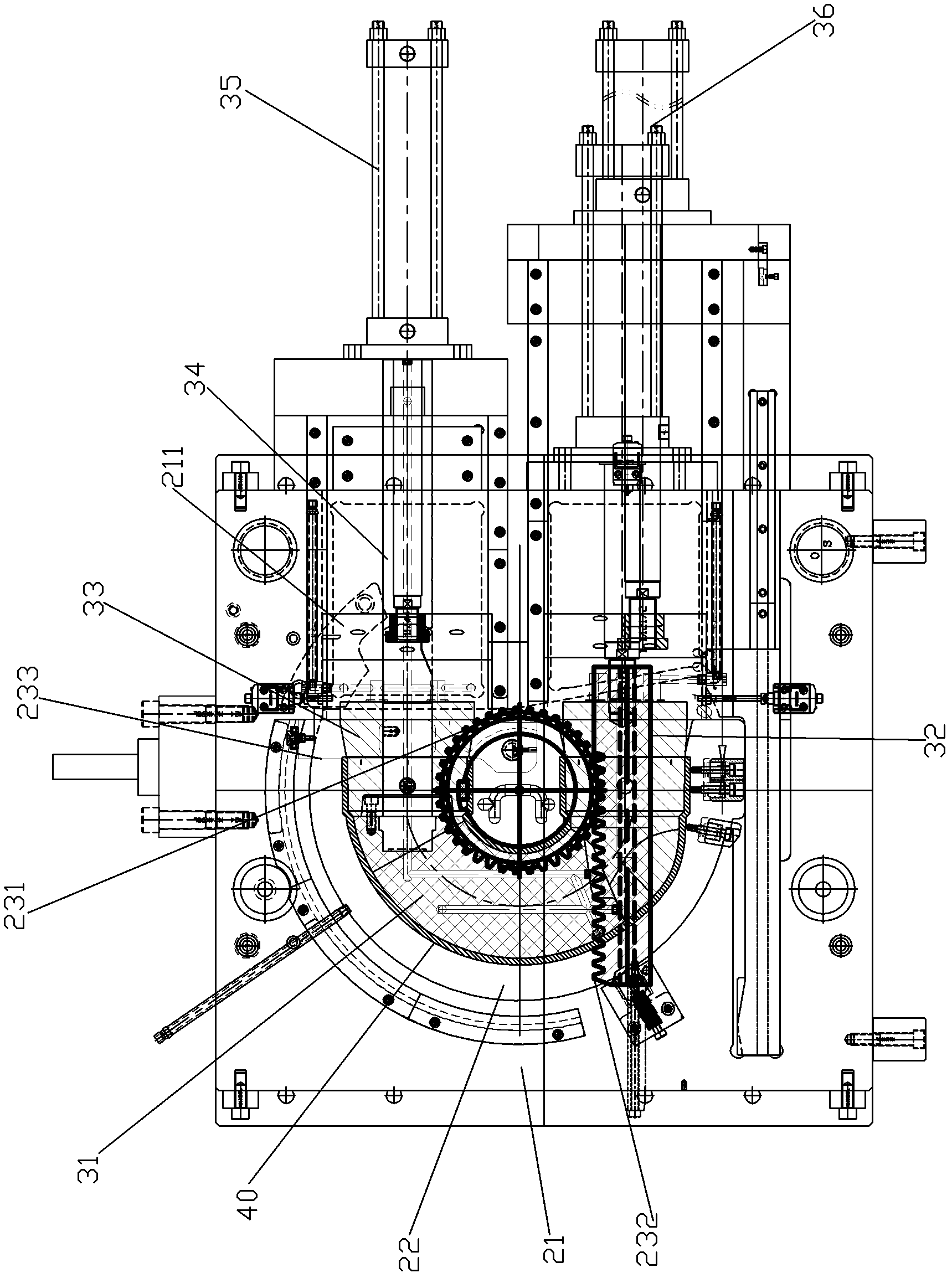

Double-safety die

PendingCN112060499ARealize in and outRealize core pulling operationStructural engineeringMechanical engineering

The invention discloses a double-safety die. The double-safety die comprises an upper die, a lower die, a die opening safety part, a die closing safety part, a top plate, side pulling blocks and a pulling rod, the upper end of the pulling rod is arranged on the top plate, and an obliquely-arranged limiting sliding rail is arranged at the lower end of the pulling rod; the side pulling blocks are arranged in the upper die in a sliding mode, a forming cavity is defined by the side pulling blocks, the upper die and the lower die, and the ends, away from the forming cavity, of the side pulling blocks are arranged in the limiting sliding rail in a sliding mode; the top plate is movably arranged on the upper portion of the upper die in the up-down direction, and the side pulling blocks can be forced to slide in and out of the forming cavity by moving the top plate up and down; and the die opening safety part is arranged between the upper die and the lower die, and the die closing safety partis arranged between the top plate and the upper die. All the side pulling blocks can be controlled to achieve core pulling and core feeding at the same time by moving the top plate up and down, the upper die and the lower die are locked through the die opening safety part before core pulling, core feeding is limited through the die closing safety part before die closing, and the double-safety dieis simple in structure, reasonable in layout, low in cost, and convenient to install and control and has small requirement for an air cylinder.

Owner:宁波华众模具制造有限公司

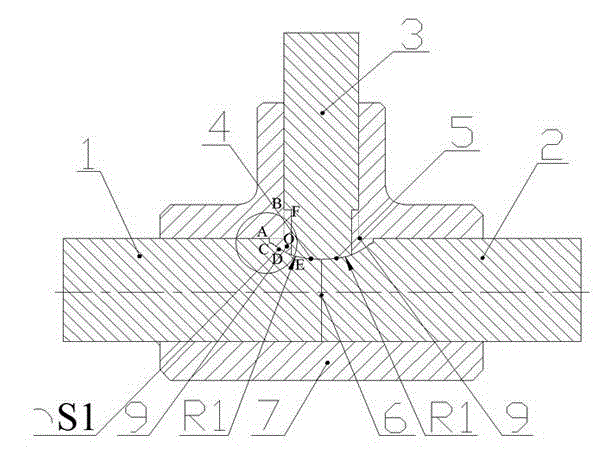

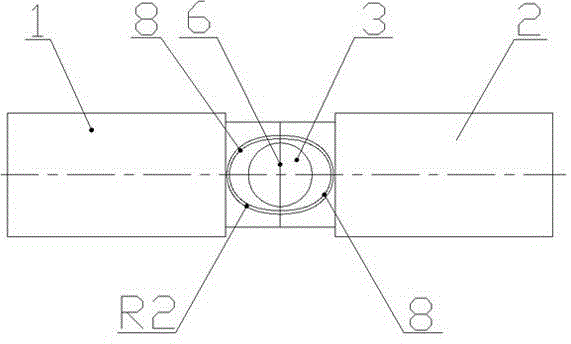

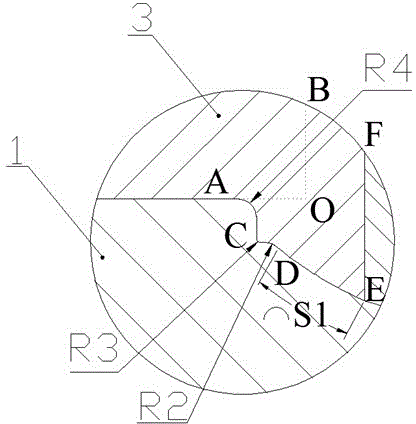

Structure for relieving stress concentration of intersecting lines inside plastic tee pipe

InactiveCN103398258AEasy to useSpeed up the flowPipe connection arrangementsStress concentrationEngineering

The invention relates to the technical field of pipes, in particular to a structure for relieving stress concentration of intersecting lines inside a plastic tee pipe. The structure for relieving the stress concentration of the intersecting lines inside the plastic tee pipe comprises the plastic tee pipe, the inside of the plastic tee pipe comprises a first pipe tube, a second pipe tube and a third pipe tube, the first pipe tube and the second pipe tube are arranged in left-right symmetry, the third pipe tube is arranged to be vertically upward, and circular-arc-shaped bosses are arranged at the intersecting position of the third pipe tube and the first pipe tube and the intersecting position of the third pipe tube and the second pipe tube. Compared with the method for improving the entire strength of the plastic pipe by increasing the thickness or adding ribs, a plastic pipe product manufactured by using the structure can effectively save materials and lower the production cost of the plastic pipe. Compared with an original structure, the plastic pipe manufactured by using the structure can effectively lower the degree of the stress concentration of the intersecting lines inside by more than 20%, crackles are prevented, the service life of the plastic pipe is prolonged, and safe using of the plastic pipe is guaranteed.

Owner:GUANGDONG LIANSU TECH INDAL

Nylon latch lock and inclined top combined core pulling mechanism

The invention provides a nylon latch lock and inclined top combined core pulling mechanism. The nylon latch lock and inclined top combined core pulling mechanism comprises a movable mould plate, a fixed mould plate, a nylon latch lock component and an inclined top component; the nylon latch lock component comprises a nylon latch lock and a nylon latch lock elastic block; the inclined top componentcomprises an inclined top bottom plate and an inclined top arranged below the inclined top bottom plate; the nylon latch lock elastic block is arranged in a nylon latch lock elastic block groove in the inclined top bottom plate; and the nylon latch lock elastic block can move along with the movement of the nylon latch lock, and then drives the inclined top bottom plate to move, so that the inclined top moves in a core pulling direction. According to the nylon latch lock component and inclined top component combined core pulling mechanism structure adopted by the invention, core-pulling molding of the inclined top is realized by driving the inclined top component to move by utilizing the nylon latch lock component; the overall structure is simple; the stability is high; and various components are embedded and spliced, so that detachment is facilitated and replacement is facilitated; the cost of a mold is also reduced; and the processing period is shortened.

Owner:NINGBO AUX ELECTRIC +1

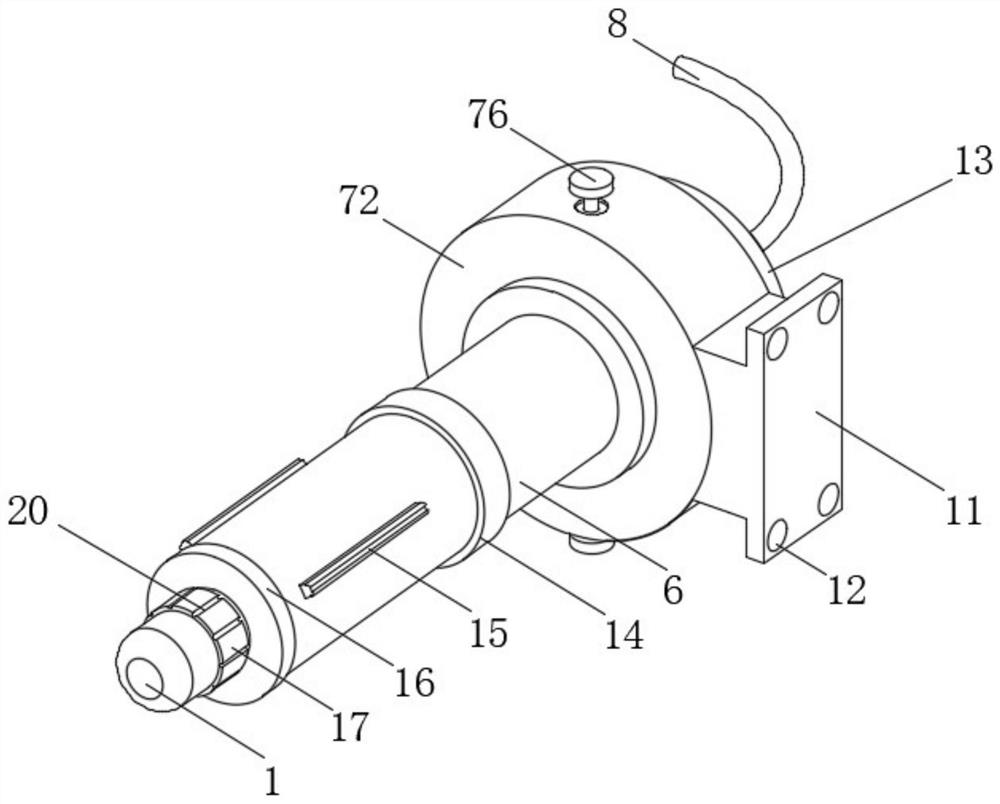

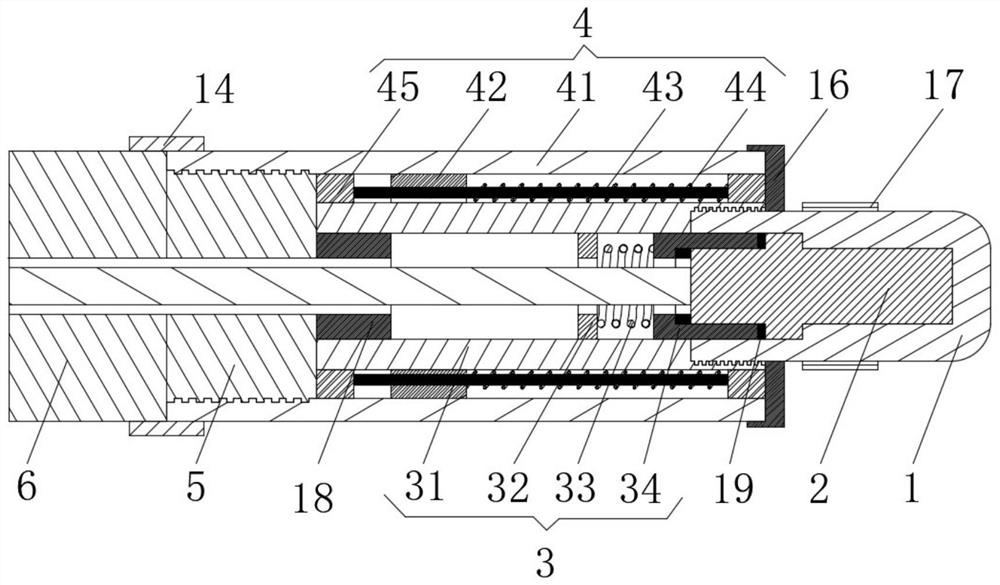

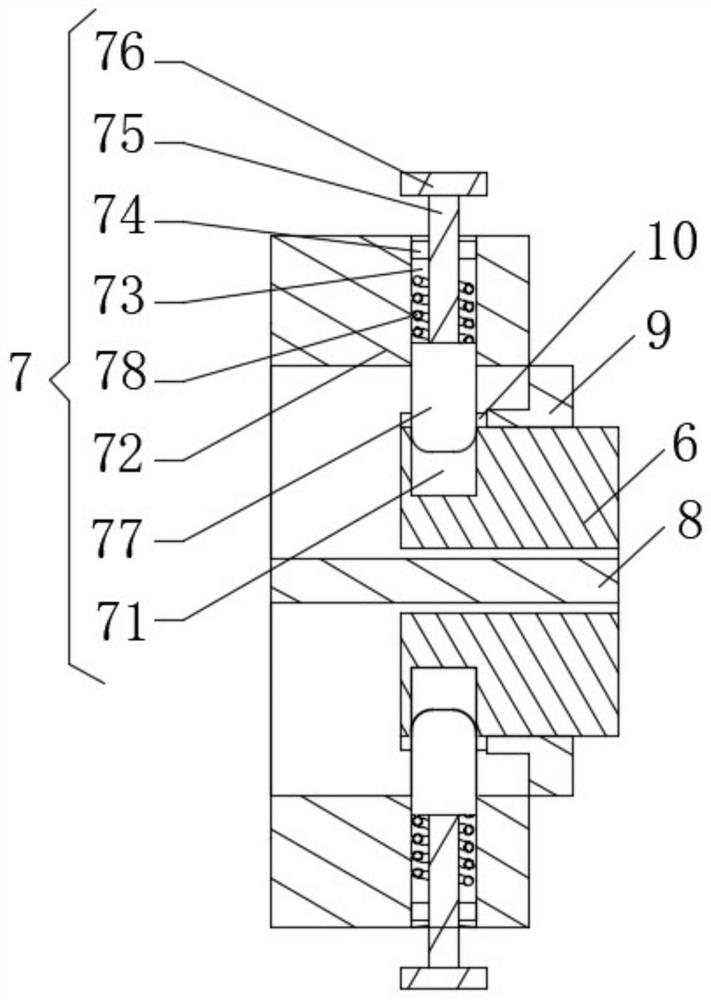

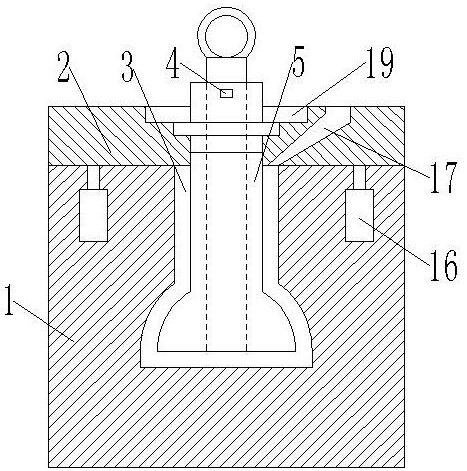

Temperature sensor facilitating core pulling

InactiveCN112304448AEasy core pullingEasy to replaceThermometer detailsThermometers using electric/magnetic elementsPhysicsThreaded pipe

The invention discloses a temperature sensor facilitating core pulling. The temperature sensor comprises a mounting shaft, a fixing assembly, a damping assembly, a rubber external threaded pipe and aconnecting assembly; a mounting groove is formed in the right end surface of the mounting shaft, and a thermocouple is arranged in the mounting groove; the fixing assembly comprises a connecting pipe,a fixing ring, an extrusion spring and an extrusion barrel, the right end of the mounting shaft is in threaded connection with the left end of the interior of the connecting pipe, the fixing ring isfixed in the connecting pipe, the extrusion spring is fixed to the left end face of the fixing ring, and the left end of the extrusion spring is fixed to the right end face of the extrusion barrel; the extrusion barrel is slidably connected to the left end of the interior of the connecting pipe, an opening is formed in the middle of the extrusion barrel, the left end of the extrusion barrel is located in a mounting groove formed in the right end face of the mounting shaft, a thermal resistor or a thermocouple is convenient to replace, and the temperature sensor has very high anti-seismic property and can be mounted very conveniently.

Owner:温州铂临信息科技有限公司

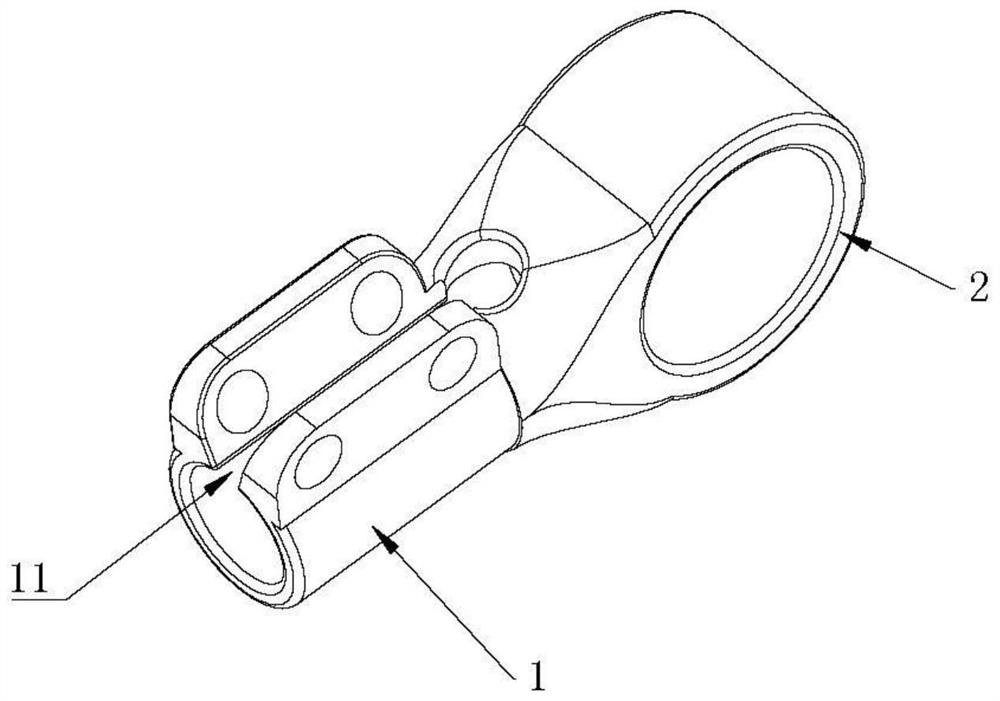

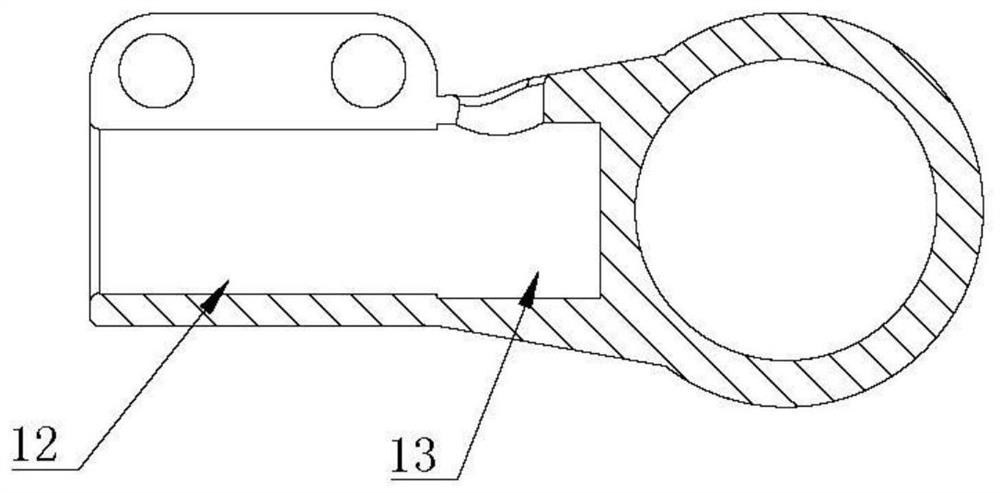

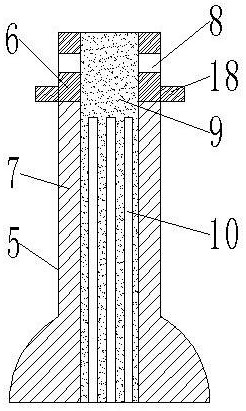

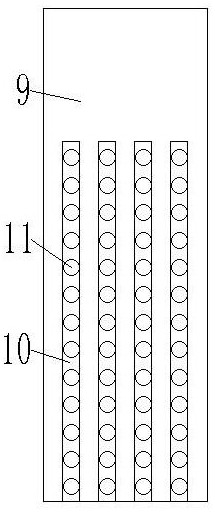

Internal core pulling structure

Mold processing is a conventional means of the existing mechanical processing, demolding is an important step of the mold processing, the existing slide-block core pulling cannot meet the requirement on pulling the core conveniently for a product with a horizontal inward concave on the inner side, secondary core pulling is needed, thus the production procedures are complicated, the processing time is wasted, the production efficiency of the product is lowered, and the processing precision of the product is low due to the incorrect location of the product after the product is restored. In order to solve the problems, the internal core pulling structure comprises a mold, a slide block and an unplugging pin, after the internal core pulling structure is used, when the core pulling is needed, the head of the unplugging pin is unplugged upwards, and the unplugging pin drives the slide block to move leftwards, so that the slide block is separated from the product; when the restoration is needed, the head of the unplugging pin is pressed down, the unplugging pin moves downwards, the slide block is driven to move rightwards, and since the position of the unplugging pin in restoration is fixed, an effect of precise location can be realized.

Owner:VANGUARD TECH WUXI

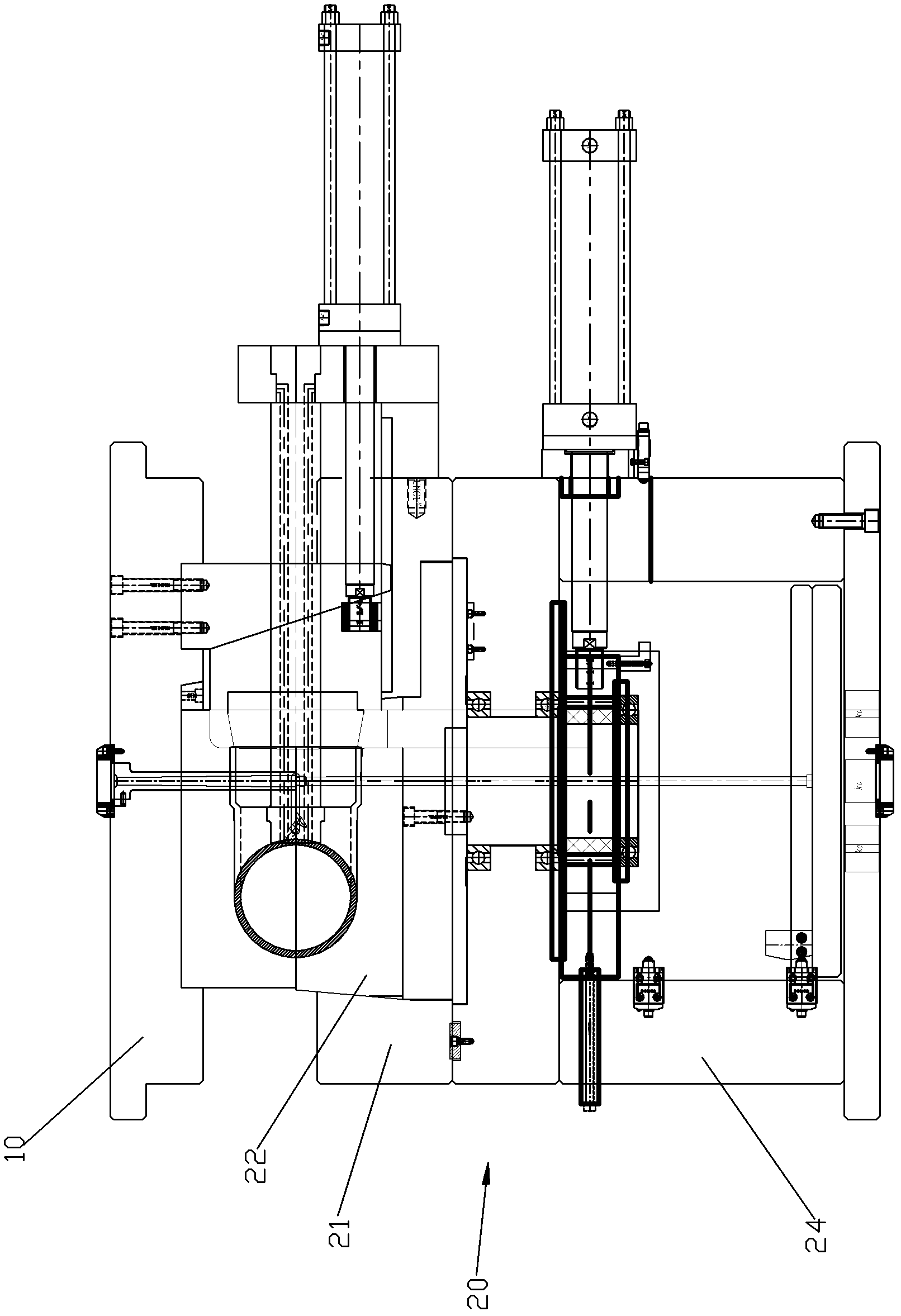

Engine exhaust pipe core pulling mechanism

The invention discloses a core-pulling mechanism for an engine exhaust pipe, comprising an upper template, a lower template, a mold foot, a product, a thimble plate and a mold core for forming a product, the upper template is located on the upper surface of the lower template, and the The lower template is located between the upper template and the die foot, the ejector plate is slidingly fitted between the die foot and the lower template, and the mold core includes a first mold core for forming the lower end of the product and a mold core for forming The second mold core in the upper end of the product, the first mold core corresponds to the linear core pulling of a small part of the product, the second mold core corresponds to the arc core pulling of most of the product, and the upper surface of the lower template is along the The width direction of the lower template is provided with a first opening groove, and the upper surface of the lower template is provided with a second opening groove along the length direction of the lower template, and one end of the second opening groove communicates with the first opening groove. The present invention provides a The core-pulling mechanism of the engine exhaust pipe is convenient and easy to pull the core.

Owner:NINGBO FANGZHENG TOOL

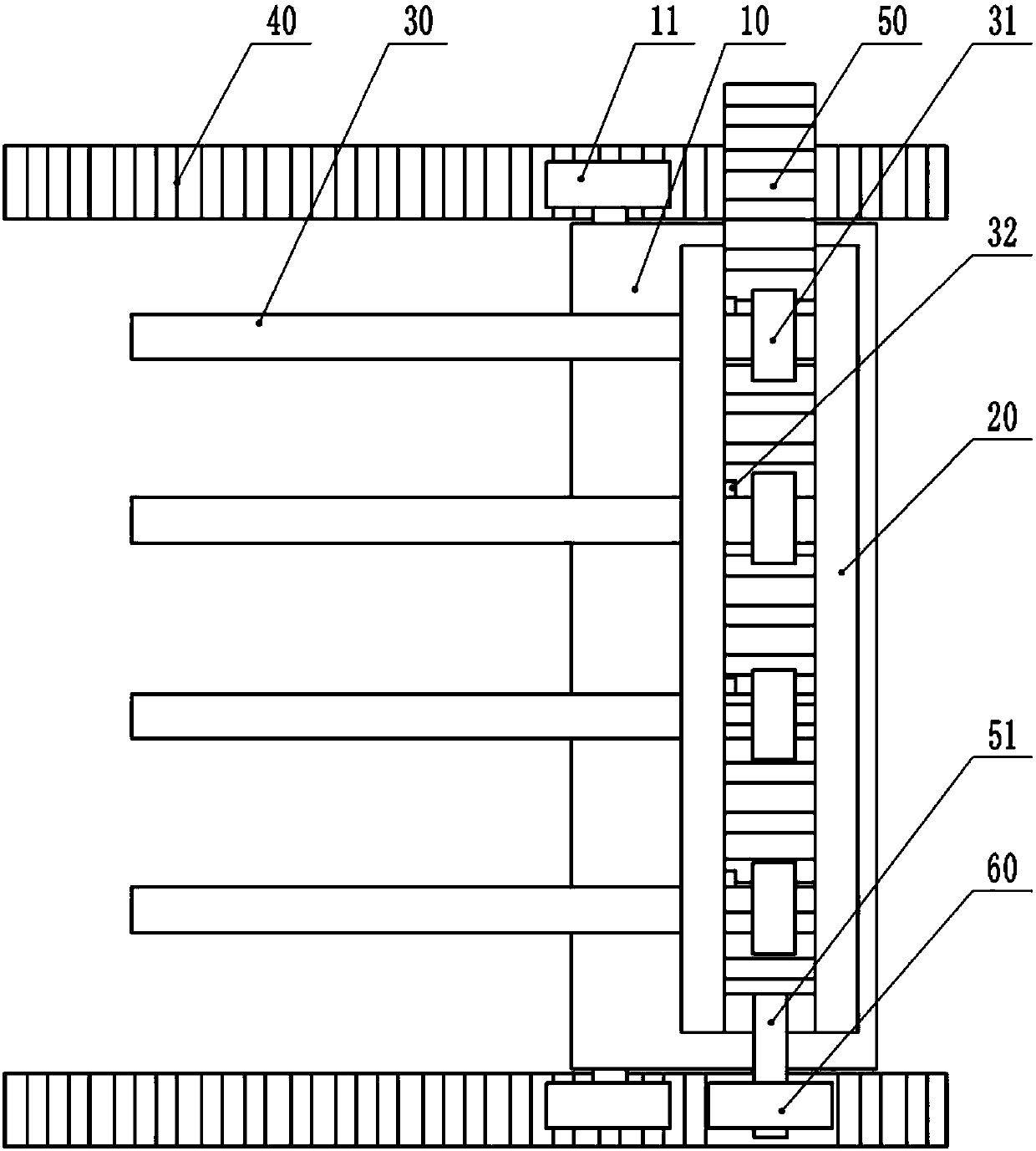

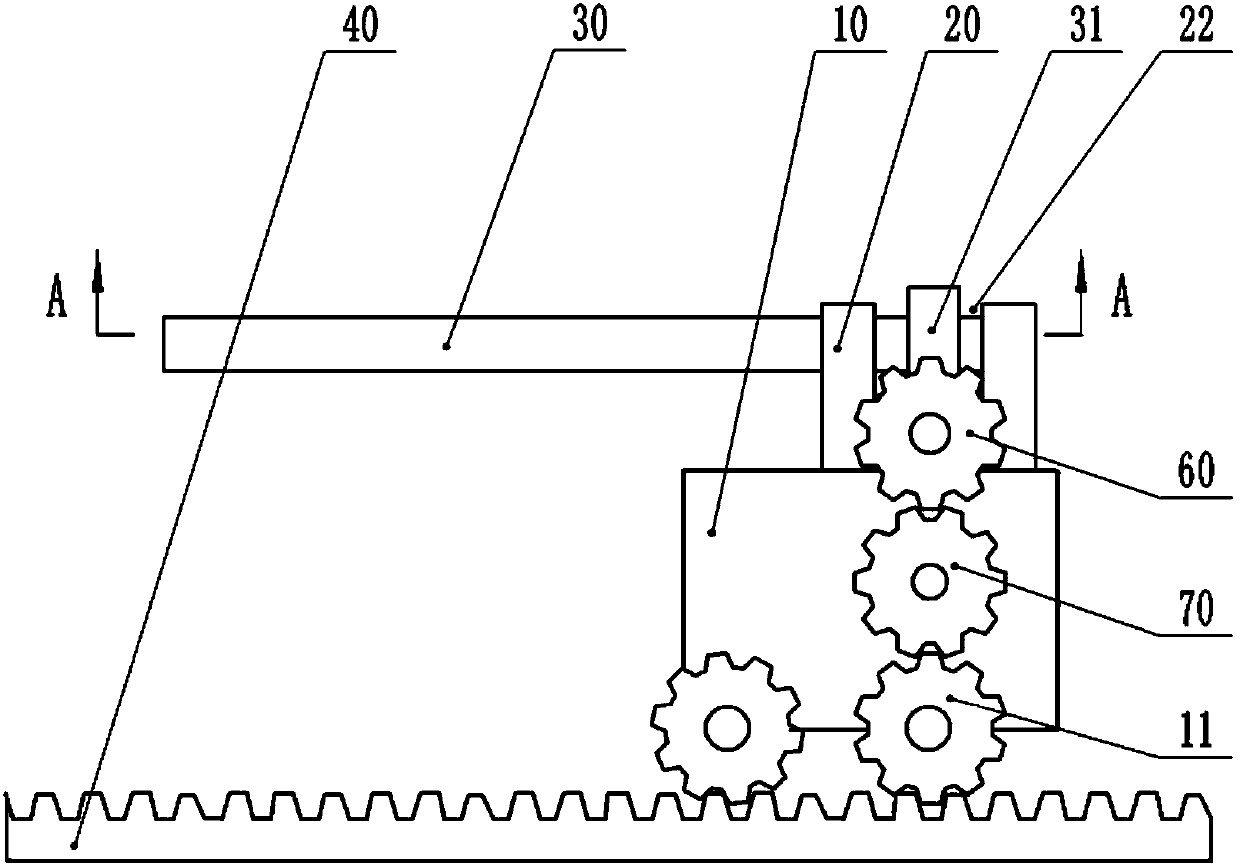

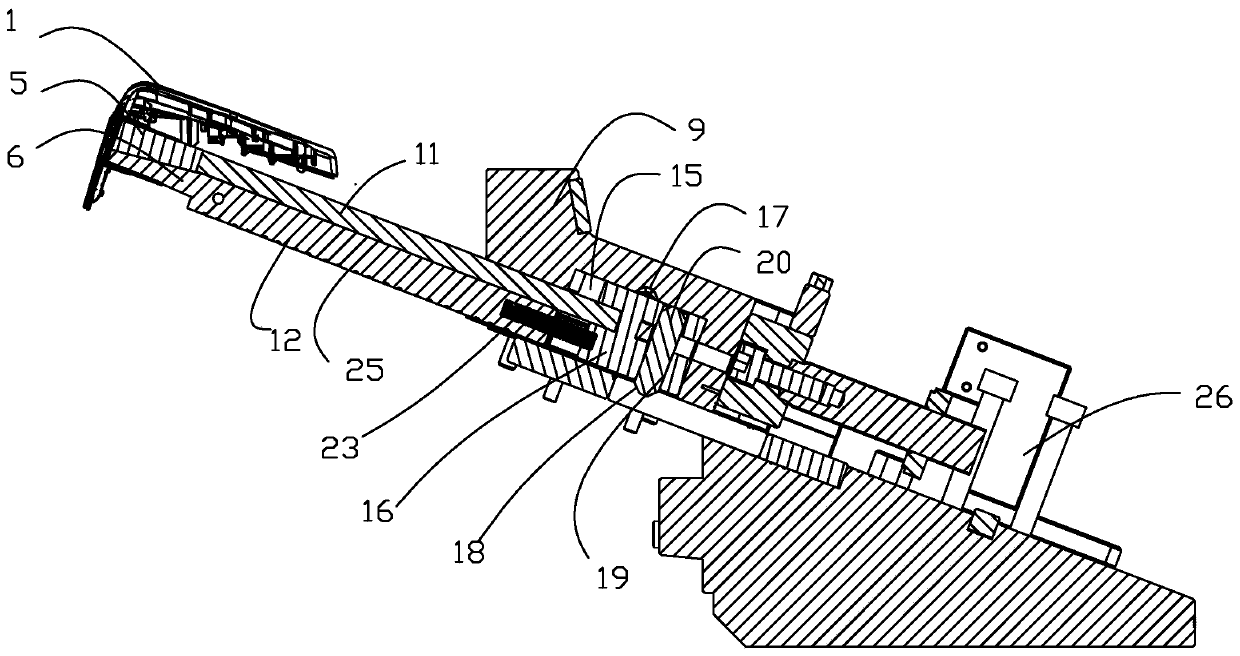

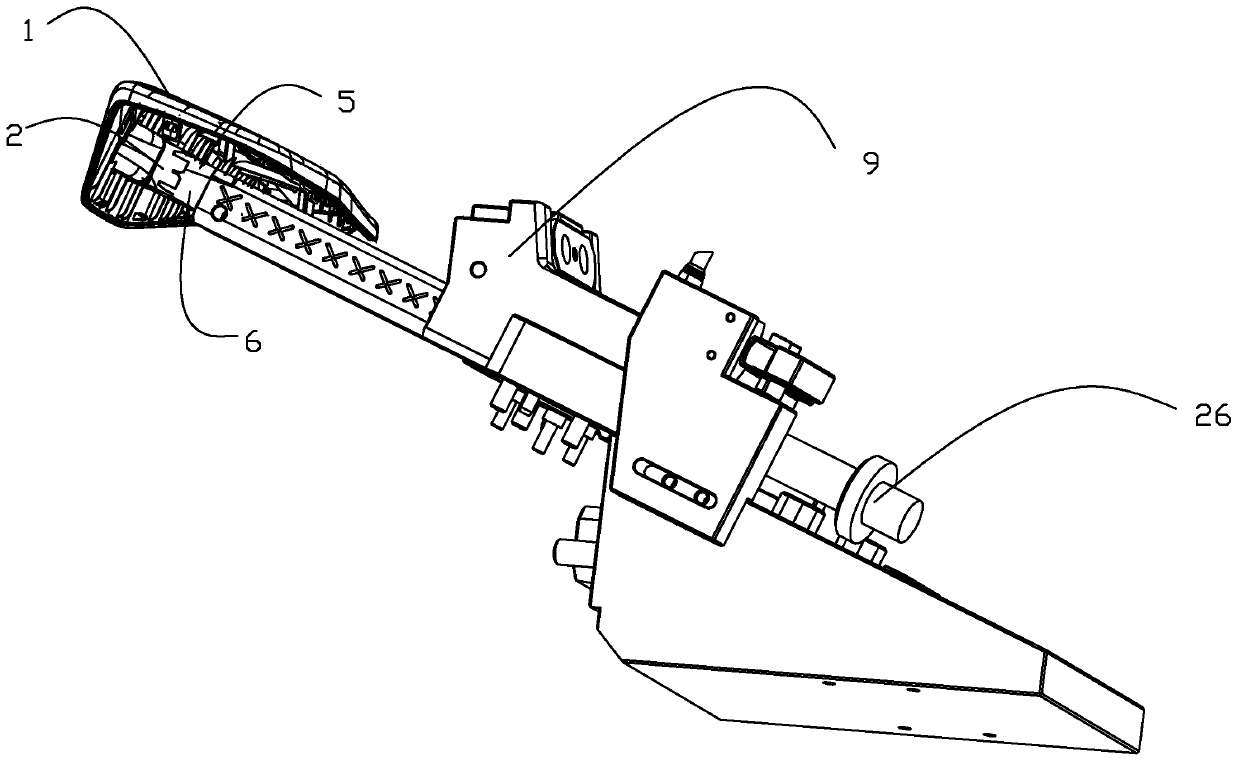

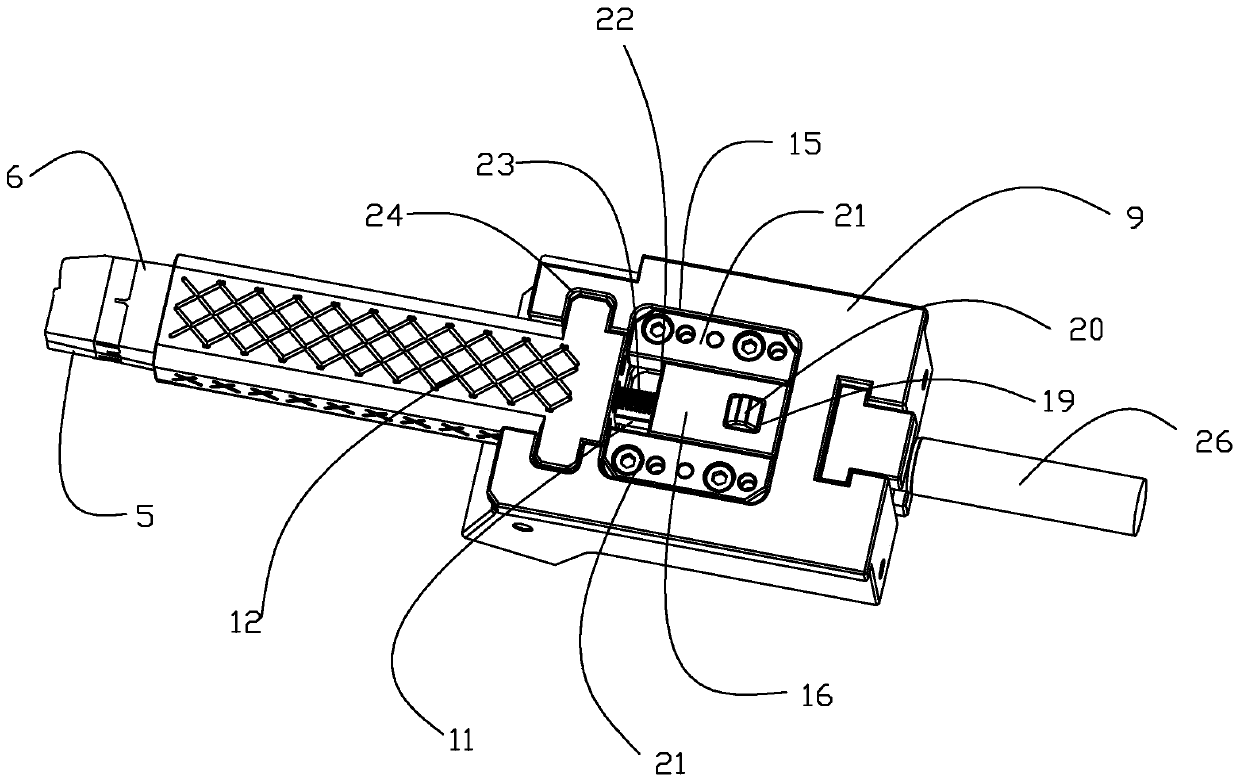

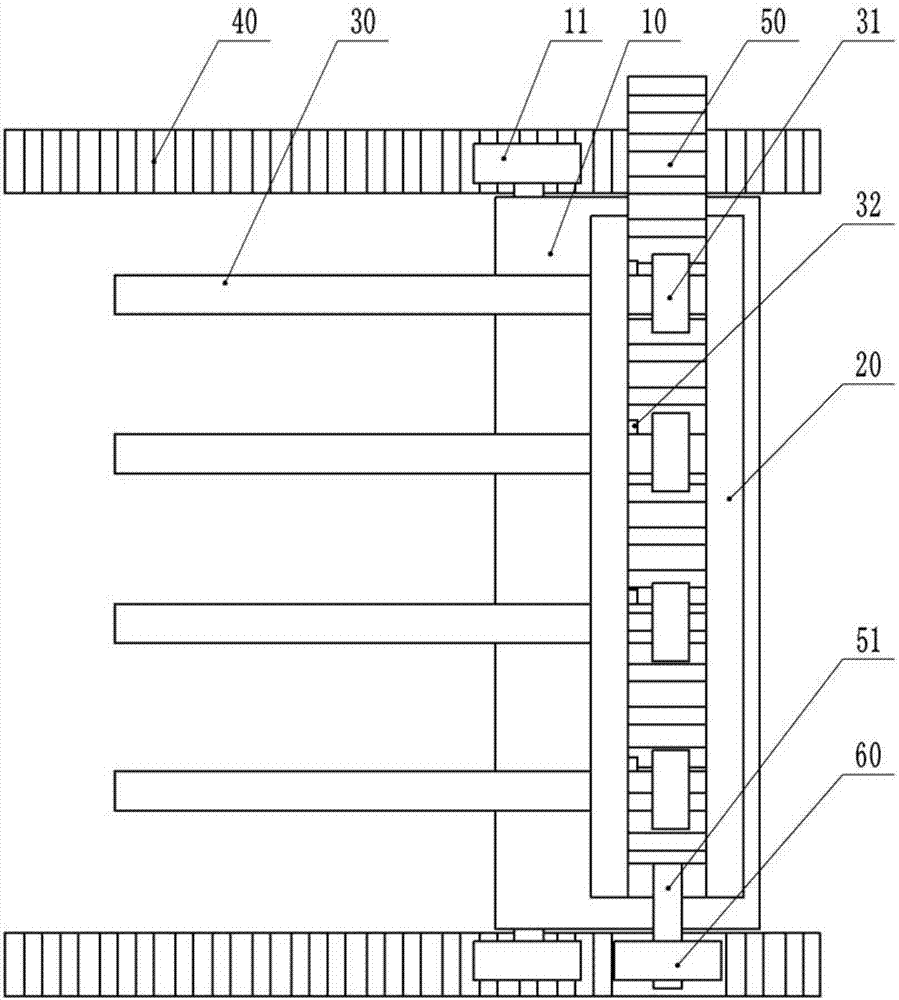

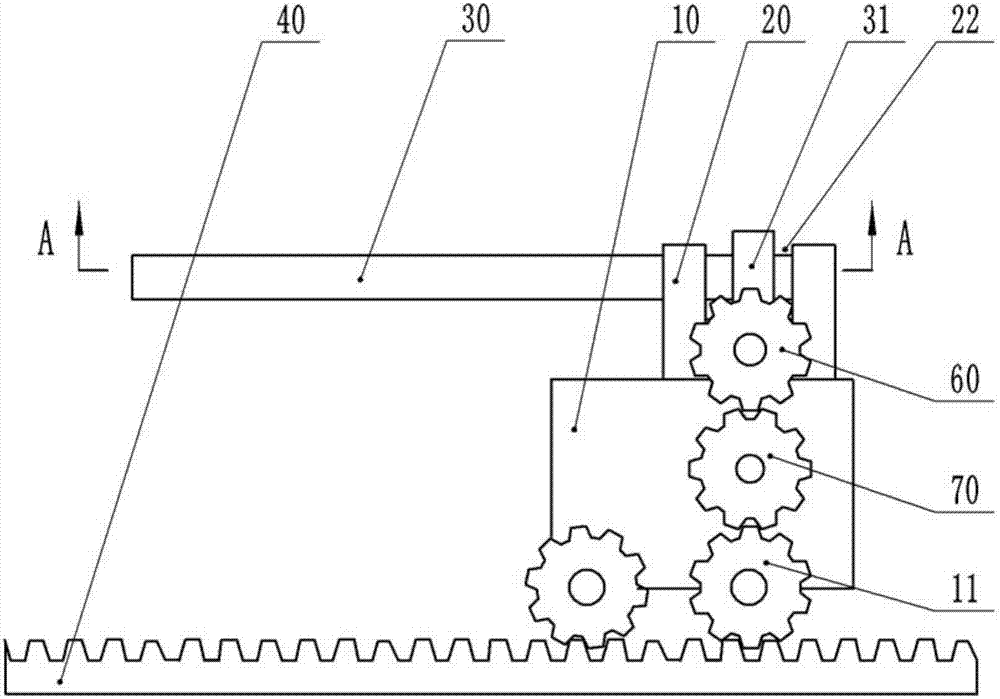

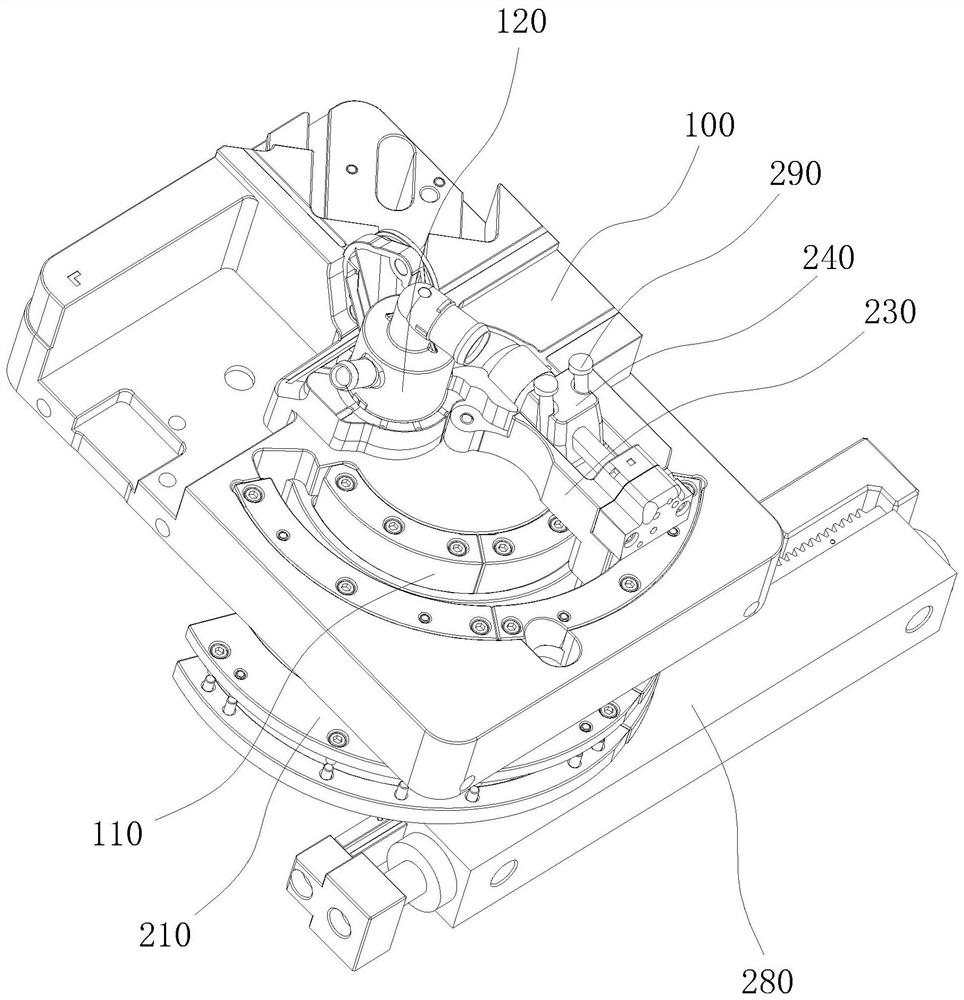

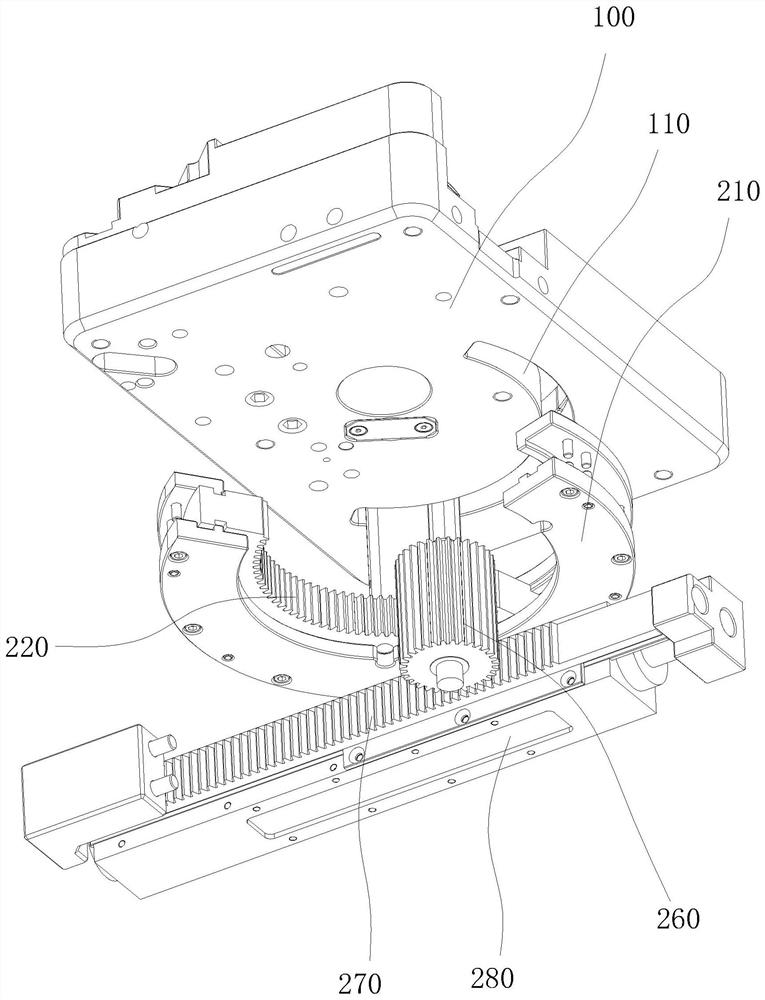

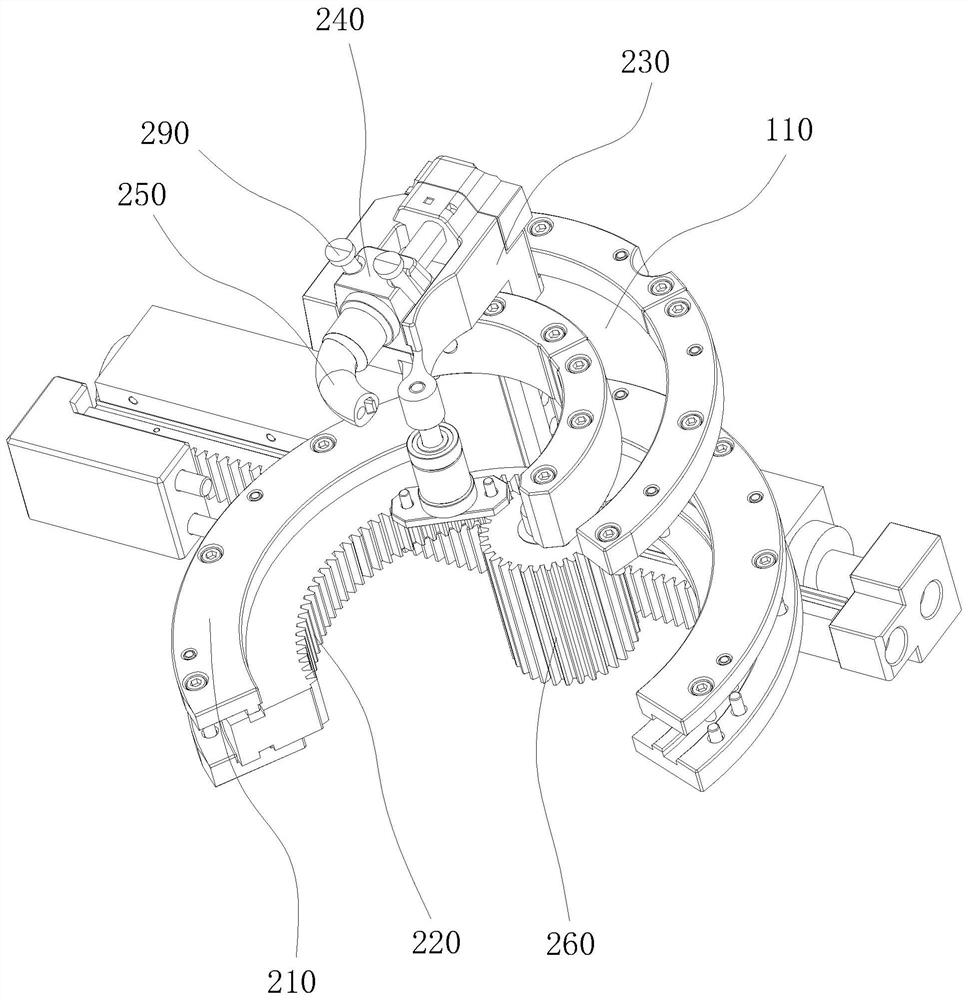

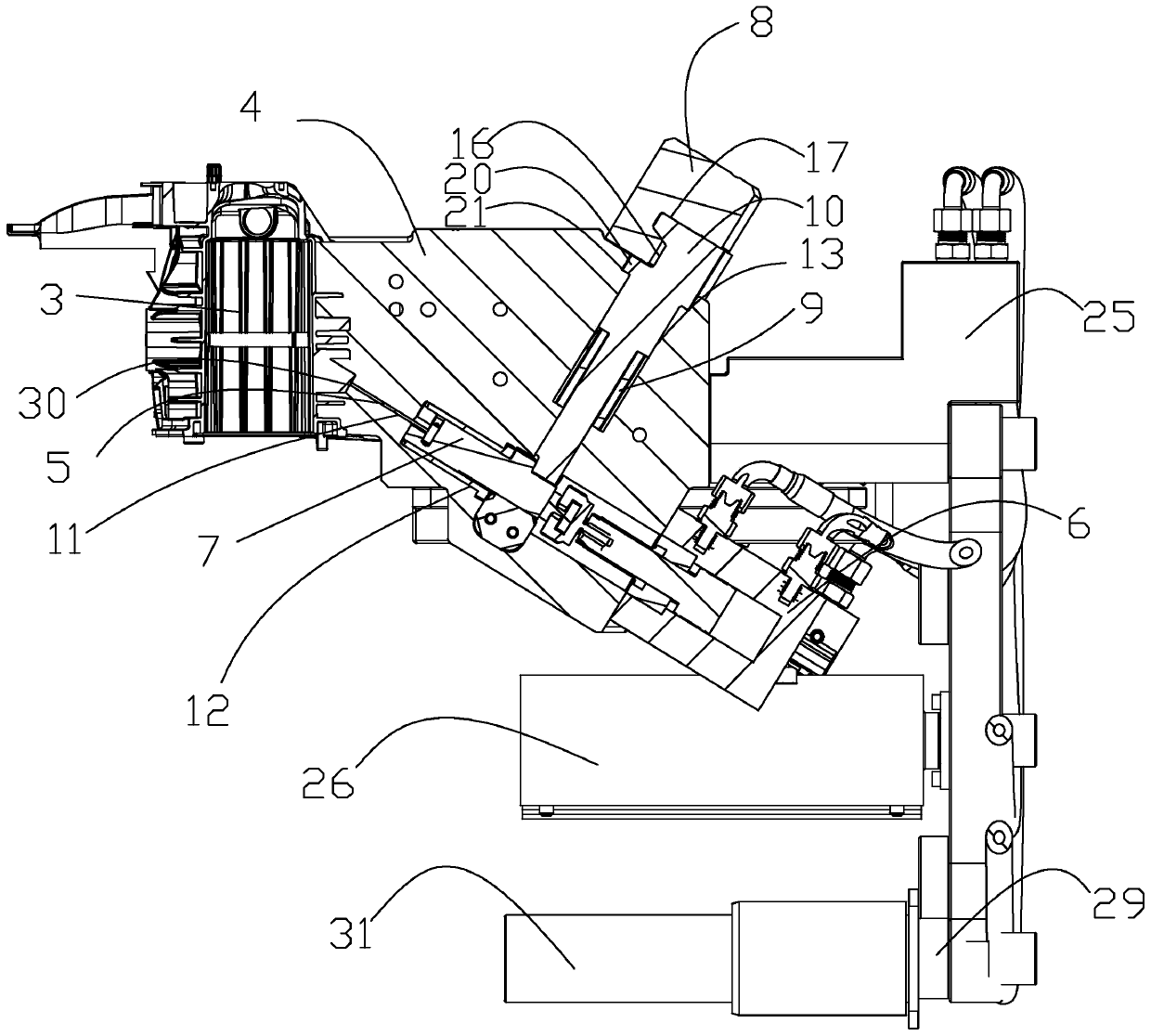

Steel pipe inserting and pulling device for light wallboard

ActiveCN107877679AEasy to drawAvoid stickingCeramic shaping mandrelsCeramic shaping coresEngineeringMechanical engineering

The invention belongs to the technical field of production equipment for light wallboards, and particularly discloses a steel pipe inserting and pulling device for a light wallboard. The steel pipe inserting and pulling device comprises a pulling-out trolley, a motor and a base; a cavity is formed in the base; a sliding groove is formed in the upper surface of the base; a rack is slidingly connected in the sliding groove; a plurality of supporting pipes are rotationally connected to the base; gears and limiting blocks are arranged on the supporting pipes; one ends of the supporting pipes are located in the cavity and communicate with the cavity, and the other ends of the supporting pipes are closed and penetrate through the base; one end of the rack is in threaded connection to a threadedcolumn; a driven gear is fixed to the threaded column; the motor is arranged on the pulling-out trolley; a driving gear is connected to an output shaft of the motor; at least one group of supporting blocks capable of being attached to the inner wall of a steel pipe are slidingly connected to the supporting pipes; one group of supporting blocks comprise at least two supporting blocks; and a plungerwith one end penetrating through the base is slidingly connected in the cavity. According to the steel pipe inserting and pulling device, in the process of steel pipe pulling operation, the steel pipe can rotate and move in a straight line as well, and the steel pipe pulling operation is simple and convenient.

Owner:重庆成维轻质墙板有限公司

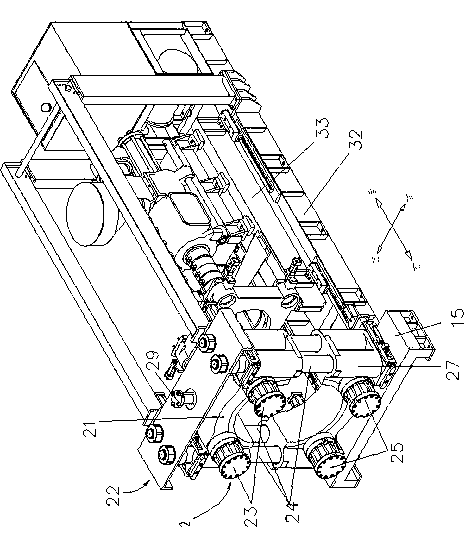

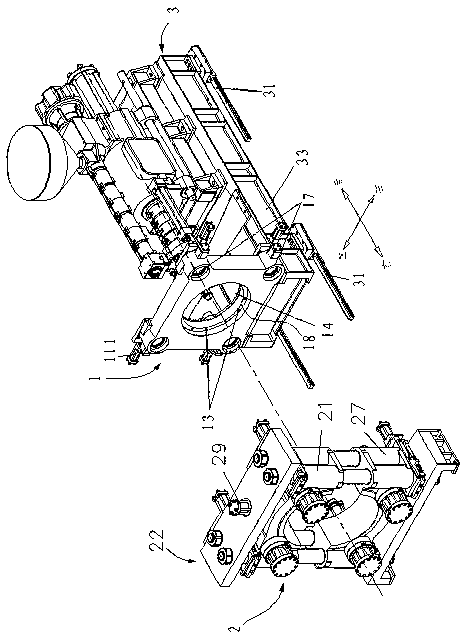

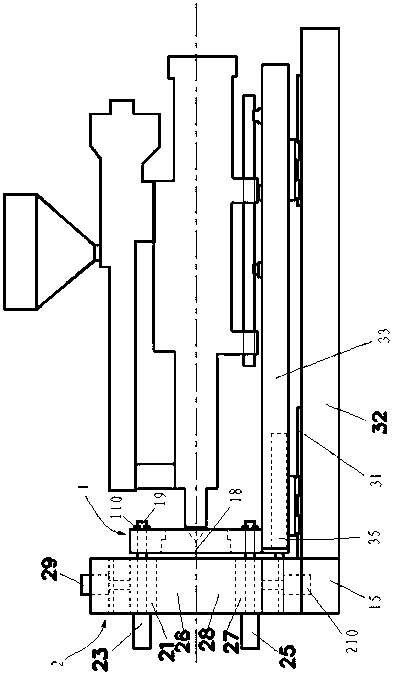

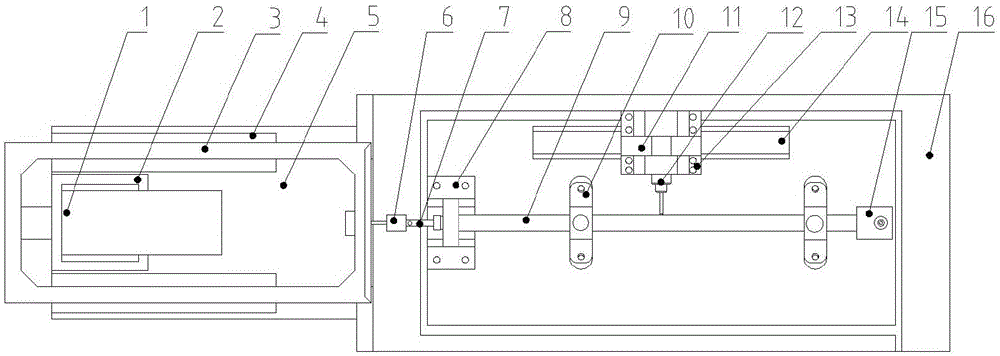

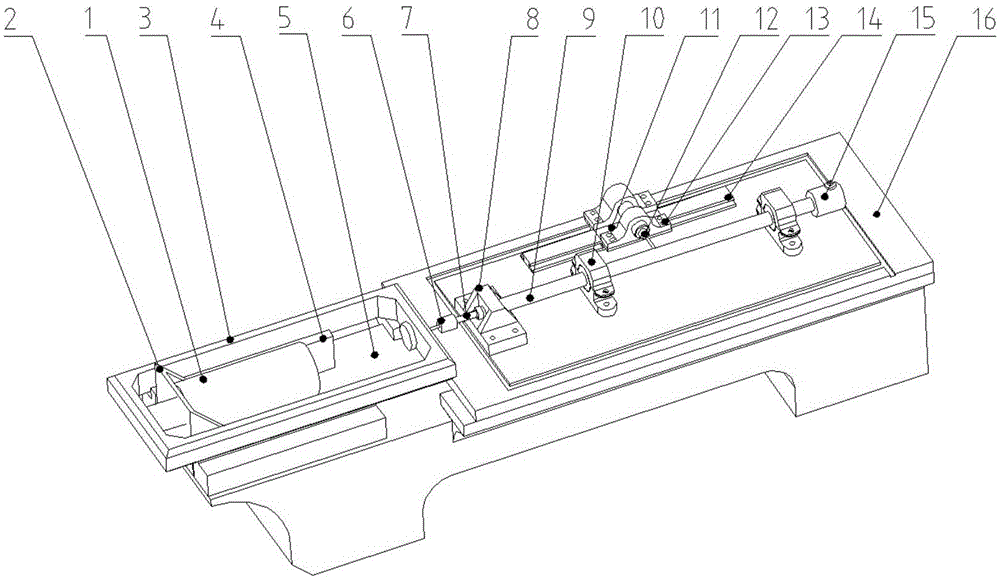

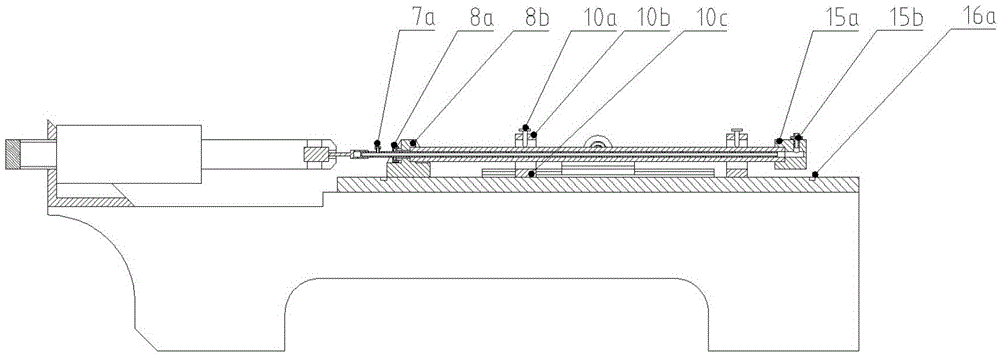

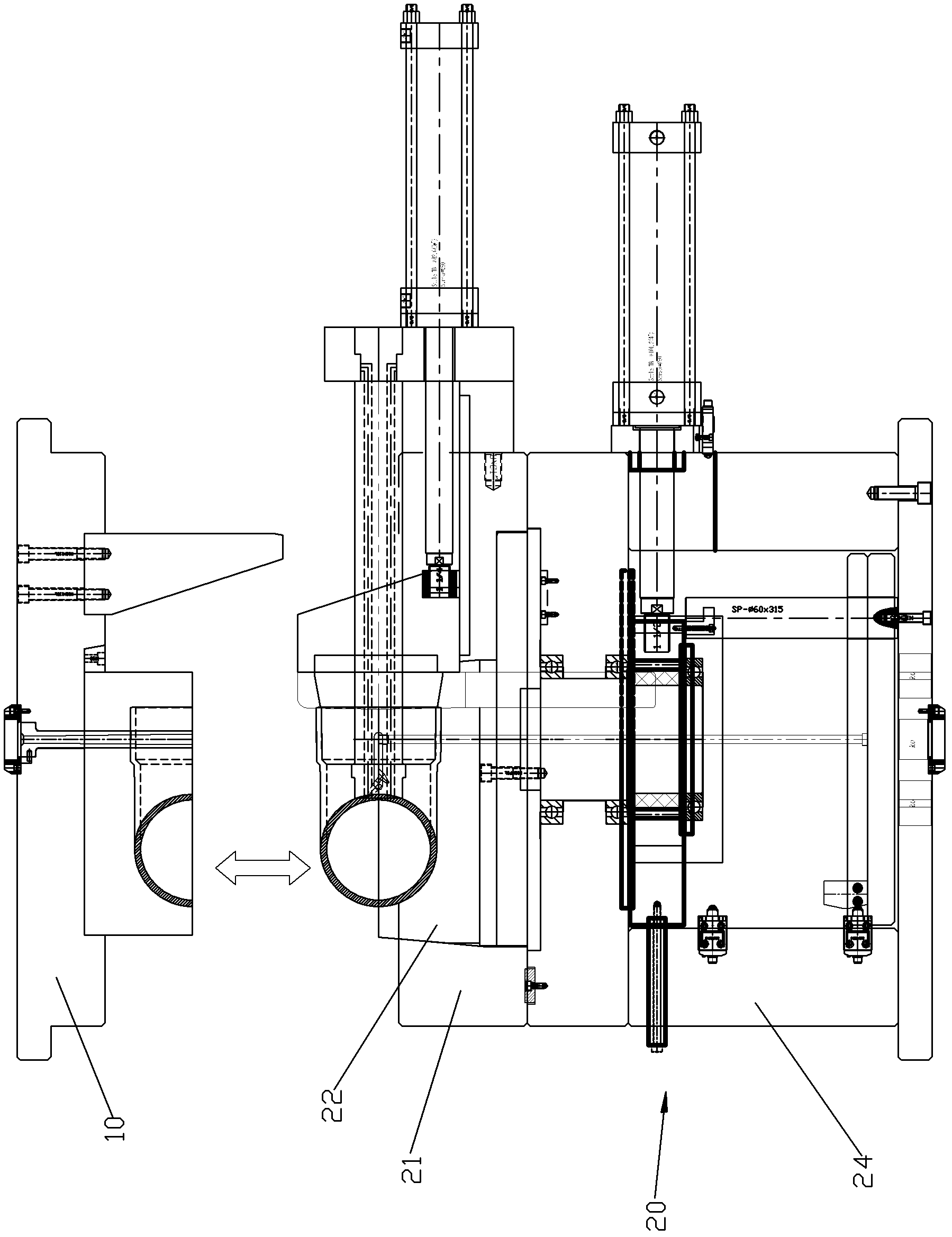

Core drawing mechanism of bellows birthmouth injection machine

The invention relates to a core drawing mechanism of a bellows birthmouth injection machine. The core drawing mechanism comprises a mandrel plate, a core drawing device and a sliding frame, the mandrel plate is a rectangular plate, the central portion of the mandrel plate is provided with a mandrel positioning hole, and four corners of the mandrel plate are respectively provided with a core drawing guide pillar hole; the core drawing device is composed of four core drawing oil cylinders, four core drawing guide pillars and four core drawing locks, the core drawing oil cylinders are fixed on the core drawing guide pillar holes at the left and right sides of the front panels of the upper template and the lower template of a film locking mechanism, and the core drawing guide pillars are horizontally arranged in a sagittal mode; and the sliding frame is a rectangular frame, a frame pedestal is arranged below the sliding frame, and a slide rail is arranged between the frame pedestal and the sliding frame. The core drawing mechanism has the advantages of very convenient entry locking and drawing of the mandrel, high stability, easy product quality guarantee, and convenience for the maintenance, dismounting and mounting of a die.

Owner:佛山市宝捷精密机械有限公司

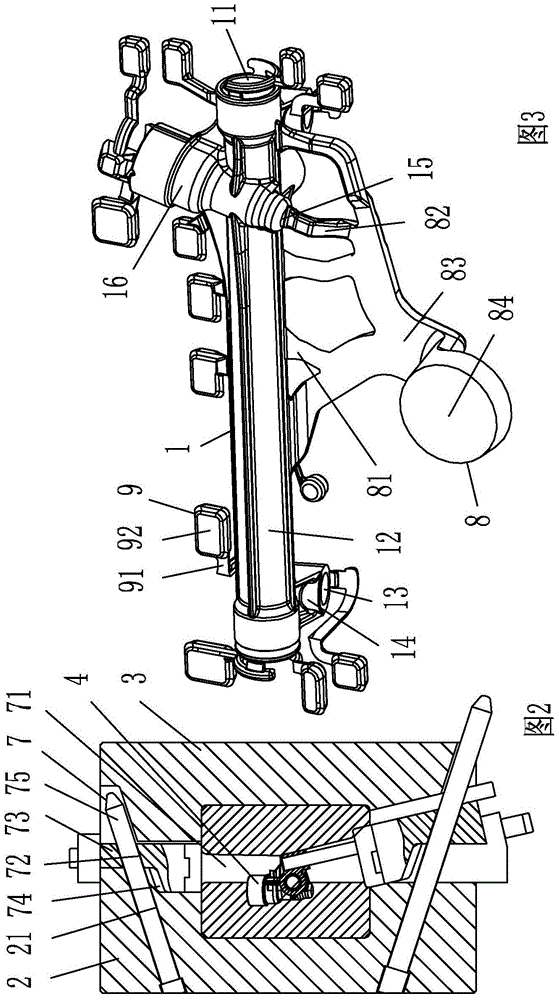

A tee pipe and its injection mold and method

ActiveCN110142934BEasy core pullingSmall footprintDomestic articlesEngineeringMechanical engineering

Owner:东莞市艺源塑胶制品有限公司

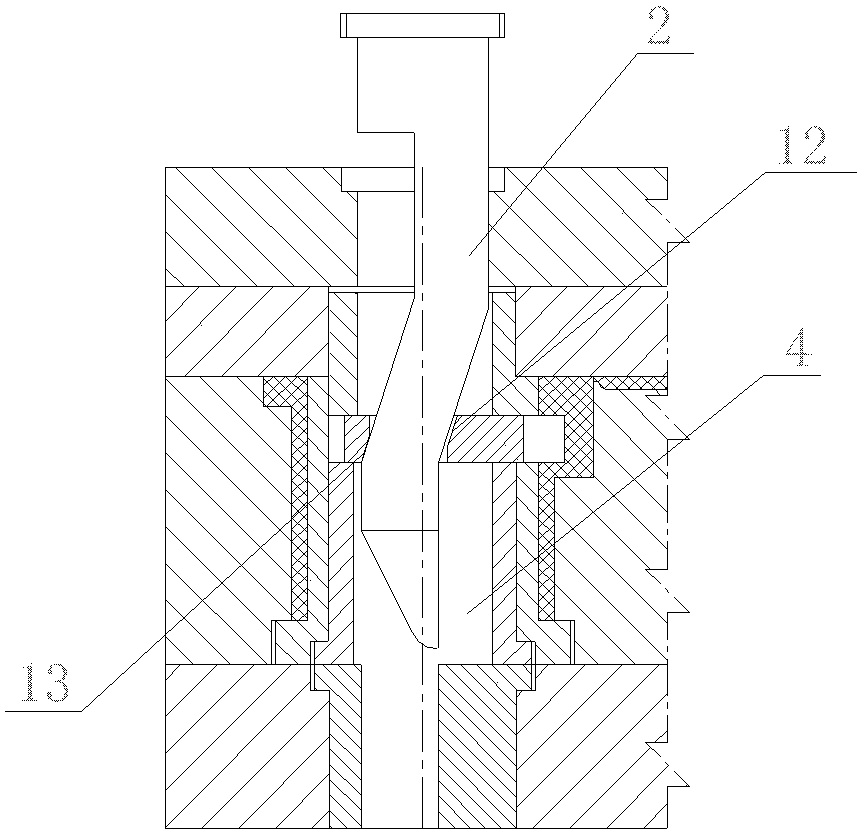

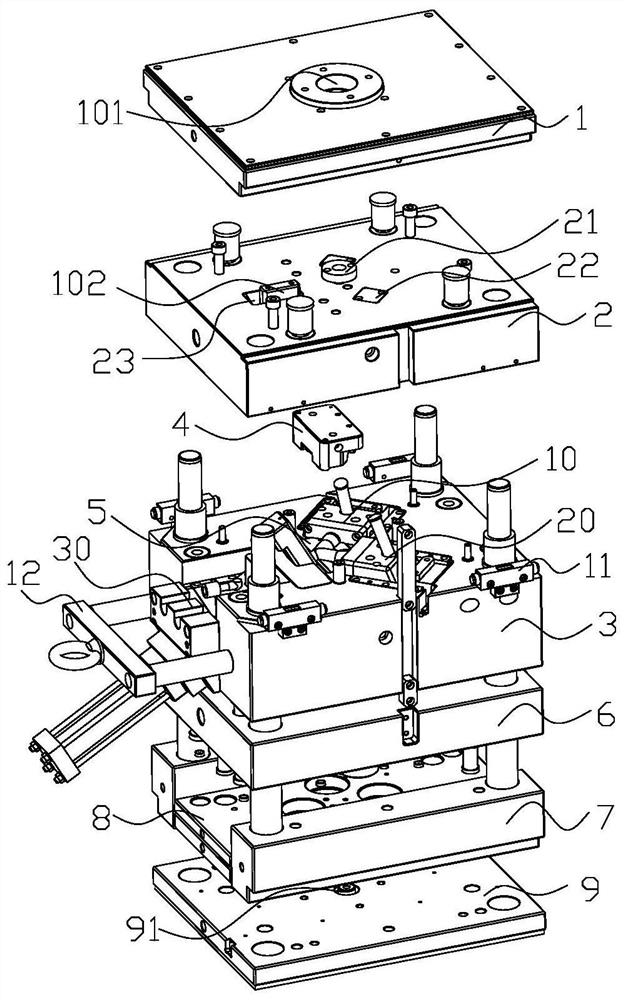

One-mold two-part injection mold

The invention relates to the technical field of molds and in particular relates to a one-mold two-part injection mold. The injection mold comprises a fixed mold bottom plate, a stripper plate, a fixed mold plate, a fixed mold core, a movable mold core, a movable mold plate, square iron, an ejector retainer plate, an ejector base plate and a movable mold bottom plate, wherein a first row orientation component, a second row orientation component and a third row orientation component are arranged between the fixed mold plate and the movable mold plate; a first cavity and a second cavity are arranged on the fixed mold core in parallel; and a first core and a second core which are correspondingly molded with the first cavity and the second cavity are respectively arranged on the movable mold core in parallel. According to the one-mold two-part injection mold, two injection parts which are similar in shape structure and are assembled in a matched mode are simultaneously molded, so that the colors and textures of the two injection parts can be consistent as far as possible.

Owner:浙江世纪华通车业有限公司

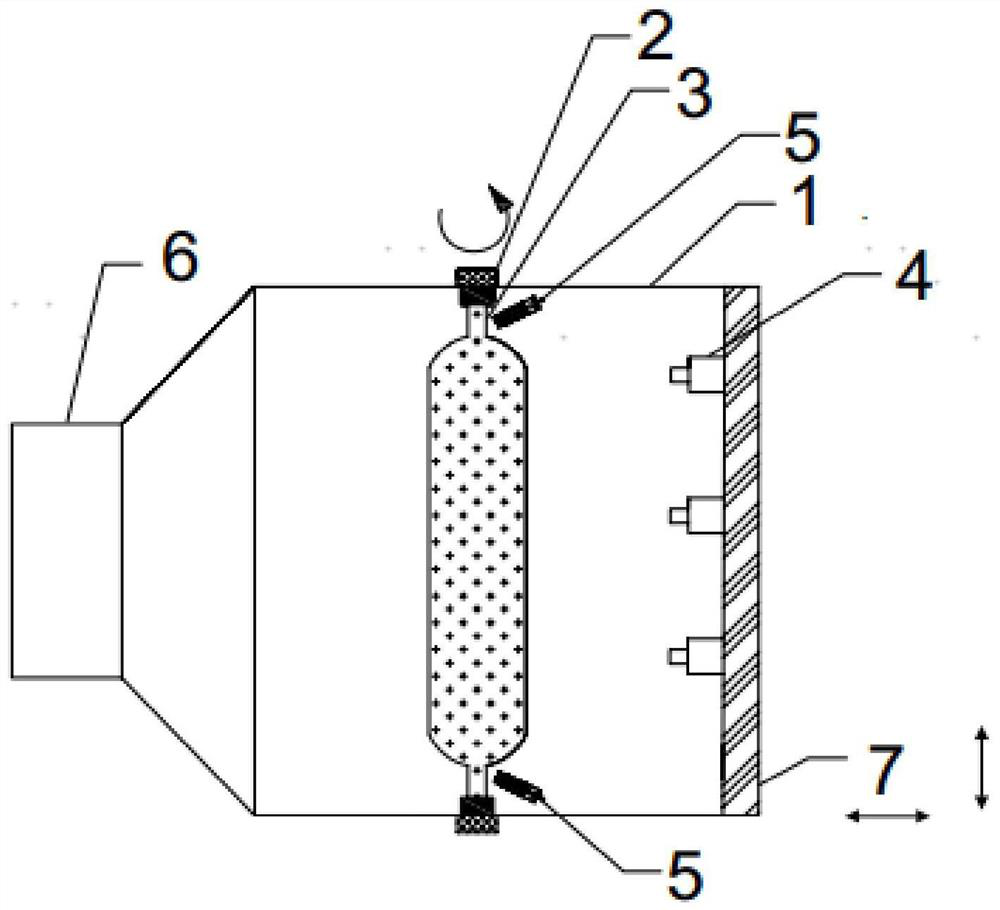

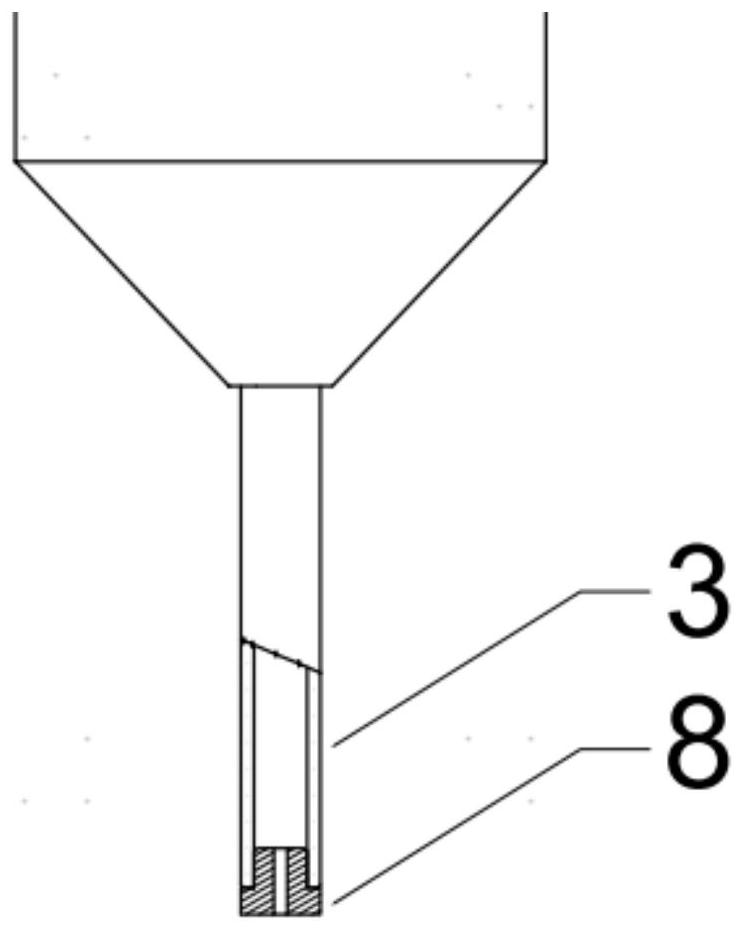

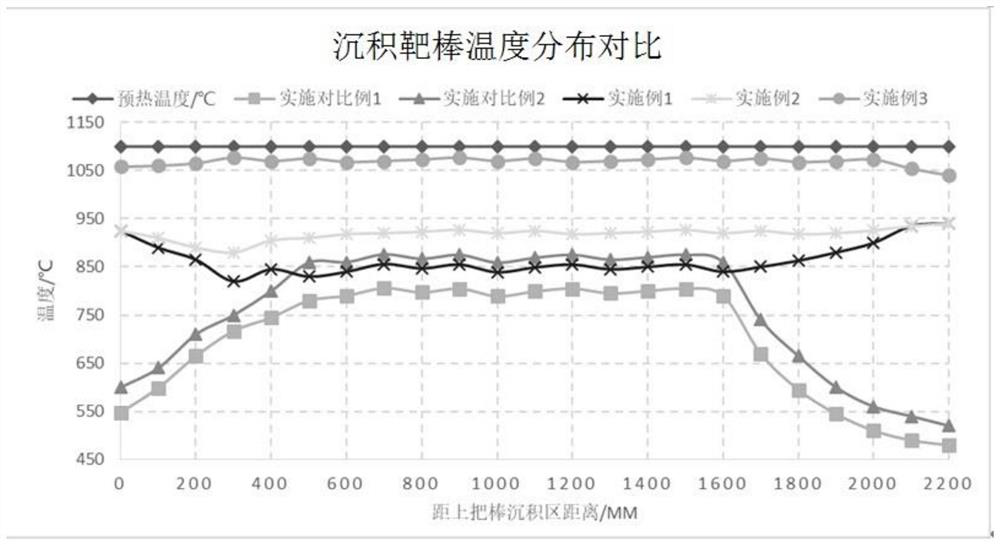

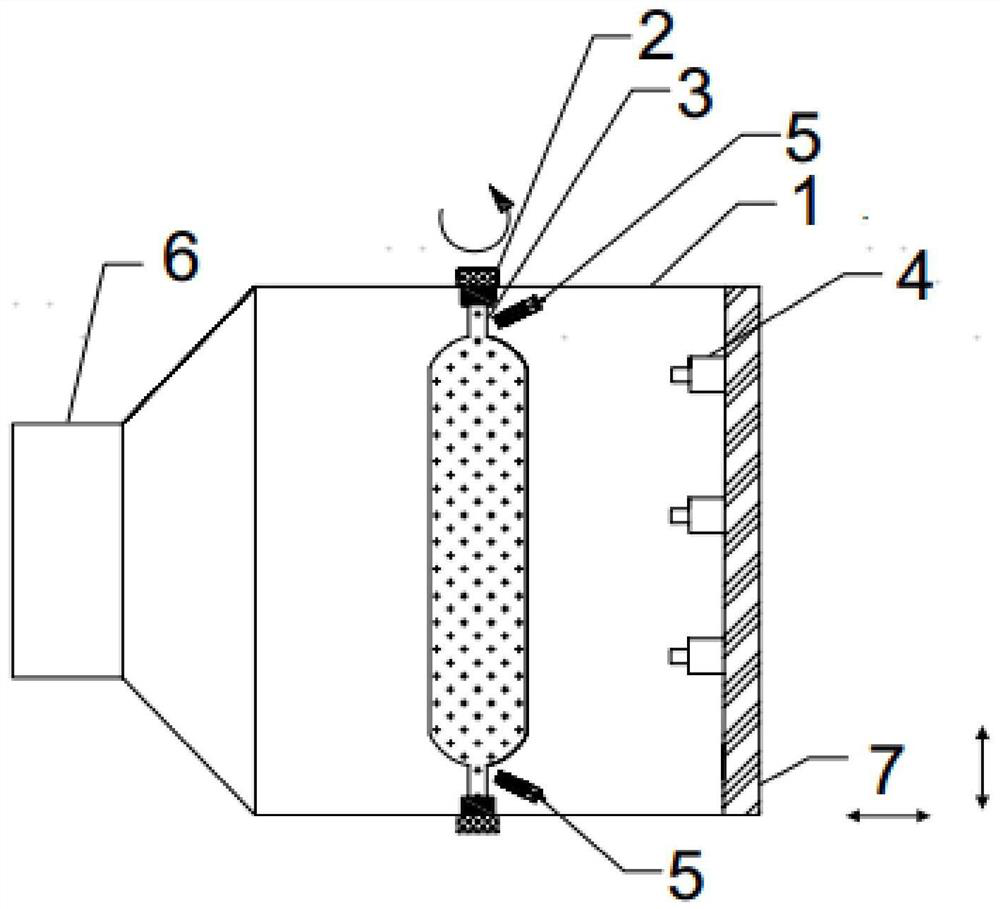

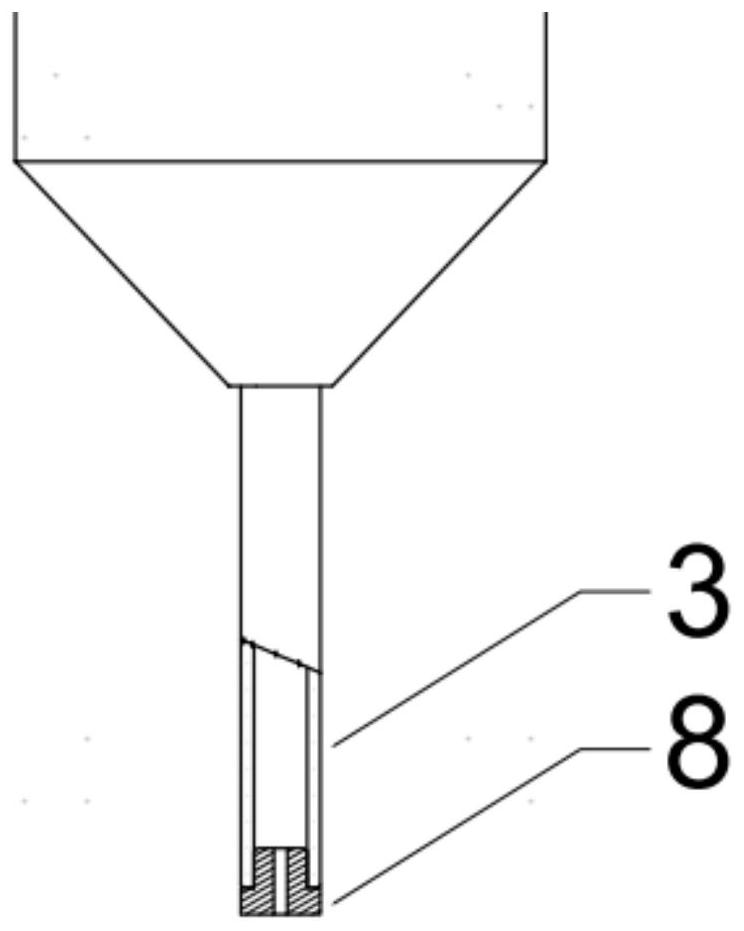

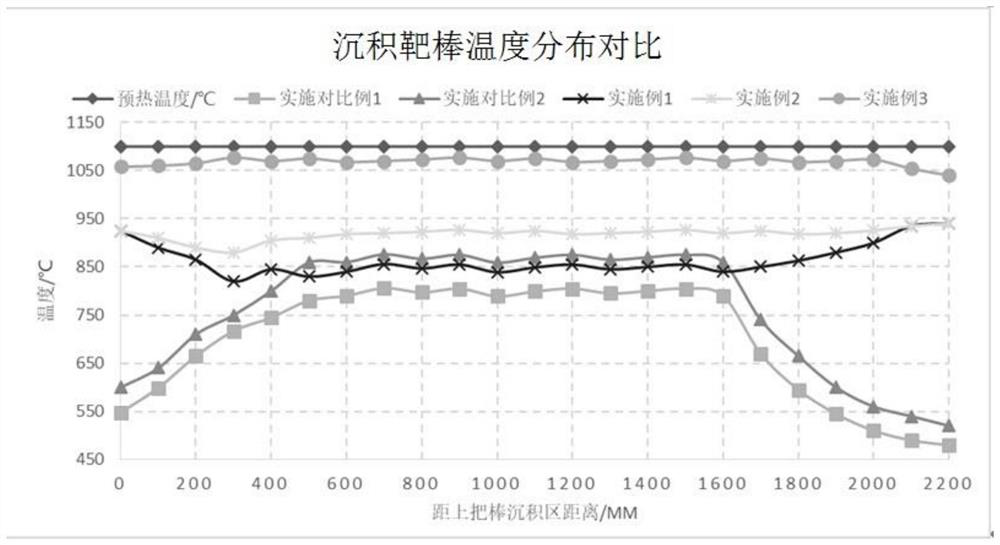

Manufacturing method of pure quartz glass hollow cylinder

The invention relates to a manufacturing method of a pure quartz glass hollow cylinder. The method adopts an external vapor deposition method to deposit a hollow glass cylindrical powder rod, a deposition cavity adopts a vertical target rod deposition mode, and the deposition target rod is a high-temperature-resistant and oxidation-resistant ceramic, alloy or a composite deposition target rod which takes alloy as a substrate and is coated with a ceramic layer. The surface of the deposition target rod keeps a certain roughness, and a blowtorch assembly is connected with a sliding seat capable of moving up and down and back and forth.During deposition, an upper rotating chuck and a lower rotating chuck drive the deposition target rod to rotate, the blowtorch assembly is started to spray deposition powder to the deposition target rod and move up and down in the direction parallel to the axis of the deposition target rod, a suction opening is opened, the temperature difference of the heated area of the whole deposition target rod is controlled within 350 DEG C, and after deposition is completed and cooling is conducted, the target rod is pulled out of the powder preform rod and sintered into the transparent pure silicon dioxide quartz glass hollow cylinder. The deposition forming quality of the powder rod is guaranteed, the processing stability is enhanced, the process is simplified, and the processing cost is reduced.

Owner:长飞石英技术(武汉)有限公司

Mandrel withdrawing device for forging forming of inner hole profile

ActiveCN105013999APromote withdrawalEasy core pullingForging/hammering/pressing machinesEngineeringHigh pressure

The invention discloses a mandrel withdrawing device for forging forming of an inner hole profile. The mandrel withdrawing device for forging forming of the inner hole profile comprises a machine body and a fixed plate connected with the machine body. A hydraulic cylinder is fixedly connected with the machine body. A punch of the hydraulic cylinder is connected with the left end of a pull ring. The two sides of the pull ring slide on pull ring supports. The right end of the pull ring is connected with one end of a mandrel through a flexible connector. The mandrel is sleeved with a workpiece. The workpiece is positioned through a workpiece supporting frame. The left end of the workpiece is abutted against an end blocking plate. The right end of the workpiece is connected with an oil cavity. A vibration exciter is arranged beside the middle of the workpiece and connected to a sliding block. The sliding block is matched with a guide rail. The end blocking plate, the workpiece supporting frame and the guide rail are fixed to the fixed plate. The vibration exciter makes the workpiece resonate, the contact surface of the workpiece and the mandrel becomes loose so that the mandrel can be withdrawn conveniently, and the mandrel can be withdrawn more easily under the action of high-pressure oil; pulling force which is large enough can be provided by the hydraulic cylinder, and thus the mandrel can be withdrawn even if the mandrel is clamped quite tightly; damage to the workpiece and the mandrel is small in the mandrel withdrawing process.

Owner:XI AN JIAOTONG UNIV

Internal thread forming injection mold

The invention discloses an internal thread forming injection mold which comprises an upper mold set and a lower mold set. A thread forming part comprises a plurality of forming blocks which are spliced in the circumferential direction and a big-end-down wedge-shaped core body, a big-end-down wedge-shaped through hole is formed among the forming blocks, the wedge-shaped core body is arranged in the wedge-shaped through hole in a penetrating mode, and the forming blocks are driven to synchronously expand and contract in the radial direction when the wedge-shaped core body moves up and down. The outer side faces of all the forming blocks are spliced to form a circumferential face, and forming threads are arranged on the circumferential face. The lower mold set comprises a lower mold block and a lower mold backup plate, and the lower mold backup plate is arranged below the lower mold block and can move up and down relative to the lower mold block. A vertically-through mounting through hole is formed in the lower mold block, the lower portion of the thread forming part is located in the mounting through hole, and the lower end of the wedge-shaped core body is fixedly connected with the lower mold backup plate. The structure of the internal thread forming injection mold is optimized in design, the structure is simplified and reasonable, the number of parts is small, the manufacturing cost is low, core pulling of the internal thread part is facilitated, and good practicability is achieved.

Owner:WENZHOU LONGHUA DAILY ELECTRONICS +1

U-shaped pipe mould device

The invention discloses a U-shaped pipe mould device. A mould comprises an upper mould plate and a lower mould plate unit. A downward upper half cavity is arranged below the upper mould plate, the lower mould plate unit comprises a lower mould plate, a U-shaped outer mould plate, a transmission unit and a driving unit, the U-shaped outer mould plate is rotatably connected onto the lower mould plate, the outer mould plate is provided with an upward lower half cavity, and the driving unit is connected with the outer mould plate to drive the outer mould plate to rotate relative to the lower mould plate. A mould core device comprises an arc section, a left section, a right section and a positioning column, wherein the arc section, the left section and the right section are abutted and are matched with an inner cavity of a U-shaped pipe, the positioning column is connected to the lower mould plate in a positioned manner, the tail end of the positioning column is connected to the right end of the arc section in a positioned manner, the right section is sleeved outside the positioning column and is capable of moving along the positioning column, and the left section is slidably connected with the lower mould plate. In addition, another driving unit is in transmission connection with the left section, and the transmission unit is in transmission connection with the second driving unit, so that the second driving unit can drive the outer mould plate to swing relative to the lower mould plate through the transmission unit to shift the U-shaped pipe and the arc section to relatively move and to release connecting force between the U-shaped pipe and the arc section.

Owner:厦门华盛弘精密模具有限公司

Die for producing four-way tube

Owner:NINGBO POLYTECHNIC

Pipe -shaped car parts die casting mold

The invention relates to the field of casting dies, and aims at providing a tubular automobile part casting die. The tubular automobile part casting die comprises an upper die body, a lower die body, a cavity defined by the upper die body and the lower die body, two main hole core-pulling devices provided with oppositely-arranged main hole cores, a through hole core-pulling device provided with a through hole core, three side hole core-pulling devices each provided with a side hole core, a casting system and an exhaust system. The cavity comprises a main tube cavity, a side tube cavity and an inclined tube cavity. The casting system comprises a plurality of main tube ingates communicated with the main tube cavity, an inclined tube ingate communicated with the inclined tube cavity, a connecting pouring gate and a main pouring gate arranged on the upper die body. The exhaust system comprises a plurality of exhaust channels and a plurality of air collecting cavities formed in the upper die body, one end of each exhaust channel is communicated with the cavity, and the other end of each exhaust channel is communicated with the side end of the lower die body. According to the tubular automobile part casting die, a cast tubular automobile part is not prone to deformation, mold filling is easy, and the tube hole die disengaging is easy.

Owner:宁波环亚机械制造有限公司

Structure for relieving stress concentration of intersecting lines inside plastic tee pipe

InactiveCN103398258BHigh strengthReduce manufacturing costPipe connection arrangementsStress concentrationEngineering

The invention relates to the technical field of pipes, in particular to a structure for relieving stress concentration of intersecting lines inside a plastic tee pipe. The structure for relieving the stress concentration of the intersecting lines inside the plastic tee pipe comprises the plastic tee pipe, the inside of the plastic tee pipe comprises a first pipe tube, a second pipe tube and a third pipe tube, the first pipe tube and the second pipe tube are arranged in left-right symmetry, the third pipe tube is arranged to be vertically upward, and circular-arc-shaped bosses are arranged at the intersecting position of the third pipe tube and the first pipe tube and the intersecting position of the third pipe tube and the second pipe tube. Compared with the method for improving the entire strength of the plastic pipe by increasing the thickness or adding ribs, a plastic pipe product manufactured by using the structure can effectively save materials and lower the production cost of the plastic pipe. Compared with an original structure, the plastic pipe manufactured by using the structure can effectively lower the degree of the stress concentration of the intersecting lines inside by more than 20%, crackles are prevented, the service life of the plastic pipe is prolonged, and safe using of the plastic pipe is guaranteed.

Owner:GUANGDONG LIANSU TECH INDAL

A kind of manufacturing method of pure quartz glass hollow cylinder

Owner:长飞石英技术(武汉)有限公司

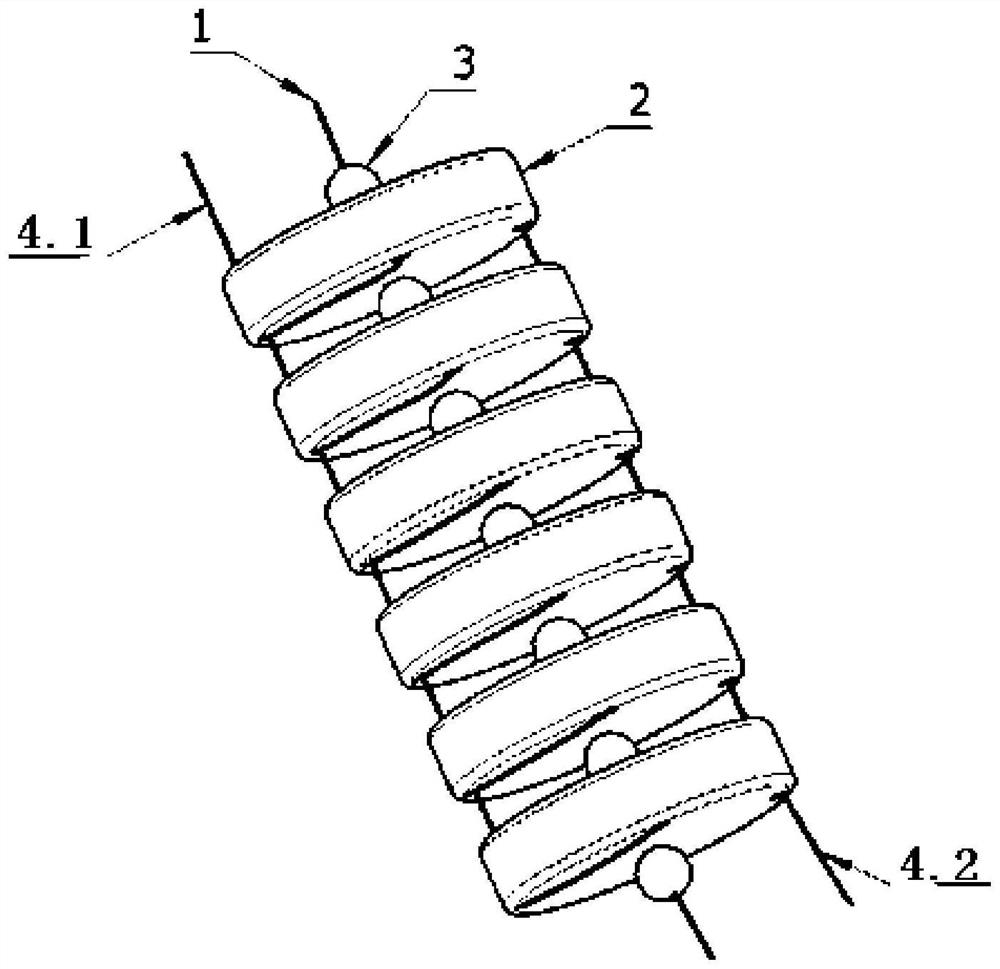

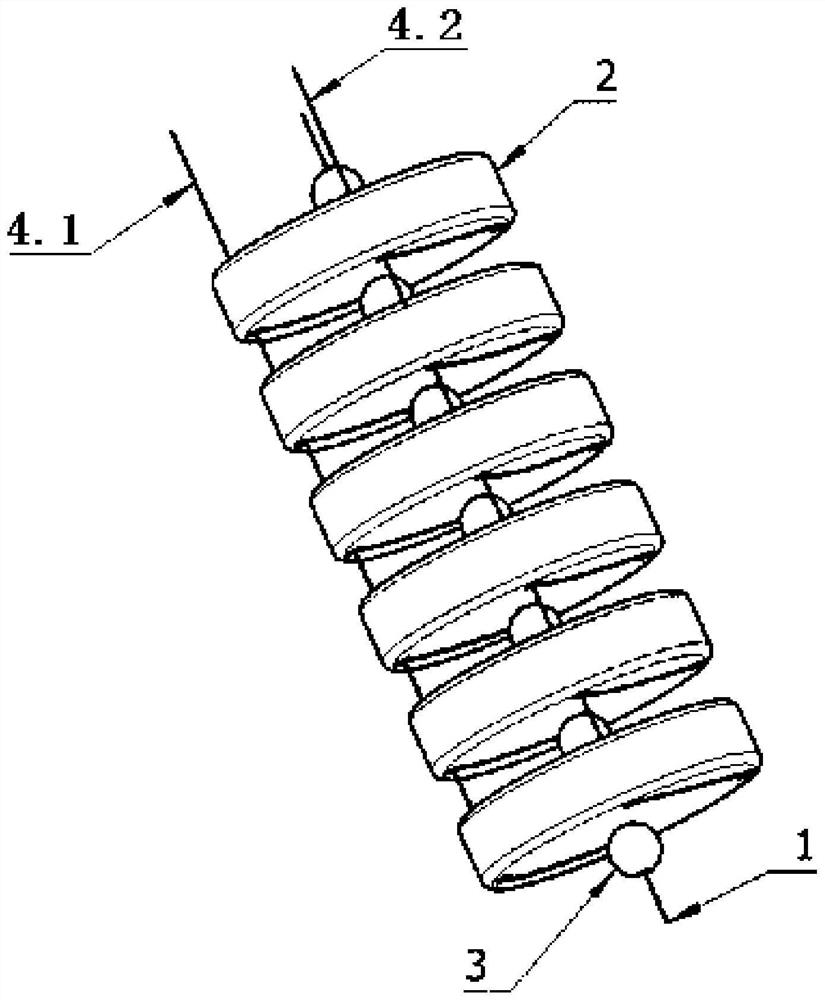

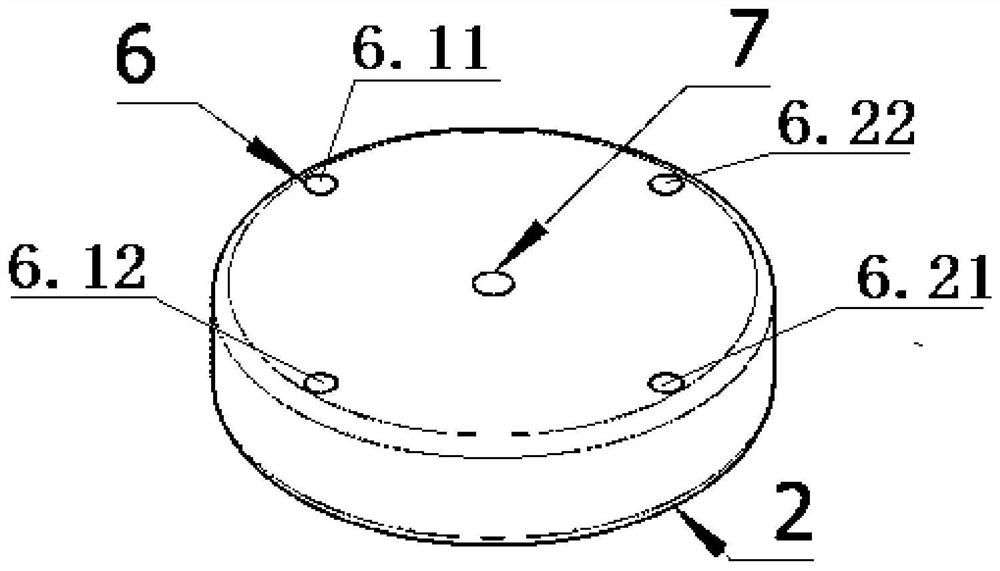

An easy-to-remove curved anti-wrinkle mandrel

The invention discloses an easy-to-detach wrinkle-proof mandrel for bent pipes, which comprises a limit core wire, a plurality of mandrel elements and limit balls. The mandrel element is respectively provided with a plurality of winding holes, and the plurality of winding holes are distributed in a circular direction, and the corresponding winding holes of the plurality of mandrel elements form a core-pulling channel; the plurality of winding holes in each mandrel element are in groups of two, The core-pulling wires correspond to the perforation groups one by one. One end of each core-pulling wire is bound to one end of the first perforation hole in the perforation grouping, and the other end passes through the first perforation hole, then bypasses the mandrel element and then reverses. Pass through the second winding hole corresponding to the grouping of winding holes, and then the other end of the core-pulling wire passes through the core-pulling passage part formed by the surrounding piercing holes corresponding to the positions of other mandrel elements in turn. The core-pulling wires are combined into a bundle to form a core-pulling wire bundle. The invention realizes the function of protecting the tube wall during the core pulling process of the flexible mandrel.

Owner:HEFEI UNIV OF TECH

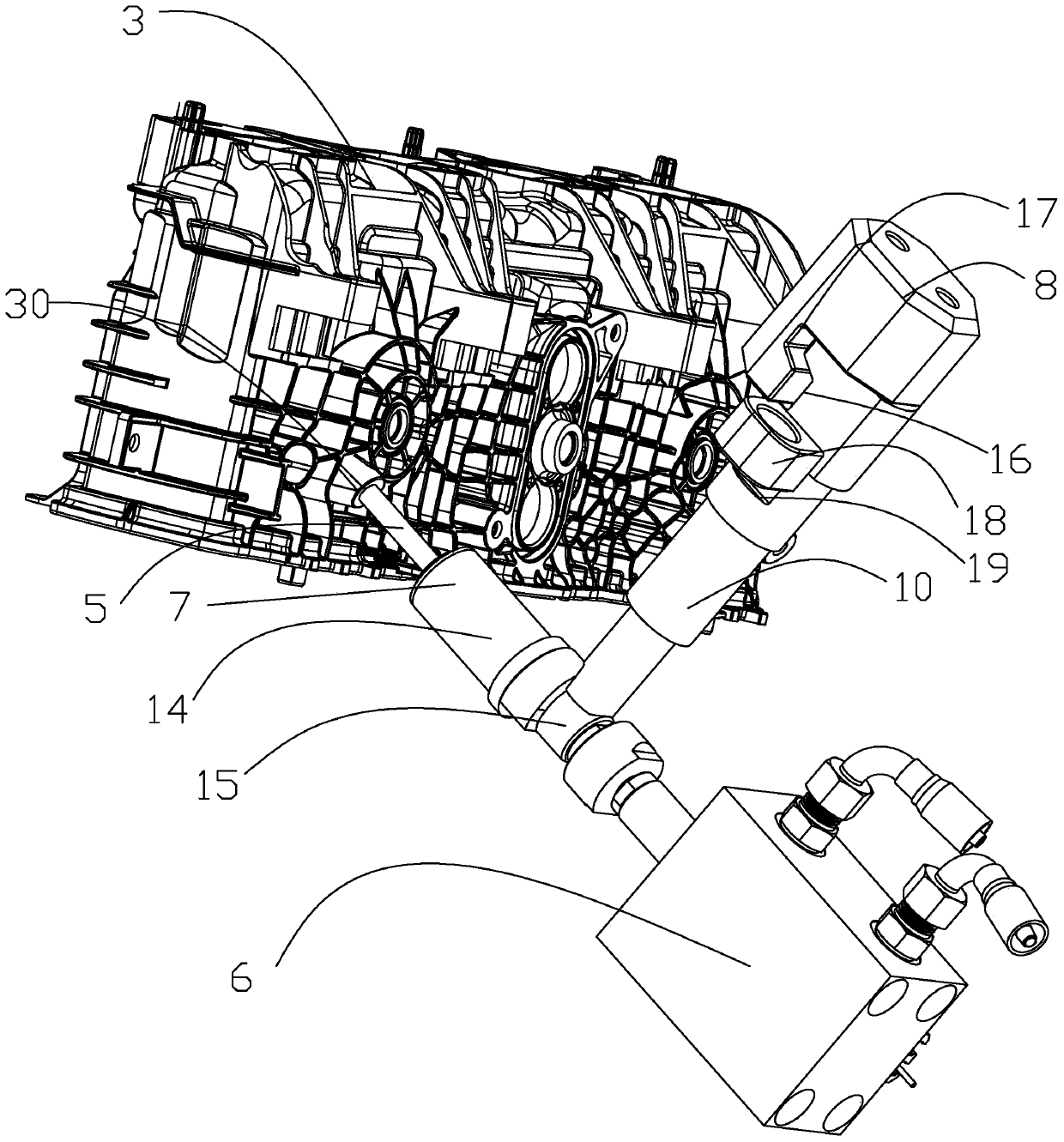

Automobile engine induction manifold oil cylinder rollback preventing mechanism

The invention discloses an automobile engine induction manifold oil cylinder rollback preventing mechanism which comprises an upper die, a lower die and a product, wherein a sliding block for formingthe outer side surface of the product is arranged on the upper surface of the lower die; a backing buckle is arranged on the outer side face of the product; the automobile engine induction manifold oil cylinder rollback preventing mechanism further comprises a core rod for forming the backing buckle; the core rod is positioned in the sliding block; a first oil cylinder is arranged on the sliding block; the piston rod of the first oil cylinder is connected with the core rod; and an oil cylinder core-pulling locking mechanism for carrying out mechanical locking on the core rod is arranged between the sliding block and the upper die. The invention provides the automobile engine induction manifold oil cylinder rollback preventing mechanism which is small in using space and low in cost.

Owner:NINGBO FANGZHENG TOOL

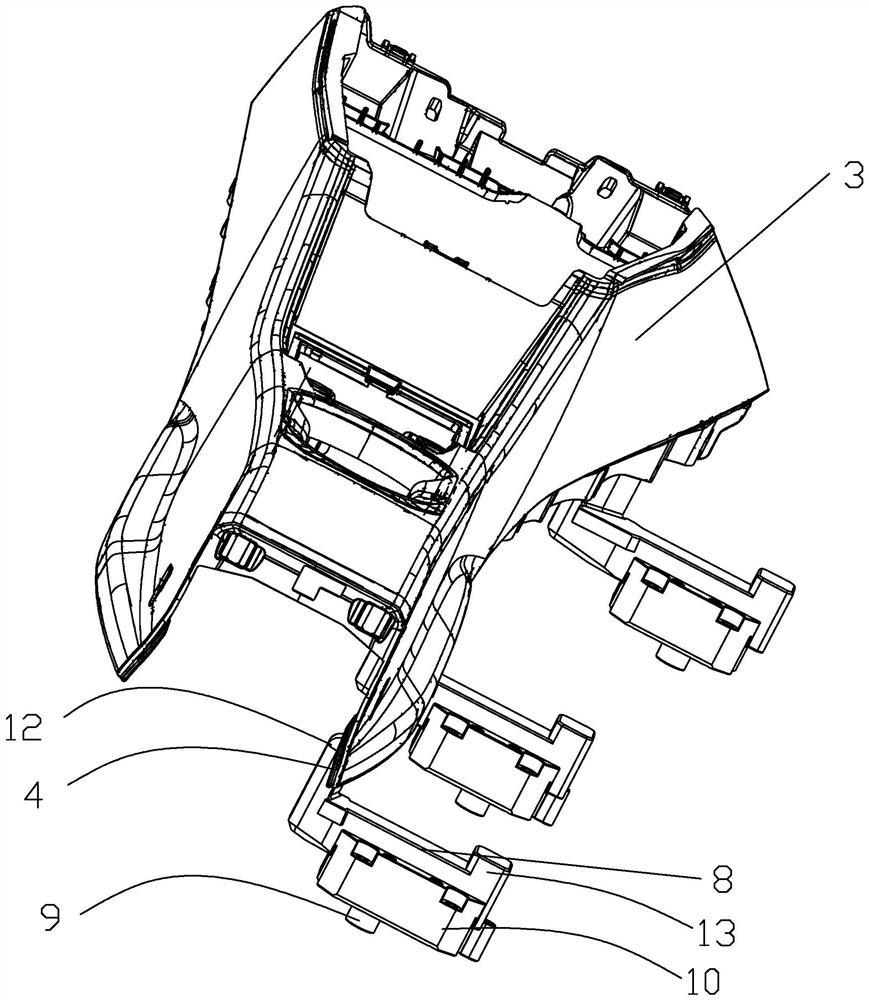

Demolition mechanism for automobile auxiliary instrument shell

ActiveCN111267301BEasy to moldGood design strengthDomestic articlesEngineeringStructural engineering

The invention discloses a demoulding mechanism for an automobile auxiliary instrument shell, which comprises an upper mold, a lower mold and a product. The inner surface of the lower end of the product is provided with an undercut, and the upper surface of the lower mold is provided with an inner surface for molding the product. The lower mold core, the lower surface of the upper mold is provided with an upper mold core for forming the upper surface of the product, the lower mold is also provided with a slider for forming the outer side of the product, the lower mold core, the upper mold There is a molded product cavity between the core and the slider when the upper mold and the lower mold are closed. The side of the lower mold core has a part for forming an undercut. A strong release mechanism is provided between the side of the lower mold core for reverse buckle release. The invention provides a release mechanism for the automobile sub-instrument shell that will not damage the product and has a high yield.

Owner:NINGBO FANGZHENG TOOL

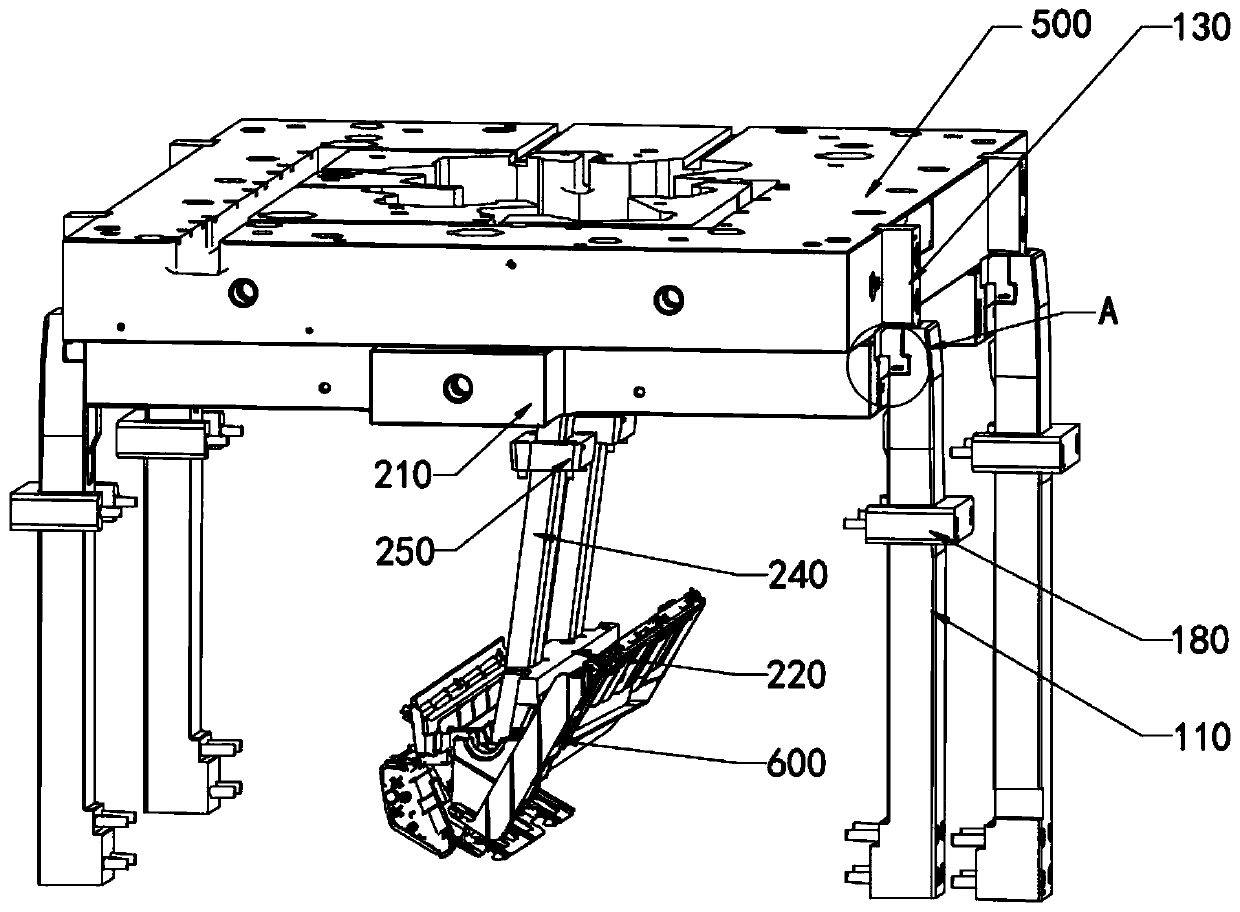

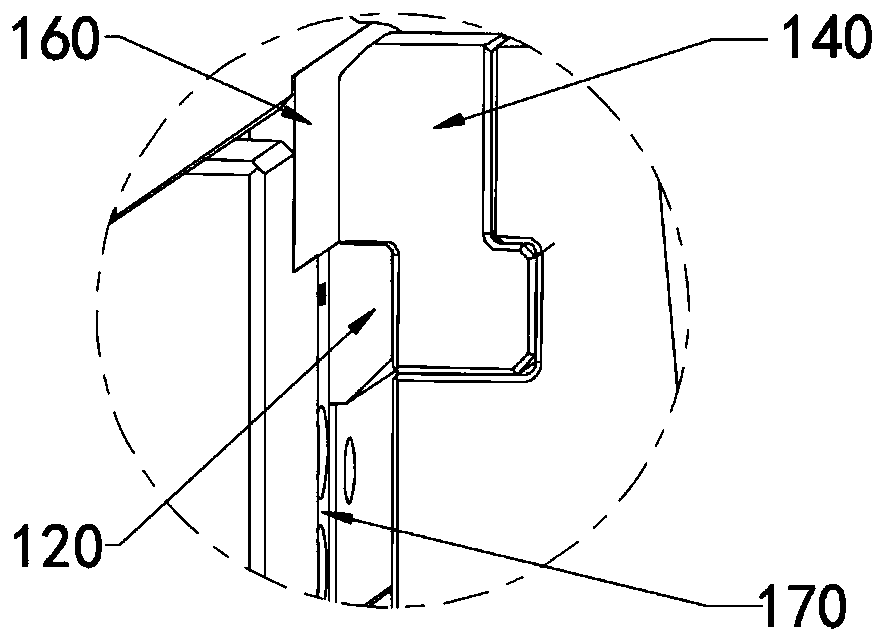

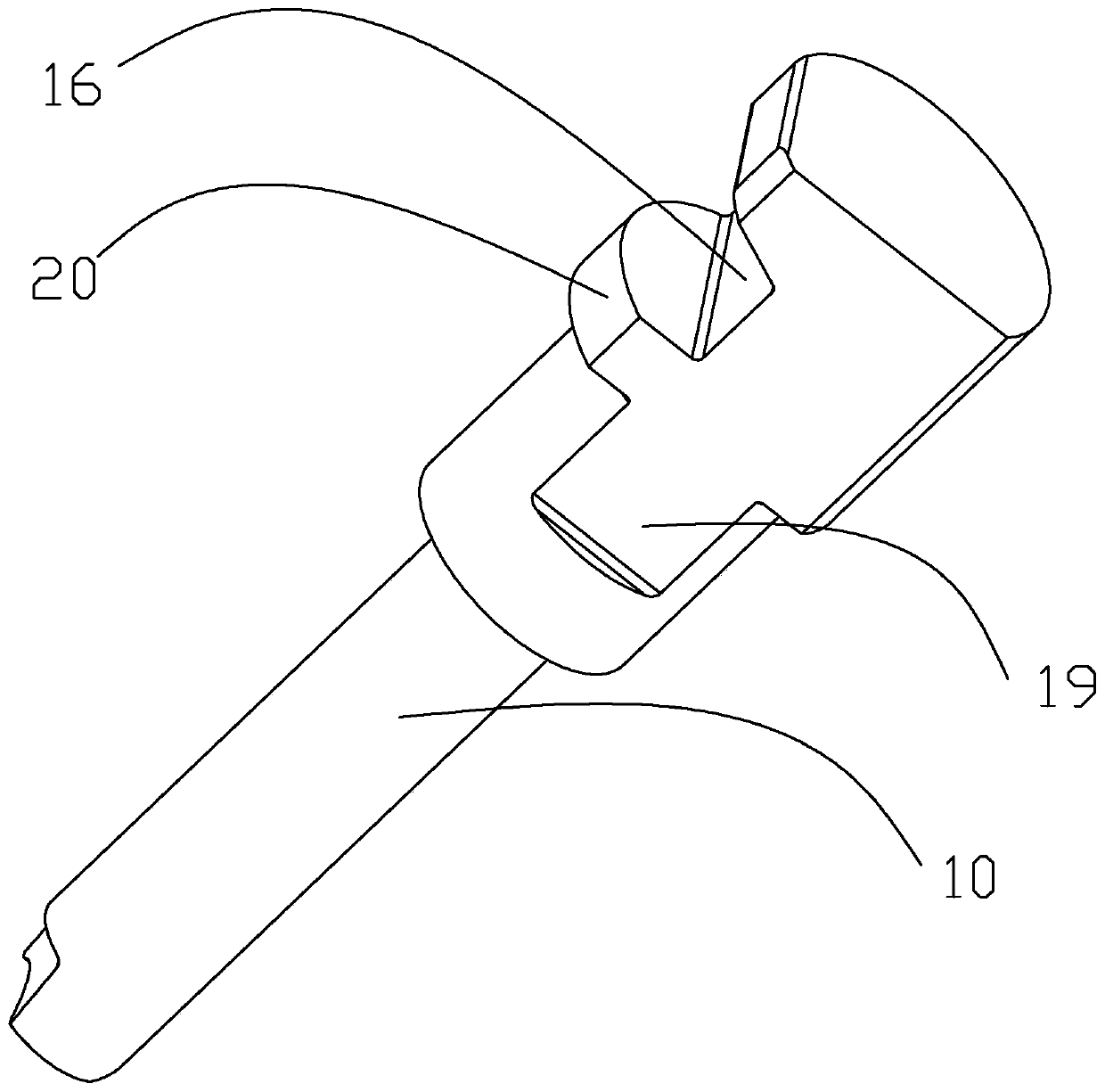

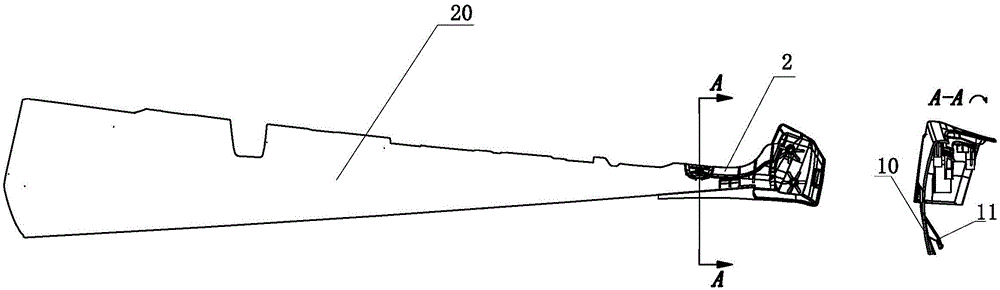

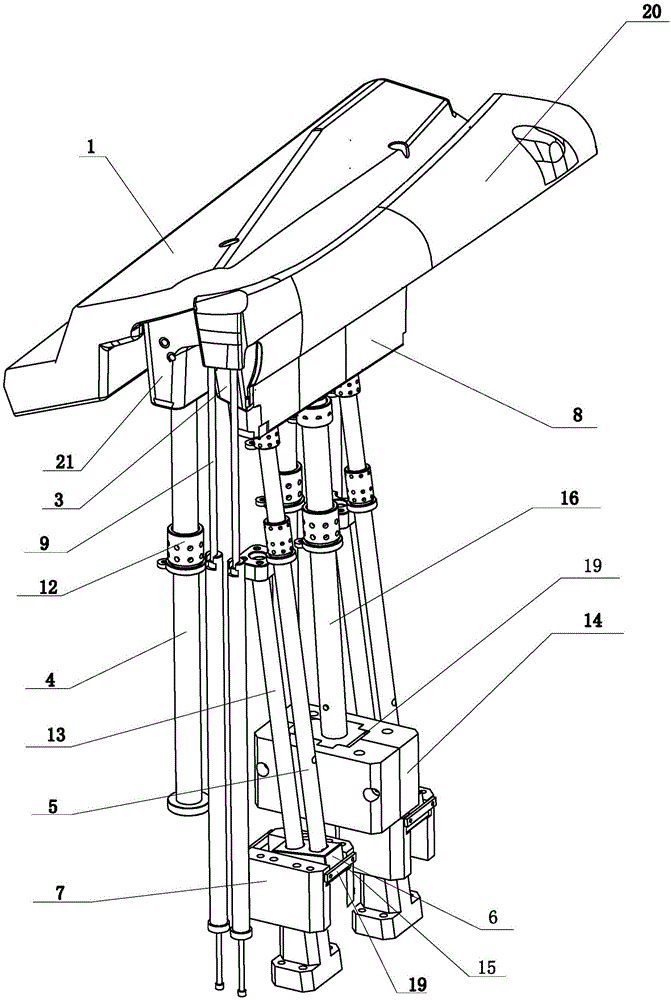

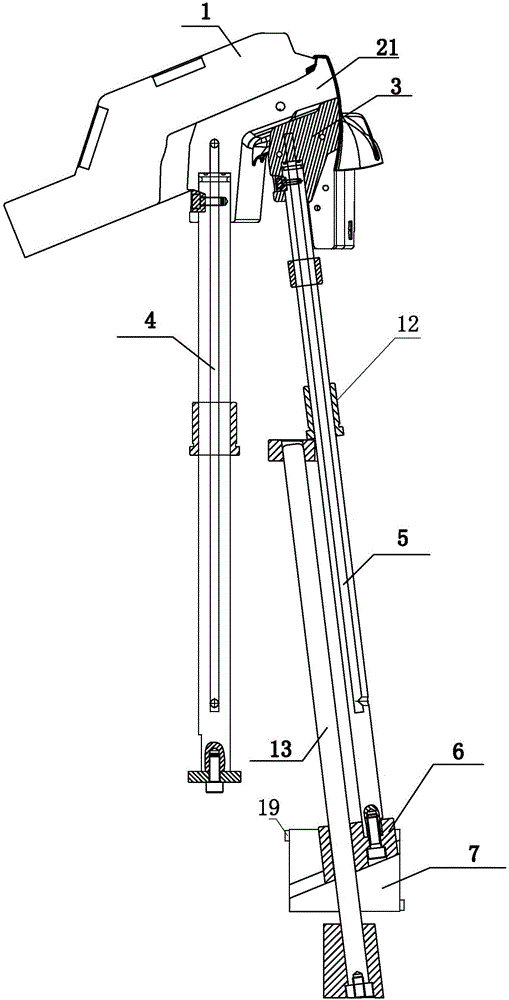

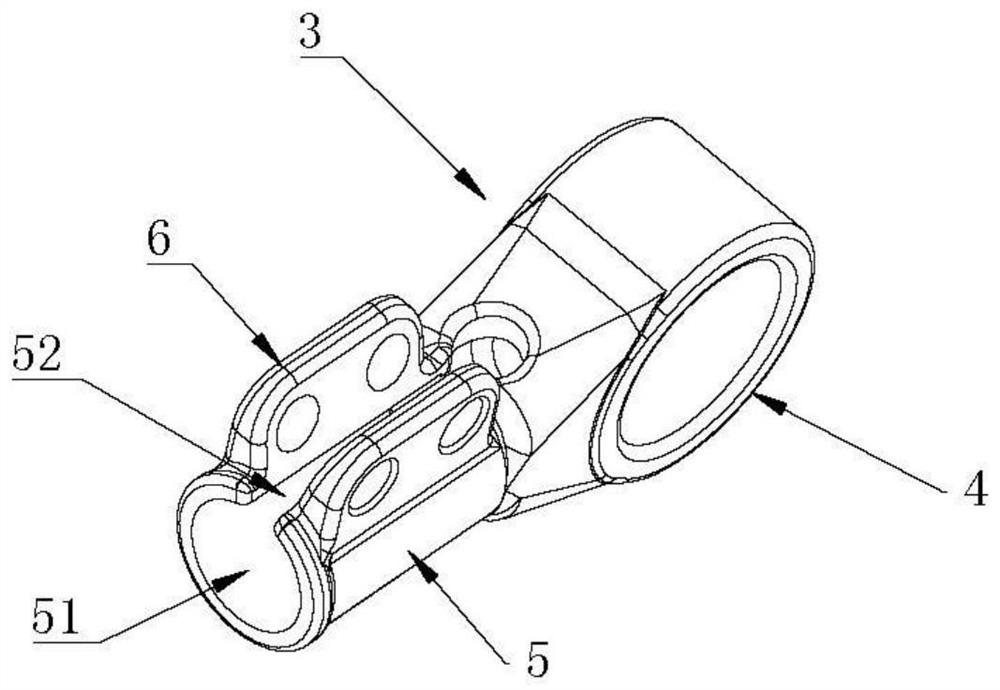

Car front door upper frame core pulling mechanism

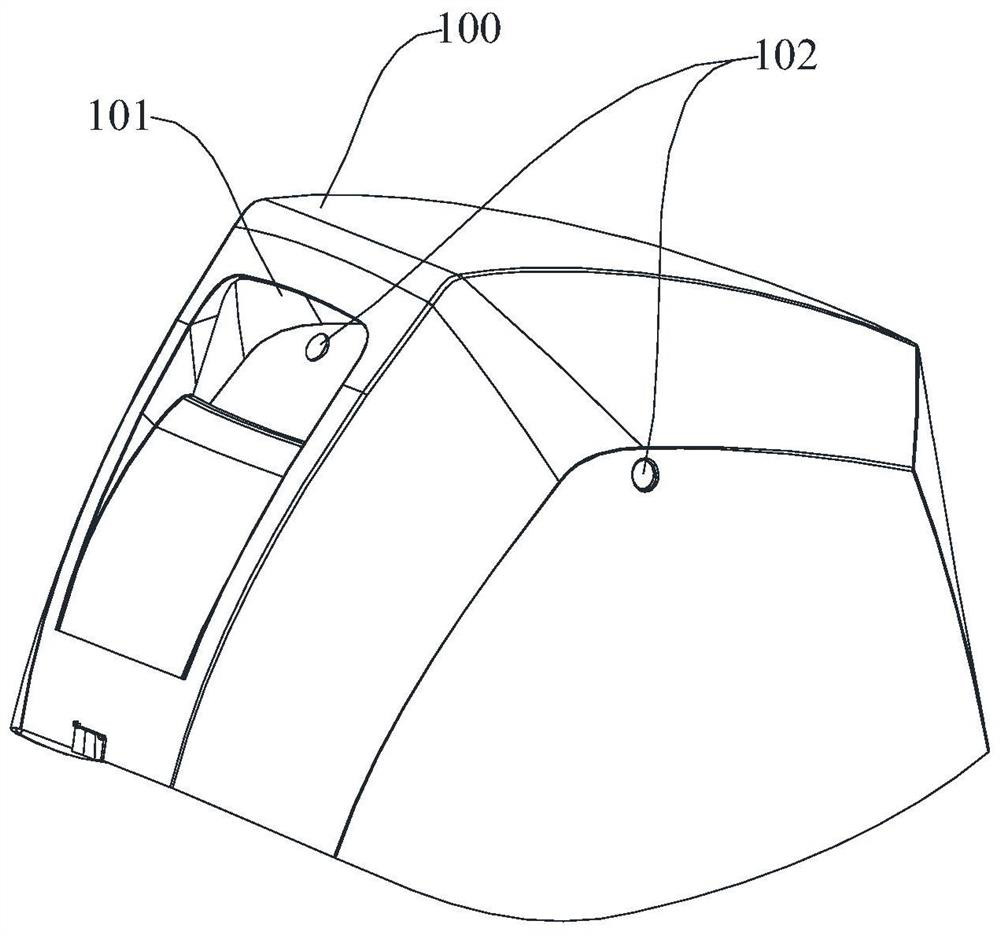

The invention discloses a core pulling mechanism of an automobile front door upper framework. The core pulling mechanism comprises a product (20), wherein the product (20) comprises a small end (2); the lower part of the small end (2) is provided with a warped surface (10); the inner side of the warped surface (10) is provided with an inverted buckle (11); an included angle between the inverted buckle (11) and the vertical direction is 50 degrees-65 degrees; the product (20) also comprises a core pulling mechanism for pulling a core of the small end (2); the core pulling mechanism comprises a slide block (1), a straight ejector (21), an oblique ejector (3), an oblique ejector body (8), a first oblique ejector slide base (7) and a second oblique ejector slide base (14), wherein the straight ejector (21) is positioned on the inner side of the upper part of the small end (2); the lower end of the straight ejector (21) is provided with a straight ejector bar (4); the slide block (1) is matched with the oblique surface of the upper end surface of the straight ejector (21). The invention provides the core pulling mechanism of the automobile front door upper framework, which is large in oblique ejector walking angle, can guarantee no seizing and self-locking in the walking process, and is beneficial to core pulling.

Owner:NINGBO FANGZHENG TOOL

Connecting rod joint wax mold forming method

PendingCN113751669AEasy to operateImprove splicing efficiencyFoundry mouldsFoundry coresInvestment castingComposite material

The invention relates to the technical field of investment casting, in particular to a connecting rod joint wax mold forming method. A first wax mold is formed in a first mold; the first wax mold comprises a first shaft sleeve, a first body and two lug parts; a first blind hole is formed in the first body; a straight-barrel-shaped wax mold is formed in a second mold; the outer wall of the straight-barrel-shaped wax mold can be matched with the inner wall of a through hole section; the straight-barrel-shaped wax mold is spliced into the first blind hole; and a complete connecting rod joint wax mold is formed. According to the connecting rod joint wax mold forming method, the first wax mold and the straight-barrel-shaped wax mold are formed respectively, the appearance structure of the first wax mold is the same as that of a connecting rod joint; the first wax mold and the straight-barrel-shaped wax mold are easy to form; in the splicing process of the two wax molds, positioning or other positioning tools are not needed; operation and splicing are very easy; the splicing efficiency is improved; and the splicing precision can be ensured.

Owner:谷城石花维福机械有限公司

Flexible demolding device

The flexible demolding device comprises a female mold and a male mold, the female mold and the male mold are correspondingly arranged, the male mold is provided with an injection molding opening, a concave cavity is formed in the female mold, the injection molding opening is communicated with the inner side of the concave cavity, a mold core is arranged on the male mold and located on the inner side of the concave cavity, a through hole is formed in the mold core, and the through hole is communicated with the injection molding opening. A through hole is formed in the female die, a metal mold core is arranged in the through hole, a gap is formed between the metal mold core and the inner wall of the mold core, a plurality of miniature steel balls are arranged in the gap, a plurality of telescopic pieces are arranged in the female die, and output shafts of the telescopic pieces make contact with the male die. And the mold core is arranged and is made of a flexible material, so that quick core pulling can be carried out after injection molding is finished, the demolding time is greatly shortened, and the demolding working efficiency is improved.

Owner:XIAMEN UNIV OF TECH

Driving structure based on eccentric shaft

InactiveCN110513388AEasy core pullingEasy to installEccentric-shaftsGearing detailsEngineeringMechanical engineering

The invention discloses a driving structure based on an eccentric shaft. The driving structure comprises a base body with an inner cavity, a driven part movably assembled in the inner cavity and an eccentric shaft in linkage fit with the driven part, the eccentric shaft comprises a first rotating shaft part and a second rotating shaft part which are coaxially arranged, an eccentric shaft part which is arranged between the first rotating shaft part and the second rotating shaft part and eccentrically arranged is further included, the diameter of the first rotating shaft part is larger than thediameter of the second rotating shaft part, a first shaft hole penetrating through the interior and the exterior is formed in the side wall of one side of the inner cavity of the base body, a second shaft hole is formed in the position, opposite to the first shaft hole position, of the other side wall of the inner cavity, the diameter of the first shaft hole is larger than that of the second shafthole, the first rotating shaft part is rotatably matched with the first shaft hole, the second rotating shaft part is rotatably matched with the second shaft hole, and the eccentric shaft part is inlinkage fit with the driven part. The base body forming of the driving structure is easier, the production cost is effectively reduced, the eccentric shaft and the base body can be more easily mounted, and the assembling efficiency can be greatly improved.

Owner:QUANZHOU YICHUANG DESIGN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com